Important safety information

Electric shock hazard! Disconnect and ISOLATE the Drive before

attempting any work on it.

High voltages are present at the terminals and within the drive for up

to 10 minutes after disconnection of the electrical supply. Always

ensure by using a suitable multimeter that no voltage is present on

any drive power terminals prior to commencing any work.

This variable speed drive product (Drive) is intended for professional

incorporation into complete equipment or systems as part of a fixed

installation. If installed incorrectly it may present a safety hazard. The

Drive uses high voltages and currents, carries a high level of stored

electrical energy, and is used to control mechanical plant that may

cause injury. Close attention is required to system design and

electrical installation to avoid hazards in either normal operation or in

the event of equipment malfunction.

Only qualified electricians are allowed to install and maintain this

product.

The entry of conductive or flammable foreign bodies should be

prevented. Flammable material should not be placed close to the

drive.

General safety instructions

WARNING! ACS260 units may become damaged if

operated without a suitable heatsink. Do not operate

the unit without providing suitable heatsink capacity

for the drive and application requirement.

• ACS260 Power Modules must be mounted onto a suitable flat

metallic surface with sufficiently low thermal resistance to allow

dissipation of the heat produced.

• Surface flatness must be =<+ / - 0.2mm over the mounting area

• The chosen mounting location must ensure the unit is not subject

to vibration levels in excess of the limits specified in section

vibration.

• Units should be mounted only using the integral mounting holes.

• The ACS260 must be installed in a pollution degree 1 or 2

environment only.

• Ensure that the ambient air temperature range around the unit

during operation does not exceed the permissible limits given in

User Manual section Technical Data.

• Do not mount flammable material close to the ACS260.

• Units may be mounted in any orientation.

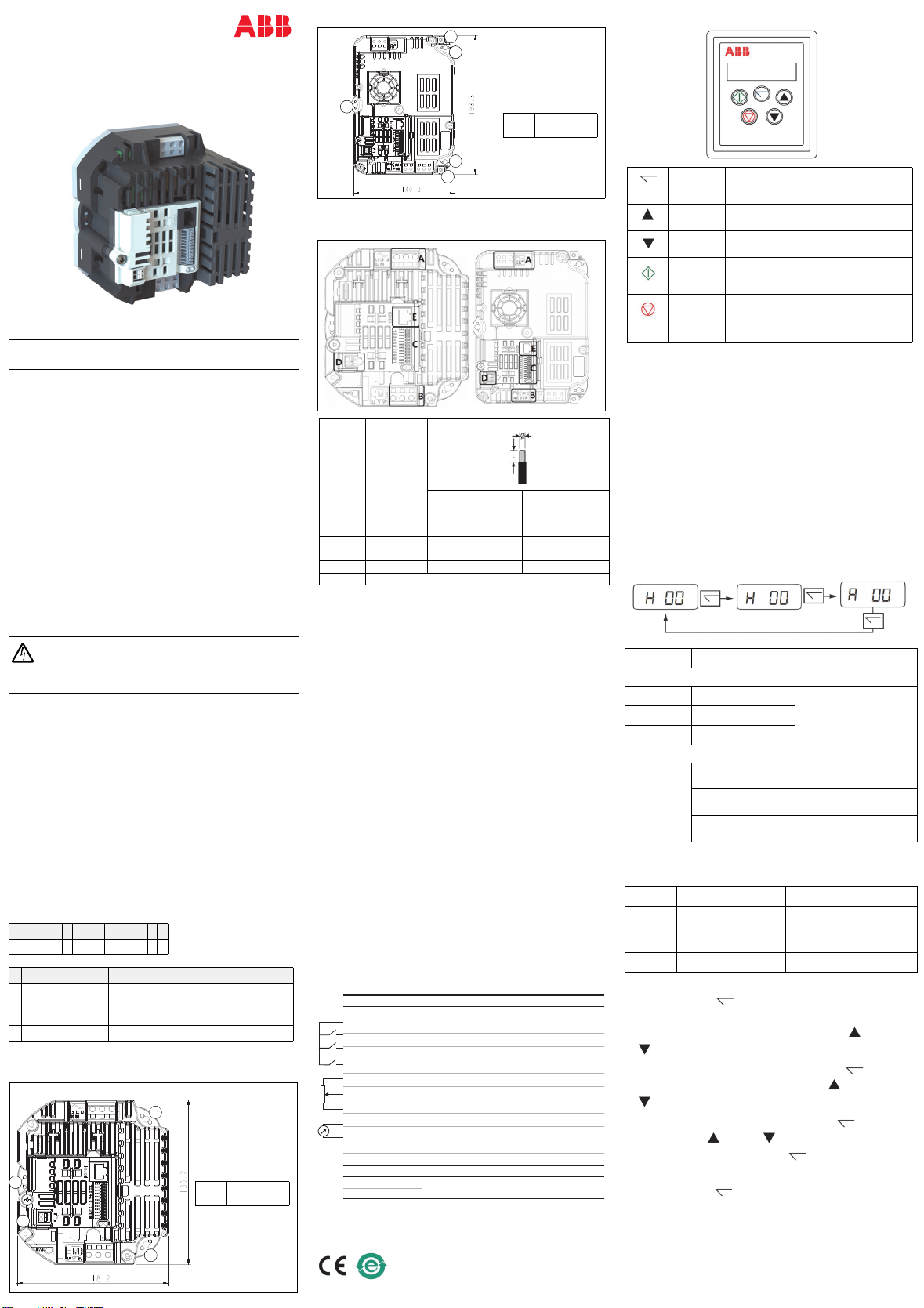

Type designation key Definition

Sample type code: ACS260-04-02A2-4

Dimension and Mounting

Frame size R1

Frame size R2

Electric connection

Frame size R1 and R2

Start-up

When delivered, ACS260 is pre-programmed to run from remote

inputs wired to the terminal strip. This default digital input

configuration provides a general purpose I/O setup with a hard-wired

start / stop enable, forward / reverse input and a selection between

an analog speed reference or preset speed input.

Parameter 1103 = 0 defines control from the terminal strip (for Keypad

Control 1103 =1) and Parameter 9902 = 0 sets up the configuration for

the inputs and outputs as shown below.

1. The drive is to run PM motor (9903=2) as default. Changing 9903=0

when induction motor is connected.

2. Connect a control switch between the control terminals 1 and 2 and

ensure that the contact is open (drive disabled). Connect a

potentiometer (1kΩmin to 10 kΩmax) between terminals 5 and 7

with the wiper to terminal 6 of the control terminal. With the

potentiometer set to zero, switch on the supply to the drive.

3. The status LED is slow flashing green and a connected RCRP-02

Keypad will display STOP. Close the control switch, terminals 1-2,

the drive is now ‘enabled’ and the output frequency speed are

controlled by the potentiometer. The status LED will change to

constant on green.

4. The display shows zero speed in Hertz as H 0.0. with the

potentiometer turned to minimum. If the display is not showing H,

change it with the navigate key. Adjust the speed using the

potentiometer, the motor will accelerate to the speed set by the

potentiometer up to the value set in parameter 2008 (maximum

frequency limit.)

5. Stop the drive by opening the control switch (terminal 1-2).

Default I/O connection for standard type

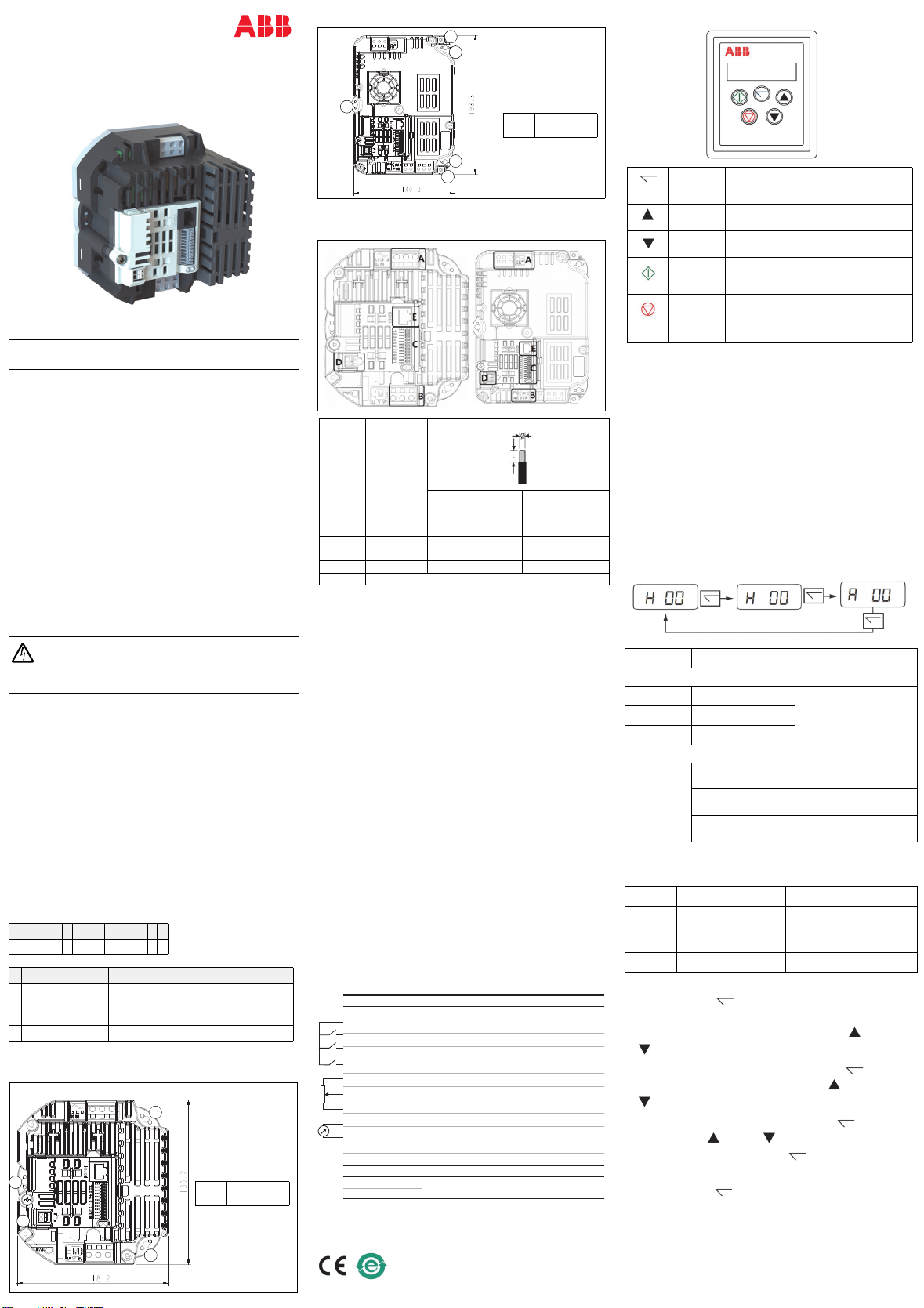

Remote Keypad RCRP-02

NOTE: For keypad control set parameter 1103=1 and 9902 to the

desired I/O configuration. Terminal 1 and 2 must be connected to

enable ACS260.

Keypad Operation

Setting parameter 1103 to a value of 1 enables keypad mode with

forward direction only, while a value of 2 enables keypad mode with

forward and reverse rotation.

Set parameter 1100 to 1 or 3 to enable the drive to start from the

previous set keypad reference speed.

While the drive is stopped, press the STOP key. The value of the digital

potentiometer will be displayed, indicating the target speed. Use the

UP and DOWN keys to select the required target speed.

Press the STOP key to return to the real time display showing STOP or

press the START key to start the drive ramping up to the target speed.

To reverse direction, press the START key again.

Keypad Display Screens

Prior to operation the keypad will show STOP, pressing the STOP key

allows setting the preset speed on the display (H x.x) While in

operation the following displays can be accessed by briefly pressing

the Navigate Key.

Accessing Parameters and Program Navigation

The parameters are arranged in Groups according the to the following

structure.

Parameter Navigation

• Press and hold the NAVIGATE key for more than 1 second

when the drive is displaying STOP. The display changes to PAr 5,

indicating the short (S) parameters group. Use the ( UP) and

(DOWN) keys to select between the S, Lor Aparameter groups.

• To enter a parameter group, press and release the (Navigate)

key while the group letter is flashing. Use the (UP) and

(DOWN) keys to change to the desired parameter number.

• To change parameter values, press and hold the (Navigate)

key then use the (UP) and (DOWN) keys to change to the

required value. Press and release the (Navigate) key once

more to store the change.

• Press and hold the (Navigate) key for more than 1 second to

return to real-time mode. The display shows STOP if the drive is

stopped or the real-time information (e.g. speed, current or power)

if the drive is running.

• To access Read Only Parameters, navigate to PAr L Group and

scroll to Parameter 0000, then press and release the navigate key.

Segment A B C

ACS260 - 04 - 02A2 - 4

Code Description

AConstruction 04 = Module

BCurrent rating For example, 02A2 refers to a nominal

output current of 2.2 A.

CVoltage rating 4 = 3-phase 380...480 V

—

ABB MACHINERY DRIVES

ACS260-04 Component Drive

Quick installation and start-up guide

Use 3 x M4 (No. 8)

bolts or screws,

tightening torque:

4Nm / 3ft-lb

Depth: 74mm

Weight: 0.7kg,

1.54lb

1Mountinghole

2PE

1

2

1

1

Location Purpose

ØL

AIncoming

Power 1.5mm2/ AWG 14 Max 5 – 6mm / 0.2in

BMotor 1.5mm2/ AWG 14 Max 5 – 6mm / 0.2in

CControl

Terminals

0.5mm2/ AWG 20

Max 6 – 7mm / 0.25in

DOutput Relay 1.5mm2/ AWG 14 Max 8 – 9mm / 0.3in

ERJ45 Serial : Warning! Not Ethernet!

Use 3 x M4 (No. 8)

bolts or screws,

tightening torque:

4Nm / 3ft-lb

Depth:89mm

Weight:1.3kg, 2.87lb

1Mountinghole

2PE

1

1

1

2

2

8IVQMREPW -RWXVYGXMSR

(MKMXEP-3GSRRIGXMSR

:C398 %Y\MPMEV]ZSPXEKISYXTYX:('

(- (MKMXEP-RTYX7XST演漕7XEVX演漕

(- (MKMXEP-RTYX*SV[EVH6IZIVWEP演漕

(-%- (-%-TVIWIXWTIIH演漕 %REPSKWTIIHVIJIVIRGI演漕

:C398 :SPXEKIVIJIVIRGI:('

%-(- %-(-WTIIHVIJIVIRGI:

%+2( %REPSKMRTYXKVSYRH

%3(3 %REPSKSYXTYX(MKMXEPSYXTYX

+2( +VSYRH

1SHFYW689

1SHFYW689

6IPE]3YX

60% '31 %'7(VMZIVIEH]

60& 23

Markings

The applicable markings are shown on the type label of the product.

CE China RoHS

NAVIGATE Used to display real-time information, to

access and exit parameter edit mode and to

store parameter changes.

UP Increase speed in real-time mode or scroll

through values in parameter edit mode.

DOWN Decrease speed in real-time mode or scroll

through values in parameter edit mode.

START When in keypad mode, the button is used to

start a stopped drive or to reverse the

direction of rotation.

STOP In normal application, when in Keypad

mode, this button is used to stop a running

drive. If in trip mode, the key is used to reset

the drive.

STOP Drive power applied and no Enable or Run signal

Drive Running

H 0.0. Output Frequency (Hz) Press Navigate to select

display

Press again to cycle display

A 0.0. Motor Current (Amps)

P 0.0. Motor Power (kW)

Drive Running, Speed Reference = 0

Stndby

Enable / disable switch open drive will decelerate to

stop and display shows STOP

A zero reference and enable/disable closed the

display with show H 0.0 (0.0Hz)

60 seconds at zero speed drive standby mode Stndby

waiting for a speed reference

PAR 5 Short Parameter Group Basic Setup Parameters

PAR L Long Parameter Group Sequential List all Parameters

Access to Display Group

PAR A Advanced Group Advanced Motor Control

0000 Read Only Display Group Parameter 0000 Par L Group

3AXD50000672103 Rev A 2020-12-18