2. INSTALLATION

2.1 Primary Gas Connections

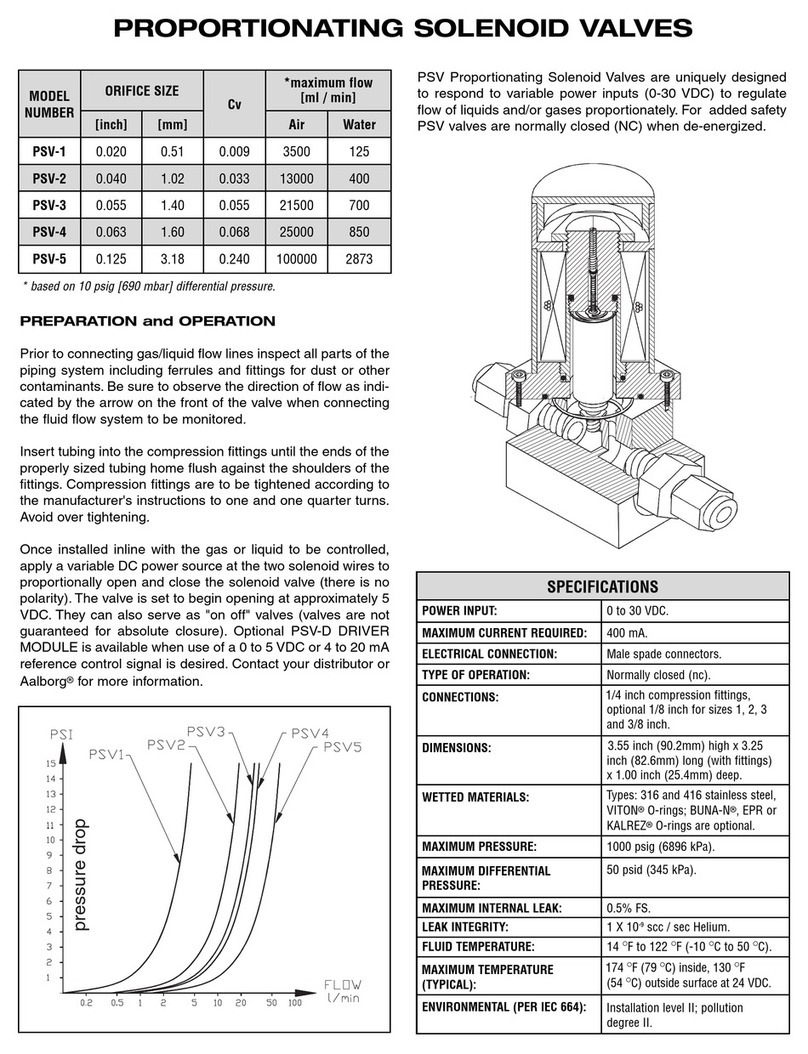

Prior to connecting gas lines inspect all parts of the piping system includ-

ing ferrules and fittings for dust or other contaminants. Be sure to observe

the direction of gas flow as indicated by the arrow on the front of the

meter when connecting the gas system to be monitored.

Insert tubing into the compression fittings until the ends of the properly

sized tubing home flush against the shoulders of the fittings.

Compression fittings are to be tightened according to the manufacturer's

instructions to one and one quarter turns. Avoid over tightening which will

seriously damage fittings.

SMV Motorized Valves are supplied with standard 3/8 inch (SMV-20), 1/2

inch (SMV-30), or 3/4 inch (SMV-40) inlet and outlet compression fittings.

Using a Helium Leak Detector or other equivalent method perform a thor-

ough leak test of the entire system. (All SMV's are checked prior to ship-

ment for leakage within stated limits. See specifications in this manual.)

2.2 Electrical Connections

The motorized valve requires a +12VDC or optional 24VDC supply with

a minimum current rating of 800 mA. Operating power and valve control

signals are supplied via the 9-pin "D" connector located at the side of the

valve. For normal operating the motorized valve requires at least two con-

trol signals:

lDirection (12V CMOS logic level, pin 8 on the 9-pin "D" connector)

lSpeed (0-2.5 VDC analog signal, pin 4 on the 9-pin "D" connector)

When direction is LOW (GND) valve goes down (closes), when direction

is HIGH valve goes up (opens). The "speed" voltage on pin 4 determines

how quickly the valve will operate. The signal amplitude for "speed" con-

trol signal must remain within the limits of 0 to +2.5 VDC.

It may be necessary to override "direction" and "speed" signals with a

preset (2.75 VDC) speed control signal. This can be accomplished with

valve CLOSE and PURGE control signals (open collector NPN compati-

ble). In order to CLOSE valve pin 3 on the 9-pin "D" connector has to be

connected to GND (pin 2). A GREEN light on the top of the valve will indi-

cate a CLOSE valve condition. In order to PURGE valve pin 7 on the 9-

pin "D" connector has to be connected to GND (pin 2). A RED light on

2