Safety instructions

Read the safety instructions in the

ACQ80-04

drive

s (0.75 to 22 kW) Hardware

manual

(3AXD50000170661[EN]).

WARNING! Obey these safety instructions to prevent physical injury or

death, or damage to the equipment. If you are not a qualified electrician,

do not do electrical installation or maintenance work.

• Keep the drive in its package until you install it. After unpacking, protect the

drive from dust, debris and moisture.

• Use the required personal protective equipment: safety shoes with metal toe

cap, safety glasses, protective gloves, etc.

• Disconnect all possible voltage sources. Lock and tag.

• When the drive or connected equipment is energized, do not do work on the

drive, motor cable, motor, control cables or control circuits.

• After you disconnect the input AC and DC (PV) power, wait for five minutes to

let the DC bus capacitors discharge. Measure and make sure that the,

•voltage between the DC bus terminals (UDC+, UDC-) is 0 V.

•DC voltage between the DC bus terminals (UDC+, UDC-) and

ground (PE) is 0 V.

• Make sure that the equipment is not energized. Use a multimeter with an

impedance of at least 1 Mohm. Make sure that the,

•voltage between the drive input power terminals (L1, L2, L3) and the

ground (PE) is 0 V.

•phase to phase voltage between the drive input power terminals (L1, L2,

L3) is 0 V.

•voltage between the drive output terminals (T1/U, T2/V, T3/W) and the

ground (PE) is 0 V.

•phase to phase voltage between drive output terminals (T1/U, T2/V, T3/

W) is 0 V AC.

• If you use a permanent magnet synchronous motor, do not do work on the

drive when the motor rotates. A permanent magnet motor that rotates

energizes the drive and the output power terminals.

WARNING! The installation, start-up and operation of this equipment

requires detailed instructions. Refer to the detailed instructions in the

ACQ80 Hardware manual

(3AXD50000170661 [EN]) and

ACQ80

Firmware manual

(3AXD50000170654 [EN]). You can download these

manuals from the ABB website.

1. Examine the installation area

The drive is intended for cabinet installation and has a degree of protection of

IP20 / UL open type.

Make sure that in the installation area:

• There is sufficient cooling and hot air does not recirculate back to air inlet of

the drive.

• There is sufficient space above and below the drive for cooling. Refer to

Free

space requirements

.

• The ambient conditions are suitable. Refer to

Ambient conditions

.

• The mounting surface is non-flammable and can hold the weight of the drive.

Refer to

Dimensions and weights

.

• Materials near the drive are non-flammable.

2. Install the drive

You can install the drive with screws or to a DIN rail [Top Hat, W x H = 35 x 7.5 mm

(1.4 x 0.3 in)].

Installation requirements:

• Make sure that there is a minimum of 75 mm (2.9 in) of free space at the top

and bottom of the drive for cooling air.

• You can install several drives side by side. Side-mounted options require

approximately 20 mm (0.8 in) of space on the right side of the drive.

WARNING! Do not install the drive upside down. Make sure that the

cooling air exhaust (at the top) is always above the cooling air inlet (at

the bottom).

To install the drive with screws

1. Make marks onto the surface for the mounting

holes. Refer to

Dimensions and weights

. The R2

and R3 drives come with a mounting template.

2. Make the holes for the mounting screws and

install suitable plugs or anchors if required.

3. Start to tighten the screws into the mounting

holes.

4. Install the drive onto the mounting screws.

5. Tighten the mounting screws.

To install the drive on a DIN rail

1. Move the locking part to the left.

2. Push and hold the locking button

down.

3. Put the top tabs of the drive onto the

top edge of the DIN installation rail.

4. Put the drive against the bottom edge

of the DIN installation rail.

5. Release the locking button.

6. Move the locking part to the right.

7. Make sure that the drive is correctly

installed.

8. To remove the drive, use a flat-head

screwdriver to open the locking part.

3. Measure the insulation resistance

Drive: Do not do voltage tolerance or insulation resistance tests on the drive,

because this can cause damage to the drive.

Input power cable: Before you connect the input power cable, measure the

insulation of the input power cable. Obey the local regulations.

Motor and motor cable:

1. Make sure that the motor cable is connected to the motor and disconnected

from the drive output terminals T1/U, T2/V and T3/W.

2. Use a voltage of 1000 V DC to

measure the insulation

resistance between each

phase conductor and the

protective earth conductor.

The insulation resistance of

an ABB motor must be more

than 100 Mohm (at 25 °C/

77 °F). For the insulation

resistance of other motors, refer to the manufacturer’s documentation.

Moisture in the motor decreases the insulation resistance. If you think that

there is moisture in the motor, dry the motor and do the measurement

again.

4. Select the cables

See the drive hardware manual for the cable selection instructions.

Note:

Input power cable: IEC/EN 61800-5-1 requires two protective earth (ground)

conductors.

Motor cable: ABB recommends to use symmetrical shielded cable (VFD cable)

for the best EMC performance.

Control cable: Use a double-shielded twisted-pair cable for the analog signals.

Use a double- or single-shielded cable for the digital, relay and I/O signals. Do

not mix 24 V and 115/230 V signals in the same cable.

5. Connect the power cables

Connection diagram (shielded cables)

CAUTION! ABB recommends to use a lightning pole to avoid lightning

strike to the drive. Make sure that the lightening pole ground is not

common for PV cell, drive, and motor.

If you do wiring in conduits, see the drive hardware manual for more

information.

1. Reverse polarity diodes.

2. EMI filter is optional but is mandatory for IEC/EN62920 standard

compliance which is required in Europe.

3. Ground connection should be common for MOV, drive, and pump.

Note: ACQ80 is intended to be used for speed control of 3ph AC pump motors

and is powered from either AC Grid or DC photo-voltaic array. ABB recommends

not to use it as an island grid forming inverter or to supply generic 1ph or 3ph

loads, other than 3ph AC pump motors.

Connection procedure (shielded cables)

If you do wiring in conduits, see the drive hardware manual for more

information.

WARNING! Obey the safety instructions in the

ACQ80 Hardware

manual

(3AXD50000170661 [EN]). If you ignore them, injury or death, or

damage to the equipment can occur.

WARNING! Make sure that the drive is compatible with the power

supply system. You can connect all drive types to a symmetrically

grounded TN-S system. You can also connect the UL (NEC) drive types

to a corner-grounded system. For other power supply systems, you may need to

disconnect the EMC filter or the ground-to-phase varistor. For more

information, see the drive hardware manual.

1. Open the front cover. To open the

front cover, loosen the locking

screw and lift the front cover up.

2. Strip the motor cable.

3. Ground the motor cable shield

under the grounding clamp.

4. Twist the motor cable shield into

a bundle, mark it accordingly and

connect it to the grounding

terminal.

5. Connect the phase conductors of

the motor cable to the T1/U, T2/V

and T3/W motor terminals. Tighten the terminals to 0.8 N·m (7 lbf·in)

torque.

6. Strip the input AC power cable.

7. Connect the DC cables as per the

connection diagram.

8. If the input AC power cable has a

shield, twist it into a bundle, mark

it and connect it to the grounding

terminal.

9. Connect the PE conductor of the

input AC power cable to the

grounding terminal. If it is

necessary, use a second PE

conductor.

10. Connect the phase conductors of

the input AC power cable to the

L1, L2 and L3 input terminals.

Tighten the terminals to 0.8 N·m

(7 lbf·in) torque.

11. Mechanically attach the cables on the outside of the drive.

Note! If you power up the drive before you install the I/O or fieldbus module, the

drive gives a warning.

6. Install the communication module

To install the communication module (I/O module or fieldbus module):

1. Open the front cover.

2. Align the communication module

contacts with the contacts on the

drive.

3. Carefully push the communication

module into position.

4. Push the locking tab in.

5. Use a Torx TX10 screwdriver and

tighten the locking screw (torque

0.8 N·m) to fully attach and

electrically ground the

communication module.

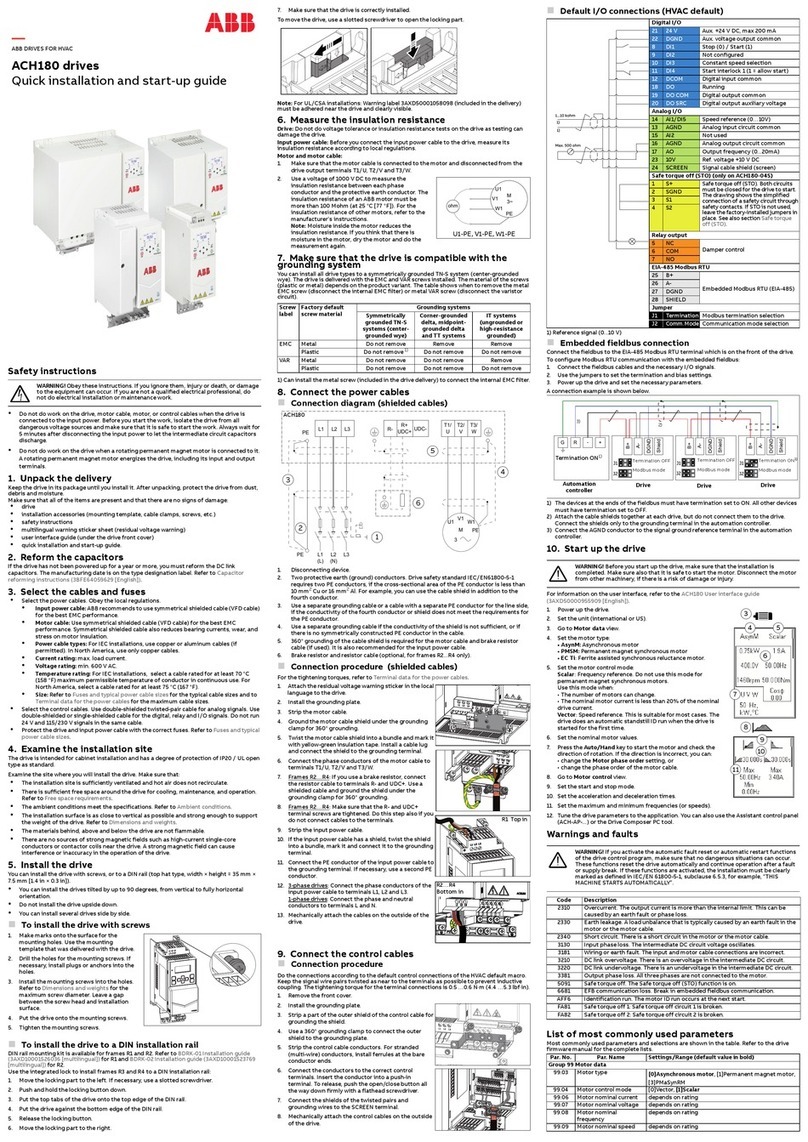

7. Connect the control cables

Connection procedure

Do the connections according to the default control connections of the

application macro that you select. For the connections of the factory default

macro (ABB standard macro), refer to

Default I/O connections (ABB standard

macro)

. For the other macros, refer to the

ACQ80 Firmware manual

(3AXD50000170654 [EN]).

Note:

• This is an IEC compliant connection procedure.

Keep the signal wire pairs twisted as near to the terminals as possible to

prevent inductive coupling.

1. Strip a part of the outer shield of

the control cable for grounding.

2. Use the metal cable tie provided

to ground the outer shield to the

grounding tab.

3. Strip the control cable

conductors.

4. Connect the conductors to the

correct control terminals. Tighten

the terminals to 0.5 N·m (4 lbf·in)

torque.

5. Connect the shields of the twisted pairs and grounding wires to the SCR

terminal. Tighten the terminals to 0.5 N·m (4 lbf·in) torque.

6. Mechanically attach the control cables on the outside of the drive.

7. Close the front cover and tighten the locking screw.

Default I/O connections (ABB standard macro)

Note

:

×

refers to terminals in the base unit. Other terminals are in the RIIO-01 I/O extension module

(installed in the standard drive variant as default).

—

ABB DRIVES FOR WATER

ACQ80-04 drives

Quick installation and start-up guide

PV input

terminal

DC/

MCB/

Fuse

MOV

EMI

filter

DC+

DC-

L1 L2 L3

U

V

W

PE

Pump

motor

AC MCB/

MPCB

AC grid or

generator

1

2

33

ACQ80-04

drive

3

Earth pit 1

MOV

Earth pit 1

Earth pit 1

Terminal Description Base unit

Reference voltage and analog I/O

SCR

Signal cable shield (screen)

AI1

Not configured

AGND

Analog input circuit common

+10 V

Reference voltage 10 V DC

AI2

Not configured

AGND

Analog input circuit common

AO1

Output frequency: 0...20 mA

AO2

Motor current

AGND

Analog output circuit common

Aux. voltage output and programmable digital inputs

+24 V

Aux. voltage output +24 V DC, max. 250 mA

×

DGND

Aux. voltage output common

×

DCOM

Digital input common for all

×

DI1

Stop (0)/Start (1)

×

DI2

Not configured

×

DI3

Not configured

DI4

Not configured

DI5

Not configured

DI6

Not configured

Relay outputs

RO1C

Ready run

×

RO1A

250VAC/30VDC

×

RO1B

2A

×

RO2C

Running

RO2A

250VAC/30VDC

RO2B

2A

RO3C

Fault (-1)

RO3B

250VAC/30VDC

RO3A

2A

EIA-485 Modbus RTU

B+

Embedded Modbus RTU (EIA-485)

A-

DGND

TERM&BIAS Serial data link termination switch

Safe torque off

SGND

Safe torque off. Factory connection. Both

circuits must be closed for the drive to start.

×

IN1

×

IN2

×

OUT1

×

+24V

Auxiliary voltage output. The alternative

terminals have the same supply as the base

unit.

DGND

DCOM