2TLC172249M0201, REV. C 2021-10-12 8

4Installation and maintenance

Installation and maintenance

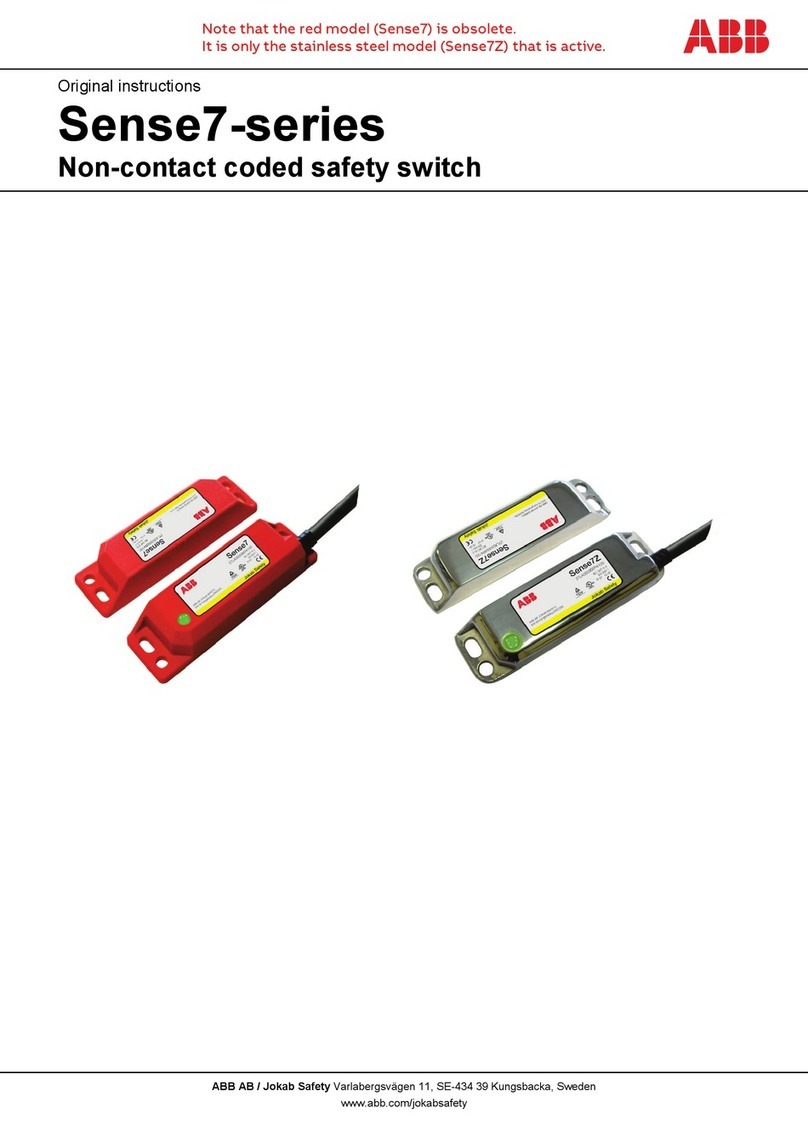

1. The installation of all ABB Electrification Sweden AB interlock switches must be done in accordance

with a risk assessment for the individual application. Installation must only be carried out by compe-

tent personnel and in accordance with these instructions.

2. The use of a safety relay is required for monitoring coded switches. These relays monitor 2 redundant

circuits as per ISO13849-1 for up to PL e / Category 4 protection. Coded non-contact switches are de-

signed to operate with most dual channel safety relays.

3. M4 mounting bolts must be used to fix the switches. Tightening torque for mounting bolts to ensure

reliable fixing is 1.0 Nm.

Installation on ferrous materials may reduce the sensing distance.

The recommended setting gap is 5 mm. The Safety switch must not be used as a mechanical stop or be

adjusted by striking with a hammer.

The actuator must not be allowed to strike the switch. Do not mount adjacent switches or actuators

closer than30mm. Typical misalignment tolerance after setting is 5 mm.

4. After installation always check each switch function by opening and closing each guard individually in

turn and ensuring that the Green LED on the switch and the LED’s on the safety relay are illuminated

when the switch is closed and are extinguished when the switch is open.

5. Check that the machine stops and cannot be re/started when each switch is open.

Warning! All the safety functions must be tested before starting up the system.

Maintenance

Monthly: Check alignment of actuator and look for signs of mechanical damage to the switch casing. Check

wiring for signs of damage.

Every 6 months: Check each switch function by opening and closing each guard individually in turn and en-

suring that the Green LED on the switch and the appropriate LED’s on the safety relay are illuminated when

the switch is closed and are extinguished when the switch is open. Check that the machine stops and can-

not be re-started when each switch is open.

Specific requirements

If the products are used in safety related applications with infrequently operated guards, then the safety

function shall be checked for hidden faults at least once per year for PL d and at least once per month for PL

e. Please see EN ISO 14119.

Warning! The safety functions and the mechanics shall be tested regularly, at least once every year to

confirm that all the safety functions are working properly.

Warning! In case of breakdown or damage to the product, contact the nearest ABB Electrification

Sweden AB Service Office or reseller. Do not try to repair the product yourself since it may accidentally

cause permanent damage to the product, impairing the safety of the device which in turn could lead to

serious injury to personnel.