Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 2.0

I0000816

HAZARDOUS ROOM SERIES

Installation & Operation Instructions Phone: 1-888-967-5224

Website: workaci.com

PRECAUTIONS

•DO NOT RUN THE WIRING IN ANY CONDUIT

WITH LINE VOLTAGE (24/120/230 VAC).

GENERAL INFORMATION

The ACI Hazardous Room Sensor is a single

point wall mounted temperature sensor that is

designed for use with electronic controllers in

commercial and industrial heating and cooling

building management systems. It is available

with multiple thermistor or RTD options.

Hazardous Room sensors come standard with a

heavy-duty Copper-Free Aluminum Connection

Head that meets Class I, Division 1 & 2, Group A,

B, C, D; Class II, Division 1, Groups E, F, G; Class II,

Division 2, Group F & G; class III standards.

For optimal temperature measurement,

follow these tips:

• Do not install on external walls.

• Do not install near heat sources. eg: lamps,

radiators, direct sunlight, copiers, chemney

walls, walls concealing hot-water pipes.

• Avoid air registers, diusers, vents and

windows

ASSEMBLY INSTRUCTIONS

The enclosure and probe assembly are shipped

separately. Insert the lead wires through the

threaded hole on the explosion proof enclosure.

Thread the probe tting into the hole and fasten

tightly with channel lock pliers/wrench.

Note: If a NIST certied sensor is ordered, the

sensor probe serial number must be paired with

the enclosure serial number.

MOUNTING INSTRUCTIONS

This product must be installed by a trained

professional with knowledge of local codes

and regulations. Before carrying out any work,

ensure local regulations and site procedures are

followed to maintain the overall certication of

the sensor. The sensor should be mounted in an

area where air circulation is well mixed and not

blocked by obstructions.

For mounting on a wall, ACI recommends a height

of 48-60” (1.2-1.5 m) o the ground and at least

1.5’ (0.5 m) from the adjacent wall. Remove the

cover from the housing by twisting o the cover.

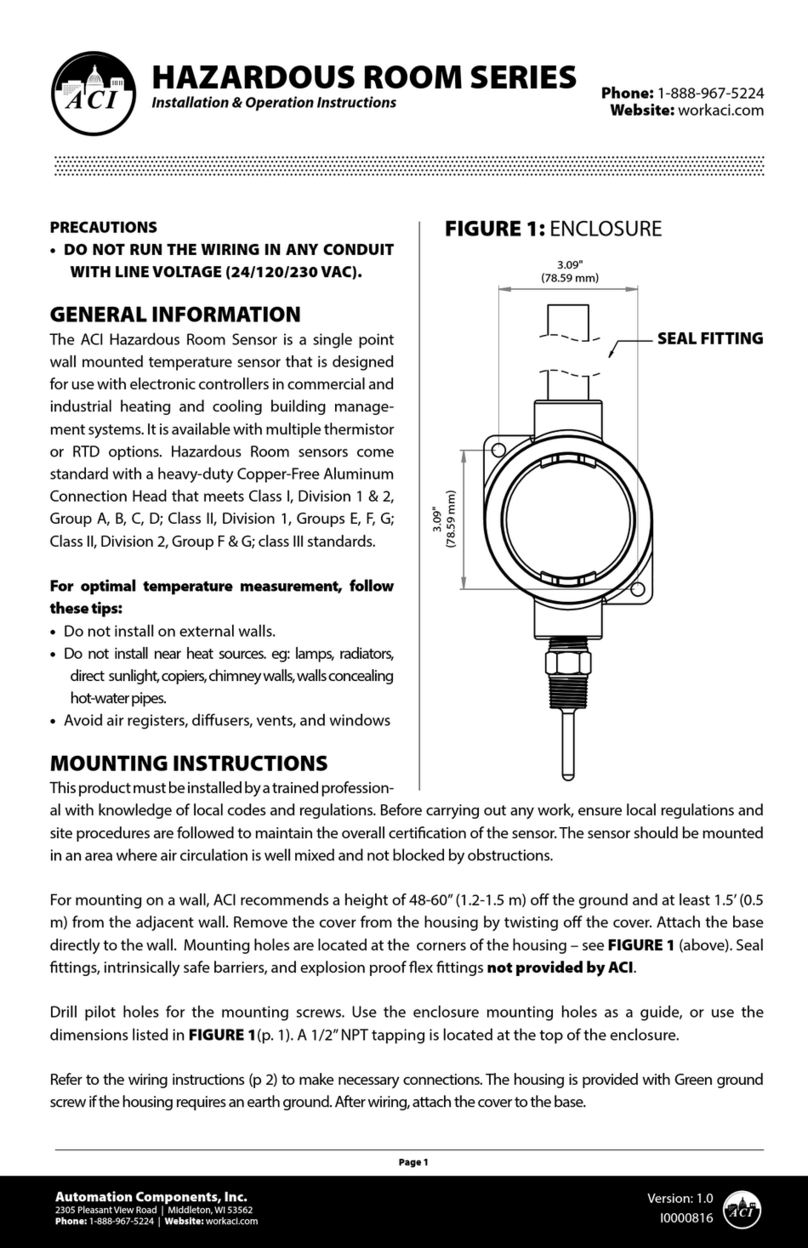

Attach the base directly to the wall. Mounting

holes are located at the corners of the housing

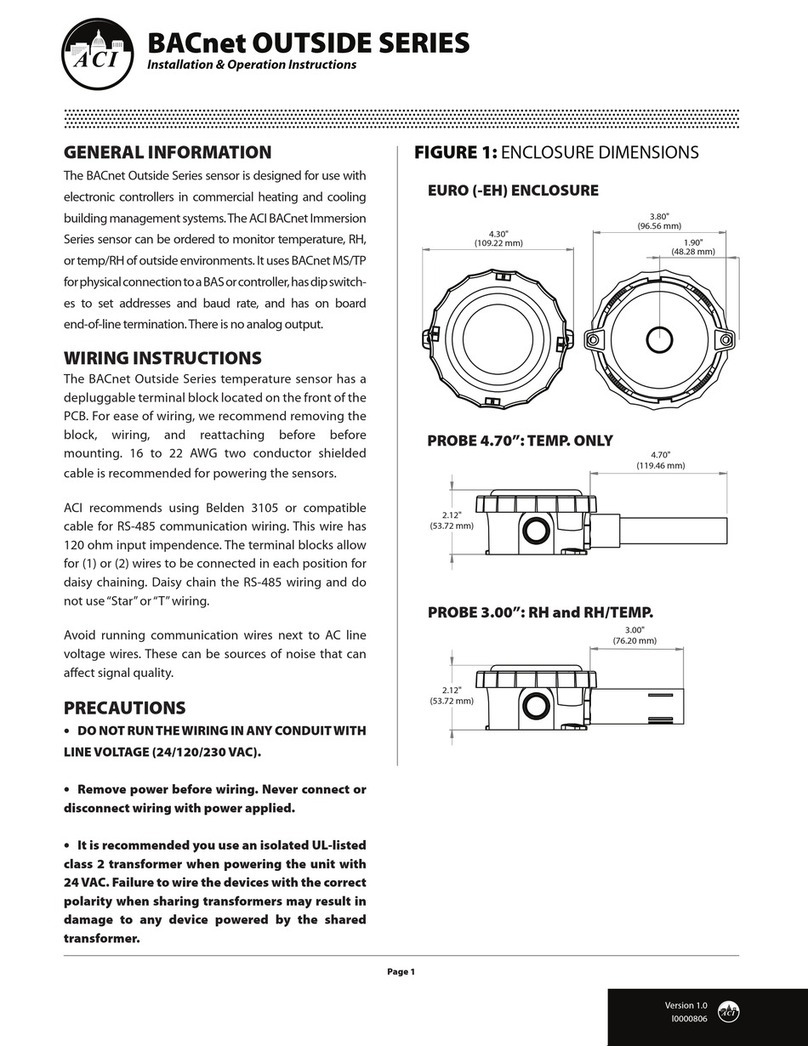

– see FIGURE 1 (above). Seal ttings, intrinsically

safe barriers, and explosion proof ex ttings are

not provided by ACI.

Drill pilot holes for the mounting screws. Use the

enclosure mounting holes as a guide, or use the

dimensions listed in FIGURE 1 (above). A 1/2”NPT

tapping is located at the top of the enclosure.

Refer to the wiring instructions (p 2) to make

necessary connections. The housing is provided

with Green ground screw if the housing requires

an earth ground. After wiring, attach the cover to

the base.