Table of Contents

1. SAFETY NOTICES.......................................................................................................... 4

2. INTRODUCTION............................................................................................................. 5

3. RECEIVING, HANDLING AND STORAGE...................................................................... 5

3.1 Receiving Inspection.....................................................................................................5

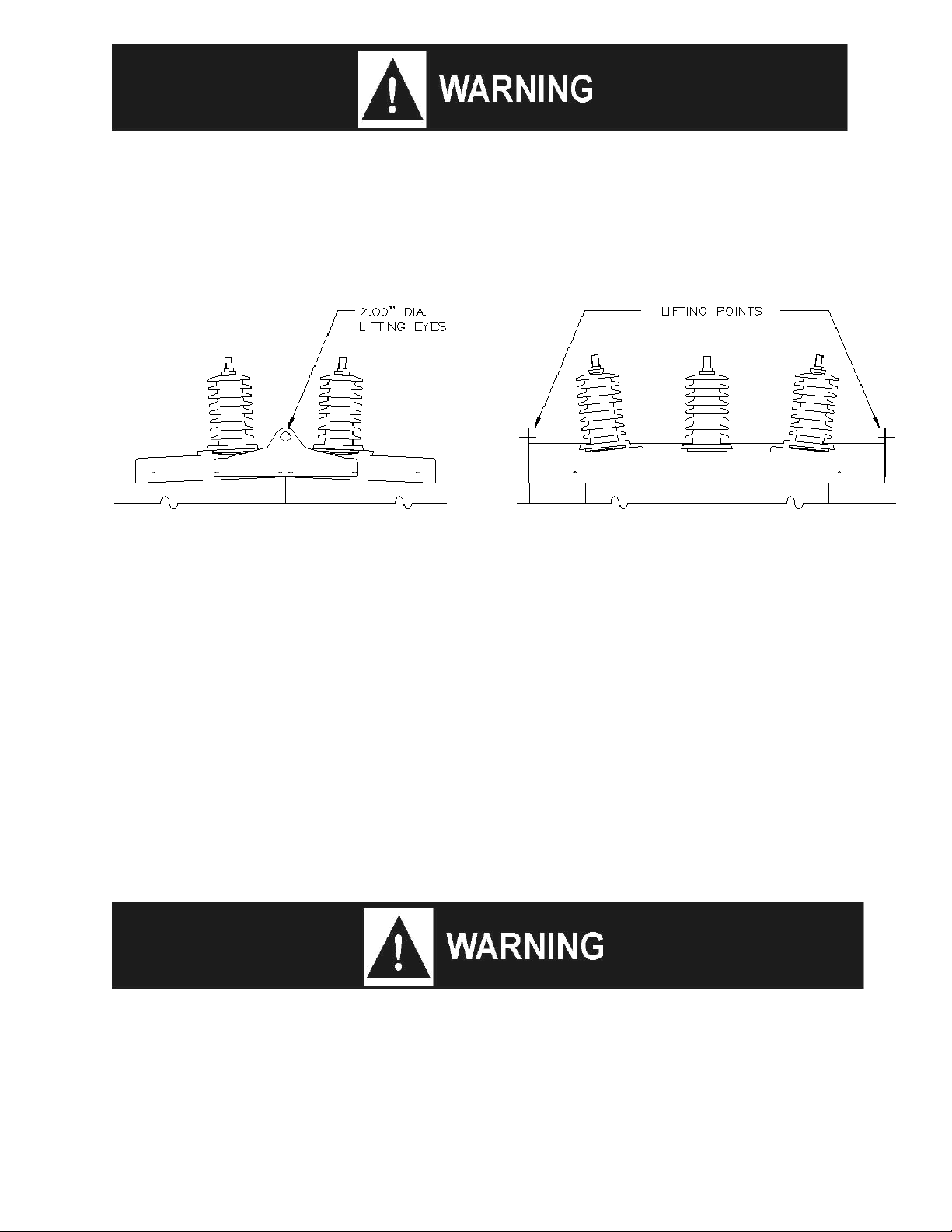

3.2 Handling........................................................................................................................5

3.3 Storage..........................................................................................................................6

4. GENERAL DESCRIPTION.............................................................................................. 6

4.1 High-Voltage Assembly.................................................................................................6

4.2 Housing.........................................................................................................................7

4.3 Magnetic Actuator .........................................................................................................7

4.4 Actuator Controller ........................................................................................................7

5. STANDARD PRODUCTION TESTS................................................................................ 7

6. OPERATION.................................................................................................................... 8

6.1 Closing..........................................................................................................................8

6.2 Opening.........................................................................................................................8

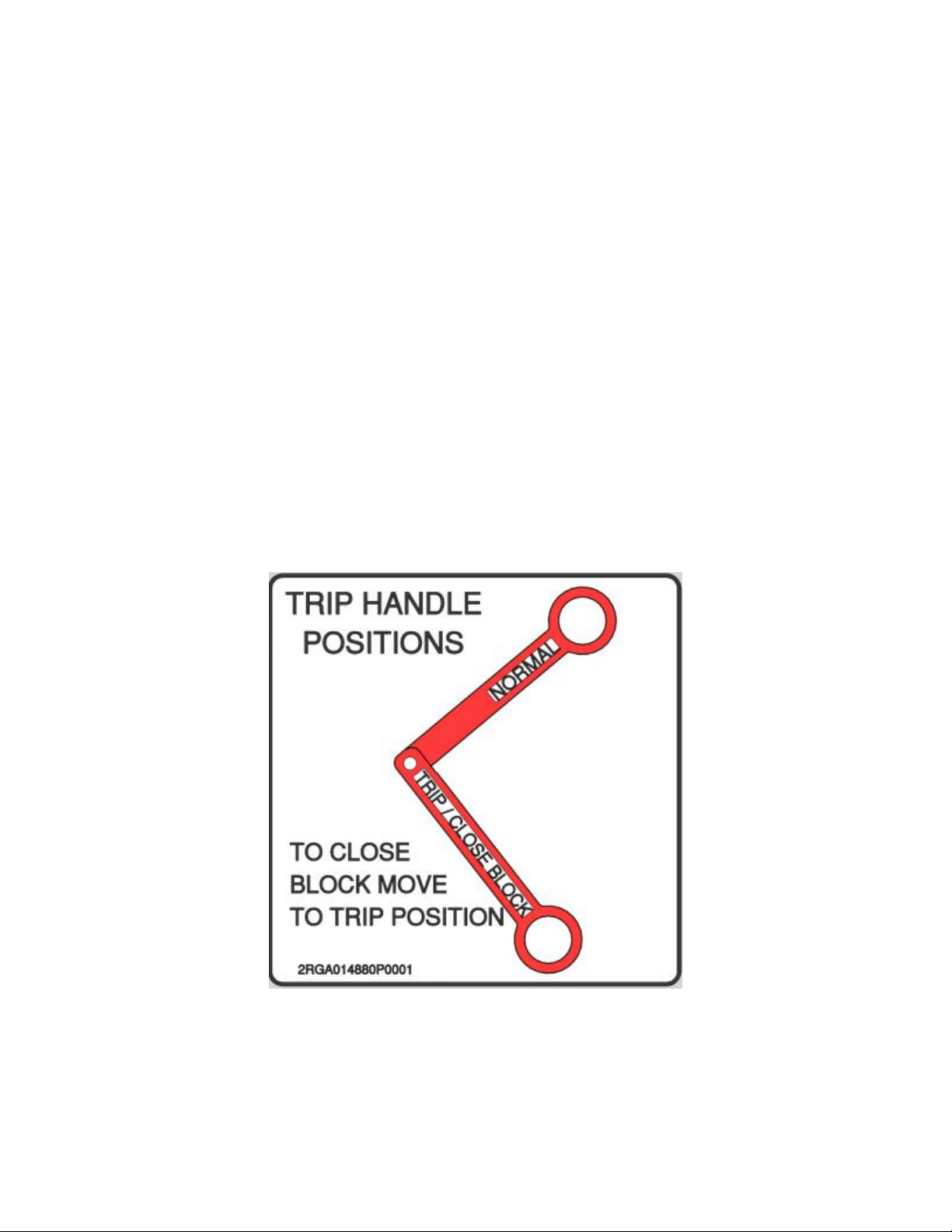

6.3 Manual Trip Handle Operation......................................................................................8

7. OPERATIONAL CHECK PRIOR TO INSTALLATION (ELECTRICAL CLOSE/OPEN).... 9

8. INSTALLATION............................................................................................................... 9

8.1 Mounting .......................................................................................................................9

8.2 Grounding .....................................................................................................................9

8.3 Arrester Protection......................................................................................................10

8.4 Control Power .............................................................................................................10

8.5 Final Inspection...........................................................................................................10

9. INSPECTION, MAINTENANCE AND ADJUSTMENT ................................................... 11

9.1 Maintenance Steps .....................................................................................................11

9.2 High-Pot Test..............................................................................................................12

9.3 Measuring Contact Travel...........................................................................................12

10. 38 kV R-MAG ELECTRICAL SPECIFICATIONS........................................................... 24

10.1 Typical Current Transformer Connections...............................................................26

10.2 Auxiliary Switch Current Specifications.................................................................... 27

10.3 Control Board Voltage Requirements ......................................................................27

10.4 Breaker Nameplate..................................................................................................28

11. RENEWAL PARTS........................................................................................................ 28

12. PRODUCT RECYCLING............................................................................................... 28

APPENDIX A............................................................................................................................. 29