ABB OTM_C_21D User manual

Other ABB Switch manuals

ABB

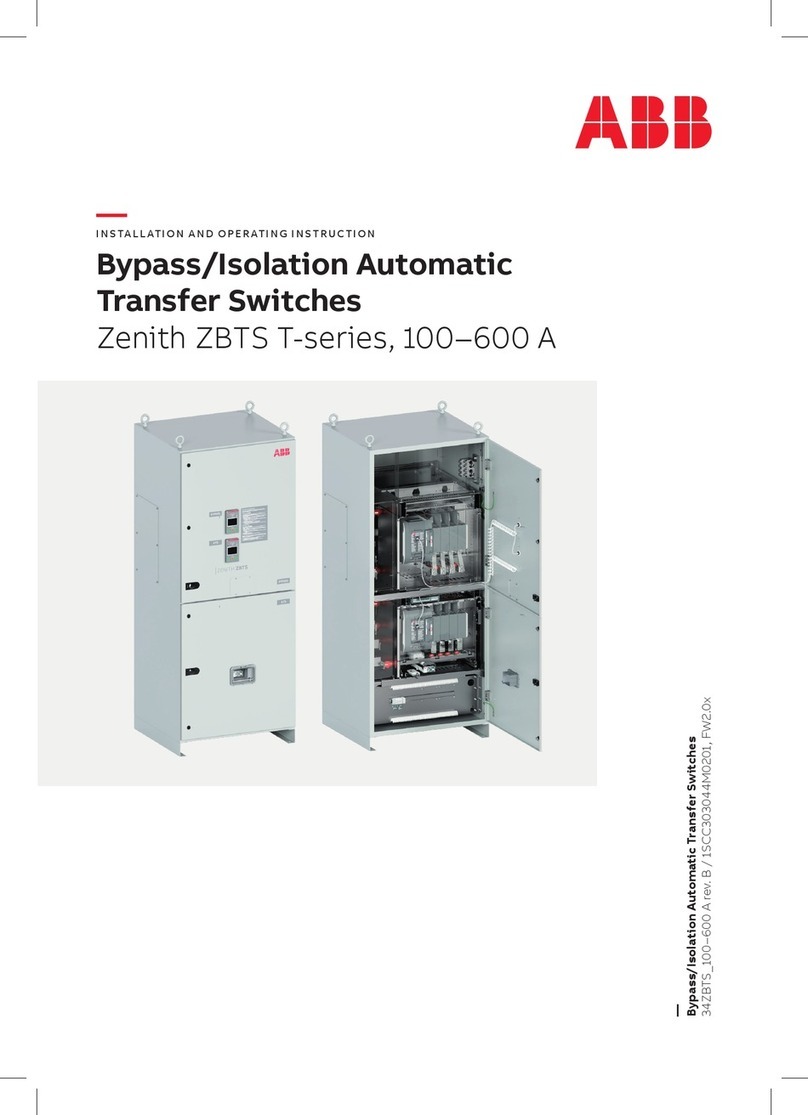

ABB Zenith ZBTS T Series User guide

ABB

ABB Sense7 Series User manual

ABB

ABB Zenith ZTG Series User manual

ABB

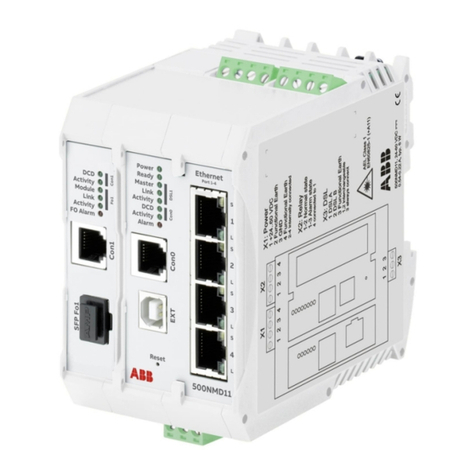

ABB EDS500 Series User manual

ABB

ABB VersaRupter General instructions

ABB

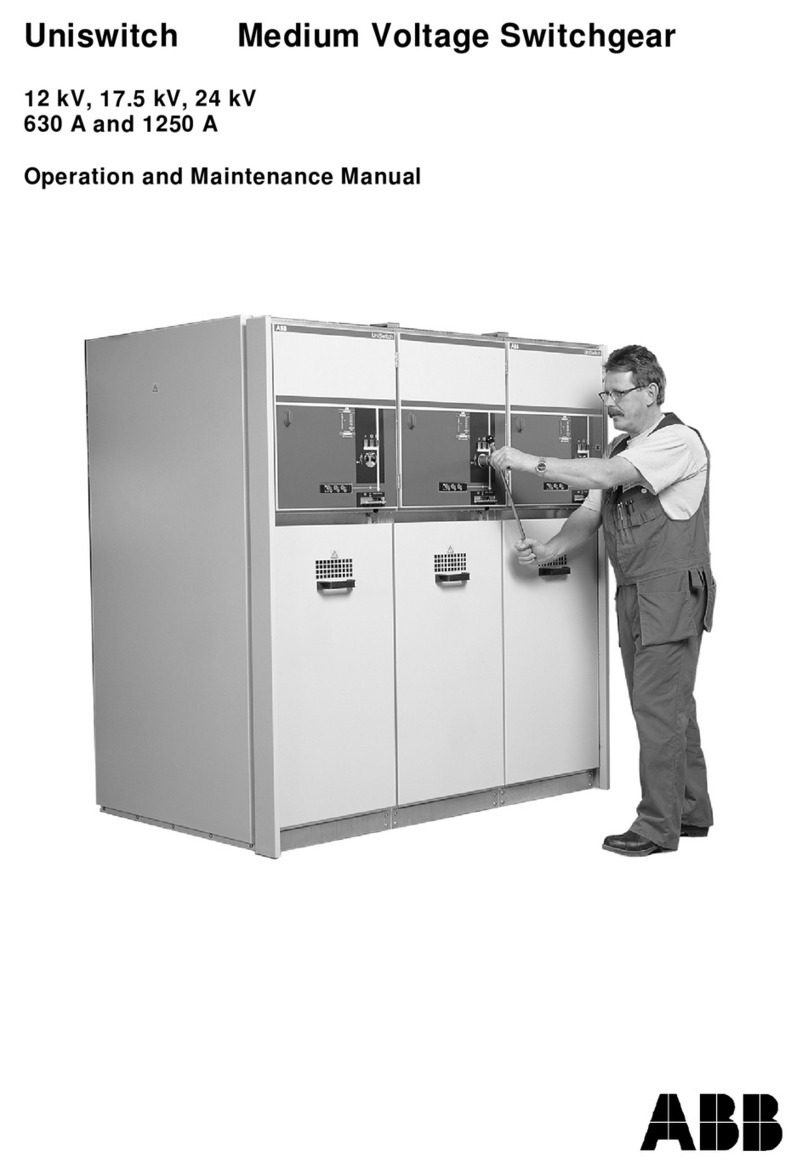

ABB Uniswitch User manual

ABB

ABB FIP2002 User manual

ABB

ABB 2CSYK1102C/S User manual

ABB

ABB E 232 E-8/230N User manual

ABB

ABB ZX1.5-R User manual

ABB

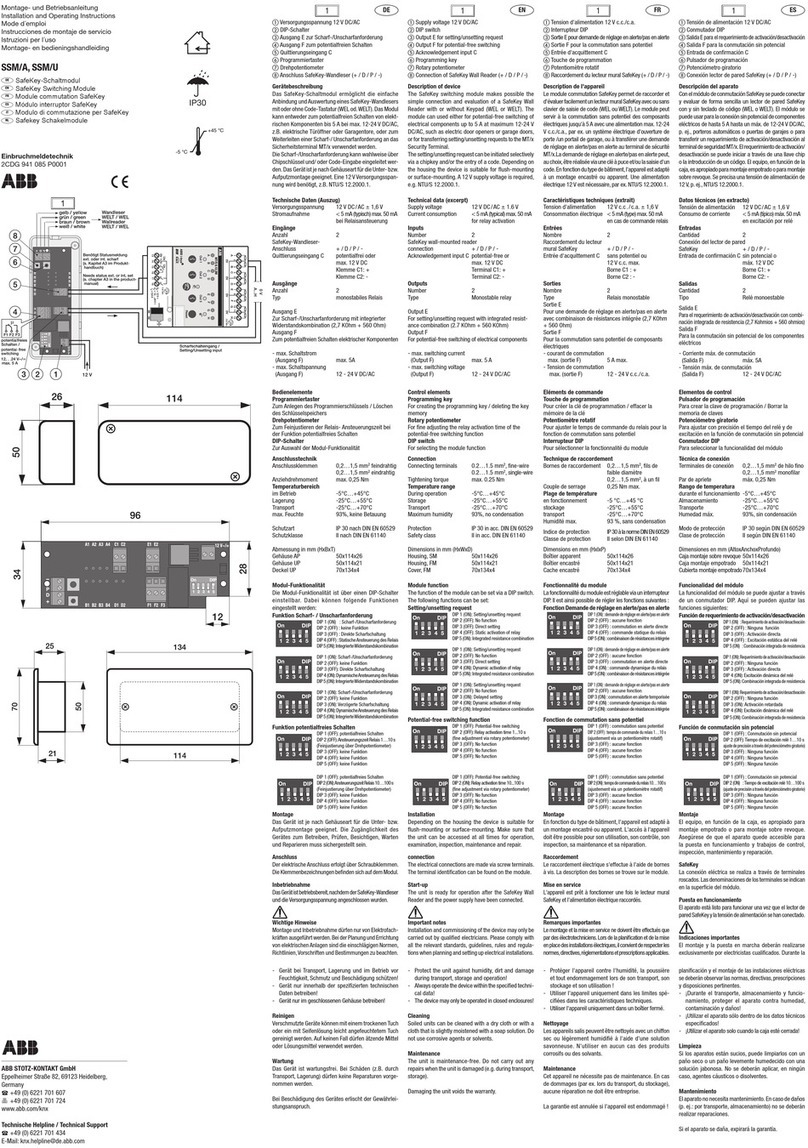

ABB SSM/A User manual

ABB

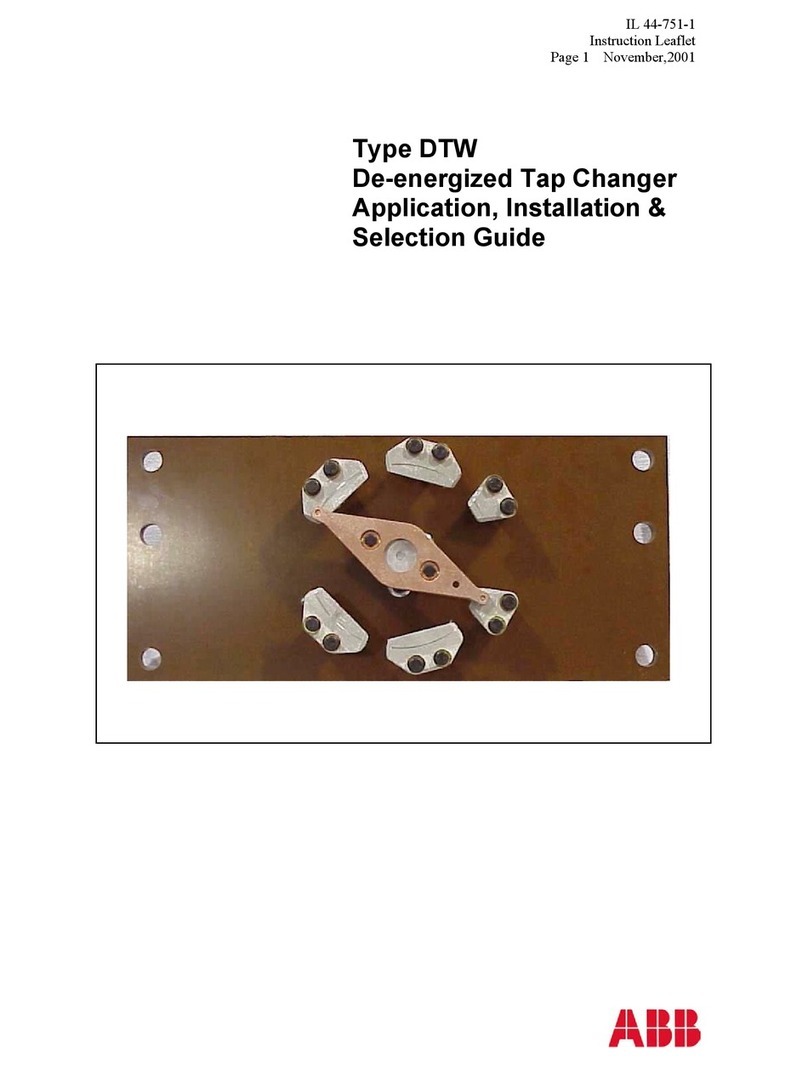

ABB DTW User guide

ABB

ABB JSTD20 User manual

ABB

ABB SafeRing User manual

ABB

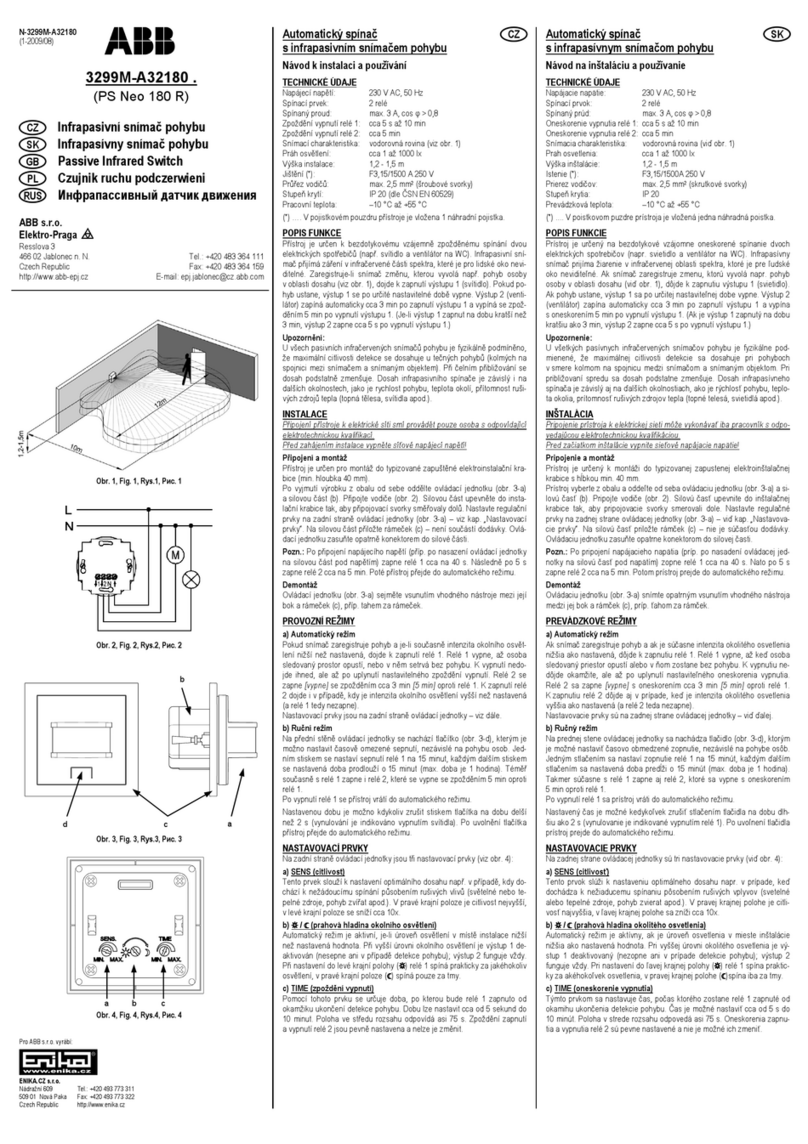

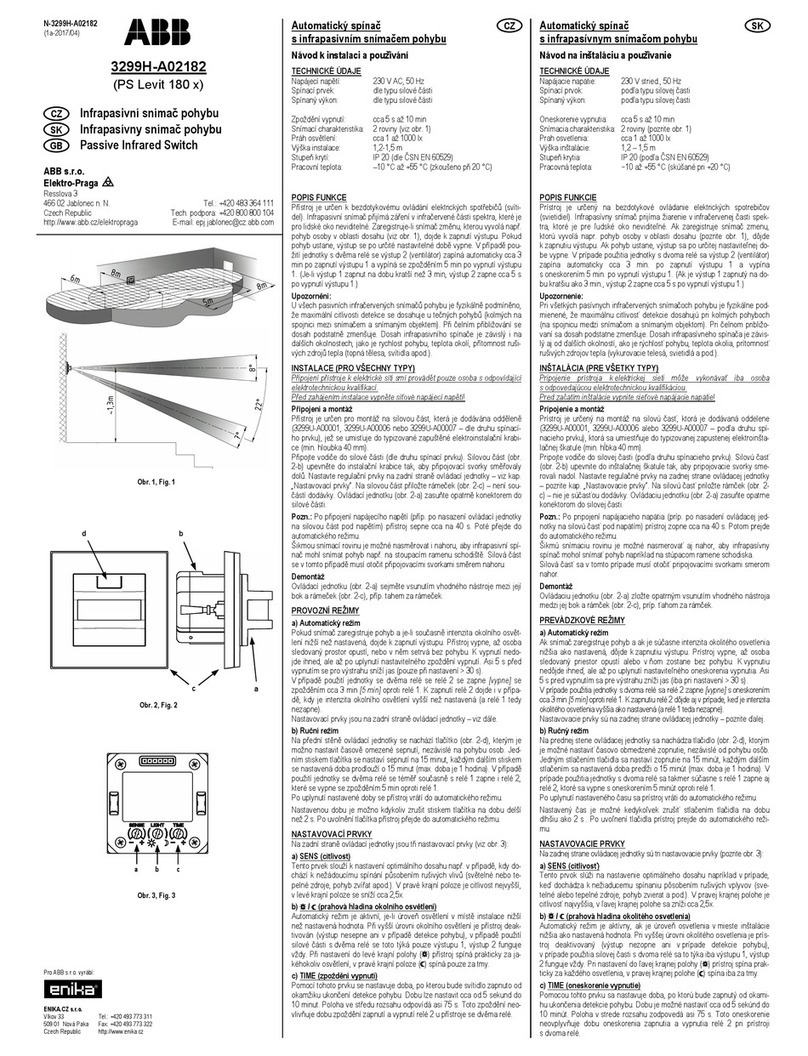

ABB 3299H-A02182 Setup guide

ABB

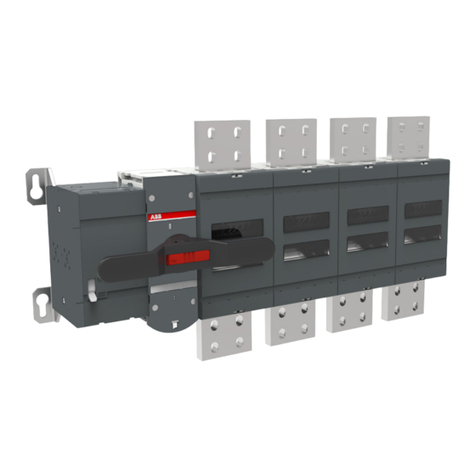

ABB OTM_C Series User guide

ABB

ABB OTM3200E4M230C-GE User manual

ABB

ABB Zenith ZTX Series User manual

ABB

ABB UniSec SDS Operating and maintenance instructions

ABB

ABB FIP1011 User manual