Installation and commissioning guide

2750 515-1 EN, REV. 14, 2020-06-26

3

Contents

1 Safety 5

1.1 Levels of safety risks ................................................................................................................................................................... 5

1.2 Hazardous working situations ..................................................................................................................................................... 6

1.3 Safety precautions....................................................................................................................................................................... 6

1.4 Competence level........................................................................................................................................................................ 6

2 Product description 7

2.1 Design ......................................................................................................................................................................................... 7

2.2 Technical specification................................................................................................................................................................. 12

2.2.1 General specifications ............................................................................................................................................... 12

2.2.2 Mechanical loading.................................................................................................................................................... 12

3 Delivery 15

3 Incoming inspection..................................................................................................................................................................... 15

3.1 Transportation ............................................................................................................................................................................. 15

3.2 Storage........................................................................................................................................................................................ 15

3.3 Lifting........................................................................................................................................................................................... 16

3.3.1 Lifting the transport box............................................................................................................................................. 16

3.3.2 Lifting the bushing out of the transport box ............................................................................................................... 17

4 Installation 19

4.1 Tools ............................................................................................................................................................................................ 19

4.2 Consumables .............................................................................................................................................................................. 19

4.3 Preparations ................................................................................................................................................................................ 20

4.3.1 Lifting the bushing ..................................................................................................................................................... 20

4.3.2 Oil-filling of the bushing for horizontal installation ..................................................................................................... 22

4.4 Horizontal installation of the bushing on the transformer ............................................................................................................24

4.5 Installation with draw lead ........................................................................................................................................................... 26

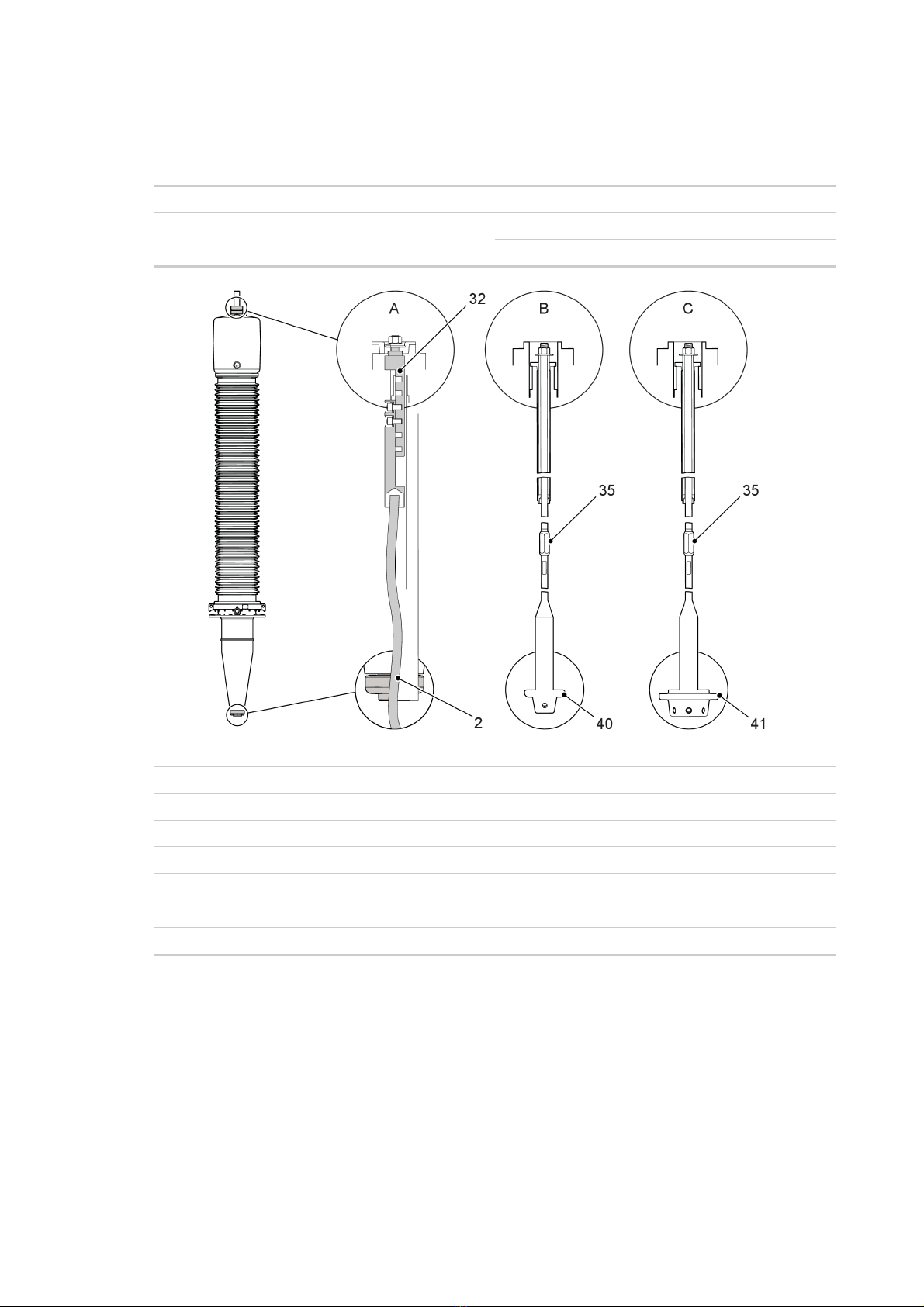

4.5.1 Calculation of the length of the draw lead ................................................................................................................. 26

4.5.2 Installation with draw lead ......................................................................................................................................... 27

4.6 Installation with draw rod at transformer factory.......................................................................................................................... 32

4.6.1 Removal of the lower draw rod with bottom contact from the bushing ..................................................................... 32

4.6.2 Installation of the small bottom contact (N1=4) in the transformer ............................................................................ 35

4.6.3 Installation of the large bottom contact (N1=6) in the transformer ............................................................................37

4.6.4 Installation of the bushing on the transformer ........................................................................................................... 39

4.7 Installation with draw rod at site .................................................................................................................................................. 43

4.7.1 Preparations at site ................................................................................................................................................... 43

4.7.2 Installation of the bushing on the transformer at site................................................................................................. 46

4.8 Hydraulic tightening of the draw-rod nut...................................................................................................................................... 49

4.9 Manual tightening of the draw-rod nut......................................................................................................................................... 53

4.10 Minimum oil-level in transformer ................................................................................................................................................. 55

4.11 Installation of the outer terminal .................................................................................................................................................. 55

4.12 Grounding of the bushing flange ................................................................................................................................................. 58