aci ACCESS series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 4.0

I0000637

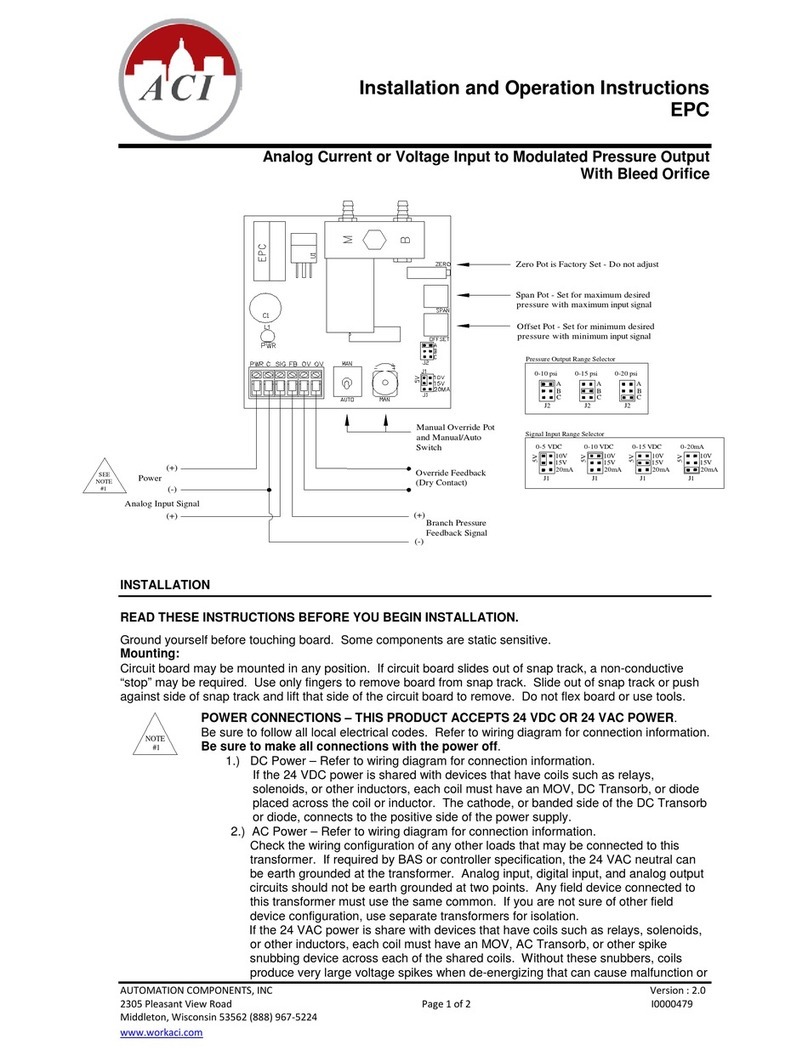

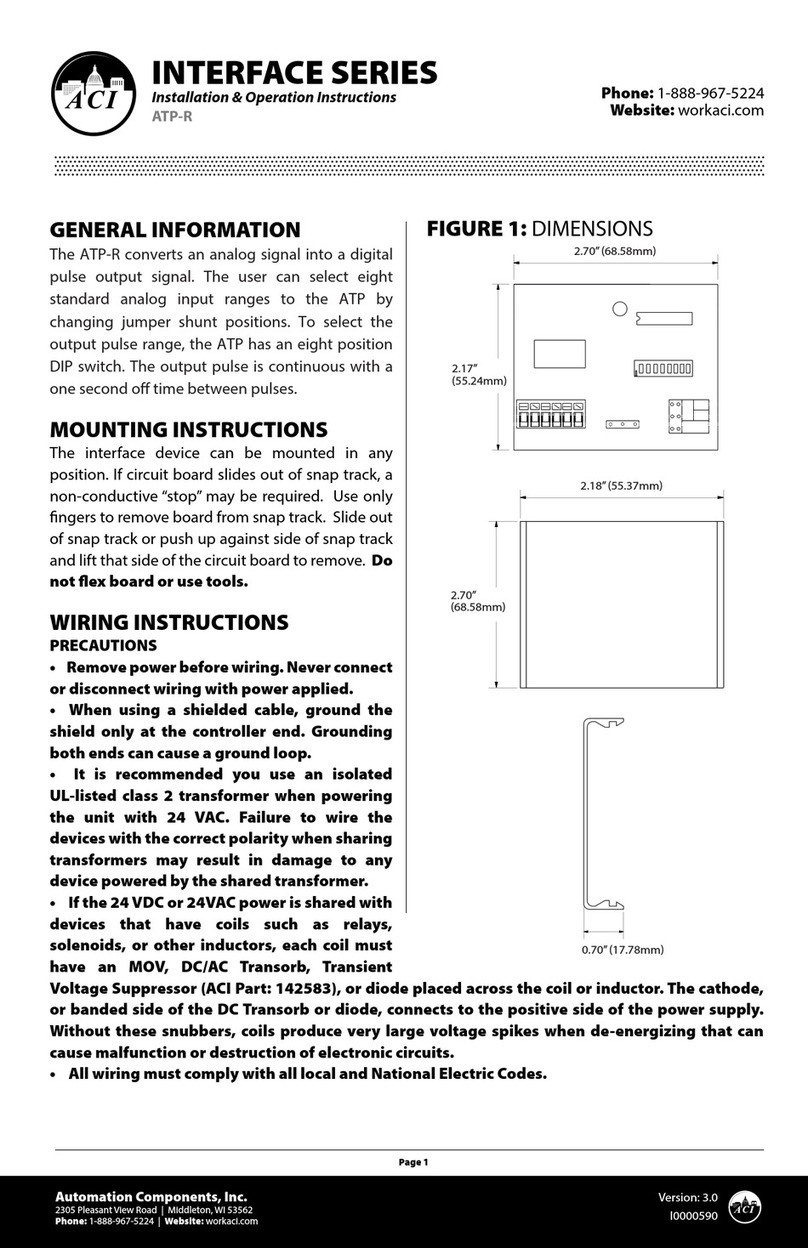

FIGURE 1: DIMENSIONS

INTERFACE SERIES

Installation & Operation Instructions

EPC2GB, EPC2FSB

Phone: 1-888-967-5224

Website: workaci.com

GENERAL INFORMATION

The EPC2 Series are electric to pneumatic

transducers which convert an analog input signal

to a proportional pneumatic output, modulating

its control valve(s) to regulate the branch line

pressure to the set point determined by the input

signal. The EPC2 series oers four selectable input

ranges. Output pressure ranges are jumper shunt

selectable and adjustable in all ranges. A feedback

signal indicating the resultant branch line pressure

is also provided. EPC2 Series is designed with

electrical terminals on one end and pneumatic

connections on the other, allowing for maximum

convenience in wiring and tubing installation

when panel mounted.

The EPC2 incorporates two

valves (one controls exhaust), does not bleed air at set

point, and has a 750 scim supply and exhaust. Its

branch exhaust ow and response time are not limited

by an internal restrictor and are similar to its load rate.

If power fails to the EPC2, branch line pressure remains

constant if the branch line does not leak air. The

EPC2FS shares the same specications as the EPC2

except its 3-way branch valve will exhaust branch line

air upon power failure.

MOUNTING INSTRUCTIONS

The EPC2 has 4 mounting holes, 2 located on the

bottom ange, and 2 on the top ange. Drill pilot

holes for the Mounting Screws(not supplied). Use

the enclosure ange as a guide. Mount the unit

vertically with the brass ttings pointing towards the ground. This ensures that any condensation that may

form in the tubing does not have an eect on the pressure sensor. If mounting the unit horizontally, care

must be taken to prevent moisture from building up in the sensor.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both ends

can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of the DC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

ADJUSTMENT OF GAUGES

If installation requires adjustment of the gauge for proper reading of the face, turn the gauge no more than

½ turn in either direction. O-rings in the bottom of the gauge port will allow this without leakage.

Warranty does not include malfunction due to clogged valve. Main air port on EPC is ltered with the

supplied 80 – 100 micron integral-in-barb lter (Part # PN004). A 5 micron external in-line lter (Part #

PN021) is supplied with the EPC2LG. Periodically check the lter for contamination and ow reduction.

Replace if needed.

The surface between the manifold and pressure transducer is a pressure seal. Minimize stress between the

circuit board and the manifold by holding the manifold in one hand while installing pneumatic tubing

onto the ttings, and use care when removing tubing to avoid damaging ttings or moving manifold.

For optimum performance and reduced noise, the EPC2FS unit requires a branch air line capacity equal to

at least 25 feet of ¼”O.D. polyethylene tubing to operate without oscillation, and the EPC2 and EPC2LG unit

require a branch air line capacity equal to at least 15 feet of ¼”O.D. polyethylene tubing to operate without

oscillation.

CHECKOUT

With power o, select one of the four input signal combinations by moving the jumper shunt J1 identied

as “Input Signal Range Selector”. Select a preset pressure output range by moving jumper shunt J2

identied as “Pressure Output Range Selector”, or set custom range as described below.

SETTING CUSTOM OUTPUT PRESSURE RANGE

Verify the MAN/AUTO switch is in the AUTO position. In AUTO, the manual override pot is inactive, the

override contacts are open, and the analog input signal is supplying the set-point. The oset pot may be

adjusted to any desired oset between 0 and 14 psig. When in the MANUAL position, the override contacts

are closed, the oset pot is inactive and the manual override pot is supplying the set point (the analog

input signal is locked out). Supply power and the LED power indicator will light, but only measurement will

verify proper voltage.

1. Setting the minimum pressure. Make sure the signal connections are made and input is at

minimum. Place the manual override switch to the AUTO position. Adjust the OFFSET pot to the

desired pressure output, or until the actuator just starts to move. The adjustment range of the OFFSET

pot is 0 to 9 psig (62.05 kPa), 0 to 14 psig (96.53 kPa), or 0 to 19 psig (131 kPa) depending on the range

selected. Zero pot is factory set – DO NOT ADJUST.

2. Setting the maximum pressure. Now place the manual override switch to the MANUAL position.

Turn the MANUAL pot to produce the maximum branch line pressure available. Turn the SPAN pot for

the maximum desired output pressure, or until the actuator just stops. Be sure the MAIN air pressure

is at least 2 psig greater than the desired maximum branch output pressure.

3. Repeat. Because the OFFSET and SPAN pots are slightly interactive, steps 1 and 2 must be repeated

until the desired minimum and maximum pressures are repeatable. Since the MANUAL pot is set for

maximum pressure, it is only required that you switch the manual override switch back and forth from

MANUAL to AUTO when repeating steps 1 and 2. Calibration is usually accomplished in less than 3

iterations. Apply minimum and maximum input signals and measure response. Response between

the minimum and maximum values will be linear, therefore software algorithms are easy to derive.

The feedback signal range on all selections is 0 to 5 VDC and is proportional to the output pressure range

selected. The output and feedback signal will continue to vary proportionally if the input signal is

increased beyond its upper limit (if there is enough main air available).

The EPC2GB and EPC2GFSB incorporate two valves and is not a constant bleed controller. Its branch

exhaust ow and response time is not limited by any internal restrictor and is similar to its load rate. The

4.30in

109.22mm

4.44in

112.78mm

3.34in

84.90mm

EPC2GB and EPC2GFSB is ideal for long branch line runs, multiple actuators, and outside air dampers

because of it’s 750 scim capacity.

Note: If power to the EPC2GB is lost, the branch line control valve will close and it will maintain branch line

pressure (assuming no branch line leaks).

If power to the EPC2GFSB (Fail-Safe) is lost, the branch line 3-way valve will open and branch line pressure

will go to 0 psig (0 kPa)

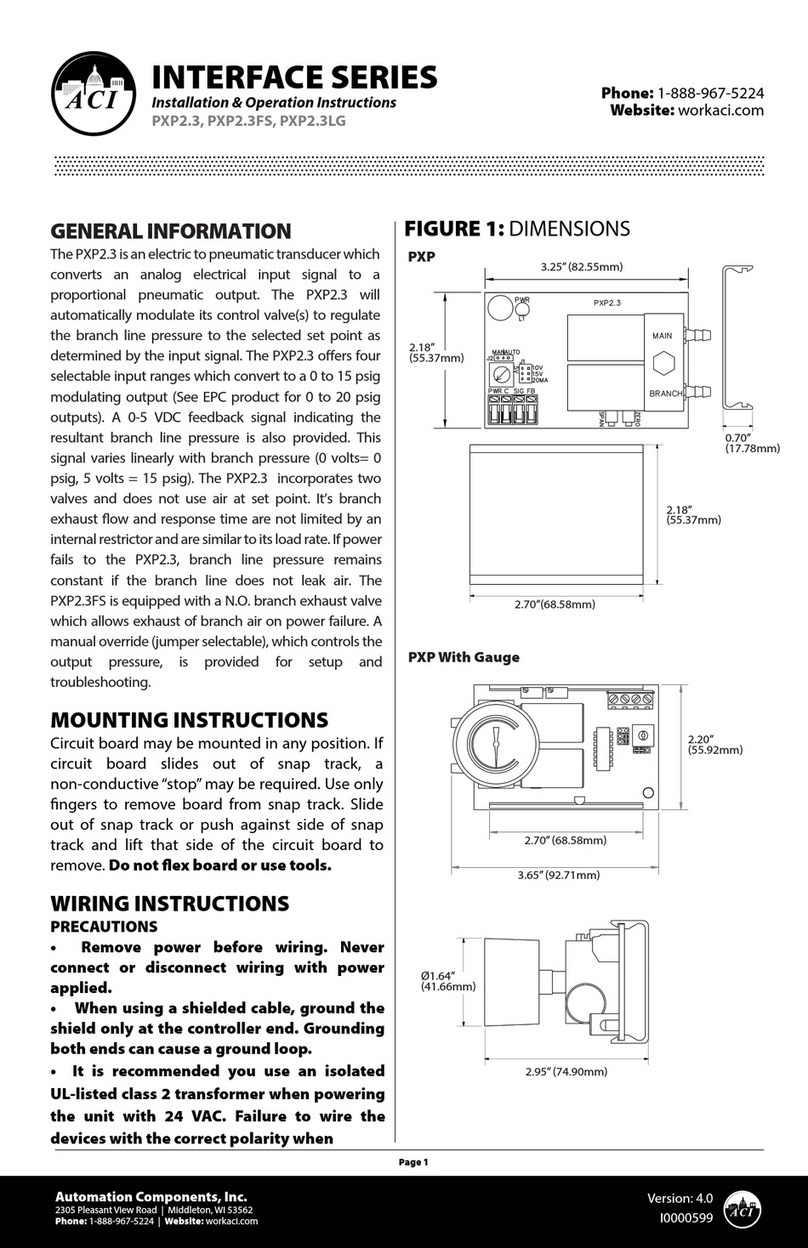

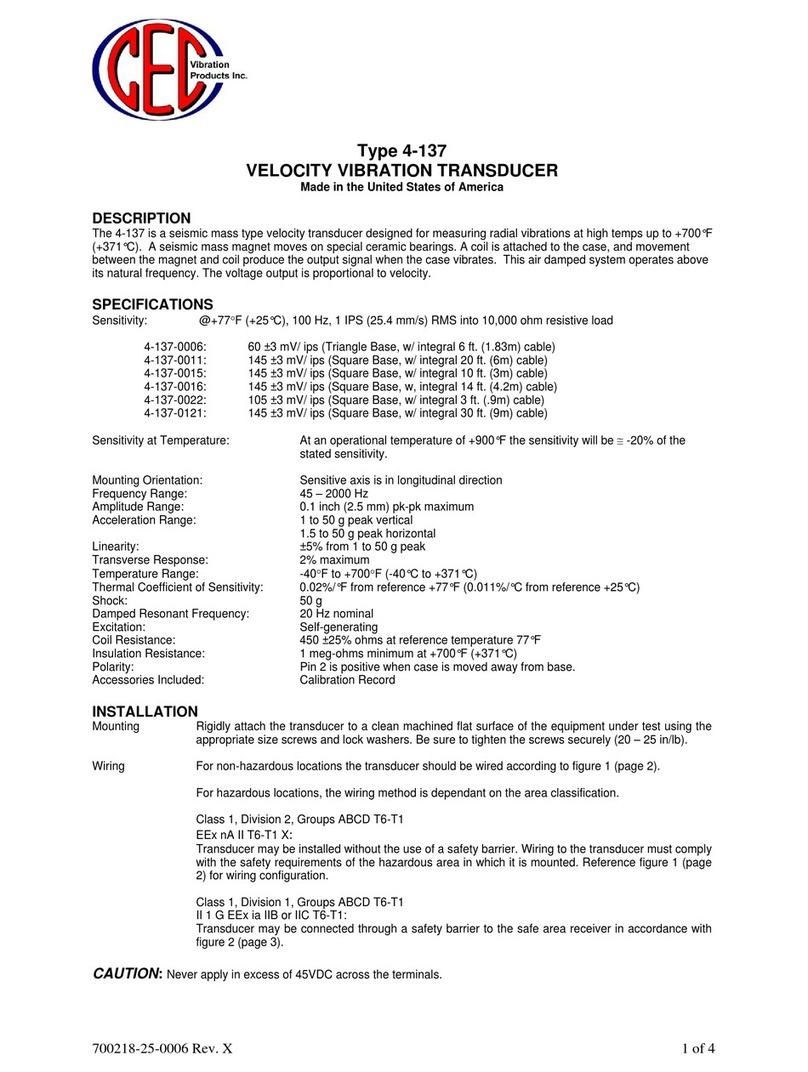

FIGURE 2: WIRING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 4.0

I0000637

GENERAL INFORMATION

The EPC2 Series are electric to pneumatic

transducers which convert an analog input signal

to a proportional pneumatic output, modulating

its control valve(s) to regulate the branch line

pressure to the set point determined by the input

signal. The EPC2 series oers four selectable input

ranges. Output pressure ranges are jumper shunt

selectable and adjustable in all ranges. A feedback

signal indicating the resultant branch line pressure

is also provided. EPC2 Series is designed with

electrical terminals on one end and pneumatic

connections on the other, allowing for maximum

convenience in wiring and tubing installation

when panel mounted.

The EPC2 incorporates two

valves (one controls exhaust), does not bleed air at set

point, and has a 750 scim supply and exhaust. Its

branch exhaust ow and response time are not limited

by an internal restrictor and are similar to its load rate.

If power fails to the EPC2, branch line pressure remains

constant if the branch line does not leak air. The

EPC2FS shares the same specications as the EPC2

except its 3-way branch valve will exhaust branch line

air upon power failure.

MOUNTING INSTRUCTIONS

The EPC2 has 4 mounting holes, 2 located on the

bottom ange, and 2 on the top ange. Drill pilot

holes for the Mounting Screws(not supplied). Use

the enclosure ange as a guide. Mount the unit

vertically with the brass ttings pointing towards the ground. This ensures that any condensation that may

form in the tubing does not have an eect on the pressure sensor. If mounting the unit horizontally, care

must be taken to prevent moisture from building up in the sensor.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both ends

can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of the DC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

J2

A

B

C

J1

10V

20MA

15V

5V

AUTO

L1

PWR

OFFSET

SPAN

OV OVPWR FBSIGC

0-10 PSI

0-15 PSI

0-20 PSI

MANUAL

0% 100%

MANUAL

MB

Analog (Current or Voltage)

to

Modulated Pressure

24 VDC/VAC

Power Supply

(+)

(-)

Analog Input

Signal

(+)

(-)

Branch Pressure

Feedback Signal

Override Feedback

(Dry Contact)

Manual Override Pot and

Manual/Auto Switch

Blue manifold

on FS models

Offset Pot - Set for minimum desired

pressure with minimum input signal

Span Pot - Set for maximum desired

pressure with maximum input signal

Zero Pot is Factory Set - Do not adjust

ADJUSTMENT OF GAUGES

If installation requires adjustment of the gauge for proper reading of the face, turn the gauge no more than

½ turn in either direction. O-rings in the bottom of the gauge port will allow this without leakage.

Warranty does not include malfunction due to clogged valve. Main air port on EPC is ltered with the

supplied 80 – 100 micron integral-in-barb lter (Part # PN004). A 5 micron external in-line lter (Part #

PN021) is supplied with the EPC2LG. Periodically check the lter for contamination and ow reduction.

Replace if needed.

The surface between the manifold and pressure transducer is a pressure seal. Minimize stress between the

circuit board and the manifold by holding the manifold in one hand while installing pneumatic tubing

onto the ttings, and use care when removing tubing to avoid damaging ttings or moving manifold.

For optimum performance and reduced noise, the EPC2FS unit requires a branch air line capacity equal to

at least 25 feet of ¼”O.D. polyethylene tubing to operate without oscillation, and the EPC2 and EPC2LG unit

require a branch air line capacity equal to at least 15 feet of ¼”O.D. polyethylene tubing to operate without

oscillation.

CHECKOUT

With power o, select one of the four input signal combinations by moving the jumper shunt J1 identied

as “Input Signal Range Selector”. Select a preset pressure output range by moving jumper shunt J2

identied as “Pressure Output Range Selector”, or set custom range as described below.

SETTING CUSTOM OUTPUT PRESSURE RANGE

Verify the MAN/AUTO switch is in the AUTO position. In AUTO, the manual override pot is inactive, the

override contacts are open, and the analog input signal is supplying the set-point. The oset pot may be

adjusted to any desired oset between 0 and 14 psig. When in the MANUAL position, the override contacts

are closed, the oset pot is inactive and the manual override pot is supplying the set point (the analog

input signal is locked out). Supply power and the LED power indicator will light, but only measurement will

verify proper voltage.

1. Setting the minimum pressure. Make sure the signal connections are made and input is at

minimum. Place the manual override switch to the AUTO position. Adjust the OFFSET pot to the

desired pressure output, or until the actuator just starts to move. The adjustment range of the OFFSET

pot is 0 to 9 psig (62.05 kPa), 0 to 14 psig (96.53 kPa), or 0 to 19 psig (131 kPa) depending on the range

selected. Zero pot is factory set – DO NOT ADJUST.

2. Setting the maximum pressure. Now place the manual override switch to the MANUAL position.

Turn the MANUAL pot to produce the maximum branch line pressure available. Turn the SPAN pot for

the maximum desired output pressure, or until the actuator just stops. Be sure the MAIN air pressure

is at least 2 psig greater than the desired maximum branch output pressure.

3. Repeat. Because the OFFSET and SPAN pots are slightly interactive, steps 1 and 2 must be repeated

until the desired minimum and maximum pressures are repeatable. Since the MANUAL pot is set for

maximum pressure, it is only required that you switch the manual override switch back and forth from

MANUAL to AUTO when repeating steps 1 and 2. Calibration is usually accomplished in less than 3

iterations. Apply minimum and maximum input signals and measure response. Response between

the minimum and maximum values will be linear, therefore software algorithms are easy to derive.

The feedback signal range on all selections is 0 to 5 VDC and is proportional to the output pressure range

selected. The output and feedback signal will continue to vary proportionally if the input signal is

increased beyond its upper limit (if there is enough main air available).

The EPC2GB and EPC2GFSB incorporate two valves and is not a constant bleed controller. Its branch

exhaust ow and response time is not limited by any internal restrictor and is similar to its load rate. The

Main Air Supply

Branch Line Output

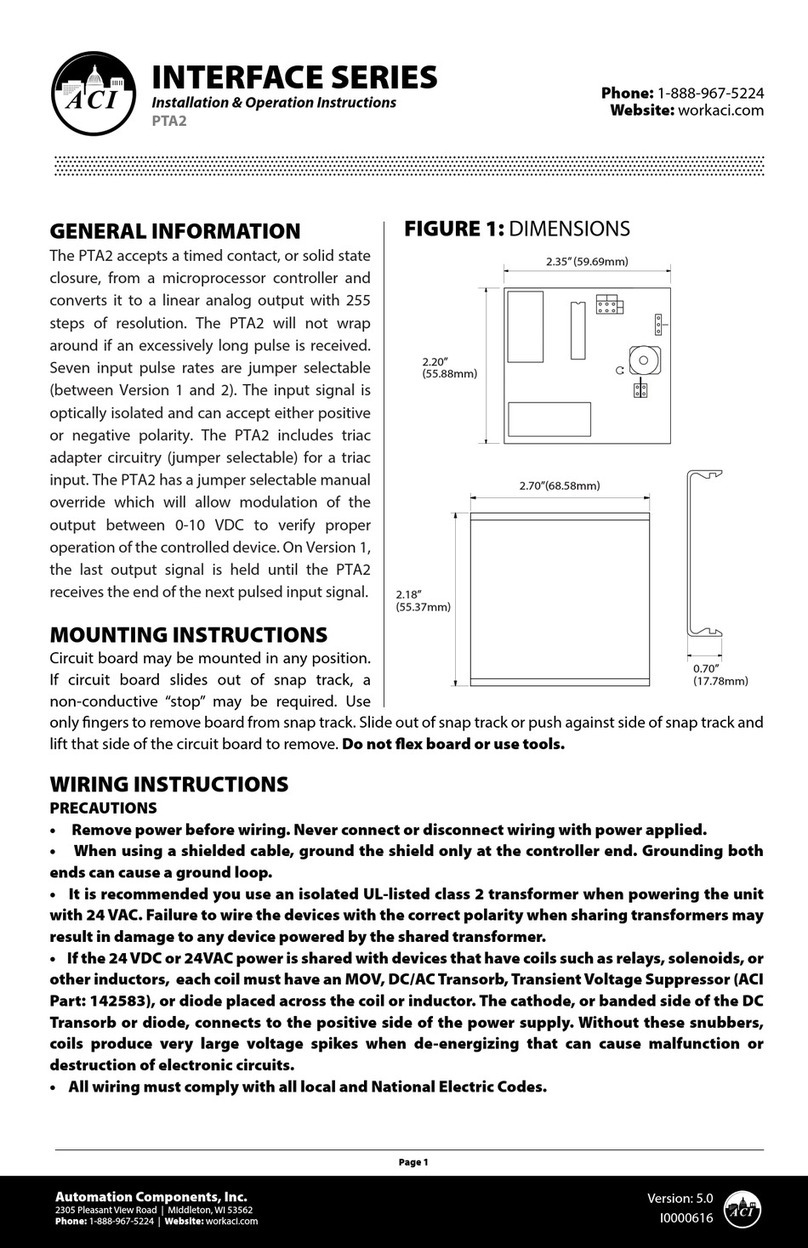

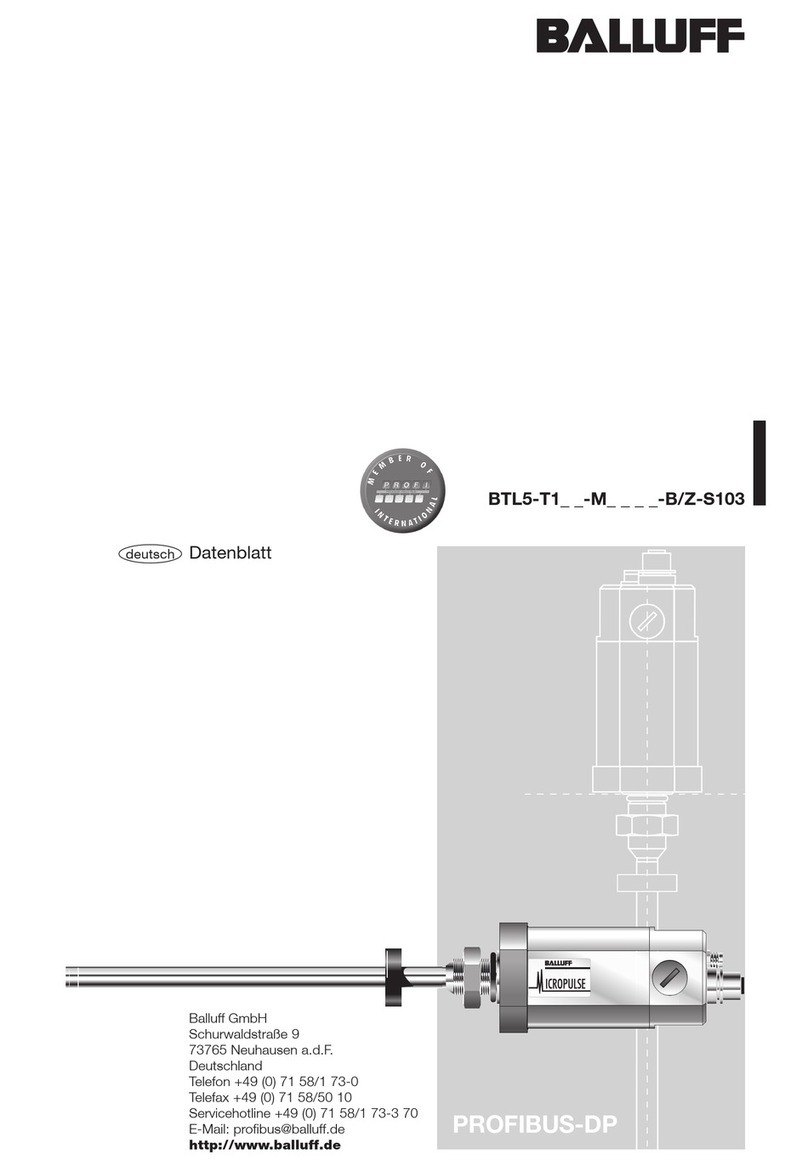

FIGURE 3: PNEUMATIC

TUBING INSTALLATION

A

B

C

J2

0-10 psi

A

B

C

J2

0-15 psi

A

B

C

J2

0-20 psi

10V

15V

J1

5V

20mA

0-5 VDC

10V

15V

J1

5V

20mA

0-10 VDC

10V

15V

J1

5V

20mA

0-15 VDC

10V

15V

J1

5V

20mA

0-20mA

Pressure Output Range Selector Signal Input Range Selector

MAIN

BRANCH

REGULATOR

AIR

COMPRESSOR

DAMPER

Min Tubing Length:

EPC2:15ft (4.572m)

EPC2FS: 25ft (7.62m)

EPC2GB and EPC2GFSB is ideal for long branch line runs, multiple actuators, and outside air dampers

because of it’s 750 scim capacity.

Note: If power to the EPC2GB is lost, the branch line control valve will close and it will maintain branch line

pressure (assuming no branch line leaks).

If power to the EPC2GFSB (Fail-Safe) is lost, the branch line 3-way valve will open and branch line pressure

will go to 0 psig (0 kPa)

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 4.0

I0000637

GENERAL INFORMATION

The EPC2 Series are electric to pneumatic

transducers which convert an analog input signal

to a proportional pneumatic output, modulating

its control valve(s) to regulate the branch line

pressure to the set point determined by the input

signal. The EPC2 series oers four selectable input

ranges. Output pressure ranges are jumper shunt

selectable and adjustable in all ranges. A feedback

signal indicating the resultant branch line pressure

is also provided. EPC2 Series is designed with

electrical terminals on one end and pneumatic

connections on the other, allowing for maximum

convenience in wiring and tubing installation

when panel mounted.

The EPC2 incorporates two

valves (one controls exhaust), does not bleed air at set

point, and has a 750 scim supply and exhaust. Its

branch exhaust ow and response time are not limited

by an internal restrictor and are similar to its load rate.

If power fails to the EPC2, branch line pressure remains

constant if the branch line does not leak air. The

EPC2FS shares the same specications as the EPC2

except its 3-way branch valve will exhaust branch line

air upon power failure.

MOUNTING INSTRUCTIONS

The EPC2 has 4 mounting holes, 2 located on the

bottom ange, and 2 on the top ange. Drill pilot

holes for the Mounting Screws(not supplied). Use

the enclosure ange as a guide. Mount the unit

vertically with the brass ttings pointing towards the ground. This ensures that any condensation that may

form in the tubing does not have an eect on the pressure sensor. If mounting the unit horizontally, care

must be taken to prevent moisture from building up in the sensor.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both ends

can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of the DC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

ADJUSTMENT OF GAUGES

If installation requires adjustment of the gauge for proper reading of the face, turn the gauge no more than

½ turn in either direction. O-rings in the bottom of the gauge port will allow this without leakage.

Warranty does not include malfunction due to clogged valve. Main air port on EPC is ltered with the

supplied 80 – 100 micron integral-in-barb lter (Part # PN004). A 5 micron external in-line lter (Part #

PN021) is supplied with the EPC2LG. Periodically check the lter for contamination and ow reduction.

Replace if needed.

The surface between the manifold and pressure transducer is a pressure seal. Minimize stress between the

circuit board and the manifold by holding the manifold in one hand while installing pneumatic tubing

onto the ttings, and use care when removing tubing to avoid damaging ttings or moving manifold.

For optimum performance and reduced noise, the EPC2FS unit requires a branch air line capacity equal to

at least 25 feet of ¼”O.D. polyethylene tubing to operate without oscillation, and the EPC2 and EPC2LG unit

require a branch air line capacity equal to at least 15 feet of ¼”O.D. polyethylene tubing to operate without

oscillation.

CHECKOUT

With power o, select one of the four input signal combinations by moving the jumper shunt J1 identied

as “Input Signal Range Selector”. Select a preset pressure output range by moving jumper shunt J2

identied as “Pressure Output Range Selector”, or set custom range as described below.

SETTING CUSTOM OUTPUT PRESSURE RANGE

Verify the MAN/AUTO switch is in the AUTO position. In AUTO, the manual override pot is inactive, the

override contacts are open, and the analog input signal is supplying the set-point. The oset pot may be

adjusted to any desired oset between 0 and 14 psig. When in the MANUAL position, the override contacts

are closed, the oset pot is inactive and the manual override pot is supplying the set point (the analog

input signal is locked out). Supply power and the LED power indicator will light, but only measurement will

verify proper voltage.

1. Setting the minimum pressure. Make sure the signal connections are made and input is at

minimum. Place the manual override switch to the AUTO position. Adjust the OFFSET pot to the

desired pressure output, or until the actuator just starts to move. The adjustment range of the OFFSET

pot is 0 to 9 psig (62.05 kPa), 0 to 14 psig (96.53 kPa), or 0 to 19 psig (131 kPa) depending on the range

selected. Zero pot is factory set – DO NOT ADJUST.

2. Setting the maximum pressure. Now place the manual override switch to the MANUAL position.

Turn the MANUAL pot to produce the maximum branch line pressure available. Turn the SPAN pot for

the maximum desired output pressure, or until the actuator just stops. Be sure the MAIN air pressure

is at least 2 psig greater than the desired maximum branch output pressure.

3. Repeat. Because the OFFSET and SPAN pots are slightly interactive, steps 1 and 2 must be repeated

until the desired minimum and maximum pressures are repeatable. Since the MANUAL pot is set for

maximum pressure, it is only required that you switch the manual override switch back and forth from

MANUAL to AUTO when repeating steps 1 and 2. Calibration is usually accomplished in less than 3

iterations. Apply minimum and maximum input signals and measure response. Response between

the minimum and maximum values will be linear, therefore software algorithms are easy to derive.

The feedback signal range on all selections is 0 to 5 VDC and is proportional to the output pressure range

selected. The output and feedback signal will continue to vary proportionally if the input signal is

increased beyond its upper limit (if there is enough main air available).

The EPC2GB and EPC2GFSB incorporate two valves and is not a constant bleed controller. Its branch

exhaust ow and response time is not limited by any internal restrictor and is similar to its load rate. The

EPC2GB and EPC2GFSB is ideal for long branch line runs, multiple actuators, and outside air dampers

because of it’s 750 scim capacity.

Note: If power to the EPC2GB is lost, the branch line control valve will close and it will maintain branch line

pressure (assuming no branch line leaks).

If power to the EPC2GFSB (Fail-Safe) is lost, the branch line 3-way valve will open and branch line pressure

will go to 0 psig (0 kPa)

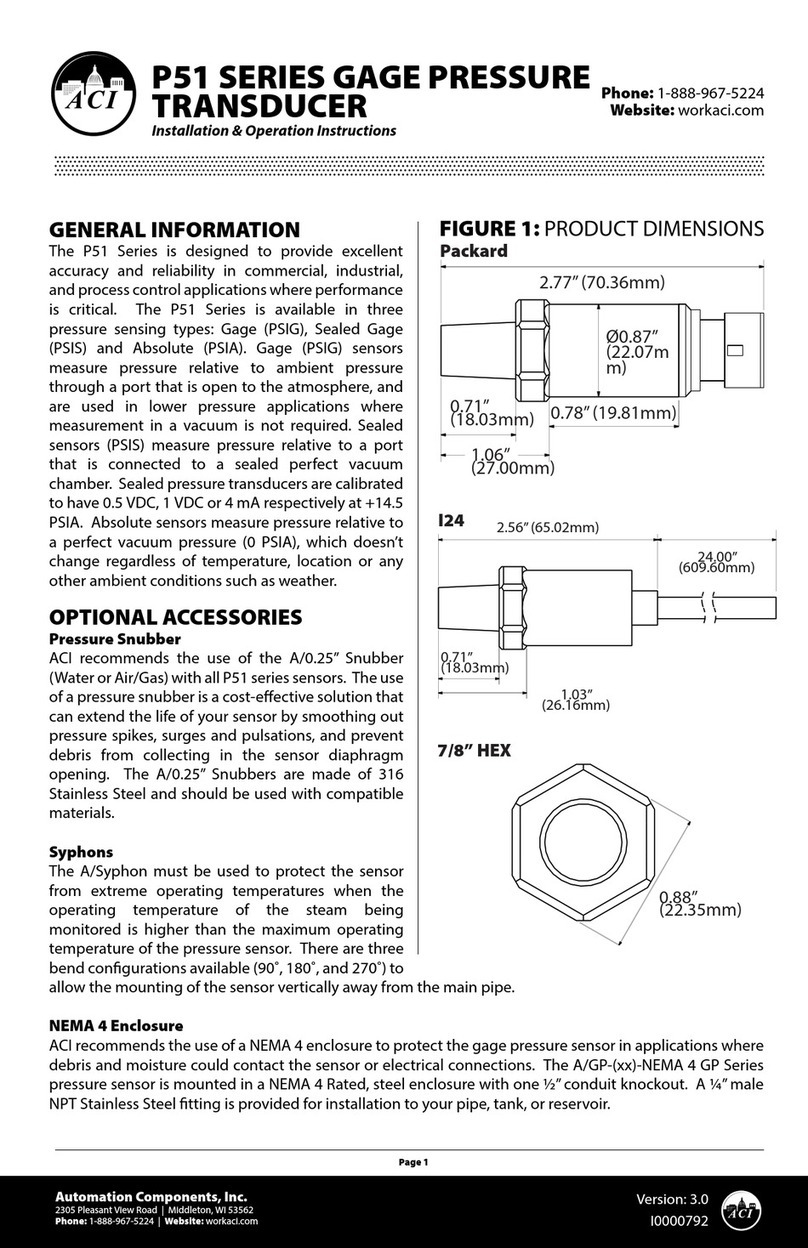

PRODUCT SPECIFICATIONS

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 4.0

I0000637

GENERAL INFORMATION

The EPC2 Series are electric to pneumatic

transducers which convert an analog input signal

to a proportional pneumatic output, modulating

its control valve(s) to regulate the branch line

pressure to the set point determined by the input

signal. The EPC2 series oers four selectable input

ranges. Output pressure ranges are jumper shunt

selectable and adjustable in all ranges. A feedback

signal indicating the resultant branch line pressure

is also provided. EPC2 Series is designed with

electrical terminals on one end and pneumatic

connections on the other, allowing for maximum

convenience in wiring and tubing installation

when panel mounted.

The EPC2 incorporates two

valves (one controls exhaust), does not bleed air at set

point, and has a 750 scim supply and exhaust. Its

branch exhaust ow and response time are not limited

by an internal restrictor and are similar to its load rate.

If power fails to the EPC2, branch line pressure remains

constant if the branch line does not leak air. The

EPC2FS shares the same specications as the EPC2

except its 3-way branch valve will exhaust branch line

air upon power failure.

MOUNTING INSTRUCTIONS

The EPC2 has 4 mounting holes, 2 located on the

bottom ange, and 2 on the top ange. Drill pilot

holes for the Mounting Screws(not supplied). Use

the enclosure ange as a guide. Mount the unit

vertically with the brass ttings pointing towards the ground. This ensures that any condensation that may

form in the tubing does not have an eect on the pressure sensor. If mounting the unit horizontally, care

must be taken to prevent moisture from building up in the sensor.

WIRING INSTRUCTIONS

PRECAUTIONS

• Remove power before wiring. Never connect or disconnect wiring with power applied.

• When using a shielded cable, ground the shield only at the controller end. Grounding both ends

can cause a ground loop.

• It is recommended you use an isolated UL-listed class 2 transformer when powering the unit

with 24 VAC. Failure to wire the devices with the correct polarity when sharing transformers may

result in damage to any device powered by the shared transformer.

• If the 24 VDC or 24VAC power is shared with devices that have coils such as relays, solenoids, or

other inductors, each coil must have an MOV, DC/AC Transorb, Transient Voltage Suppressor (ACI

Part: 142583), or diode placed across the coil or inductor. The cathode, or banded side of the DC

Transorb or diode, connects to the positive side of the power supply. Without these snubbers,

coils produce very large voltage spikes when de-energizing that can cause malfunction or

destruction of electronic circuits.

• All wiring must comply with all local and National Electric Codes.

WARRANTY

The EPC Series is covered by ACI’s Two (2) Year Limited Warranty, which is located in the front of ACI’S SENSORS &

TRANSMITTERS CATALOG or can be found on ACI’s website: www.workaci.com.

24 VAC (+/-10%), 50 or 60Hz, 24 VDC (+10%/- 5%)

180 mA maximum, 200 mA on fail safe models

0-5 VDC @ innite | 0-10 VDC @ innite | 0-15 VDC @ innite | 0-20 mA

/ 250

0-5 VDC = Output Span

Field Calibration Possible: 0 to 20 psig (0-138 kPa) maximum

0-10 psig (0-68.95 kPa), 0-15 psig (0-103.43 kPa) or 0-20 psig (137.9 kPa)

Maximum 28 psig (193.06 kPa), minimum 22 psig (151.69 kPa)

41 SCIM (0.6419 Liters)

MAN function = output can be varied | AUTO function = output is controlled

from input signal

Dry Contacts: 24 VDC/VAC @ 1A maximum, N.O. in AUTO operation (Optional: N.O.

in MAN operation)

Supply valves @ 25 psig (172.38 kPa) main/20 psig (137.9 kPa) out, 750 scim

Branch Line requires 2 in / 33.78 cm (min.) | Min. 25 ft of 1/4” O.D. poly

branch tubing

Furnished with integral-in-barb 80-100 micron lter (Part # PN004)

90° Pluggable Screw Terminal Blocks | 16 (1.31 mm) to 26 AWG (0.129 mm)

0.5 Nm (Minimum); 0.6 Nm (Maximum)

1/4" O.D. nominal (1/8” I.D.) polyethylene

Removeable brass ttings for Main & Branch in machined manifold, Plugged

1/8-27-FNPT gauge port

35 to 120°F (1.7 to 48.9°C)

10 to 95% non-condensing

-20 to 150°F (-28.9 to 65.5°C)

NON-SPECIFIC INFORMATION

Supply Voltage:

Supply Current:

Input Signal Source (@

Impedance):

Feedback Signal Output Range:

Output Pressure Range:

Output Pressure Range-Jumper

Selectable:

Air Supply Pressure:

Air Consumption:

Manual / Auto Override Switch:

Manual / Auto Override

Feedback Output:

Air Flow:

Filtering:

Connections | Wire Size:

Terminal Block Torque Rating:

Connections | Pneumatic

Tubing Size-Type:

Pneumatic Fitting:

Operating Temperature Range:

Operating Humidity Range:

Storage Temperature:

ADJUSTMENT OF GAUGES

If installation requires adjustment of the gauge for proper reading of the face, turn the gauge no more than

½ turn in either direction. O-rings in the bottom of the gauge port will allow this without leakage.

Warranty does not include malfunction due to clogged valve. Main air port on EPC is ltered with the

supplied 80 – 100 micron integral-in-barb lter (Part # PN004). A 5 micron external in-line lter (Part #

PN021) is supplied with the EPC2LG. Periodically check the lter for contamination and ow reduction.

Replace if needed.

The surface between the manifold and pressure transducer is a pressure seal. Minimize stress between the

circuit board and the manifold by holding the manifold in one hand while installing pneumatic tubing

onto the ttings, and use care when removing tubing to avoid damaging ttings or moving manifold.

For optimum performance and reduced noise, the EPC2FS unit requires a branch air line capacity equal to

at least 25 feet of ¼”O.D. polyethylene tubing to operate without oscillation, and the EPC2 and EPC2LG unit

require a branch air line capacity equal to at least 15 feet of ¼”O.D. polyethylene tubing to operate without

oscillation.

CHECKOUT

With power o, select one of the four input signal combinations by moving the jumper shunt J1 identied

as “Input Signal Range Selector”. Select a preset pressure output range by moving jumper shunt J2

identied as “Pressure Output Range Selector”, or set custom range as described below.

SETTING CUSTOM OUTPUT PRESSURE RANGE

Verify the MAN/AUTO switch is in the AUTO position. In AUTO, the manual override pot is inactive, the

override contacts are open, and the analog input signal is supplying the set-point. The oset pot may be

adjusted to any desired oset between 0 and 14 psig. When in the MANUAL position, the override contacts

are closed, the oset pot is inactive and the manual override pot is supplying the set point (the analog

input signal is locked out). Supply power and the LED power indicator will light, but only measurement will

verify proper voltage.

1. Setting the minimum pressure. Make sure the signal connections are made and input is at

minimum. Place the manual override switch to the AUTO position. Adjust the OFFSET pot to the

desired pressure output, or until the actuator just starts to move. The adjustment range of the OFFSET

pot is 0 to 9 psig (62.05 kPa), 0 to 14 psig (96.53 kPa), or 0 to 19 psig (131 kPa) depending on the range

selected. Zero pot is factory set – DO NOT ADJUST.

2. Setting the maximum pressure. Now place the manual override switch to the MANUAL position.

Turn the MANUAL pot to produce the maximum branch line pressure available. Turn the SPAN pot for

the maximum desired output pressure, or until the actuator just stops. Be sure the MAIN air pressure

is at least 2 psig greater than the desired maximum branch output pressure.

3. Repeat. Because the OFFSET and SPAN pots are slightly interactive, steps 1 and 2 must be repeated

until the desired minimum and maximum pressures are repeatable. Since the MANUAL pot is set for

maximum pressure, it is only required that you switch the manual override switch back and forth from

MANUAL to AUTO when repeating steps 1 and 2. Calibration is usually accomplished in less than 3

iterations. Apply minimum and maximum input signals and measure response. Response between

the minimum and maximum values will be linear, therefore software algorithms are easy to derive.

The feedback signal range on all selections is 0 to 5 VDC and is proportional to the output pressure range

selected. The output and feedback signal will continue to vary proportionally if the input signal is

increased beyond its upper limit (if there is enough main air available).

The EPC2GB and EPC2GFSB incorporate two valves and is not a constant bleed controller. Its branch

exhaust ow and response time is not limited by any internal restrictor and is similar to its load rate. The

EPC2GB and EPC2GFSB is ideal for long branch line runs, multiple actuators, and outside air dampers

because of it’s 750 scim capacity.

Note: If power to the EPC2GB is lost, the branch line control valve will close and it will maintain branch line

pressure (assuming no branch line leaks).

If power to the EPC2GFSB (Fail-Safe) is lost, the branch line 3-way valve will open and branch line pressure

will go to 0 psig (0 kPa)

Other manuals for ACCESS series

16

This manual suits for next models

5

Other aci Transducer manuals

Popular Transducer manuals by other brands

Balluff

Balluff BTL5-T1 Series datasheet

HBM

HBM U2B Mounting instructions

HBM

HBM U93 operating instructions

Mianyang Weibo Electronic

Mianyang Weibo Electronic WBV417U01 user manual

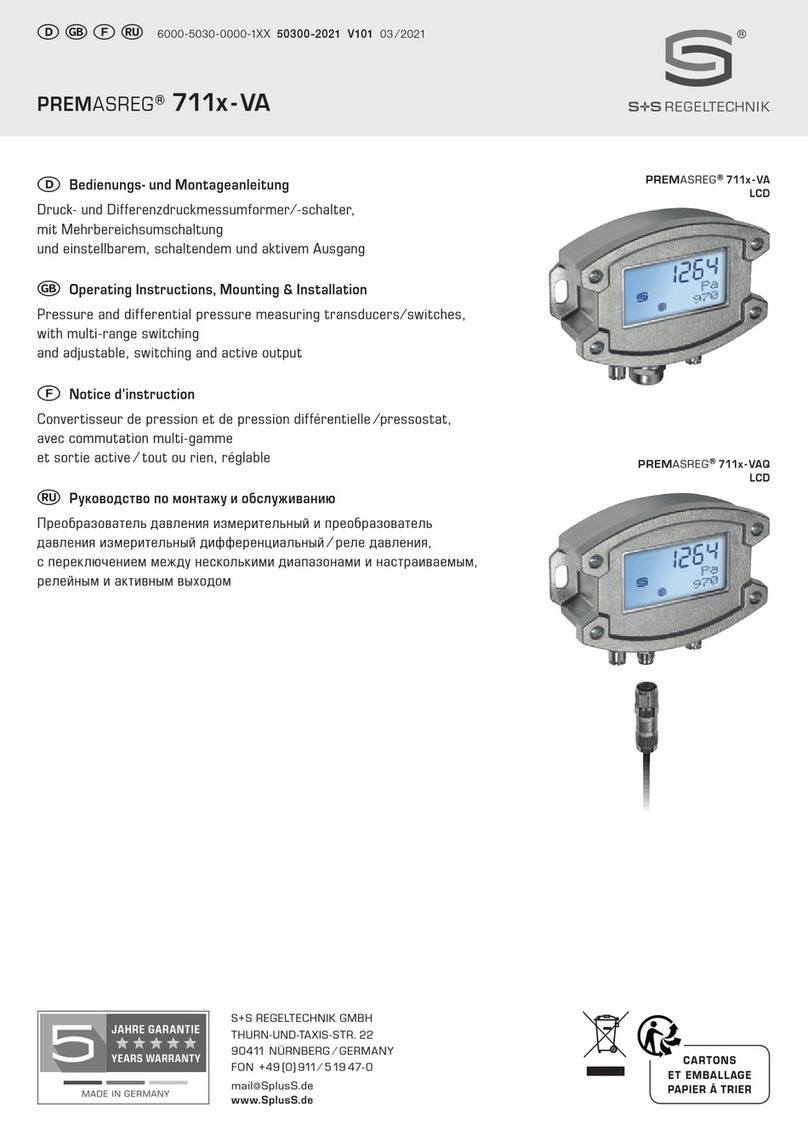

S+S Regeltechnik

S+S Regeltechnik THERMASGARD TM54 Series Operating Instructions, Mounting & Installation

S+S Regeltechnik

S+S Regeltechnik PREMASREG 711x-VA Series Operating Instructions, Mounting & Installation