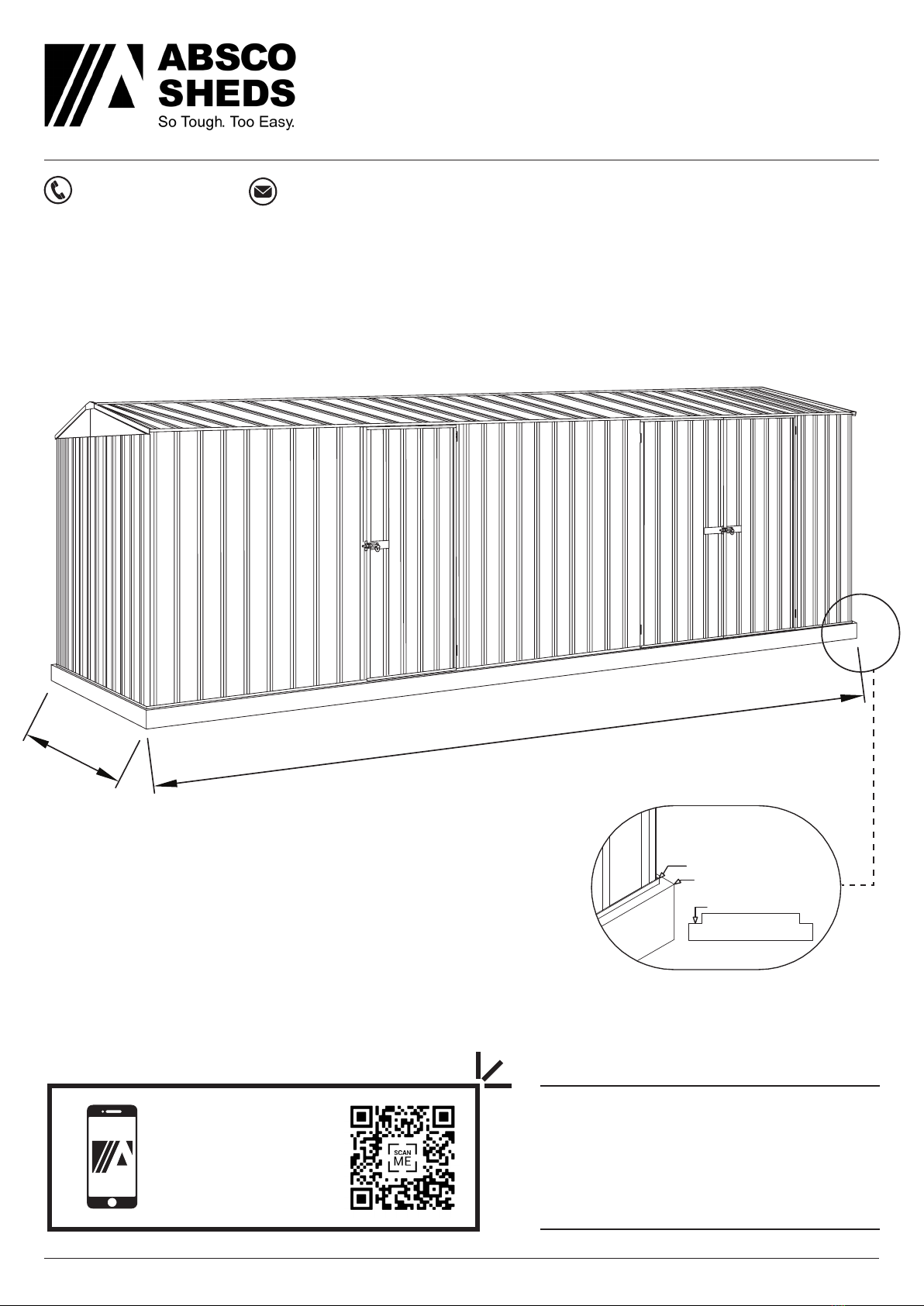

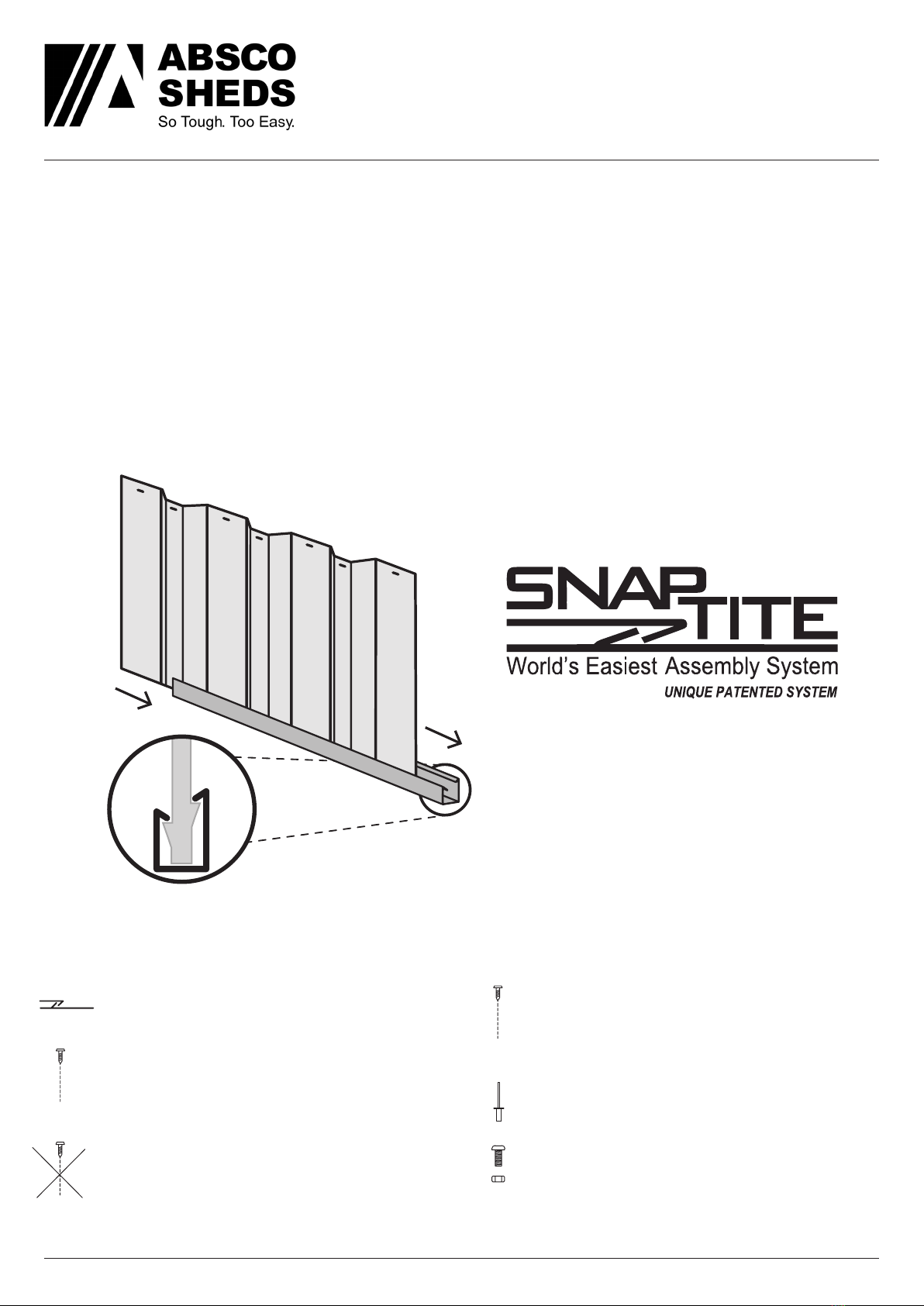

ABSCO HIGHLANDER SHED

MODEL: 60303HK

5.96mW x 3.00mD x 2.30mH

Model: 60303HK 29/11/2021 1.4 9

Absco Industries Assembly Instruction Manual

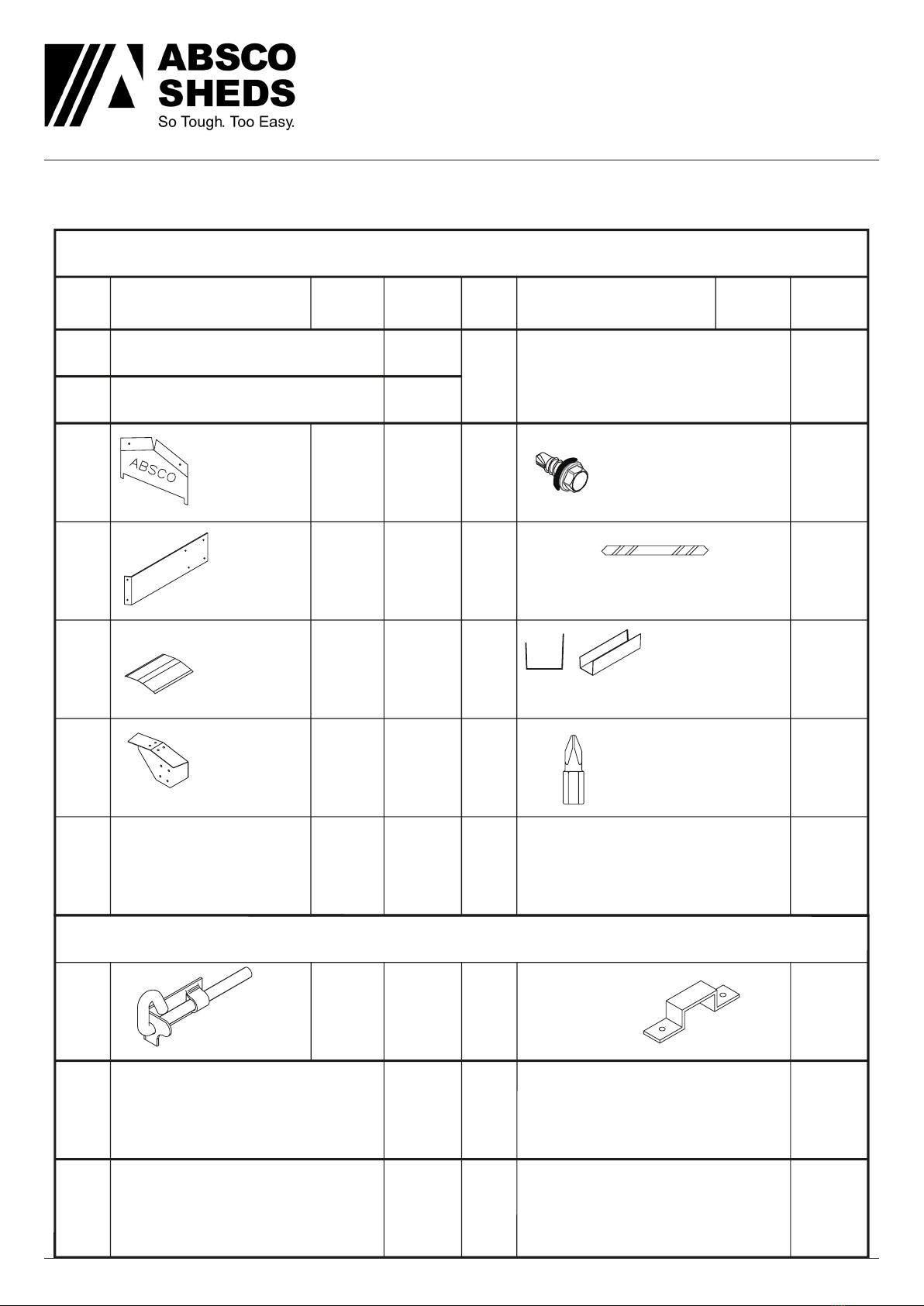

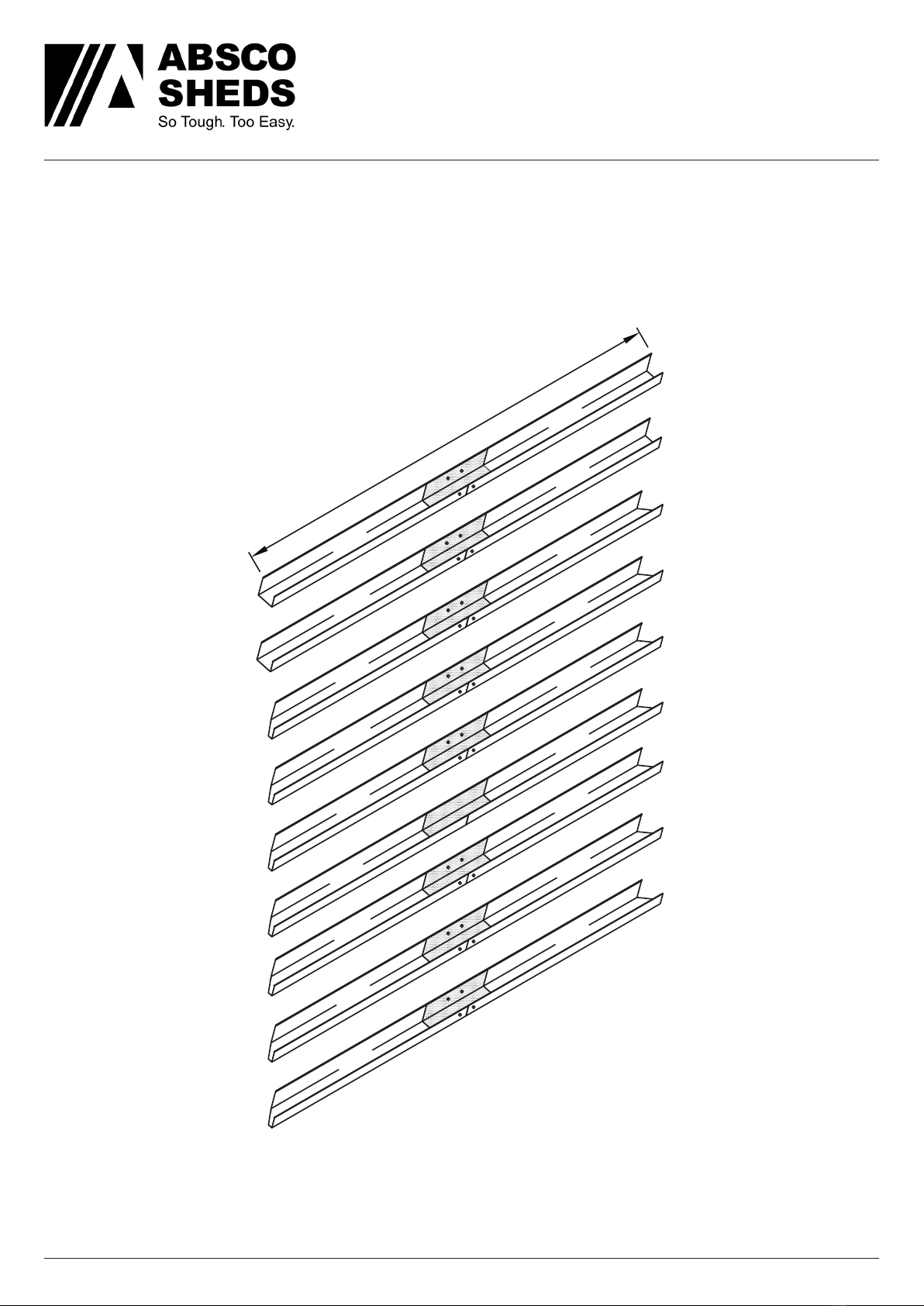

Guide on Joining Spliced Channels

The text marked on all parts must be shown on the same side as each other

Step 1.

Position the channels and the

CSJ joiner so the centre of

the CSJ is in line with the end

of each channel to be joiner

together.

Step 2.

Join the first channel to the CSJ

by inserting the centre of the

CSJ, on an angle, to the end of

the channel where the JOIN>>

text is marked.

Push down one side of the CSJ

until you hear a ‘click’.

Step 3.

Join the second channel to the

CSJ by positioning the <<JOIN

of the channel at the centre of

the CSJ, on an angle. Push the

CSJ into the channel until you

hear a ‘click’.

Finished Channel.

The joined channels should

now look like the picture with

the CSJ positioned equally

inside of the joined channels.

Drill out holes with 3mm drill

bit in CSJ to match the holes

in channel. Drilling of screws

on the joined channels is being

done after sheets are locked on

the spliced channels.

= =

JOIN>> <<JOIN

CSJ

==

JOIN>>

J

==

JOIN>> SJ

= =

JOIN>>

<<JOIN

= =

JOIN>> <<JOIN

Finished Spliced

Channel

Channel

Push

20mm 15mm

CSJ

.

...