4

1.MAIN FEATURES

1.1 CLASSIFICATION OF EQUIPMENT

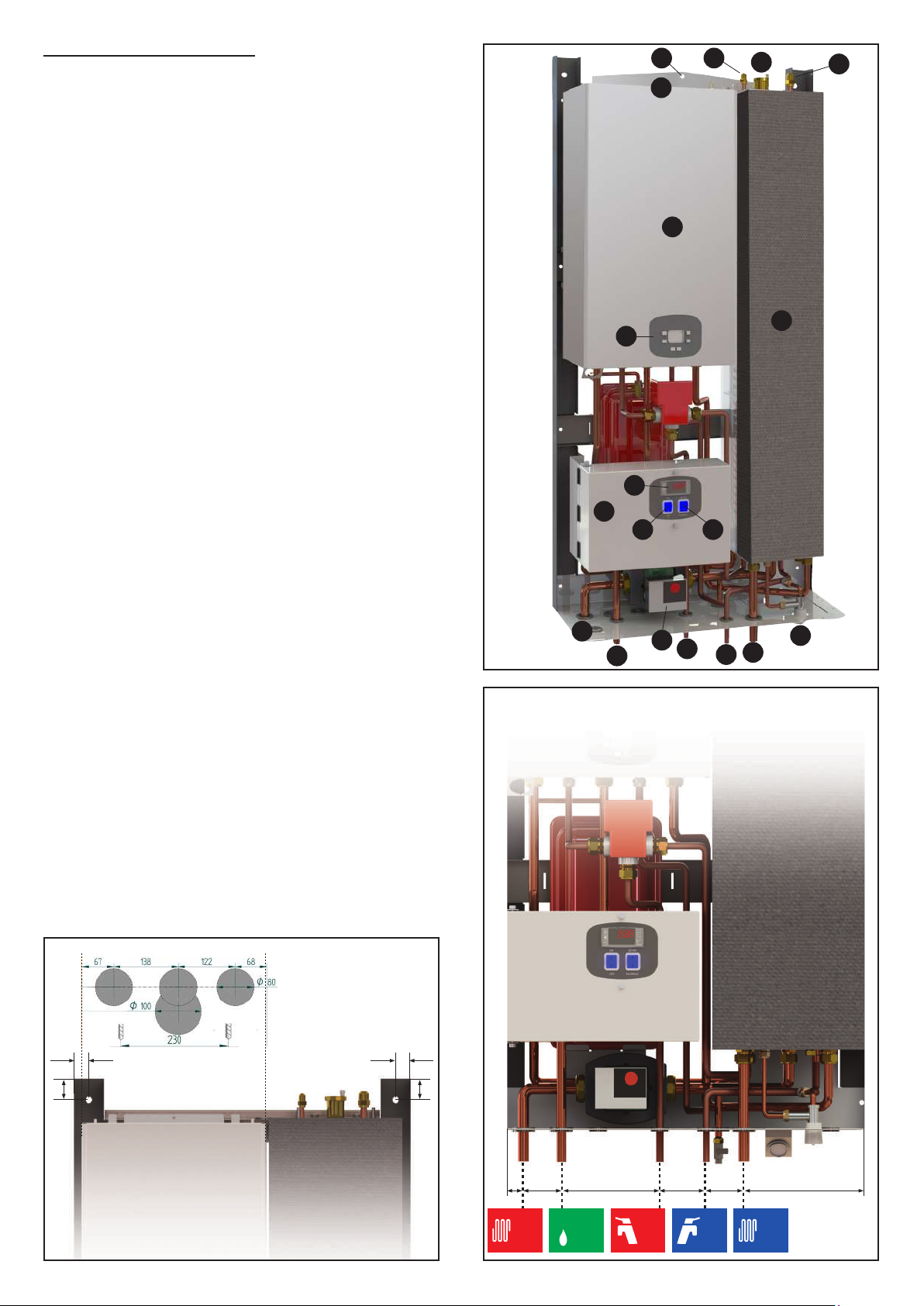

The fundamental elements that make up the HUB RADIATOR

PACK CF system are:

1) Electronically controlled external moto-evaporator dened

as: “Split air-water heat pump”, fed by R410A refrigerant uid with

ON - OFF compressor model Booster HR 7.8 (HUB RADIATOR

PACK CF 7.8) or HR 3.0 (HUB RADIATOR PACK CF 3.0).

2) Indoor unit consisting of a modulating condensing boiler from

2.9 to 24.9 kW which works as a support to the heat pump and

a 48-liter closed vessel accumulator of technical water inside

which all the copper exchangers are positioned both for the

production of DHW and for the heat exchange with the external

motor-evaporator.

1.2 CERTIFICATIONS - CE MARKING

The patented HUB RADIATOR PACK CF system complies with

directives 97/23 / EC and 98/37 / EEC.

They also comply with the provisions of the following directives:

73/23 / EEC, 89/336 / EEC, as amended by directive 93/68 /

EEC.

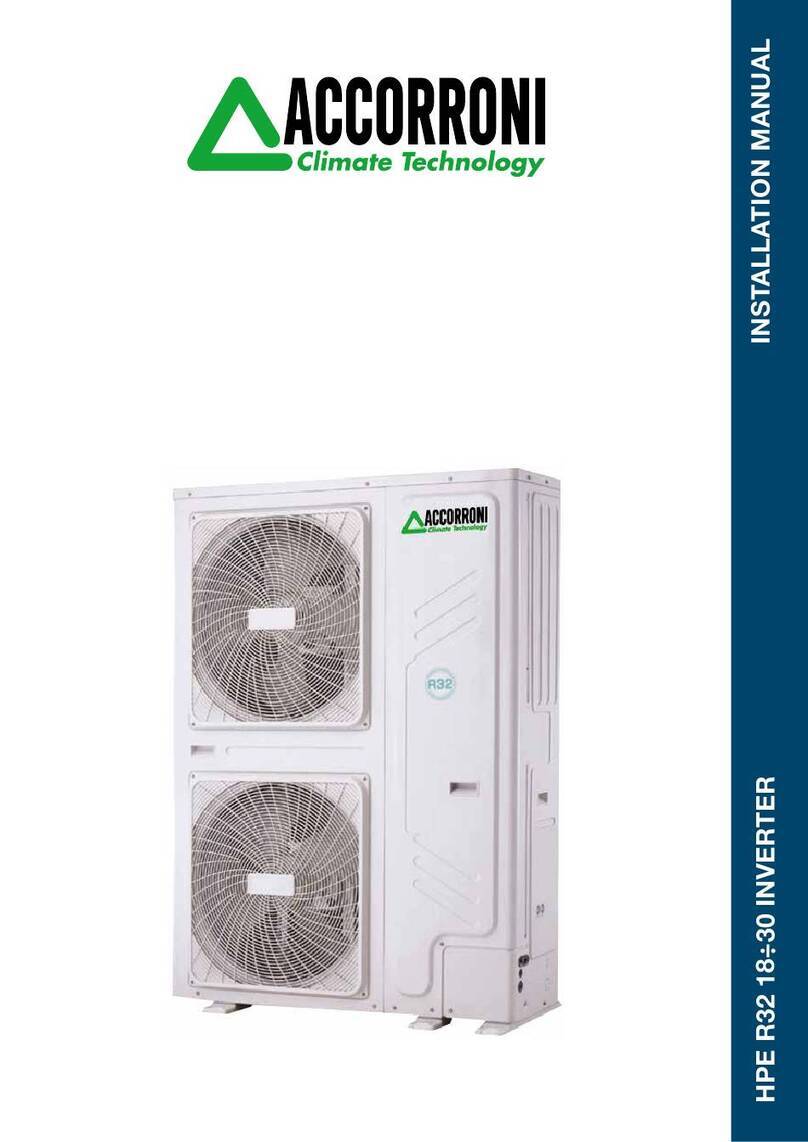

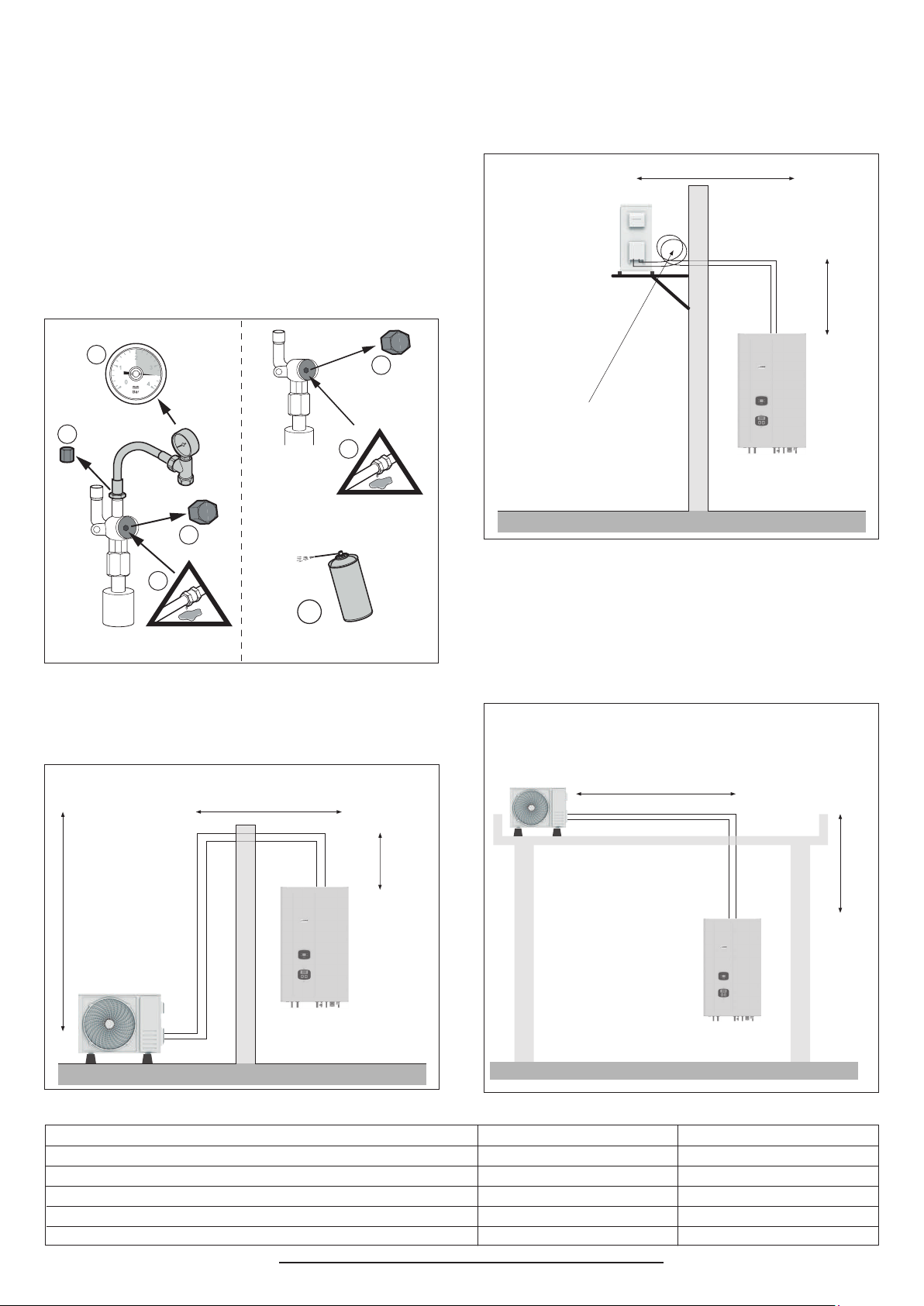

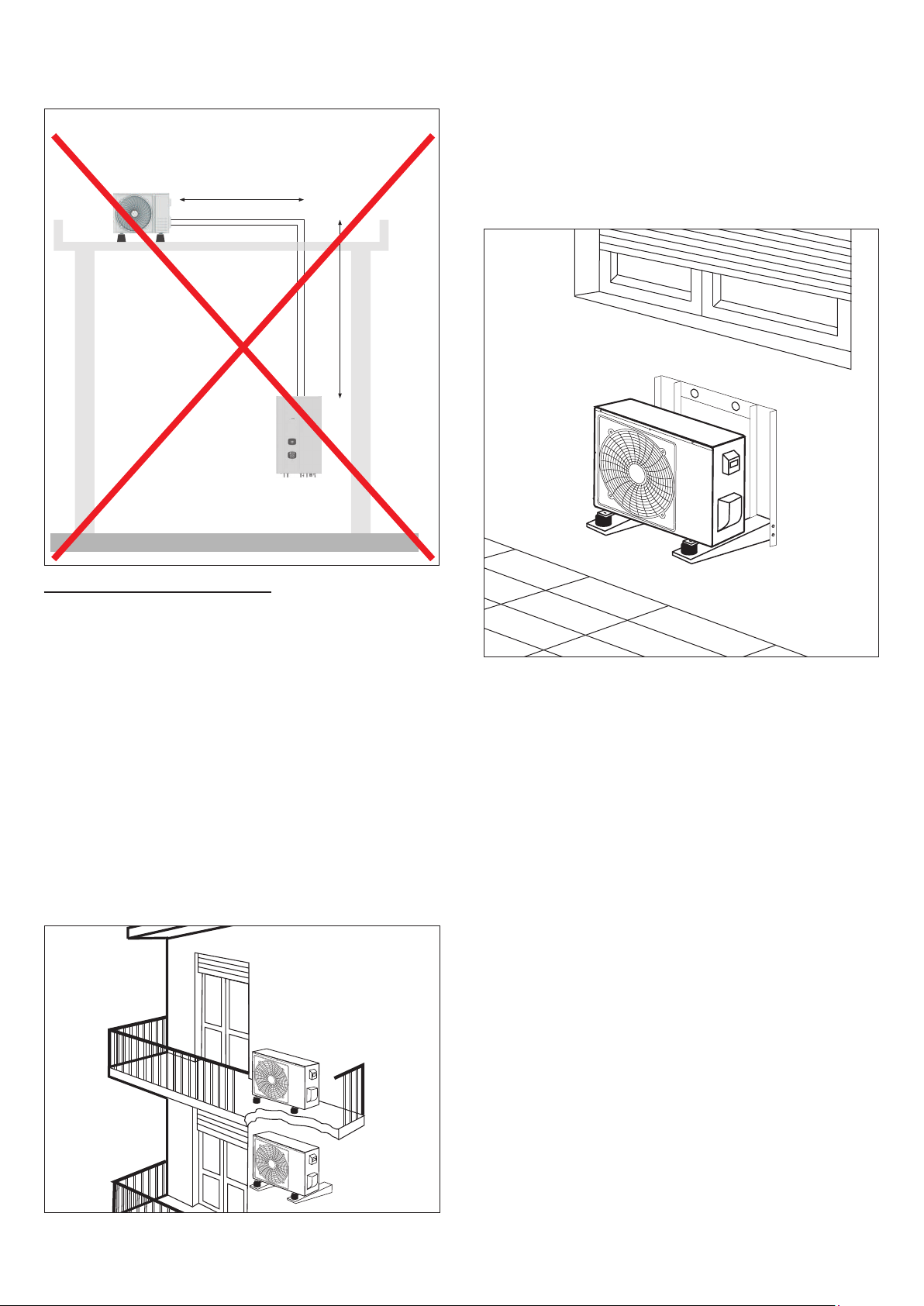

The indoor unit of the HUB RADIATOR PACK CF hybrid system

has been designed to be installed only and exclusively inside

buildings or on a special external niche that is thermally insulated

and protected from atmospheric agents.If this indication is not

respected, any type of warranty is void.

1.3 CONSTRUCTION FEATURES

All the machines are equipped with a microprocessor for

controlling and adjusting the operation and safety of the units.

Thanks to the patented direct exchange condensers, the products

of the HUB RADIATOR PACK CF series are able to reach high

standards of energy efciency and SCOP.Altre caratteristiche

costruttive:

- the cabinet covering the outdoor unit is made for everyone

the models in sheet metal pre-painted with epoxy powder.

The compressor compartment is completely isolated from the

compartment refrigerant air exchanger; this allows you to

protect the better the electromechanical components;

- the compressor is of the high efciency rotary type, working

with R 410A refrigerant, mounted on supports anti-vibration

rubber bands, driven by a single-phase electric motor for all

models;

- the air / refrigerant gas exchanger

it is made with copper pipes and blocked aluminum ns by

mechanical expansion of the pipes, with high heat exchange

surface;

- the fan unit it consists of a helical fan driven directly by

single-phase asynchronous motor with internal thermal

protection. The fan is equipped with safety protection grid;

- the quick heat exchanger DHW is made of copper

directly immersed in the technical water of the indoor unit

with the FIRST IN - FIRST OUT method, so as to eliminate

the problem of legionella within the accumulation.

- the refrigeration circuit and the links between individuals

components are made of copper tube specic for refrigeration.

The body of lamination, the reverse cycle valve the separator

of liquid;

- the electrical command and control panel is directly

positioned inside the cover cabinet.

- the microprocessor control system with keyboard is

located on the control plate accessible directly on the front of

the cover cabinet, and can be remotely via the appropriate

command and control panel remote, available as an

accessory, to be installed a wall or recessed.

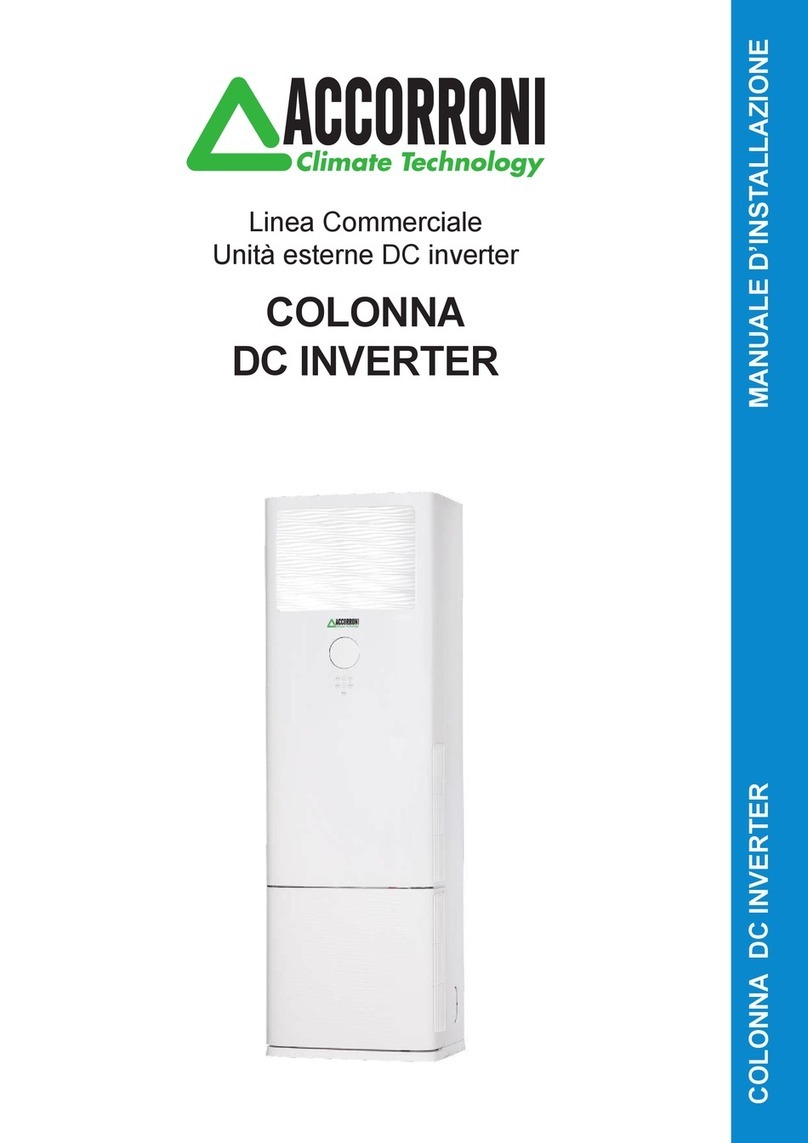

- the indoor unit is supplied complete with all the appropriate

internal copper exchangers, R410A refrigerant gas

connections, DHW connections, air vent jolly valve, safety

valve, lling tap, pressure gauge, electronic circulator, 9-liter

expansion tank, temperature probes, I unload.

1.4 CONTENT OF THE PACKAGING

The device is shipped on wooden pallets, with extruded expanded

polystyrene protections and wrapped in a layer of plastic fabric

with air bubbles.

The identication data of the device are shown both on the label

on the packaging and on the technical data plate applied inside

the cover cabinet. Do not remove the technical data plate for

any reason, as the references it contains are necessary for any

maintenance interventions.

Inside the packaging there is also an envelope containing

this manual and the warranty certicate, which must be

delivered to the owner of the device so that he can keep

them carefully for any future use or for consultation.

1.5 STANDARD EQUIPMENT AND ACCESSORIES SUPPLIED

ON REQUEST

The wide range of standard equipment and accessories available

on request allow optimal exploitation of all the functions of the

machines and system to which they are served.

1.6 FIELD OF USE

The appliances designed and manufactured for heating water

in hydronic air conditioning systems and to produce DHW must

be used only for this purpose, in relation to their technical

specications and performance.

The quality and dimensions of the materials used guarantee a

good life span and are suitable for the operation of the devices

both as a whole and in their individual components, subject

to an installation carried out in a workmanlike manner and

under conditions of mechanical stress. chemical and thermal

corresponding to a suitable use.

ATTENTION! All uses not expressly indicated in this manual

are considered improper and are not permitted; in particular,

the use of the equipment in industrial processes and / or

installation in environments with a corrosive or explosive

atmosphere is not envisaged.

The manufacturer declines any liability for damage to

persons, animals or property resulting from non-compliance

with the instructions in this manual, from modications or

tampering with the product, from installation, adjustment,

maintenance errors and from improper use.

Failure to comply with what is indicated in this manual also

results in forfeiture of the warranty conditions.

1.7 SAFETY RULES

ATTENTION! Installation and maintenance must be carried

out exclusively by specialized and specially authorized

personnel.

The connection to the power supply must be performed in

accordance with current national plant standards.

During installation and maintenance operations, it is always

necessary to operate in conditions of maximum safety,

follow the instructions given in this manual and any warning

labels applied to the product.

Respect the installation and operating limits indicated in

this manual, never modify the internal electrical wiring and

refrigeration pipes, do not modify or disable the safety and

regulation devices.

Before any inspection, maintenance, or anything else

involving access to the internal parts of the appliance,

disconnect the general power supply.

In case of need or clarication for installation and maintenance,

contact a Technical Assistance Center authorized by A2B

ACCORRONI E.G.