Operation Manual / A130-M.. - A145-M..

Page 7 /

© Copyright 2013 ABB. All rights reserved.

2 Safety

2.1 Introduction

Turbochargers manufactured by ABB Turbo Systems are state of the art and comply with the

respective health and safety standards in effect at the time the turbocharger was built. This

ensures safe operation of the turbocharger. Nevertheless, there may be some residual risks

during operation of and work on the turbocharger which:

Are caused by the turbocharger itself or its accessories.

Are caused by the operating equipment used or supplies and materials.

Are a consequence of insufficient compliance with safety instructions.

Are a consequence of insufficient or inappropriate performance of maintenance and in-

spection work.

The operating company is responsible for the organisational measures that regulate the safe

handling of the turbocharger by its personnel.

All instructions contained in this chapter must be observed for safe and trouble-free operation

of the turbocharger and during all work on the turbocharger.

All further safety instructions contained and specifically identified in every chapter of this ma-

nual (Definition of safety instructions [➙ 7]) must also be observed.

2.2 Definition of safety instructions

The following symbols and nomenclature are used in this manual, referring to safety or indi-

cating potential hazards:

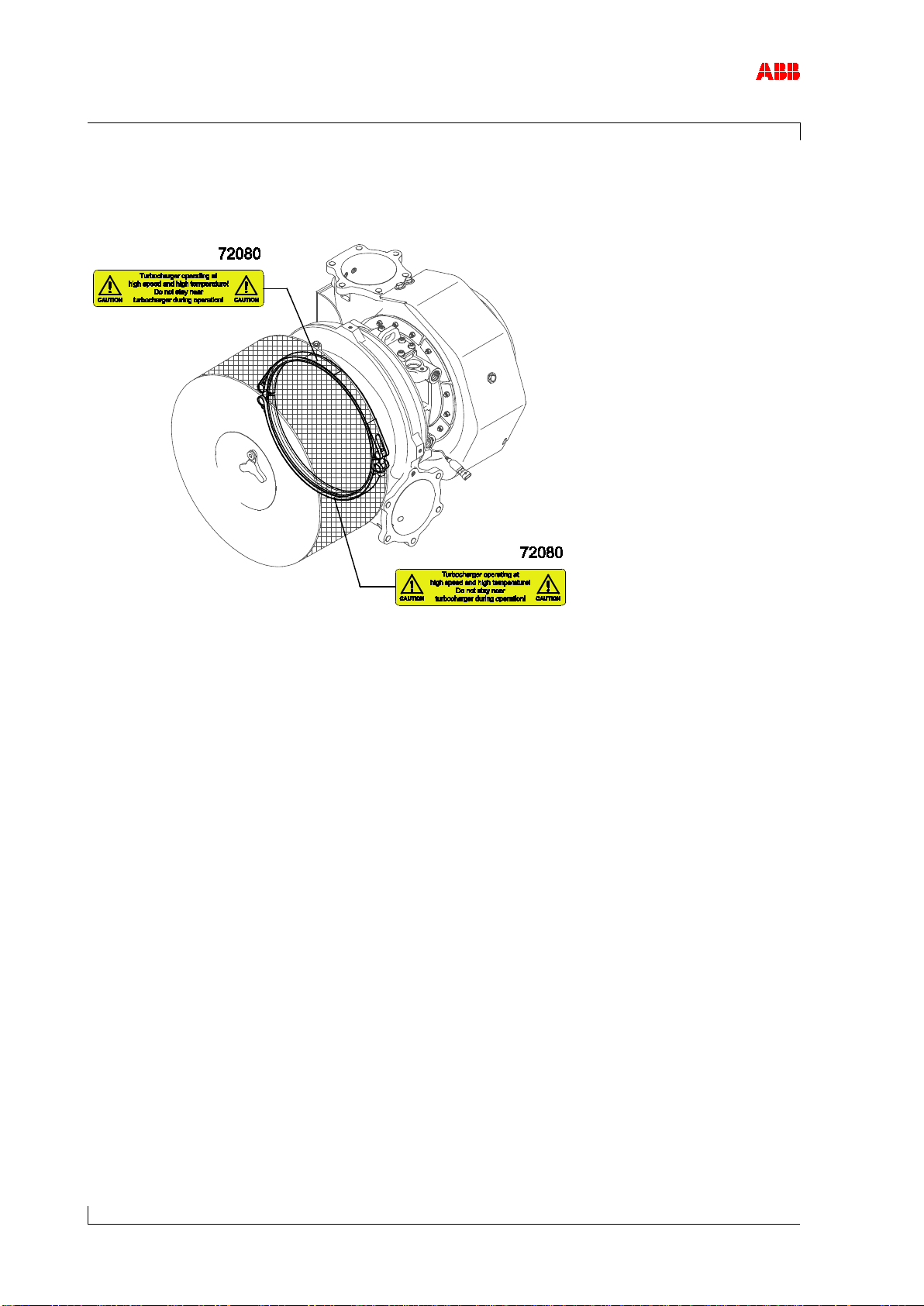

Non-compliance or inaccurate compliance with working or operating instruc-

tions indicated by this symbol and the word

can lead to serious

injuries to personnel and even to fatal accidents.

Warning signs must always be observed.

Non-compliance or inaccurate compliance with working or operating instruc-

tions indicated by this symbol and the word

can lead to serious

damage to engine or property with grave consequences.

Caution signs must always be observed

.