LOF-2 (4) 2UEA001270 Rev. F ACS2000 User manual

Figure 3-10 IOEC I/O system overview 3-11

Figure 3-11 Module identification 3-12

Figure 3-12 IOEC module location 3-14

Figure 3-13 IOEC2 (A1541) module 3-15

Figure 3-14 IOEC4 (A1621) module 3-19

Figure 3-15 Fieldbus communication 3-24

Figure 3-16 Fieldbus location 3-24

Figure 4-1 Transport dimensions (Frame 2 pictured) 4-2

Figure 4-2 Transporting the cabinet by crane using lifting brackets

(Frame 3 pictured) 4-3

Figure 4-3 Transporting the cabinet by forklift (Frame 2 pictured) 4-4

Figure 4-4 - Frame 1 Prepare drive for storage 4-6

Figure 4-4 - Frame 2 Prepare drive for storage 4-6

Figure 4-4 - Frame 3 Prepare drive for storage 4-7

Figure 5-1 Anchor bolt 5-3

Figure 5-2 Direct-to-floor base mounting 5-3

Figure 5-3 - Frame 1 Fan outlet box 5-4

Figure 5-4 - Frame 1 Fan outlet box installation 5-4

Figure 5-3 - Frames 2, 3 Fan outlet box and external fan 5-5

Figure 5-4 - Frames 2, 3 Fan outlet box and external fan installation 5-6

Figure 5-4a - Frame 2 External fan power supply connections 5-6

Figure 5-5 - Frame 1 Redundant fan unit 5-7

Figure 5-6 - Frame 1 Redundant fan box 5-8

Figure 5-7 - Frame 1 Redundant fan installation 5-8

Figure 5-8 - Frame 1 Redundant fan power supply connections 5-9

Figure 5-9 - Frame 1 Inlet ring installation 5-9

Figure 5-10 - Frame 1 Fan installation 5-9

Figure 5-5 - Frames 2, 3 Redundant fan unit (Frame 2 pictured) 5-10

Figure 5-6 - Frames 2, 3 Redundant fan box 5-11

Figure 5-7 - Frames 2, 3 Redundant fan installation 5-12

Figure 5-8 - Frame 2 Redundant fan power supply connections 5-12

Figure 5-8 - Frame 3 Redundant fan power supply connections 5-13

Figure 6-1 Isolating means 6-2

Figure 6-2 Terminal entry unit 6-5

Figure 6-3 Cable entry 6-6

Figure 6-4 Ground bus 6-7

Figure 6-5 Grounding and bonding drive equipment 6-8

Figure 6-6 Typical line and motor cable 6-9

Figure 6-7 Typical cable entry 6-10

Figure 6-8 Busbars 6-11

Figure 6-9 Connection with Belleville spring and flat washer 6-12

Figure 6-10 Typical busbar connections 6-13

Figure 6-11 Check power fuses 6-14

Figure 6-12 Auxiliary, control, and fieldbus cable entry 6-16

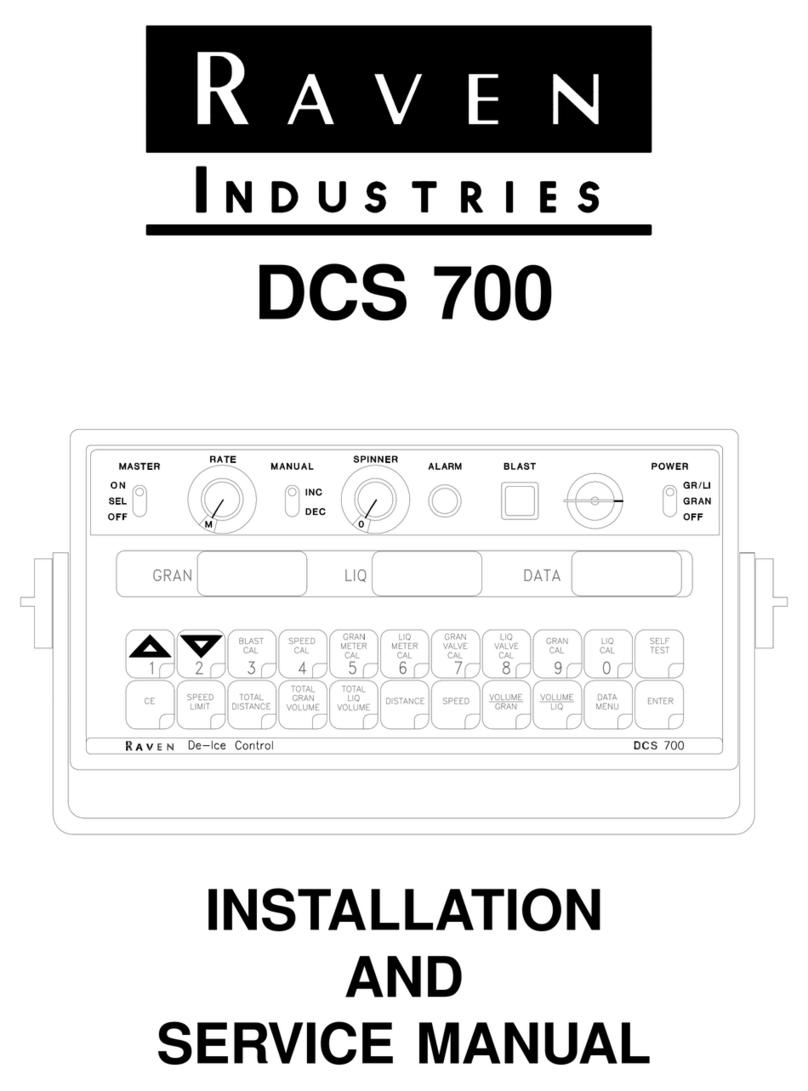

Figure 8-1 Local operator panel functions 8-2

Figure 8-2 Connecting a grounding set 8-15

Figure 9-1 CDP control panel 9-1