ABB ACS310 Installation and operating manual

Other ABB Controllers manuals

ABB

ABB i-bus SA/S 12.16.6.1 User manual

ABB

ABB ACS355 series User manual

ABB

ABB Triguard SC300E User guide

ABB

ABB ACS880-17 User manual

ABB

ABB COMMANDER 100 User manual

ABB

ABB ACH550-PCR User manual

ABB

ABB 6153 EB-500 User manual

ABB

ABB COM600 series User manual

ABB

ABB COMMANDER 351 User manual

ABB

ABB ACS800-04 User manual

ABB

ABB PSTX Series Parts list manual

ABB

ABB Totalflow mflo Series User guide

ABB

ABB CBXi-8R8 User manual

ABB

ABB Advant Controller 80 User manual

ABB

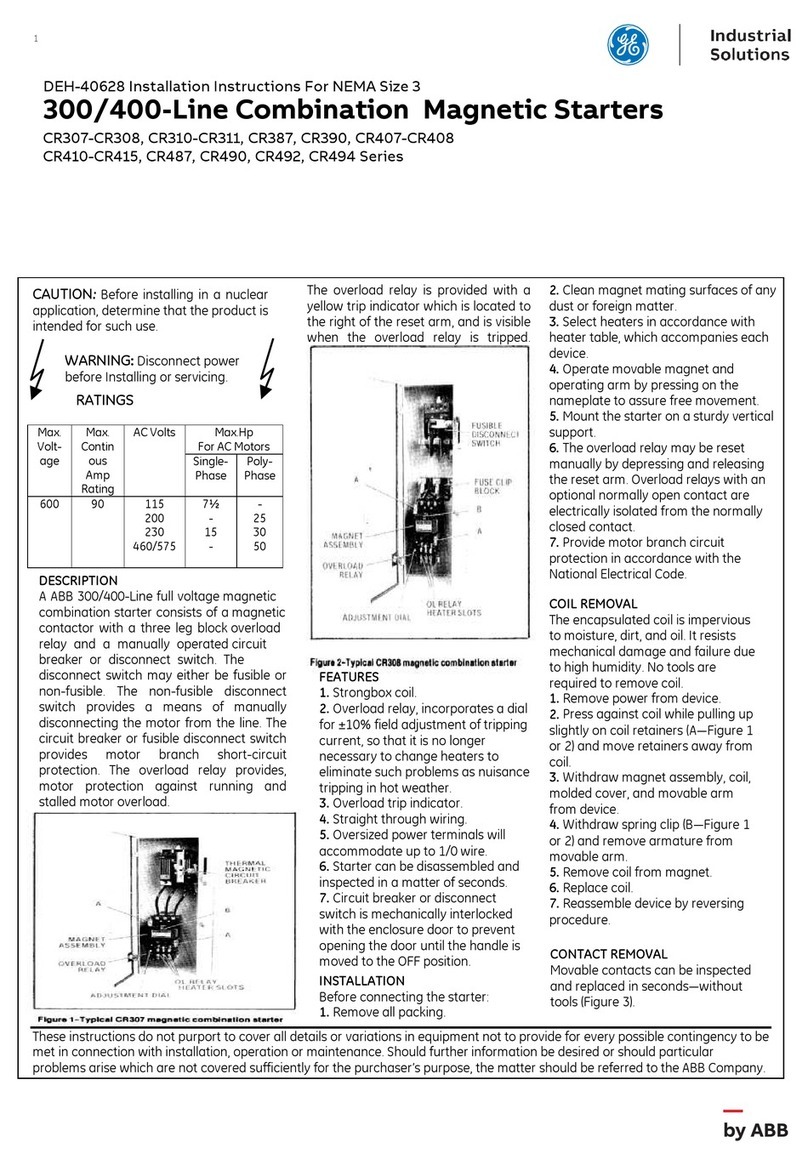

ABB CR307 Series User manual

ABB

ABB ACS880 Series Use and care manual

ABB

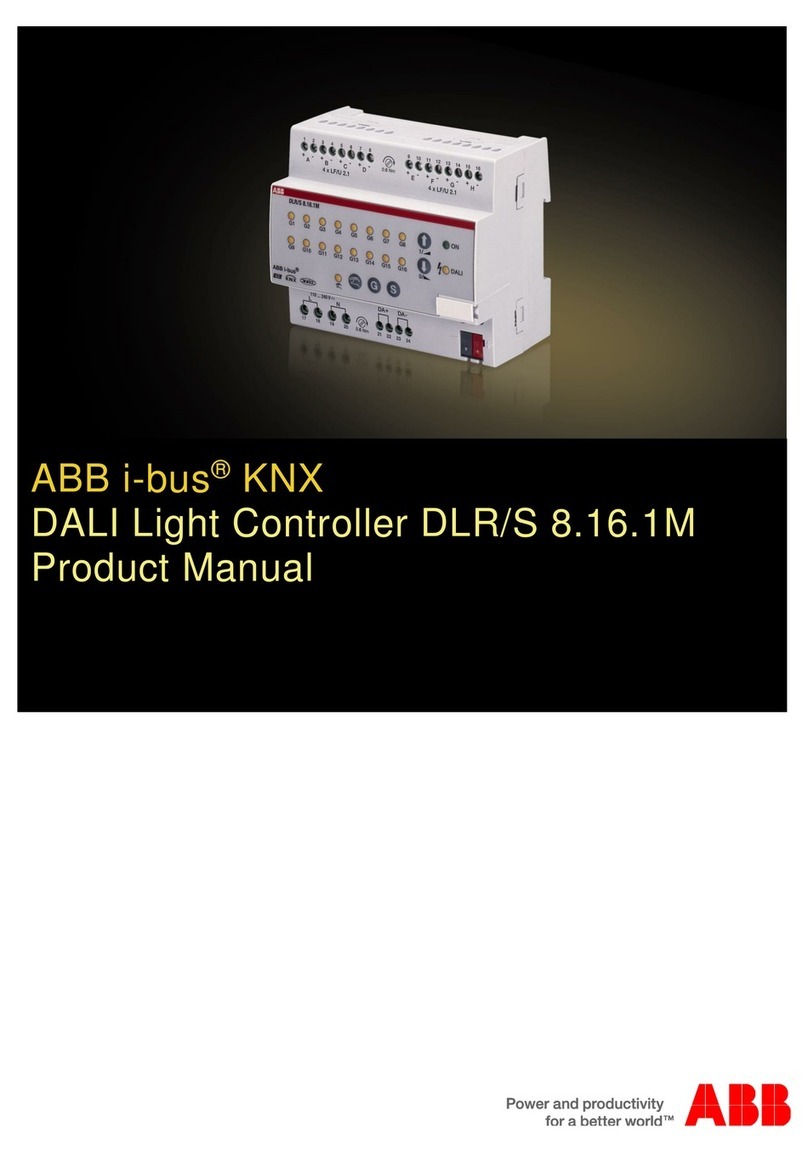

ABB i-bus KNX User manual

ABB

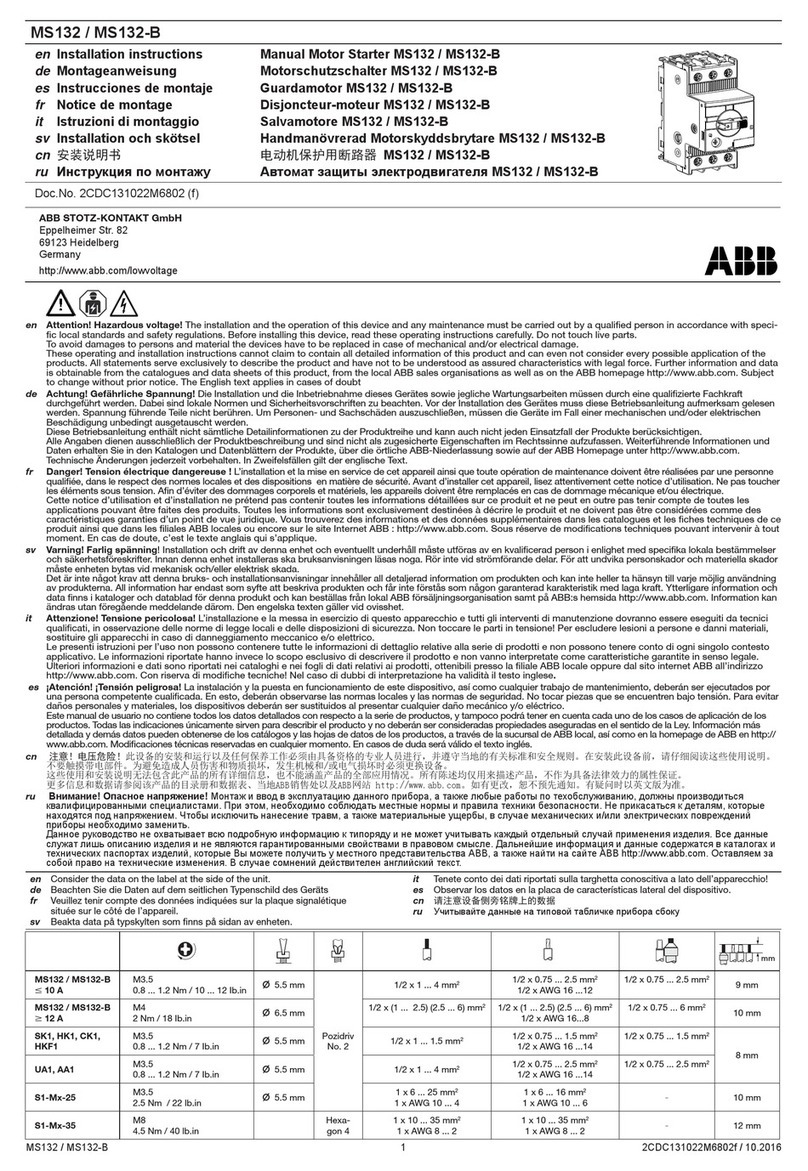

ABB MS132 User manual

ABB

ABB Relion 670 series User manual

ABB

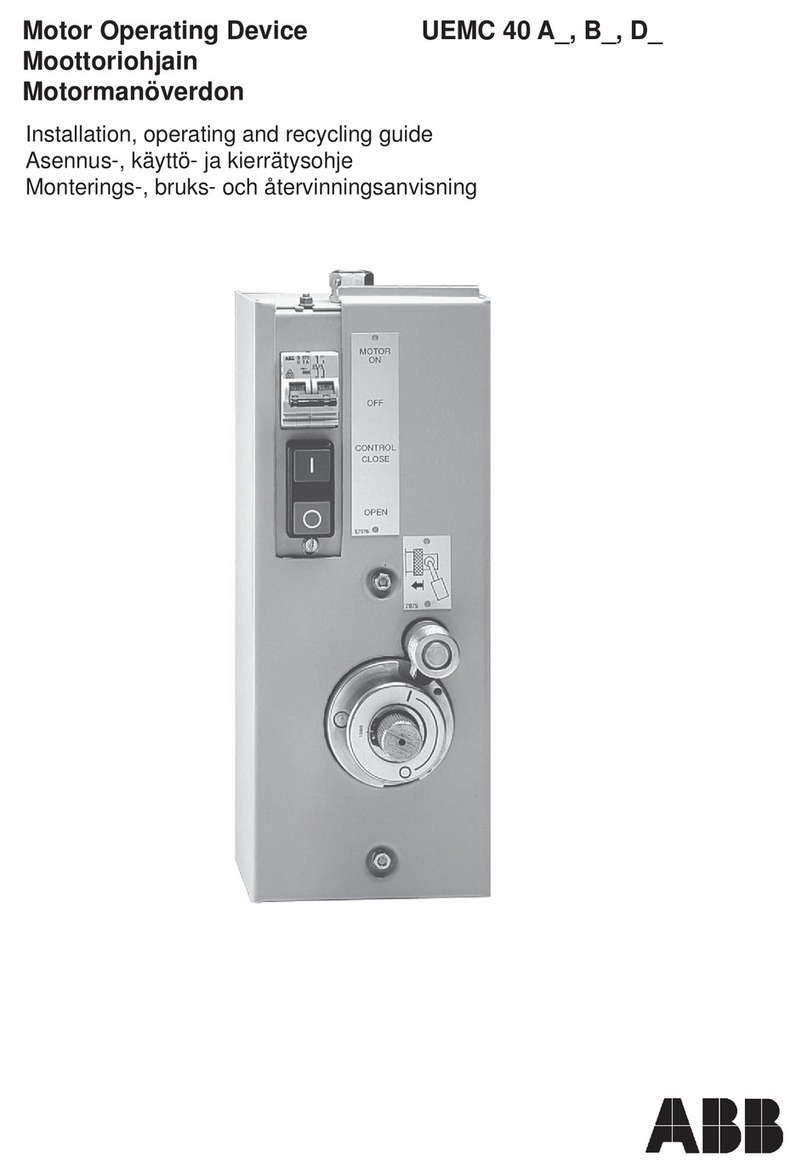

ABB UEMC 40 B Series Installation guide

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions