Document: v0.6 / Document No.: 6AGA000008-0102-EN | Date: 22-05-2019 Page 4of 23

Contents

Glossary...............................................................................................................................................................5

1Introduction ...................................................................................................................................................6

1.1 Preface................................................................................................................................................................ 6

1.2 Intended use of this document..................................................................................................................... 6

1.3 Intended use of the charger .......................................................................................................................... 6

1.4 Owner responsibilities.................................................................................................................................... 7

1.5 Signs.................................................................................................................................................................... 7

1.6 Safety regulations............................................................................................................................................ 9

2Description of the product.........................................................................................................................10

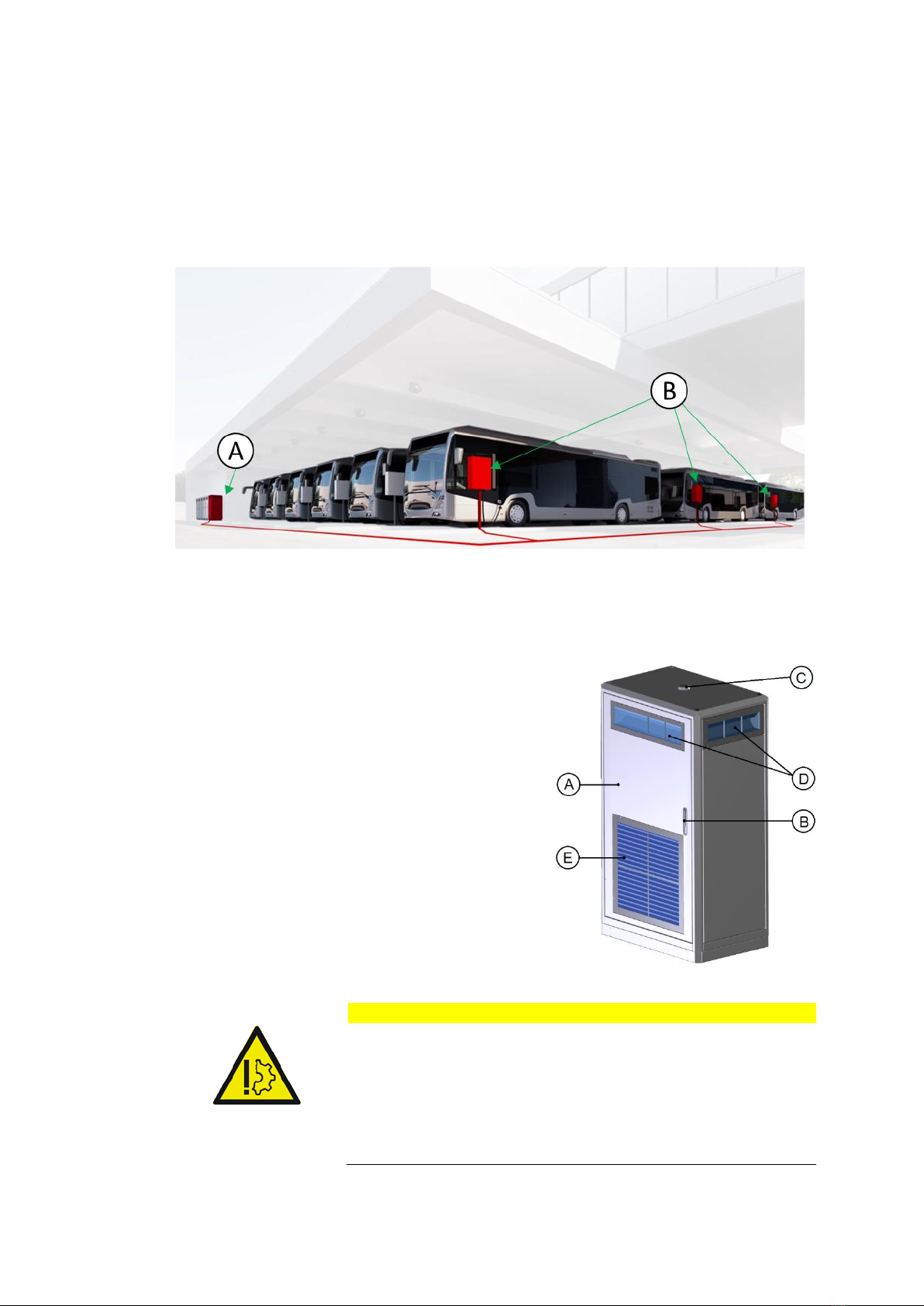

2.1 Overview of the system................................................................................................................................ 10

2.2 Charge cabinet................................................................................................................................................ 10

2.3 Depot charge box............................................................................................................................................11

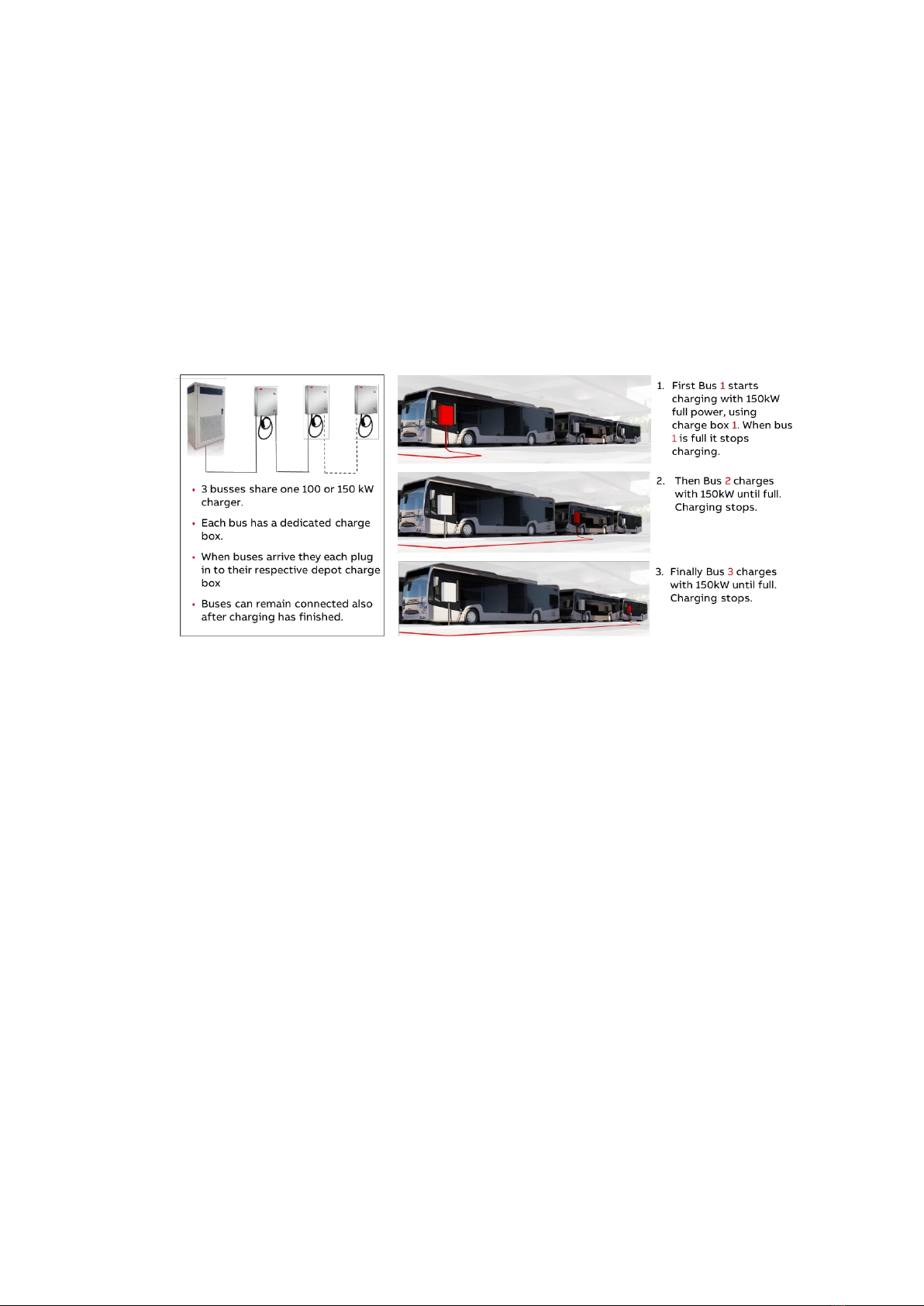

2.4 Charger configurations ................................................................................................................................ 12

2.5 Authorization to charge................................................................................................................................ 12

3Charging instruction................................................................................................................................... 13

3.1 Charging with 1 Depot Charge Box............................................................................................................ 13

3.2 Charging with 2 or 3 Depot Charge Boxes ............................................................................................... 13

3.3 Emergency stop.............................................................................................................................................. 14

4Operator Instructions ................................................................................................................................. 15

4.1 Cleaning of the cabinet and Depot charge box ...................................................................................... 15

4.2 Preventive maintenance................................................................................................................................ 15

4.2.1 Service inspection of the cabinets........................................................................................... 15

4.2.2 Emergency stop inspection ....................................................................................................... 16

4.2.3 Special inspections...................................................................................................................... 16

4.3 Problem resolving .......................................................................................................................................... 16

4.3.1 Overview of the Power Cabinet................................................................................................. 16

4.3.2 Overview of the Depot charge box............................................................................................17

4.3.3 Component overview Power Cabinet ...................................................................................... 18

4.3.4 Component overview Depot Charge Box................................................................................ 18

4.4 Technical functioning.................................................................................................................................... 19

4.4.1 Normal operation......................................................................................................................... 19

4.4.2 Switch the charger system on/off ........................................................................................... 19

4.4.3 Switch the depot box .................................................................................................................. 19

5Contact information ................................................................................................................................... 21