Accucraft trains Climax User manual

Other Accucraft trains Toy manuals

Accucraft trains

Accucraft trains Lilly Belle User manual

Accucraft trains

Accucraft trains Shay Electric User manual

Accucraft trains

Accucraft trains UNION PACIFIC 4-8-8-4 BIG BOY User manual

Accucraft trains

Accucraft trains Ruby 0-4-0T Kit User manual

Accucraft trains

Accucraft trains Lilly Belle User manual

Accucraft trains

Accucraft trains L&B LEW User manual

Accucraft trains

Accucraft trains SP 2-10-2 F4/F5 User manual

Accucraft trains

Accucraft trains Baldwin 4-4-0 1:20.3 Scale User manual

Accucraft trains

Accucraft trains SOUTHERN PACIFIC 2-10-2 F4 User manual

Accucraft trains

Accucraft trains Mogul User manual

Accucraft trains

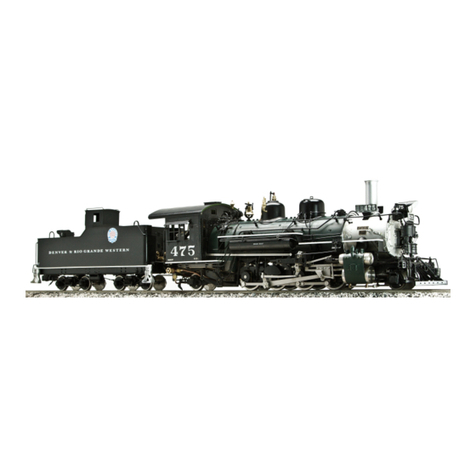

Accucraft trains D&RGW C-25 2-8-0 COAL FIRED User manual

Accucraft trains

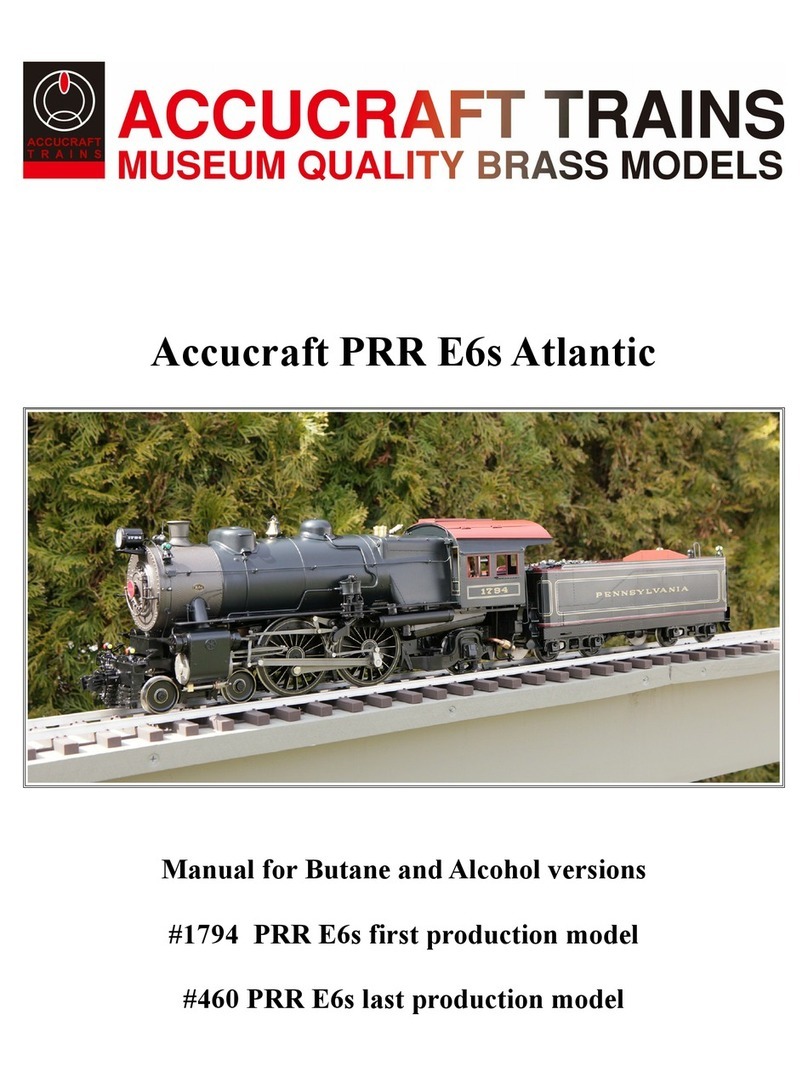

Accucraft trains PRR E6s Atlantic User manual

Accucraft trains

Accucraft trains D&RGW K37 2-8-2 User manual

Accucraft trains

Accucraft trains D&RGW C-25 2-8-0 User manual

Accucraft trains

Accucraft trains AL97-372 User manual

Accucraft trains

Accucraft trains RUBY #5 User manual

Accucraft trains

Accucraft trains D&RGW K-28 COAL FIRED User manual

Accucraft trains

Accucraft trains WHITCOMB 45T SIDE ROD DIESEL ELECTRIC User manual

Accucraft trains

Accucraft trains DECAUVILLE 0-4-0T User manual

Accucraft trains

Accucraft trains C.P. Royal Hudson Live Steam - Alcohol Fired User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions