—

1 Getting started with example projects

1.1 Introduction

This document gives an overview of the steps for the first use of a PLC with AC500 V2

processor module and describes:

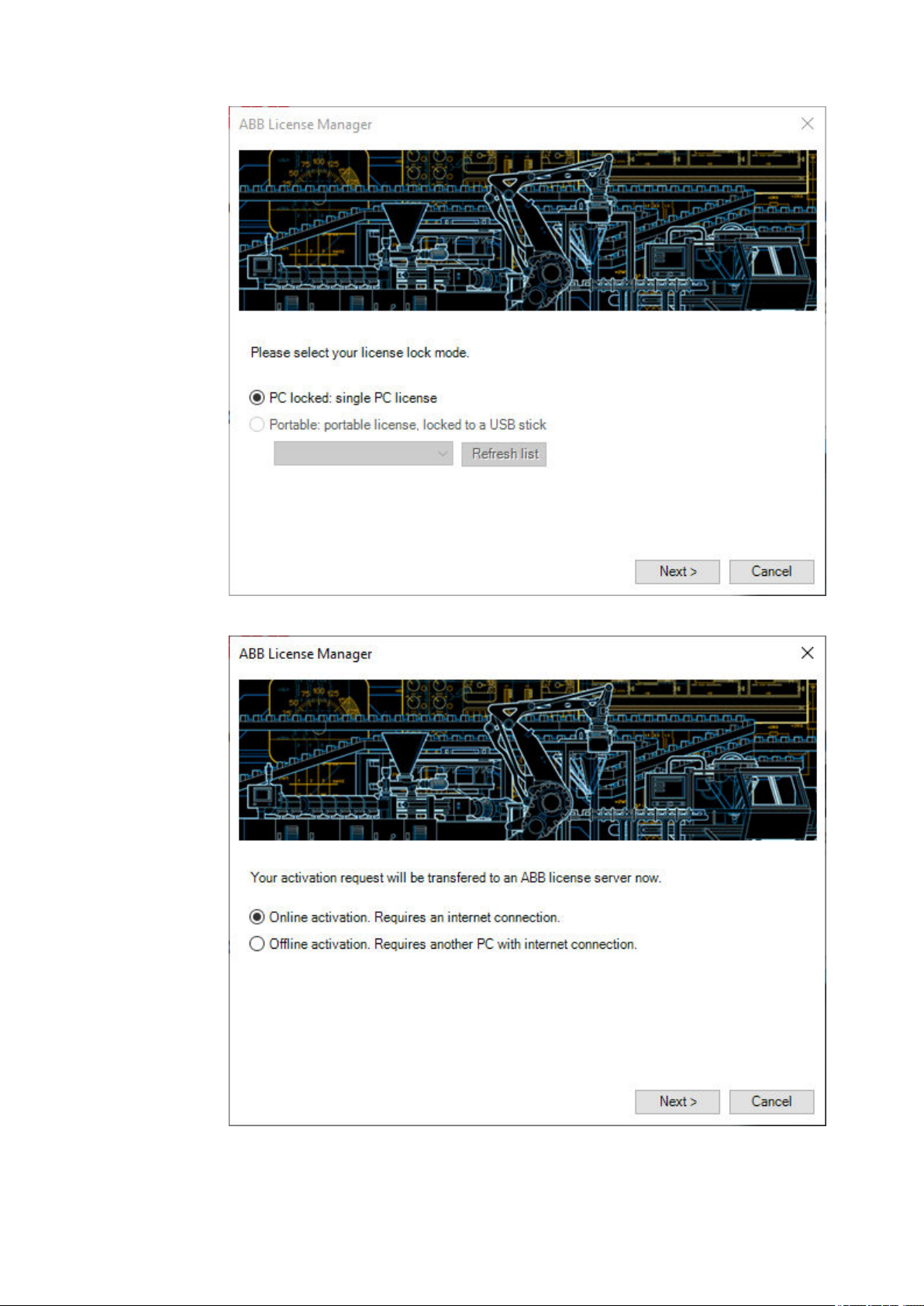

● installation of the engineering software

Ä

Chapter 1.3 “Engineering software Automation

Builder” on page 6

● hardware needed for example projects

Ä

Chapter 1.4 “Hardware AC500 V2” on page 10

● setting up a first, simple project for a stand-alone CPU with central I/O expansion, including

visualization and web visualization

Ä

Chapter 1.5 “Example project for central I/O expan-

sion” on page 13

● commissioning a project for remote I/O expansion with PROFINET

Ä

Chapter 1.6 “Example

project for remote I/O expansion with PROFINET” on page 52

1.2 Safety instructions

Relevant standards and regulations, accident prevention regulations and regulations on spe-

cial environmental conditions must be observed (e.g., hazardous areas due to explosive sub-

stances, heavy soiling or corrosive influences).

The devices must be handled and operated within the specified technical data and system data.

The devices contain no serviceable parts and must not be opened.

Removable covers must be closed during operation unless otherwise specified.

Any liability for the consequences of incorrect use or unauthorized repairs is rejected.

Both the AC500 control system and other components in the vicinity are operated with dan-

gerous touch voltages. Touching live components can lead to serious health implications or

even death.

To avoid such risks and the occurrence of property damage, persons involved in the installation,

commissioning and maintenance must have relevant knowledge about:

● Automation technology

● Handling of hazardous voltages

● Application of relevant standards and regulations, accident prevention regulations and reg-

ulations on special environmental conditions (e.g., hazardous areas due to explosive sub-

stances, heavy soiling or corrosive influences).

The AC500-S safety user manual must be read and understood before using the safety configu-

ration and programming tools of Automation Builder/PS501 Control Builder Plus. Only qualified

personnel are permitted to work with AC500-S safety PLCs.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variants and requirements associated with any particular installation, ABB

cannot assume responsibility or liability for actual use based on the examples and diagrams.

The PLC was developed according to the relevant standards. Any module-specific measures

are described in the individual descriptions of the modules.

Qualified per-

sonnel

Functional

safety

General infor-

mation

Getting started with example projects

2023/03/03 3ADR010649, 3, en_US 3