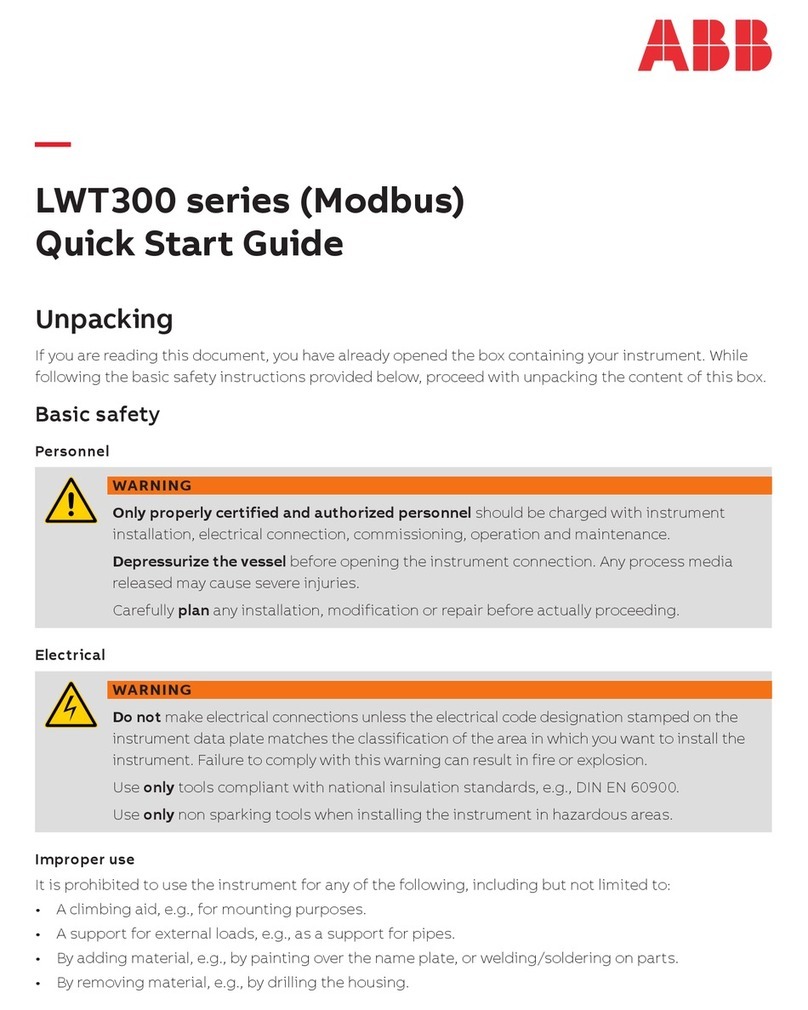

ABB LWT300 series User manual

Other ABB Measuring Instrument manuals

ABB

ABB VA Master FAM540 Training manual

ABB

ABB EXCOUNT-II User manual

ABB

ABB C1300 User manual

ABB

ABB AV1 User manual

ABB

ABB PROFIBUS FEX100-DP User manual

ABB

ABB LWT300 series User manual

ABB

ABB Sensyflow FMT200-D User manual

ABB

ABB CoreSense M10 User manual

ABB

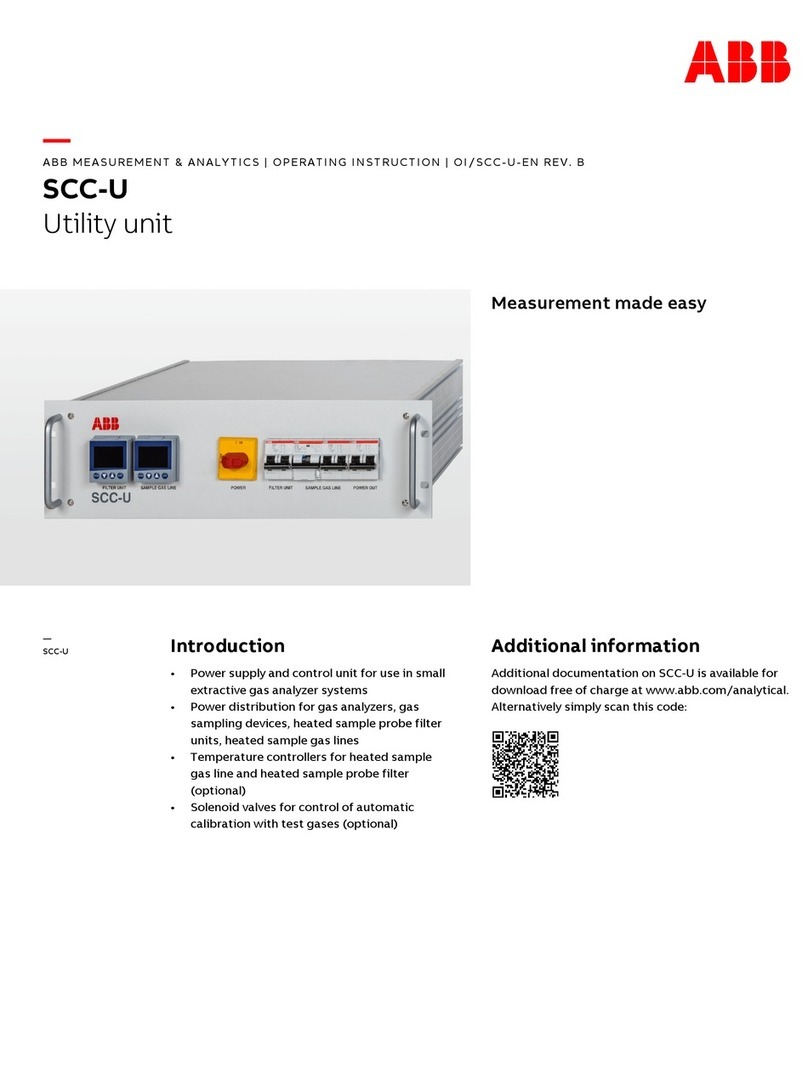

ABB SCC-U User manual

ABB

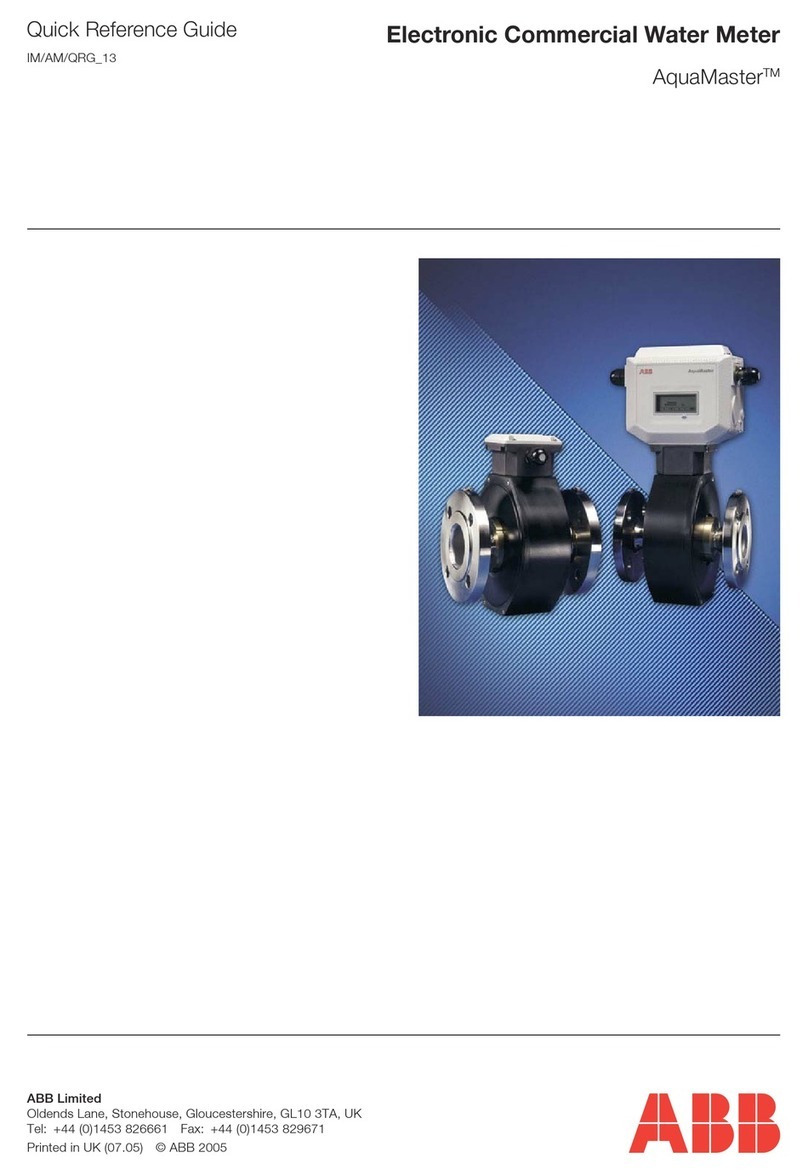

ABB aquamaster User manual

ABB

ABB 10D1476 User manual

ABB

ABB Advance Optima Caldos 15-Ex User manual

ABB

ABB Nitrate 8236 User manual

ABB

ABB AX418 User manual

ABB

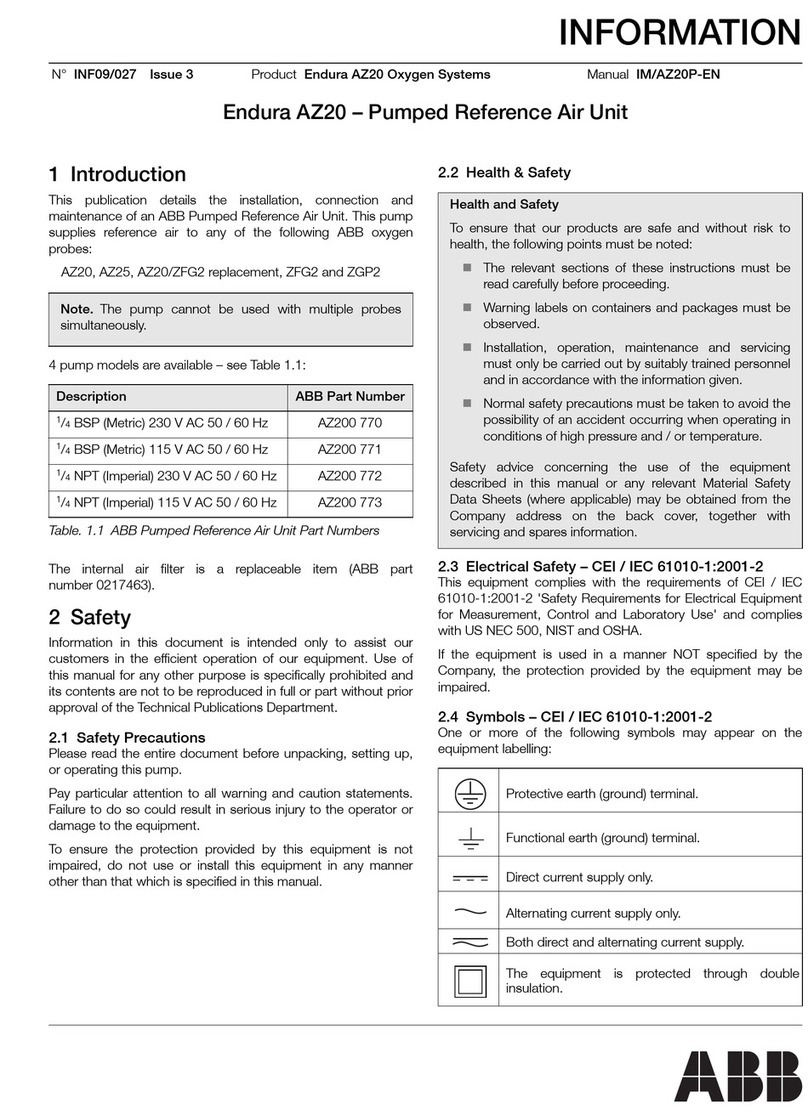

ABB Endura AZ20 series User manual

ABB

ABB Advance Optima magnos206 User manual

ABB

ABB ZEE600 User manual

ABB

ABB Endura AZ20 series User manual

ABB

ABB M4M 30 User manual

ABB

ABB Sensyflow FMT500-IG User manual