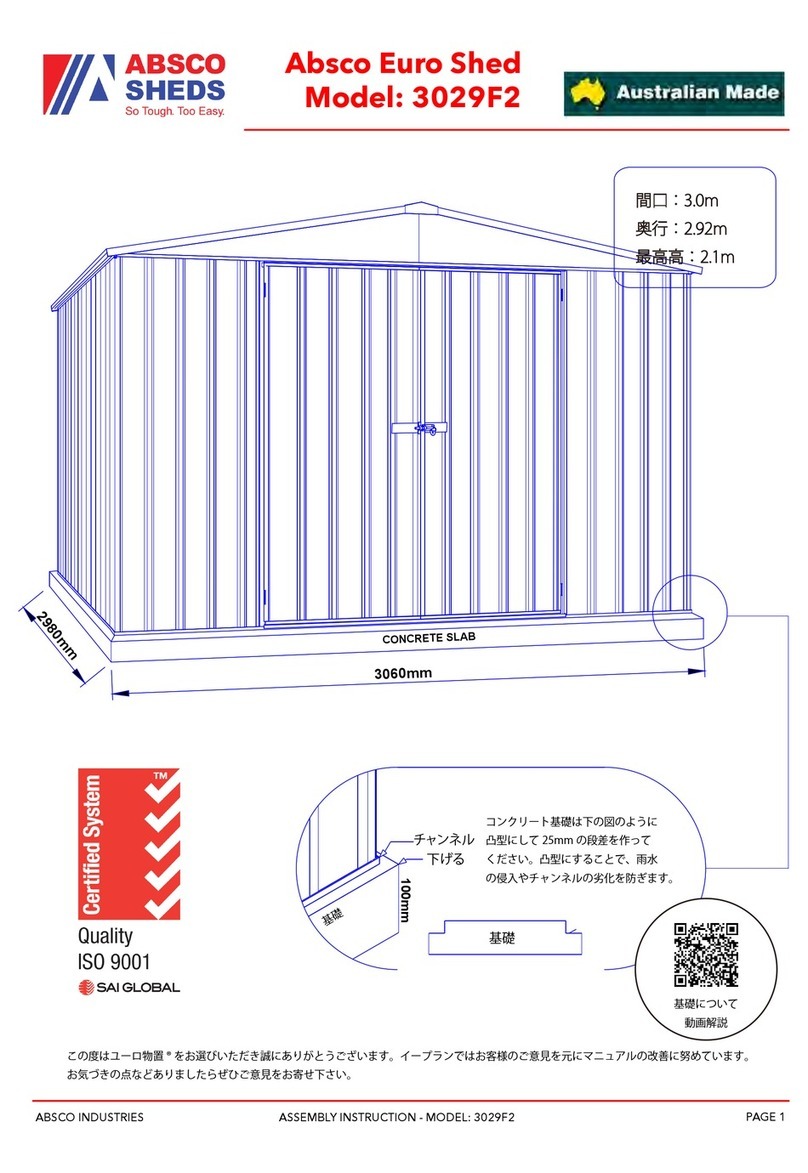

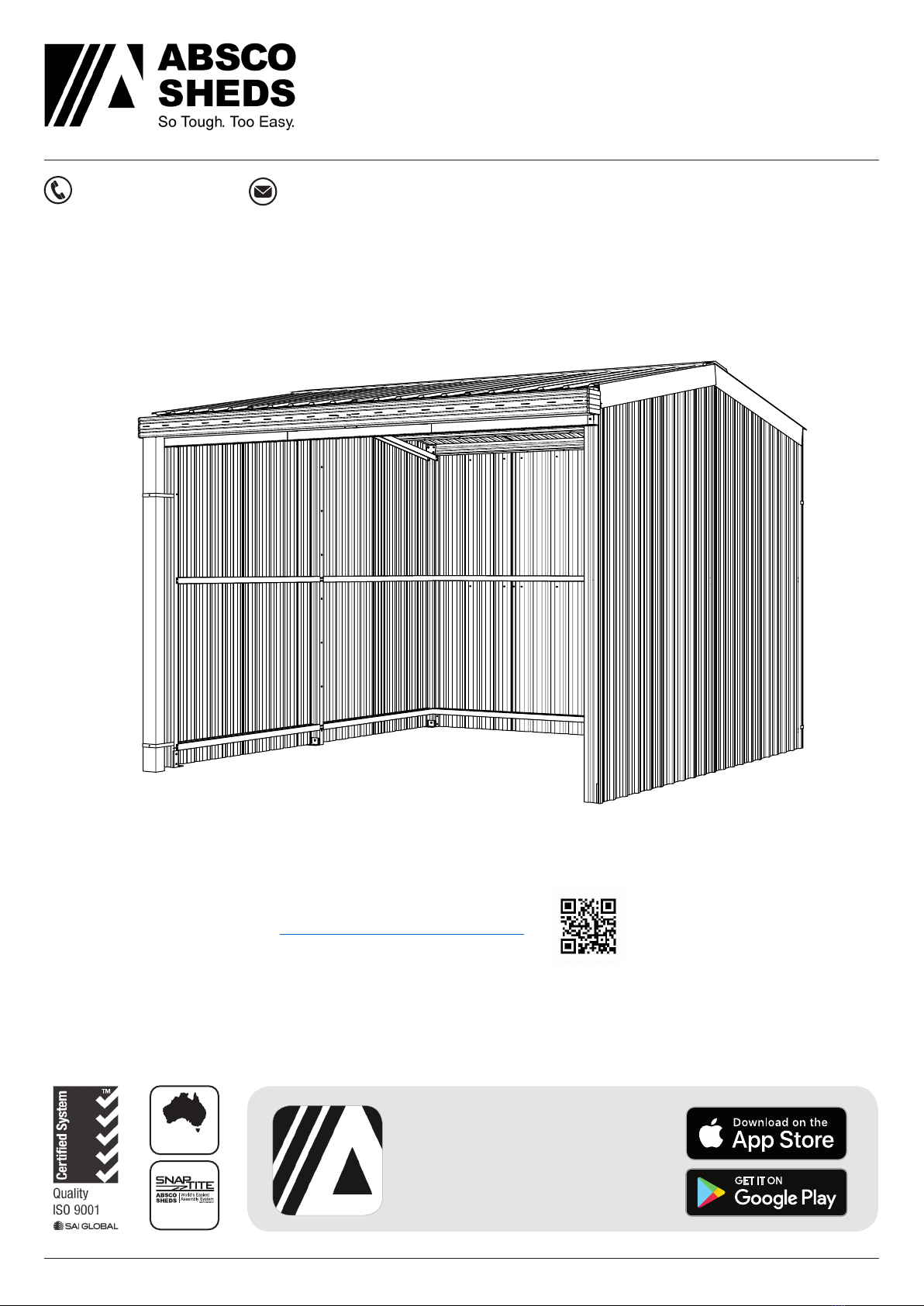

Absco Industries Assembly Instruction Manual

ABSCO RURAL SHED

MODEL: 3030RS-PTX

9’ 9 5/16” W x 9’ 9 5/16” D x 8’ 7/16” H

Model: 3030RS-PTX 19/07/2019 1.10 6

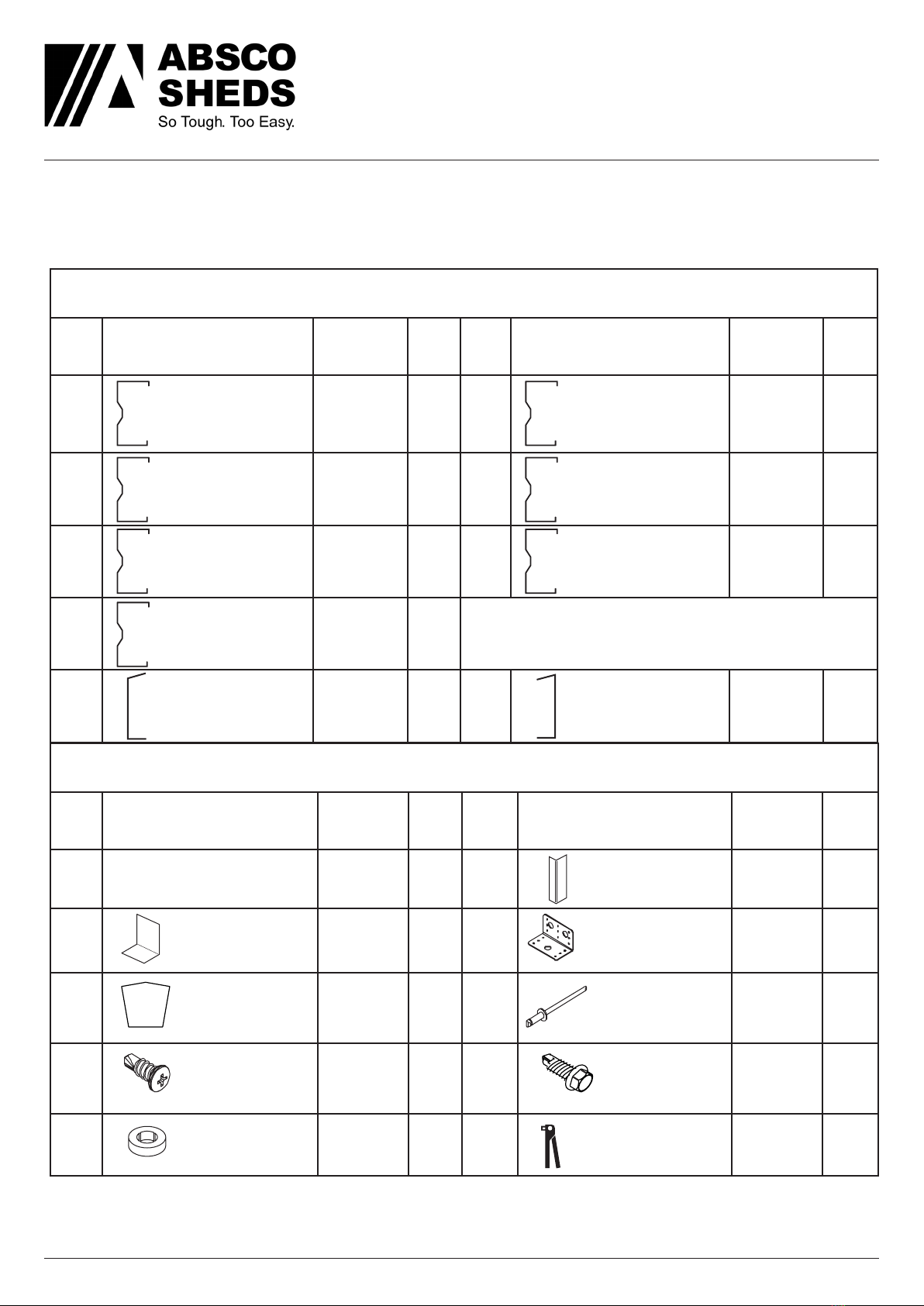

Guide for Connecting Frame Sections

Absco sheds’ frame assemblies are supplied with

10-16x16 self drilling wafer head phillips drive tek

screws

The wafer head minimises distortion to the sheet

cladding once it is fitted to the frame

Ensure that driver bits used to fasten these screws

is phillips drive, as similar alternatives (EG. Pozi

drive) increases the risk of stripping the head of

these screws.

Some holes are pre-punched in Absco sheds’ frame

sections, however the wide range of positions that

most fasteners are required for means that the

remainder have to be drilled as per the connection

being made

A 3mm drill bit is supplied for pre-drilling holes

where self drilling screws may be more difficult to

establish holes with (EG. Fitment of purlin brackets).

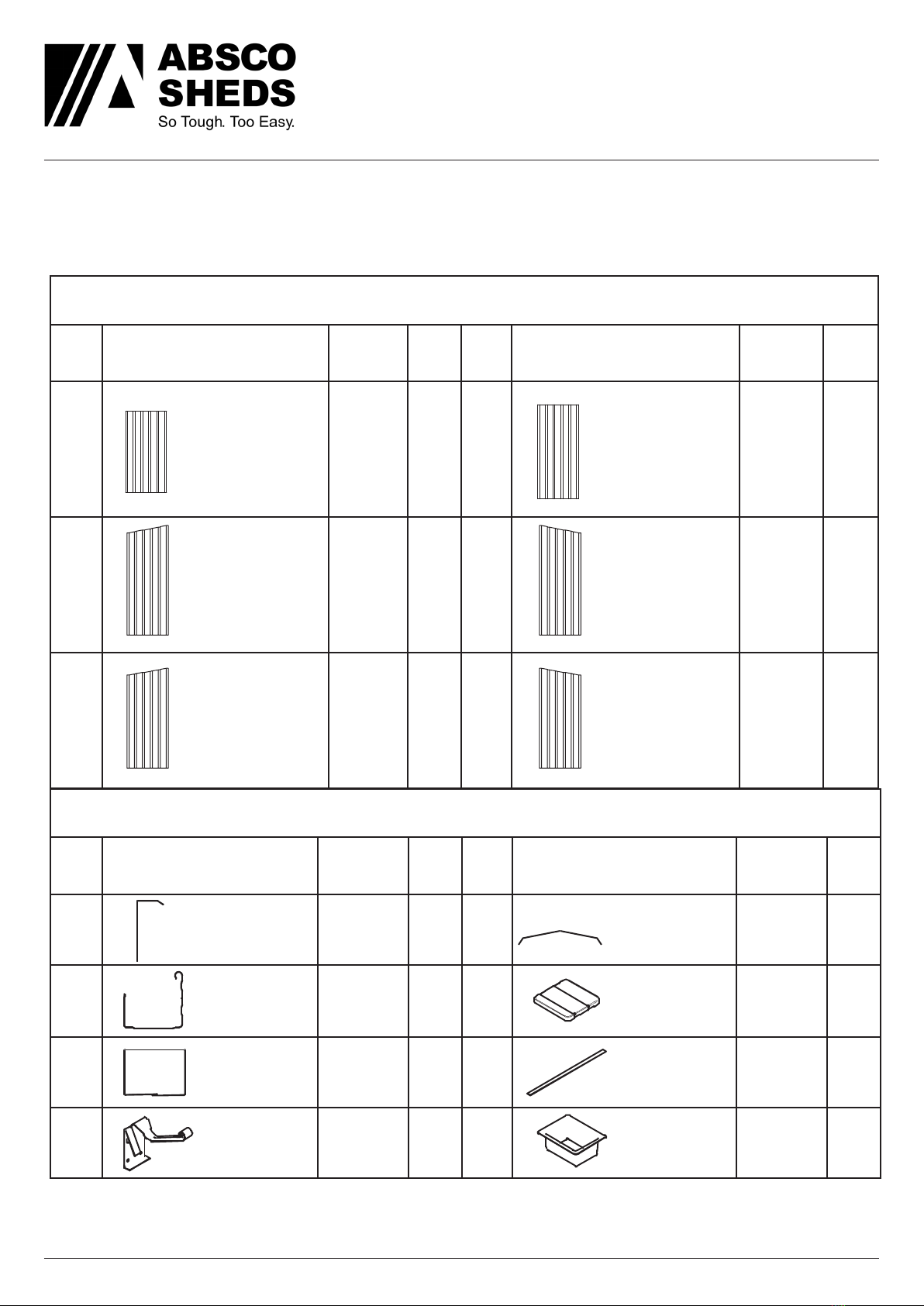

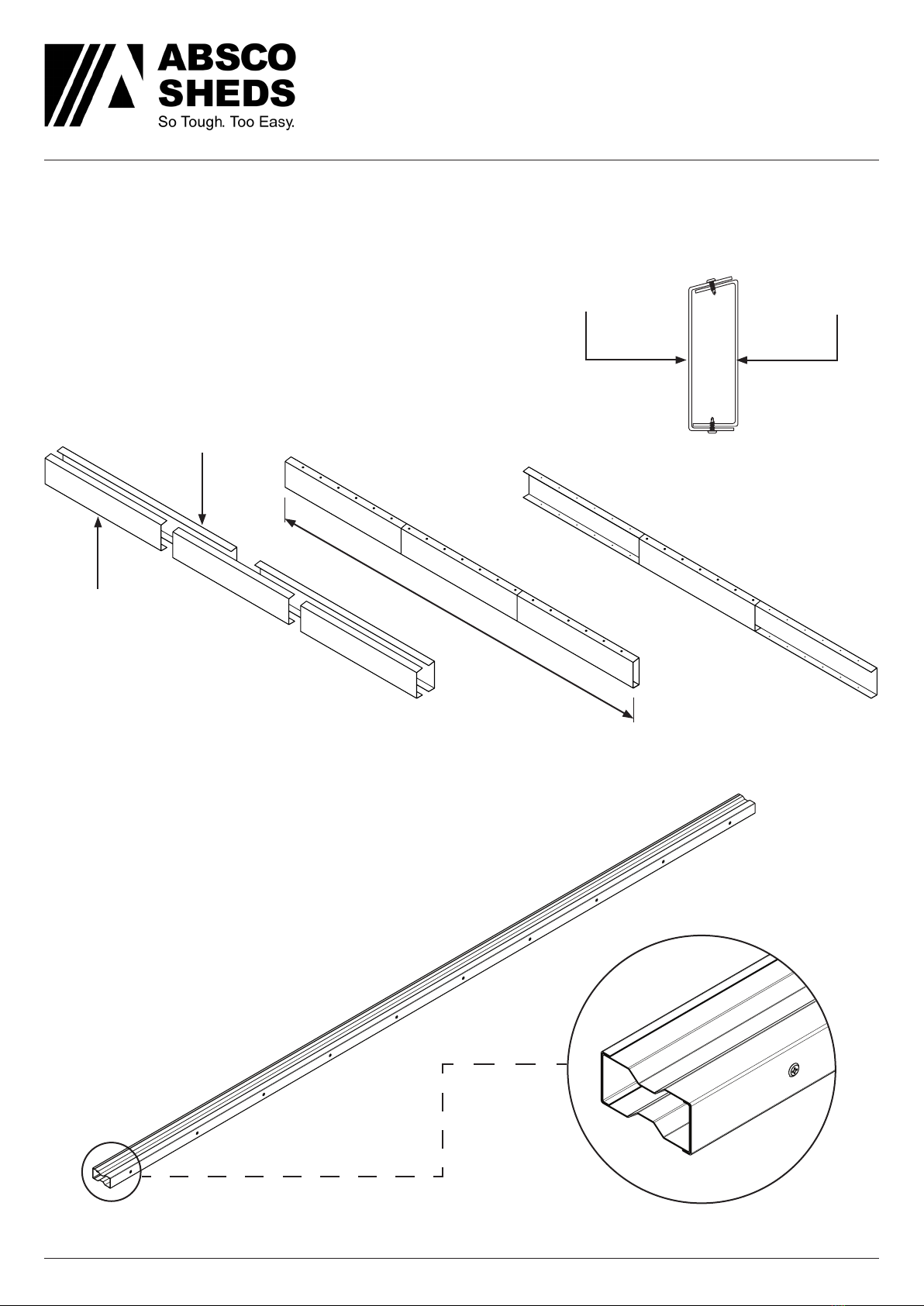

Absco sheds’ frame sections are manufactured

from light gauge steel, enabling for the notched

ends or lengths of one frame section to be spread

over the sides of another frame section, boxed

frame section or H-section.

Absco sheds’ frame sections are designed to nest

into one another to create boxed frame sections

Boxed frame sections are only required in some

parts of the entire frame assembly

Boxed frame sections are fastened together using

the FAST014 tek screws supplied at 11 13/16”

centres along the length of each boxed frame

section

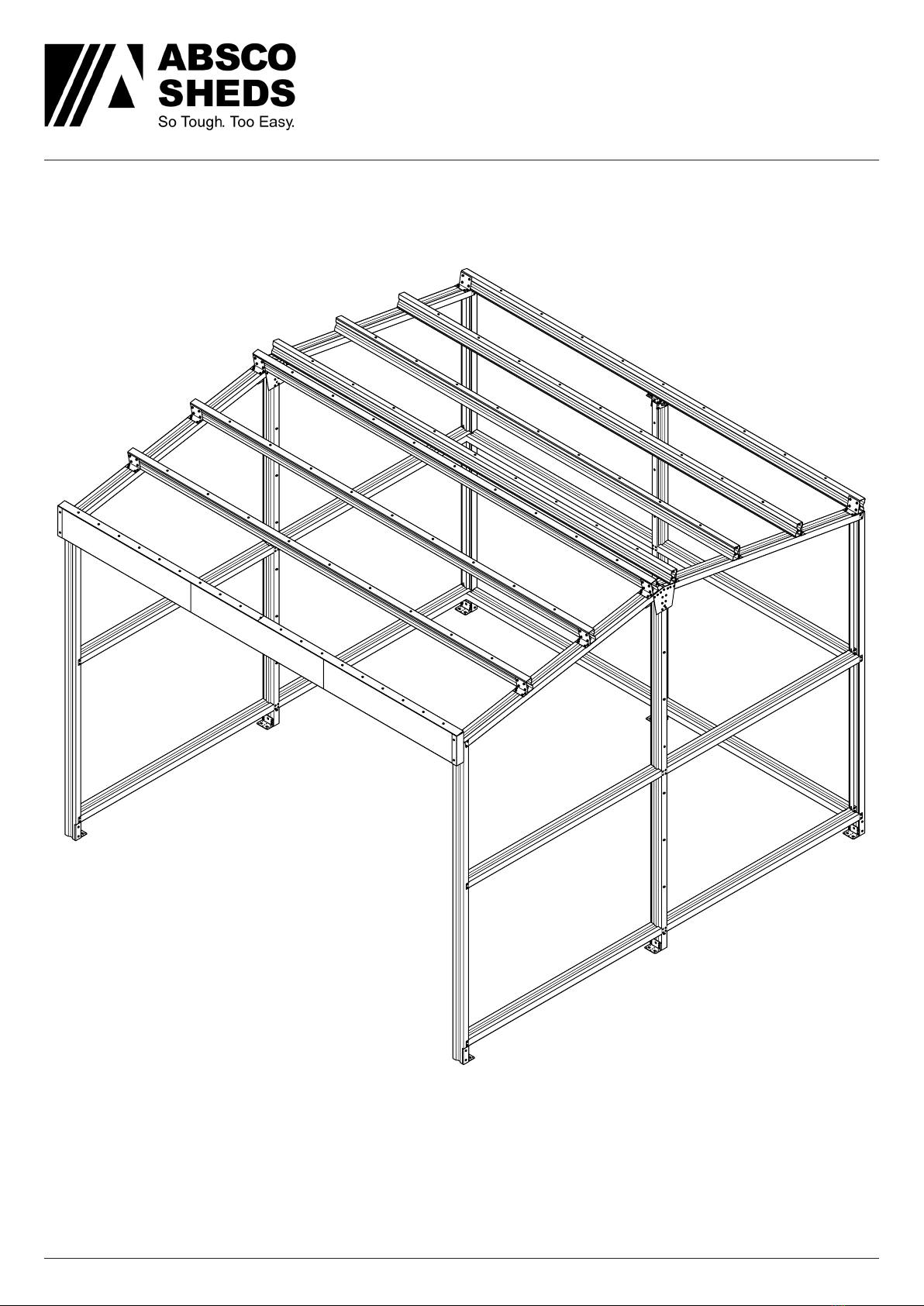

Some connections are designed to fasten more than two parts together. Connections may also not

feature a defined alignment or physical stop.

For these reasons, focus on arranging all parts of a frame assembly or subassembly together (to

the overall sizes and check measurements nominated) using minimal screws. This allows for easier

adjustment to various connections which may be necessary to achieve the overall dimensions and

check measurements that are nominated.

Fit the remaining screws once the frame assembly or subassembly is assembled as per the overall

dimensions and check measurements that are nominated

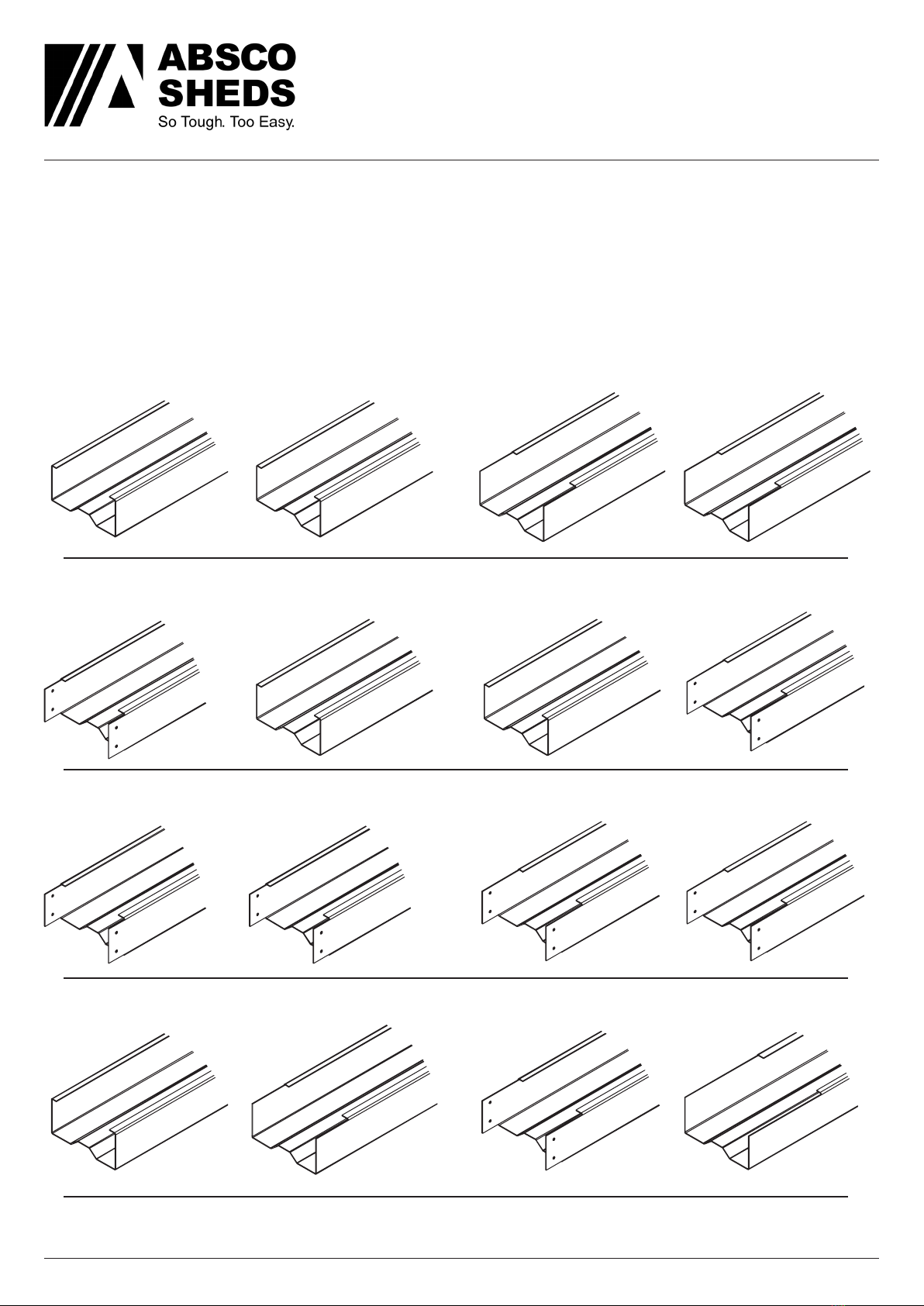

Boxing Frame Sections

A B

HIGH SIDE A

HIGH SIDE B

LOW SIDE B

LOW SIDE A FAST014

FAST014

HIGH SIDE

HIGH SIDE

(PRINT)

(PRINT)

LOW SIDE

LOW SIDE