B1 copy starts here

B2 copy starts here

B3 copy starts here

Headline starts here

2

TPME AND TPHE NSBX AND NSWM SERIES INTEGRAL SPDS

—

Guide to installation and assistance

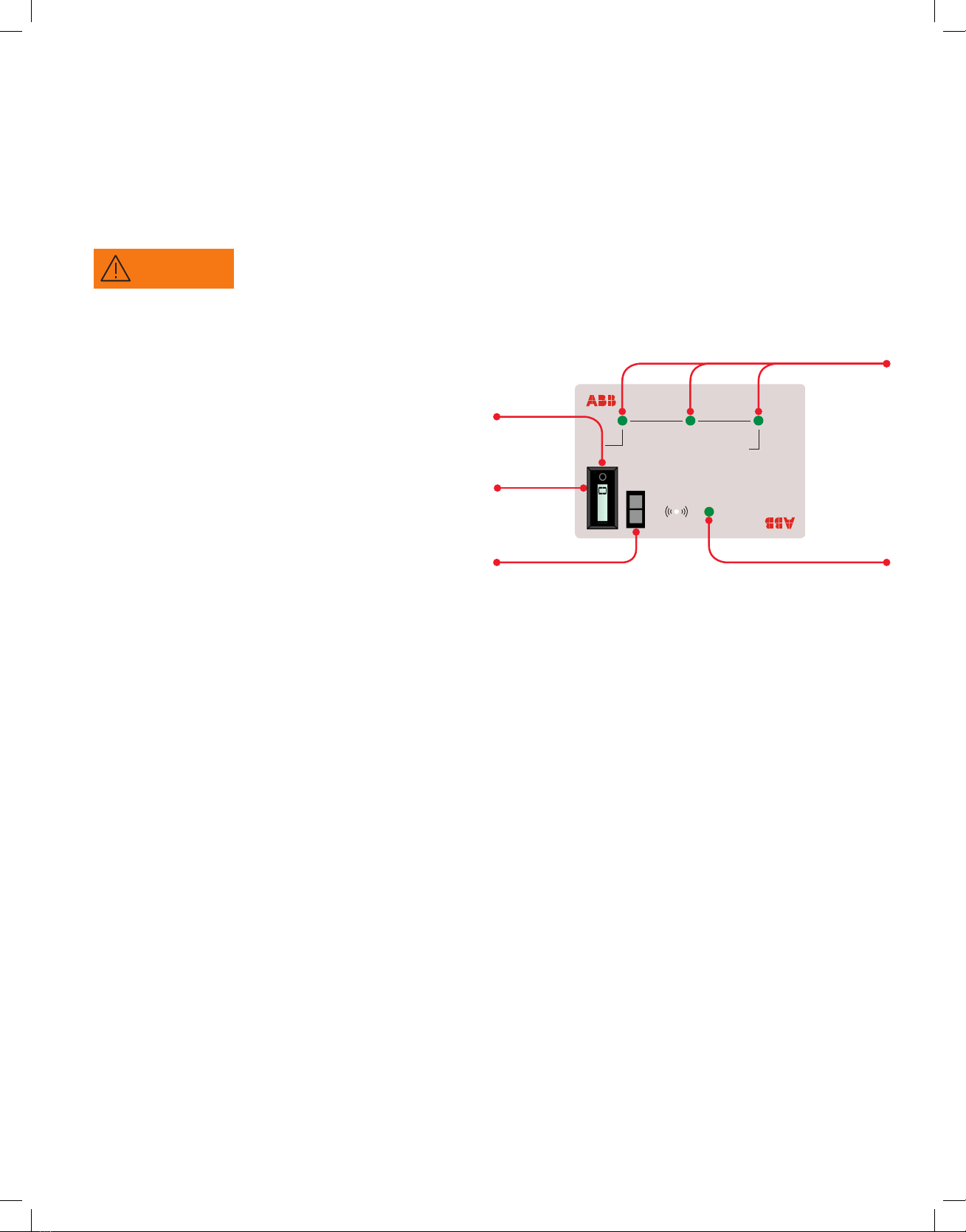

WARNING

The SPD warranty is voided if the unit is damaged as a

result of improper installation. Improper installation or

misapplication may result in serious personal injury or

damage to the electrical system. Read the complete

installation instructions before proceeding with

installation.

La garantie du SPD est annulée si l’appareil est

endommagé à la suite d’une mauvaise installation. Une

mauvaise installation, ou utilisation, peut entraîner des

blessures graves ou des dégâts au système électrique.

Lisez les instructions d’installation en intégralité avant

de procéder à l’installation.

WARNING

The equipment covered by these instructions should

be installed and serviced only by competent qualified

personnel utilizing proper safety practices and

procedures. These instructions are written for such

personnel and are not intended as a substitute for

adequate training and experience in safe procedures

for this type of equipment.

L’équipement couvert par ces instructions doit être installé

et entretenu uniquement par un personnel compétent et

qualifié, utilisant des pratiques et des procédures de

sécurité appropriées. Ces instructions sont rédigées à

l’intention de ce personnel et ne sauraient se substituer

à une formation adéquate et à une expérience des

procédures de sécurité pour ce type d’équipement

WARNING

Remove all power to the electrical panel before installing

or servicing the SPD. All work must be performed by

licensed and qualified personnel. Follow applicable

electrical codes and regulations for the country/location

in which the unit is being used.

Coupez l’alimentation du panneau électrique avant

d’installer ou de procéder à l’entretien du SPD. Tous les

travaux doivent être effectués par un personnel qualifié et

agréé. Respectez les codes et réglementations électriques

en vigueur dans le pays / lieu où l’appareil est utilisé.

WARNING

Do not HIPOT the SPD unit or the electrical system to which

the SPD unit is connected without disconnecting the SPD unit’s

conductors, including phases, neutral and ground.

Ne procédez PAS à des ESSAIS DE RIGIDITÉ DIÉLECTRIQUE sur

le SPD ou le système électrique auquel il est connecté sans

déconnecter les conducteurs des SPD, y compris les phases,

le neutre et la terre.

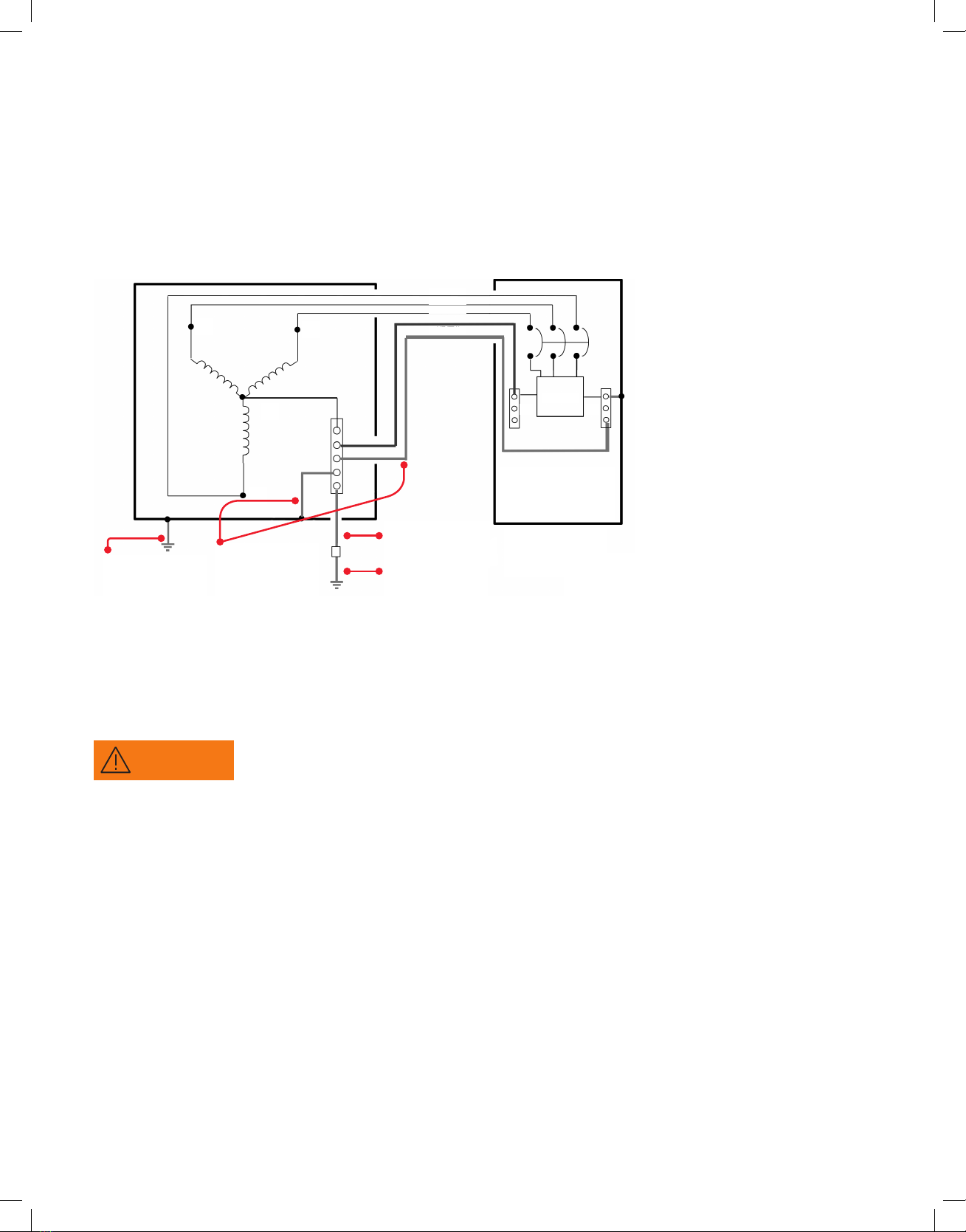

WARNING

Check to ensure that a proper bond is installed between neutral

and ground at the transformer upstream from all 3-phase wye,

3-phase high-leg or 2-phase SPD devices. If the transformer is

not accessible, check the main service disconnect/panel for the

NG bond. Lack of a proper bond may damage the SPD and void

the warranty. Failure to provide this bond, as required per article

250.30 of the National Electrical Code, can result in elevated

phase-to-ground source voltage potentials. These voltages can

cause damage to electrical equipment as well as safety hazards

including fire, electrical shock, serious injury or death.

Vérifiez qu’une liaison correcte est installée entre le neutre et

la terre au niveau du transformateur en amont de tous les SPD

triphasés en étoile, triphasés en triangle ou biphasés. Si le

transformateur n’est pas accessible, vérifiez la liaison NG sur

le sectionneur / panneau de service principal. L’absence d’une

liaison appropriée peut endommager le SPD et annuler la

garantie. L’absence de cette liaison, telle que requise par l’article

250.30 du Code national de l’électricité, peut entraîner des

potentiels de tension élevés entre la phase et la terre. Ces

tensions peuvent causer des dégâts aux équipements électriques

ainsi que des risques en matière de sécurité, notamment des

incendies, des chocs électriques, des blessures graves ou la mort.

WARNING

Installation by person with electrotechnical expertise only.

WARNUNG!

lnstallation nur durch elektrotechnische Fachkraft.

AVERTISSEMENT!

lnstallation uniquement par des personned qualifiées

électrotechnique.

IADVERTENCIA!

La instalación deberá ser realizada únicamente

por electricistas especializados.