W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

WARRANTY

The ACI Hazardous Series temperature sensors are covered by ACI’s Five (5) Year Limited Warranty, which is

located in the front of ACI’S SENSORS & TRANSMITTERS CATALOG or can be found on ACI’s website:

www.workaci.com.

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 1.0

I0000816

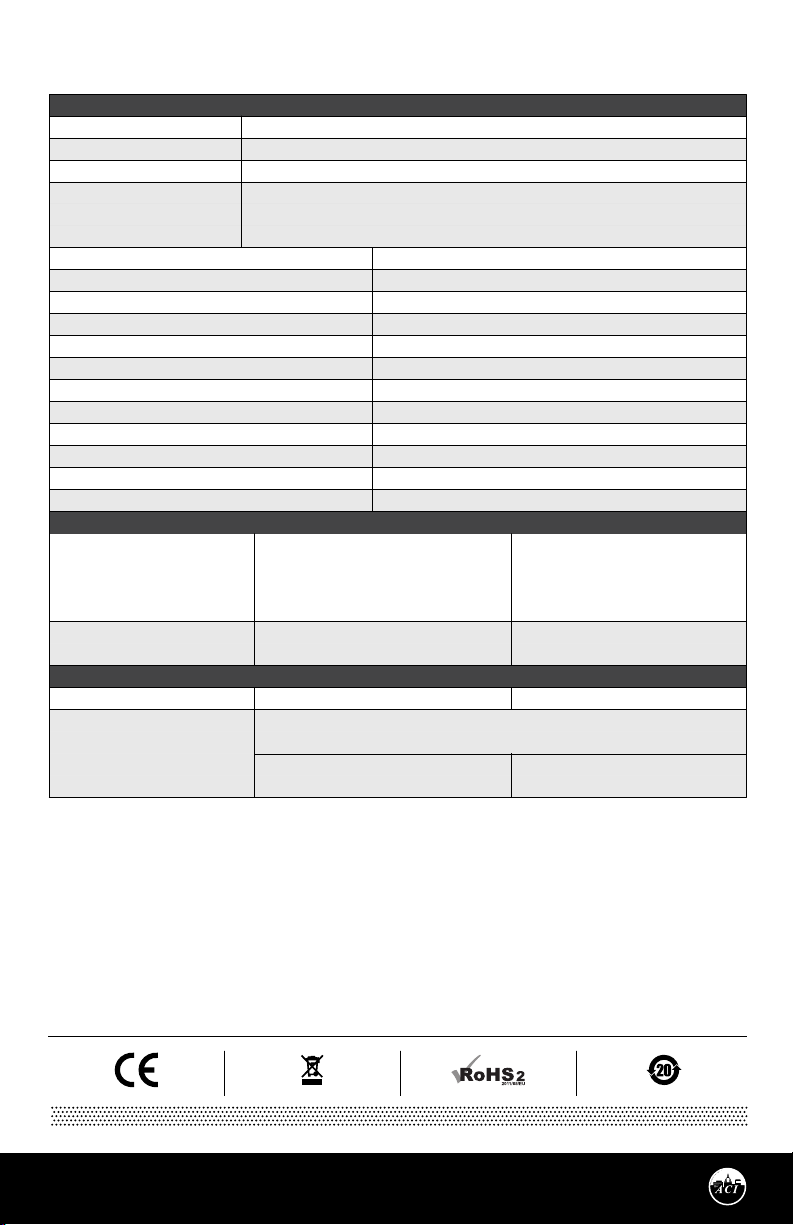

A/AN (Type III): 10 KΩ nominal (White/White)

A/CP (Type II): 10 KΩ nominal (White/Green)

A/CP-HT (Type II): 10 KΩ nominal (White/Green)

A/10K-E1: 10 KΩ nominal (Orange/Gray)

A/1.8K Series: +/- 0.5 °C @ 25 °C (77 °F)

and (+/-1.0 °C) (+/-1.8 °F)

A/100: 100 Ω nominal

+/- 0.06% Class A (Tolerance Formula: +/- °C = (0.15 °C + (0.002 * |t|))

where |t| is the absolute value ofTemperature above or below 0 °C in °C)

@ -40 °C (-40 °F): +/- 0.23°C (+/- 0.414 °F)

@ 0 °C (32 °F): +/- 0.15°C (+/- 0.27 °F)

One

-40 to 85 °C (-40 to 185 °F)

10 to 95% RH, non-condensing

“-D” Enclosure: Feraloy® Iron Alloy, -50 to 60

°C

(-58 to 140

°F

), NEMA 3, 4, 7ABCD, 9EFG

“-I” or “-INW” Enclosure: Feraloy® Iron Alloy, -50 to 60

°C

(-58 to 140

°F

), NEMA 3, 4, 7ABCD, 9EFG

“-R” Enclosure: Copper-Free Aluminum, -50 to 60

°C

(-58 to 140

°C

), NEMA 3, 4, 7ABCD, 9EFG

(see Enclosure Specifications)

CL. I, Div. 1 & 2, Groups A, B, C, D

CL. II, Div. 1, Groups E, F, G

CL. II, Div. 2, Groups F, G

CL. III

“-R” Enclosure: UL 1203 | “-D”, “-I” or “-INW” Enclosure: UL 886

C22.2 No. 30

Two | 1/2” NPT (National Pipe Tapered) Female Hubs

0.250” (6.35mm) | ½” NPT Thread

304 Stainless Steel

304 Stainless Steel | 0.260”

½” NPS Female Thread | ½” NPT Male Thread

A/1.8K: 1.8 KΩ nominal (Red/Yellow)

A/3K: 3 KΩ nominal (White/Brown)

A/20K: 20 KΩ nominal (Brown/Blue)

A/100KS: 100 KΩ nominal (Black/Yellow)

A/10K-E1 Series: +/- 0.3 °C (+/- 0.54 °F)

All Else: +/- 0.2 °C (+/- 0.36 °F)

A/1K: 1 KΩ nominal

@ 200 °C 392 °F): +/- 0.55 °C (+/- 0.99 °F)

SENSOR NON-SPECIFIC INFORMATION

Number Sensing Points:

Storage Temperature Range:

Operating Humidity Range:

Enclosure Specifications:

(Temperature, NEMA Ratings)

Operating Temperature Range:

Enclosure Explosion Proof Rating:

Enclosure Dust-Ignition Proof Rating:

Enclosure Raintight Rating:

Enclosure Wet Locations Rating:

Enclosure UL Standards:

Enclosure CSA Standards:

Enclosure Hubs | Hub Size:

Probe Diameter | Sensor Threads:

Probe Material:

Thermowell Material | Bore Diameter:

Thermowell Instrument Thread | Process Thread:

THERMISTOR

Sensor Output @ 25ºC (77ºF):

(Lead Wire Colors)

Accuracy 0-70ºC (32-158ºF):

PLATINUM

Sensor Output @ 0°C (32°F):

Accuracy:

PRODUCT SPECIFICATIONS