ABB i-bus®KNX

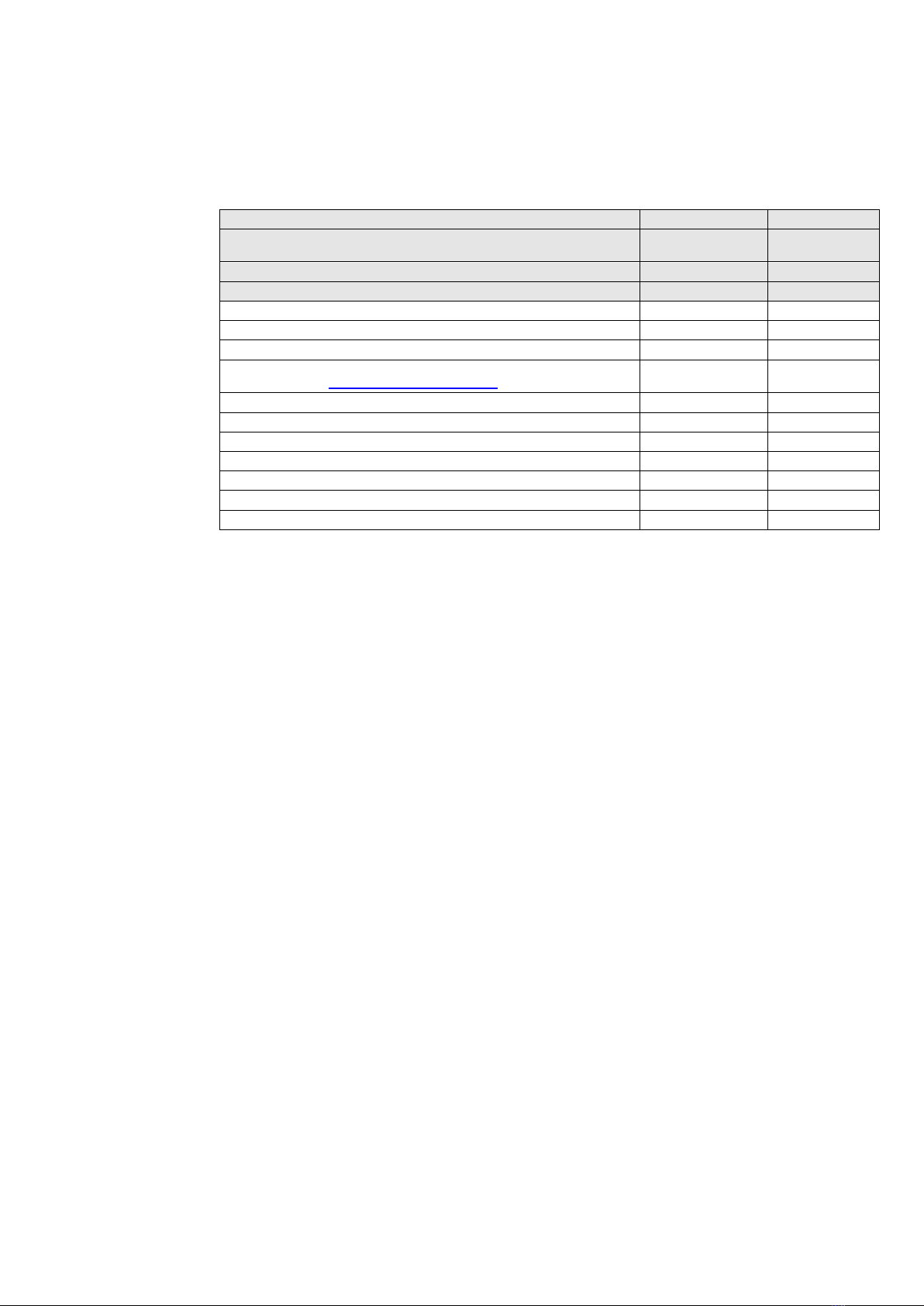

Contents

IPR/S 3.5.1 | 2CDC502099D0211 Rev. A iii

1General ................................................................................................. 5

1.1 Using the product manual............................................................................................................ 5

1.1.1 Notes ........................................................................................................................................... 5

1.2 Cyber security (network security) ................................................................................................ 6

1.3 Preventing access to the different media..................................................................................... 6

1.4 Twisted pair cabling..................................................................................................................... 6

1.5 IP cabling inside the building ....................................................................................................... 6

1.6 Connection to the Internet ........................................................................................................... 7

1.7 KNXnet/IP Security...................................................................................................................... 7

1.8 Overview of product and functions .............................................................................................. 7

1.8.1 Monitoring for bus voltage failure................................................................................................. 8

1.8.2 Overview of versions ................................................................................................................... 9

2Device technology ............................................................................. 11

2.1 Technical data ............................................................................................................................11

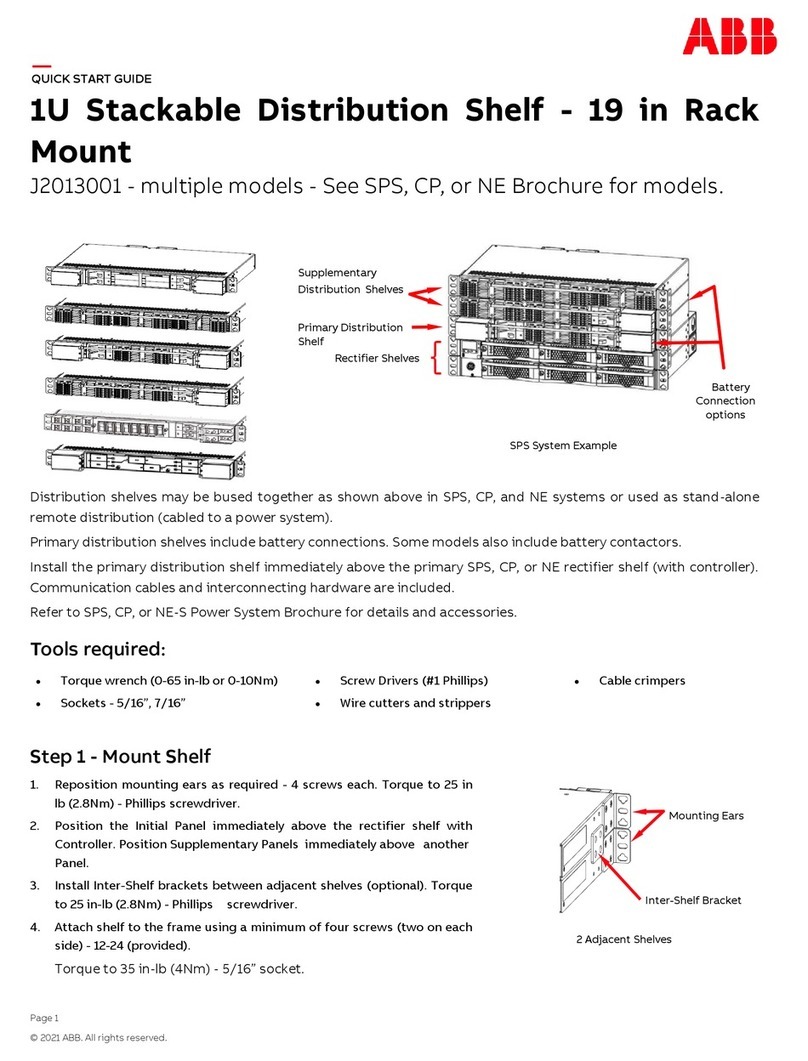

2.2 Connection diagram ...................................................................................................................13

2.3 Dimension drawing .....................................................................................................................14

2.4 Mounting and installation............................................................................................................15

2.4.1 Prerequisites for commissioning.................................................................................................15

2.4.2 Supplied state.............................................................................................................................15

2.4.3 Assignment of the physical address ...........................................................................................16

2.4.4 Download reaction......................................................................................................................16

2.4.5 Unloading the device and resetting to factory settings ...............................................................16

2.4.6 Cleaning .....................................................................................................................................17

2.4.7 Maintenance ...............................................................................................................................17

2.5 Description of inputs and outputs ...............................................................................................17

2.6 Operating controls ......................................................................................................................18

2.7 Display elements ........................................................................................................................18

3Commissioning.................................................................................. 19

3.1 Overview.....................................................................................................................................19

3.2 Parameters .................................................................................................................................19

3.2.1 Parameter window KNX -> LAN .................................................................................................20

3.2.2 Parameter window LAN -> KNX .................................................................................................23

3.2.3 Parameter window IP settings ....................................................................................................26

3.3 Group objects .............................................................................................................................30

3.4 Use of the integrated tunneling servers......................................................................................31

3.4.1 Settings in ETS 5........................................................................................................................32

3.5 KNX Secure................................................................................................................................33

4Planning and application .................................................................. 35

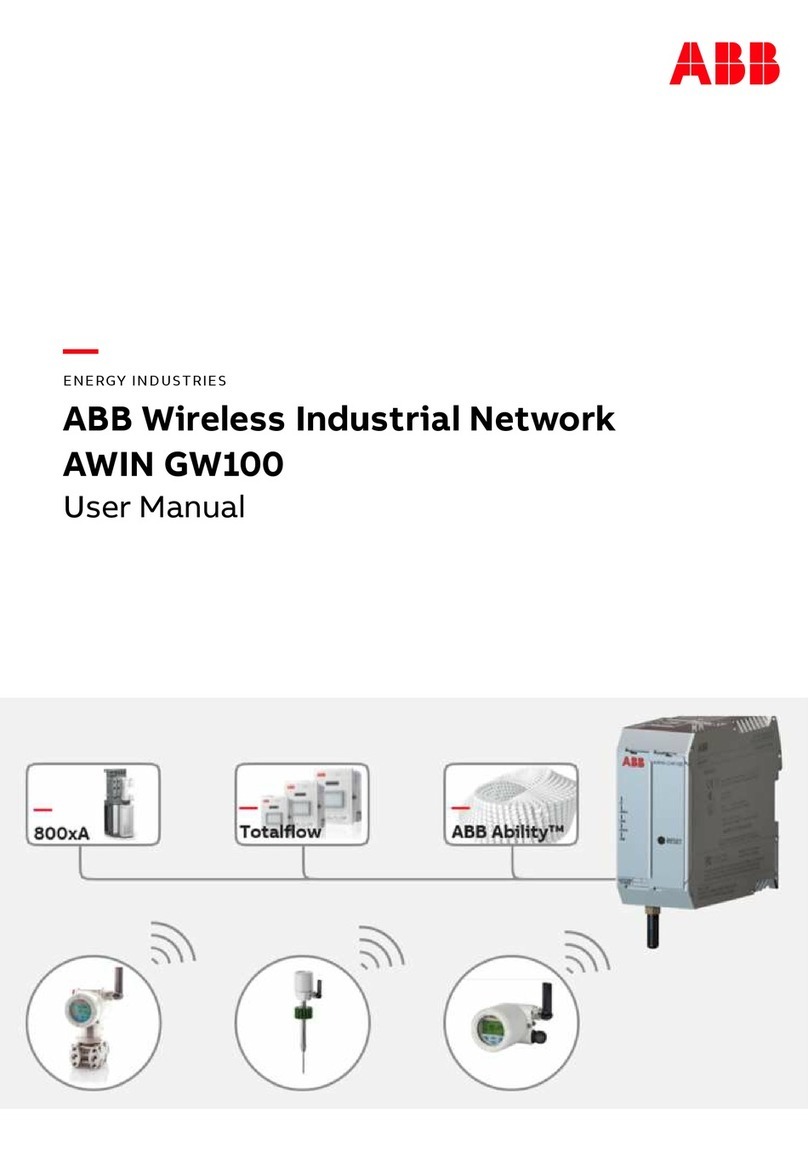

4.1 The IP Router Secure in the network..........................................................................................35

4.1.1 Assignment of IP address...........................................................................................................35

4.1.2 KNX telegrams in the network ....................................................................................................36

4.1.3 Monitoring an IPR/S 3.5.1...........................................................................................................37

4.1.4 System broadcast.......................................................................................................................37

4.1.5 IGMP ..........................................................................................................................................38

4.1.6 IPR/S as an area coupler............................................................................................................38

4.1.7 IPR/S as a line coupler ...............................................................................................................39

4.1.8 Mixed topology ...........................................................................................................................40

4.2 The i-bus®Tool...........................................................................................................................41

4.2.1 Discovery....................................................................................................................................41

4.2.2 Firmware update.........................................................................................................................42

AAppendix ............................................................................................ 43

A.1 Ordering details ..........................................................................................................................43

A.2 Open source software components ............................................................................................43