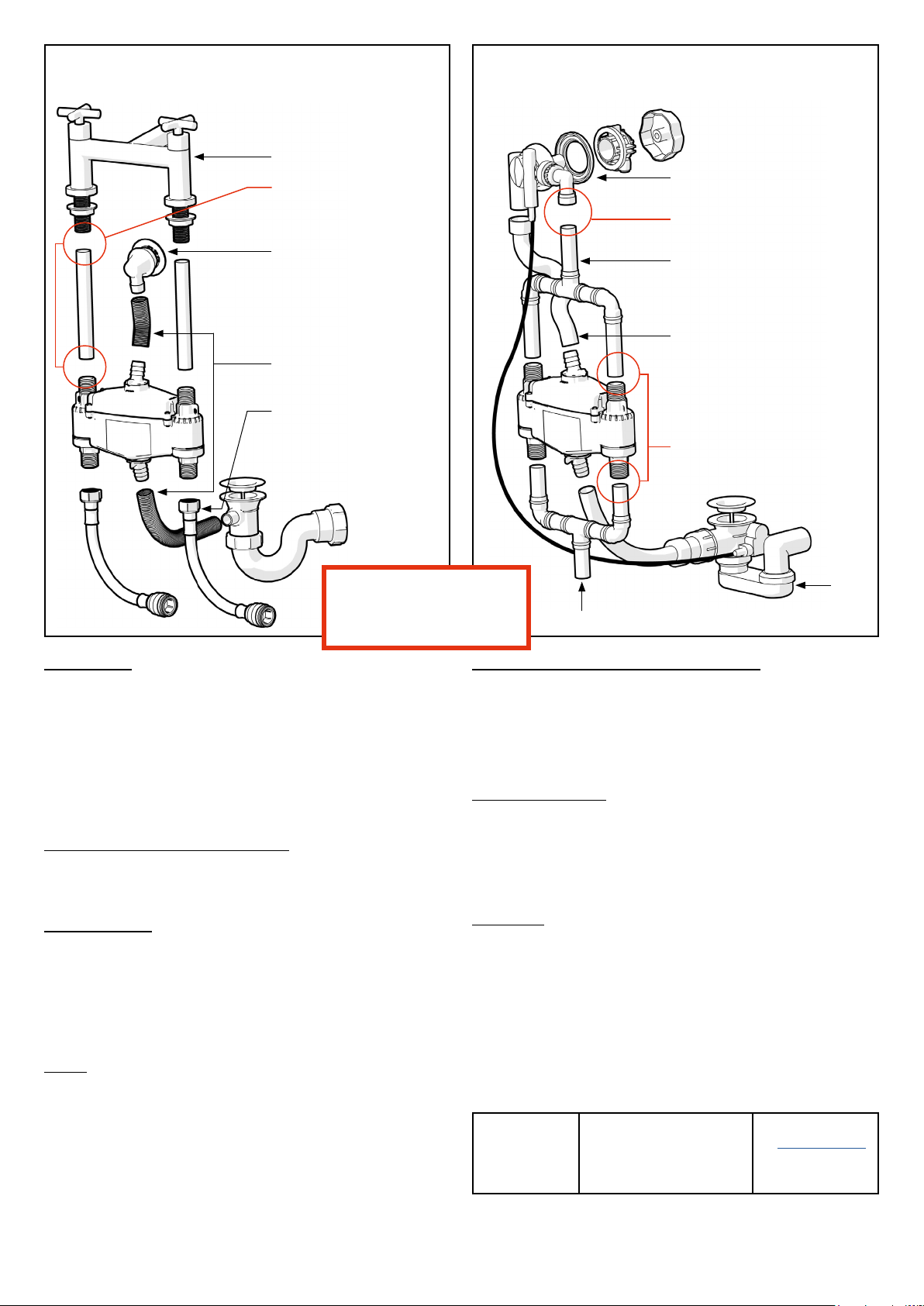

Fig. 4

Part descriptions & dimensions (mm)

Water supplies

The Nova-Flo® valves are not hot or cold specic, so hot or cold water

can be run through either side.

1. Bath and Wall Mounted taps: (See Fig. 3)

The water supplies for the hot and cold feeds must pass up through

each side valve (Fig. 1, E) of the Nova-Flo®unit respectively with the

upper ¾" BSP connectors (Fig. 1, B) leading to the tap controls or mixer.

2. Bath Filler and Waste Combinations: (See Fig. 4)

The mixed water supply fed from the tap controls is to be split and

directed equally to both side valves. The upper connections are then

to be reconnected and a branch led to the ller and waste head.

Use of a Thermostatic Mixing Valve (TMV)

It is recommended that a TMV be installed prior to the Nova-Flo®unit.

e.g. Thermally mixed water should be directed through one side valve

of the Nova-Flo®unit. Nova-Flo® is rated at a maximum hot water

temperature of 60 degrees Centigrade.

Purging of system

Once tted, the system will need to be purged to clear any air trapped

inside. This is done by allowing the taps to run at full ow for 1 minute,

then turning them off. Repeat this procedure three times. Should the

valves actuate, simply turn off the taps, wait for ve seconds then turn

them on gently. Once the system is purged of air, activation of the valves

such as this will not occur. In some installations with an exceptionally fast

ow rate, unexpected water shut off may occur before the bath is full. In this

occurrence simply restrict the water ow by closing the supply valves slightly.

Testing

Test for leaks before replacing any bath surround or cladding.

To ensure correct operation, you are advised to check its operation

once every six months. To do this, keep the taps on and direct water

from a shower head or pour water from a large jug into the overow

outlet until activation. Whilst doing this it can be quicker to cup a cloth

with your hand below the overow outlet to channel more water into it.

Should the overow system ever become clogged with soap, hair etc.

resulting in a blockage remove the lower barb connector by rotating

it 45 degrees anti-clockwise and clear any debris with a cotton bud or

similar, then ret the barb connector. Care should be taken not to lose

the o-ring. Should more intensive cleaning be required you can nd

more maintenance guidance at www.nova-o.com

Resetting the water upon activation of the valves

If water pours down the overow outlet, the taps will be substantially shut

off. There will remain a small trickle of water which is intentional and reminds

the user to turn off the taps (the overow can easily handle this trickle).

To reset the unit, ensure there is no more water going through the

overow then simply turn off the taps and wait for ve seconds. Upon

opening the taps full ow is resumed. Your taps and water supply will be

unaffected in normal use.

Recommended ttings

To ensure compatibility we recommend installers use the Nova-Flo®

push-t or compression xing packs. Where the xing pack is not used

installers must ensure compatibility of their chosen ttings with the ¾"

BSP side valve connections, which are designed for use with hand

tightened plastic connectors. The lower port of each side valve should be

connected to a exible hose to ensure that the unit is not installed under

tension. We recommend the use of shower pump exible hoses or similar.

WARRANTY Nova-Flo® (the device) is warranted to be free of defective

parts, material and construction for a period of 2 years from date of

purchase. The device is designed for occasional use as a preventative

device and should not be used as a means of automatically setting your

bath water level on a regular basis.

About Time Design Ltd (the company) and our suppliers take no

responsibility for the quality of tment of Nova-Flo®or any loss or

damage caused by defective installation. We recommend installation by

a qualied professional to ensure there are no leaks and that the device

performs according to specication. The company takes no responsibility

for consequential loss under any circumstances. In event of queries,

in the rst instance please our helpline on +44 (0)1608 811 707.

Nova-Flo and Flowban are registered trademarks of About Time Design Ltd

Patent Protected: GB: 2428800, 2458783, 2476539, 2476351, 2476542, 2476353,

2476707, 2476540, 2476541, 2458783; Europe: 2279367; USA: 8215335 & 8517045.

Water Regulations Advisory Scheme Limited (WRAS Ltd.) owns WRAS Approved Product

Certication Mark and reserves all rights to it.

Manufactured by

About Time

Design Ltd

Distributed by

Lifescience Products Ltd

Unit 19, Cheltenham Trade Park

Gloucestershire GL51 8LZ

Contact

W: www.nova-o.com

E: info@nova-o.com

T: +44 (0)1608 811707

© Copyright About Time Design Ltd, 2022

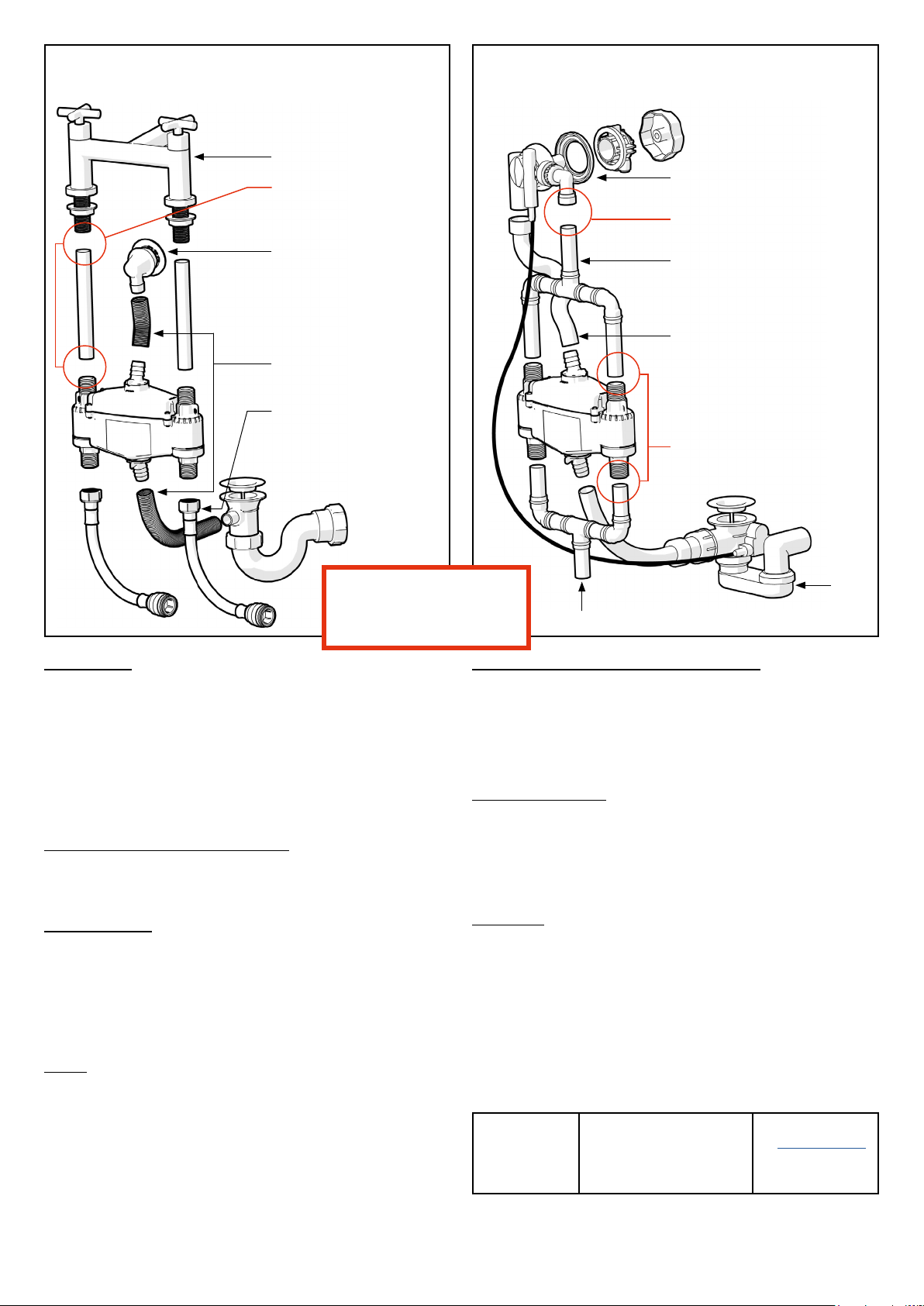

Fig. 3

Part descriptions & dimensions (mm)

These parts not supplied:

Taps.

(4 of) ¾" BSP to 22mm

hand tighten pipe

connectors.

Overow outlet.

22mm pipe (Length to be

calculated according to

bath, taps and plumbing

connections used).

Overow exy-pipe

(trim to t).

Flexible hose with ¾" BSP

hand tighten connector.

IMPORTANT:

Nova-Flo®must not be

installed under any tension

Bath ller and

waste combination.

Suitable 22mm pipe

to tap connector.

22mm pipe (shown

with soldered ttings). The

lengths need to be calculated

according to conguration.

Overow exy-pipe

(trim to t) For some

installations a replacement

may be necessary. A washing

machine hose is often ideal,

secured with Jubilee clips

(4 of) ¾" BSP to 22mm

hand tighten pipe connectors.

Channelling mixed water supply from tap controls

Trap

Trap

These parts not supplied: