B1 copy starts here

B2 copy starts here

B3 copy starts here

Headline starts here

—

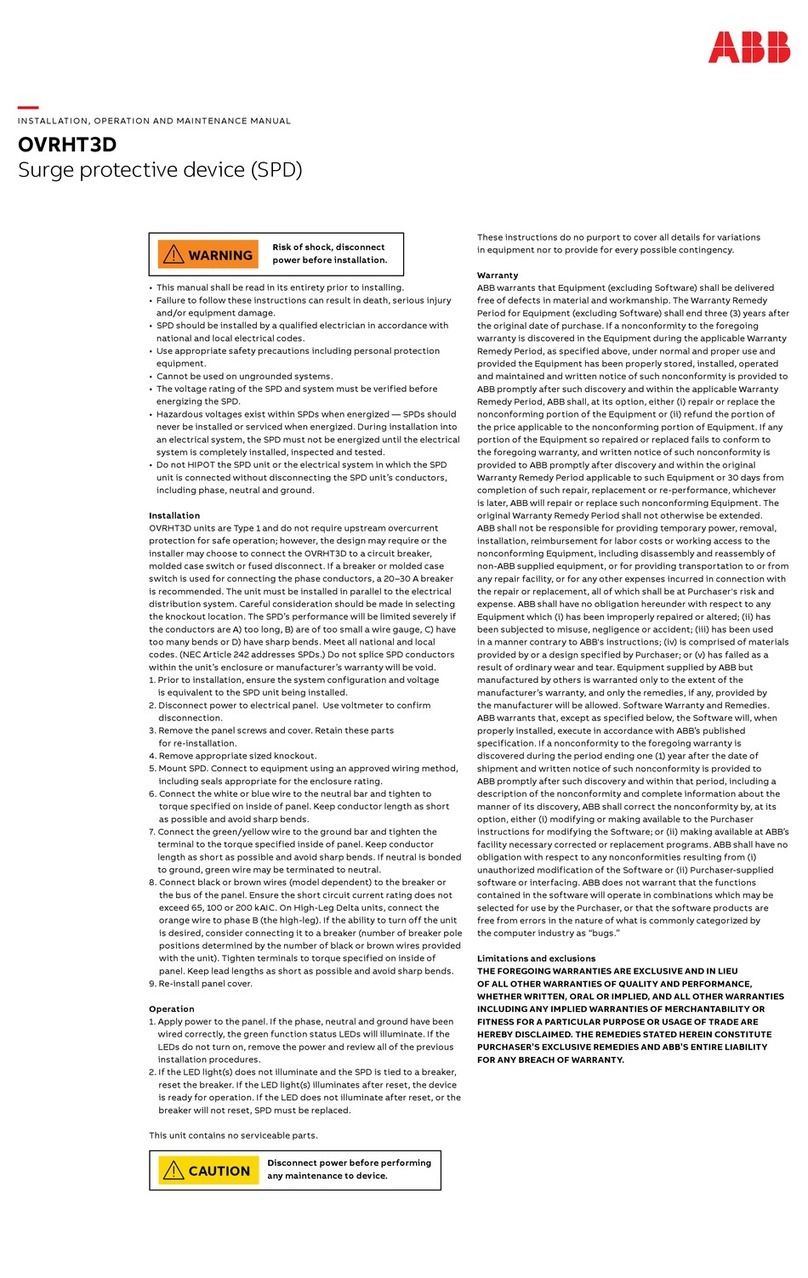

Warranty

ABB warrants that Equipment (excluding Software) shall be

delivered free of defects in material and workmanship. The

Warranty Remedy Period for Equipment (excluding Software)

shall end ten (10) years after the original date of purchase. If a

nonconformity to the foregoing warranty is discovered in the

Equipment during the applicable Warranty Remedy Period, as

specified above, under normal and proper use and provided

the Equipment has been properly stored, installed, operated

and maintained and written notice of such nonconformity is

provided to ABB promptly after such discovery and within the

applicable Warranty Remedy Period, ABB shall, at its option,

either (i) repair or replace the nonconforming portion of the

Equipment or (ii) refund the portion of the price applicable to

the nonconforming portion of Equipment. If any portion of the

Equipment so repaired or replaced fails to conform to the

foregoing warranty, and written notice of such nonconformity

is provided to ABB promptly after discovery and within the

original Warranty Remedy Period applicable to such

Equipment or 30 days from completion of such repair,

repair or replace such nonconforming Equipment. The original

Warranty Remedy Period shall not otherwise be extended.

ABB shall not be responsible for providing temporary power,

removal, installation, reimbursement for labor costs or

working access to the nonconforming Equipment, including

or for providing transportation to or from any repair facility, or

for any other expenses incurred in connection with the repair

or replacement, all of which shall be at Purchaser's risk and

expense. ABB shall have no obligation hereunder with respect

to any Equipment which (i) has been improperly repaired or

altered; (ii) has been subjected to misuse, negligence or

accident; (iii) has been used in a manner contrary to ABB's

instructions; (iv) is comprised of materials provided by or a

design specified by Purchaser; or (v) has failed as a result of

ordinary wear and tear. Equipment supplied by ABB but

manufactured by others is warranted only to the extent of

the manufacturer’s warranty, and only the remedies, if any,

provided by the manufacturer will be allowed. Software

Warranty and Remedies. ABB warrants that, except as

specified below, the Software will, when properly installed,

execute in accordance with ABB's published specification. If a

nonconformity to the foregoing warranty is discovered during

the period ending one (1) year after the date of shipment and

written notice of such nonconformity is provided to ABB

promptly after such discovery and within that period,

including a description of the nonconformity and complete

information about the manner of its discovery, ABB shall

correct the nonconformity by, at its option, either (i)

modifying or making available to the Purchaser instructions

for modifying the Software; or (ii) making available at ABB's

facility necessary corrected or replacement programs. ABB

shall have no obligation with respect to any nonconformities

resulting from (i) unauthorized modification of the Software

not warrant that the functions contained in the software will

operate in combinations which may be selected for use by the

Purchaser, or that the software products are free from errors

in the nature of what is commonly categorized by the

computer industry as “bugs.”

THE FOREGOING WARRANTIES ARE EXCLUSIVE AND IN LIEU

OF ALL OTHER WARRANTIES OF QUALITY AND PERFORMANCE,

WHETHER WRITTEN, ORAL OR IMPLIED, AND ALL OTHER

WARRANTIES INCLUDING ANY IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE

OR USAGE OF TRADE ARE HEREBY DISCLAIMED. THE

REMEDIES STATED HEREIN CONSTITUTE PURCHASER’S

EXCLUSIVE REMEDIES AND ABB’S ENTIRE LIABILITY FOR

ANY BREACH OF WARRANTY.

GUIDE TO INSTALLATION AND ASSISTANCE

5