aci P51 Series Installation instructions

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 1

Version: 3.0

I0000792

GENERAL INFORMATION

The P51 Series is designed to provide excellent

accuracy and reliability in commercial, industrial,

and process control applications where performance

is critical. The P51 Series is available in three

pressure sensing types: Gage (PSIG), Sealed Gage

(PSIS) and Absolute (PSIA). Gage (PSIG) sensors

measure pressure relative to ambient pressure

through a port that is open to the atmosphere, and

are used in lower pressure applications where

measurement in a vacuum is not required. Sealed

sensors (PSIS) measure pressure relative to a port

that is connected to a sealed perfect vacuum

chamber. Sealed pressure transducers are calibrated

to have 0.5 VDC, 1 VDC or 4 mA respectively at +14.5

PSIA. Absolute sensors measure pressure relative to

a perfect vacuum pressure (0 PSIA), which doesn’t

change regardless of temperature, location or any

other ambient conditions such as weather.

OPTIONAL ACCESSORIES

Pressure Snubber

ACI recommends the use of the A/0.25” Snubber

(Water or Air/Gas) with all P51 series sensors. The use

of a pressure snubber is a cost-eective solution that

can extend the life of your sensor by smoothing out

pressure spikes, surges and pulsations, and prevent

debris from collecting in the sensor diaphragm

opening. The A/0.25” Snubbers are made of 316

Stainless Steel and should be used with compatible

materials.

Syphons

The A/Syphon must be used to protect the sensor

from extreme operating temperatures when the

operating temperature of the steam being

monitored is higher than the maximum operating

temperature of the pressure sensor. There are three

bend congurations available (90˚, 180˚, and 270˚) to

allow the mounting of the sensor vertically away from the main pipe.

NEMA 4 Enclosure

ACI recommends the use of a NEMA 4 enclosure to protect the gage pressure sensor in applications where

debris and moisture could contact the sensor or electrical connections. The A/GP-(xx)-NEMA 4 GP Series

pressure sensor is mounted in a NEMA 4 Rated, steel enclosure with one ½” conduit knockout. A ¼” male

NPT Stainless Steel tting is provided for installation to your pipe, tank, or reservoir.

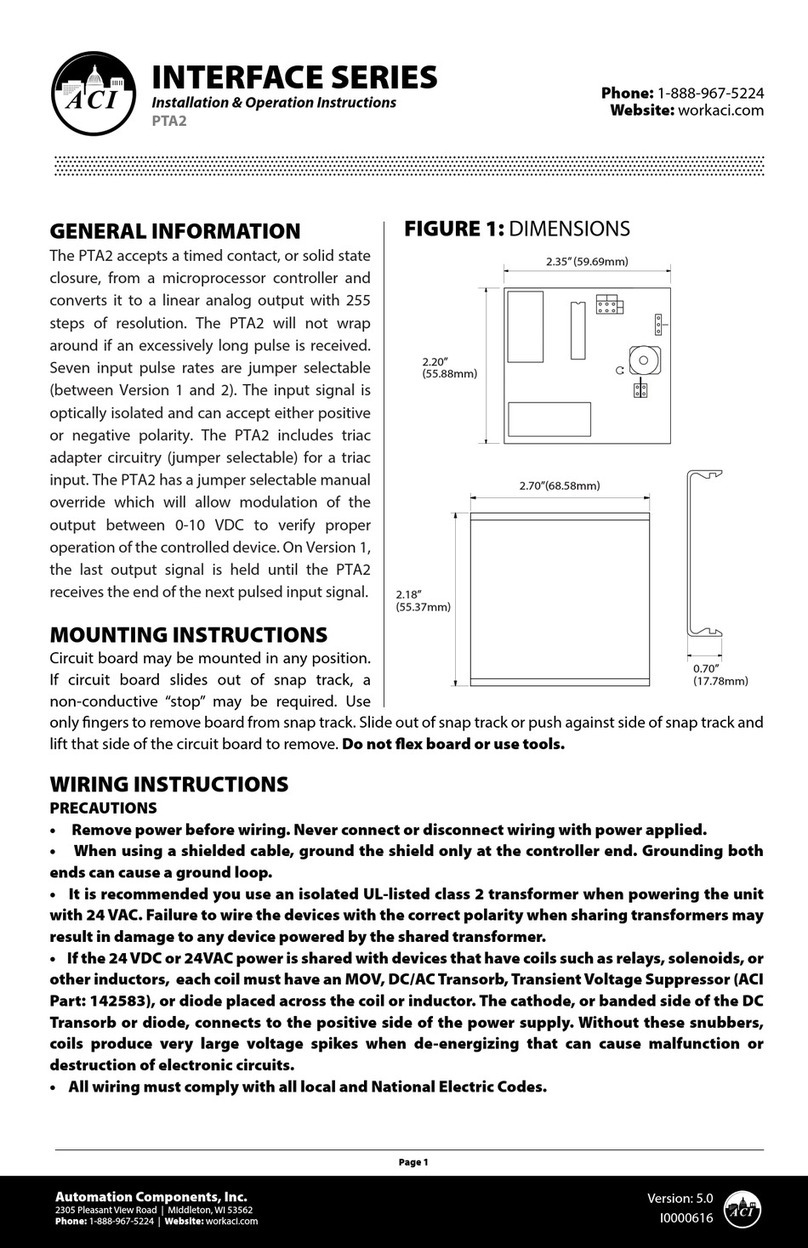

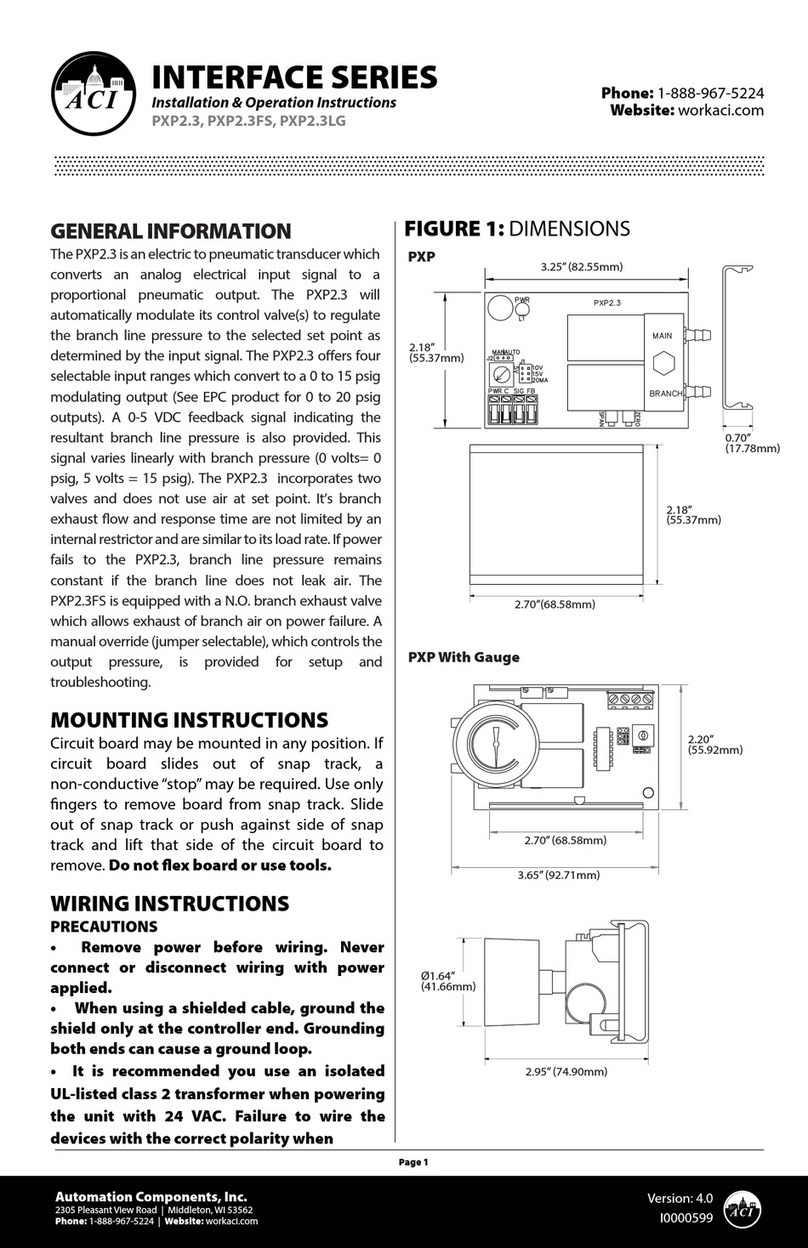

FIGURE 1: PRODUCT DIMENSIONS

P51 SERIES GAGE PRESSURE

TRANSDUCER

Installation & Operation Instructions

Phone: 1-888-967-5224

Website: workaci.com

I24

Packard

2.56” (65.02mm)

24.00”

(609.60mm)

0.71”

(18.03mm)

1.03”

(26.16mm)

2.77” (70.36mm)

Ø0.87”

(22.07m

m)

0.71”

(18.03mm)

1.06”

(27.00mm)

0.78” (19.81mm)

7/8” HEX

0.88”

(22.35mm)

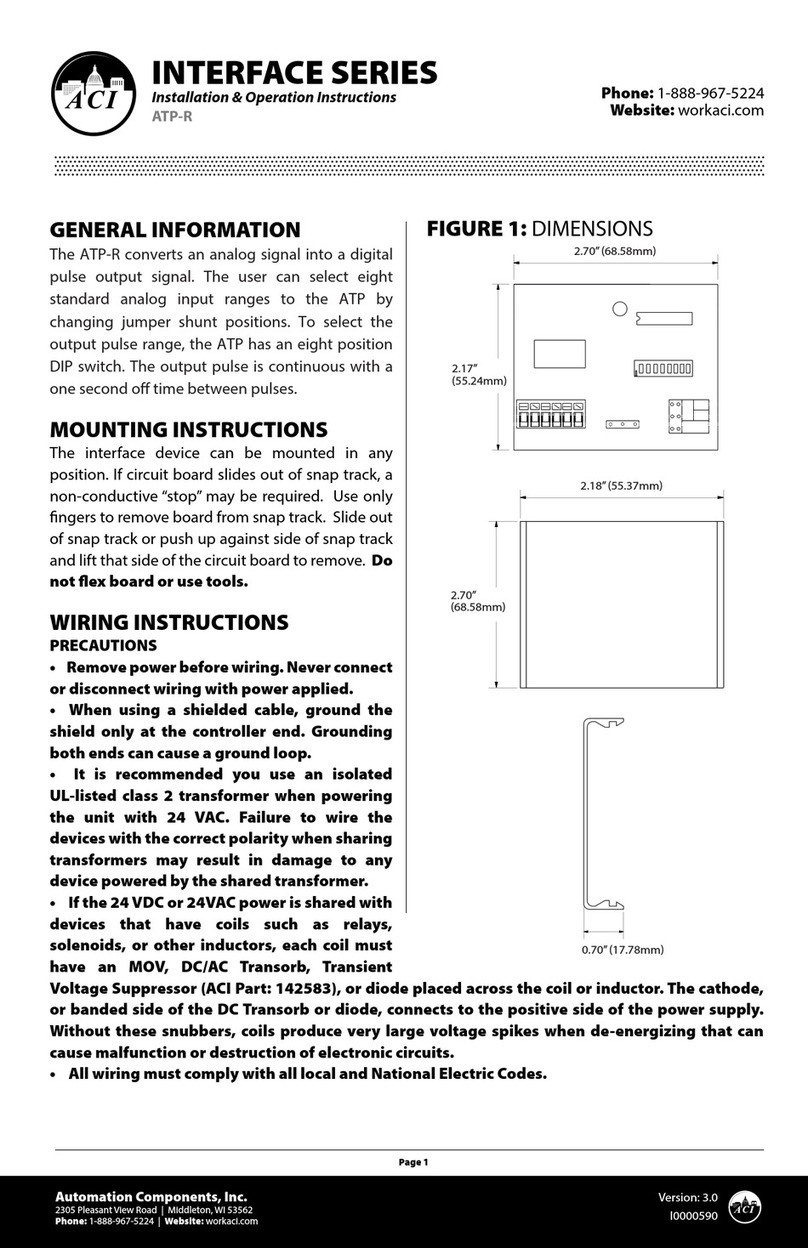

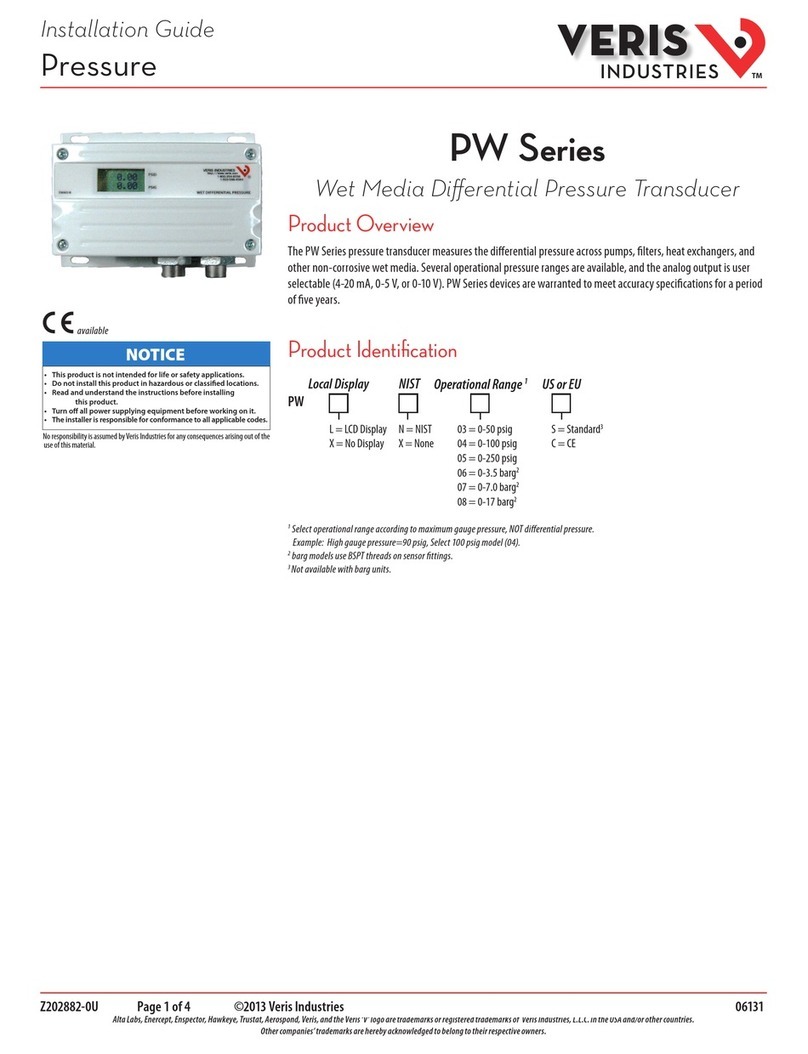

FIGURE 2: ASSEMBLY

TABLE 1: TORQUE LIMITS

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 2

Version: 3.0

I0000792

MEDIA COMPATIBILITY

The bulk micro-machined transducer features a stainless steel diaphragm with welded construction that

contains no O-rings, which makes them compatible with any gas or liquid that’s compatible with 304L or

316L stainless steel. Some compatible gasses and liquids include refrigerants, glycol, motor oil, diesel,

hydraulic uid, brake uid, water, waste water, hydrogen, nitrogen and air.

Installation

LOCATION

Install the sensor in a location where it will not be exposed to extreme temperatures, vibration or shock.

Install the pressure sensor above or on the side of pipes, in a location where liquid will not drip on the unit.

Condensation can potentially build up and run down the harness; position the unit and harness so water

does not pool on the back of the sensor. Do not install the sensor at the end of a long run of pipe.

CONNECTION

The P51 series sensor is available with multiple

external thread sizes, see the Datasheet chart

for more details. Standard pipe ttings and

installation procedures should be used during

installation. Install pipe tape, thread sealant or

other suitable pipe compound when

connecting the sensor to the pressure source or

any of the accessories. For pressure ranges

more than 500 PSI (3447.4 kPa), we recommend

the use of a sealant such as Loctite Hydraulic

Sealant. Do not use excessive amounts of

sealant or you might block the pressure going

into the transducer. Install the device using a

wrench on the hex ats provided. Do not use a

strap wrench on the body. When installing the

sensor, the torque limit will vary, see the Torque

Limits Table for more detail. Do Not over

tighten. Overtightening metal ttings may

cause a slight zero shift. The use of plastic

ttings typically results in no noticeable zero

shift. The torquing eect does not appreciably

aect linearity or sensitivity. In liquid pressure

monitoring applications, air present in the lines

will cause erratic readings, use bleed ttings to

bleed o any air that has been trapped before

transducer installation.

WIRING INSTRUCTIONS

The supply voltage and current required will

vary per unit, see the General Specications

Table for more details. If you’ve selected a Packard connector make the proper connections to the harness,

then install the P51 Sensor onto the harness.

Note: Be careful not to kink the vent tube if cutting the 24” PVC wire down or removing all together.

Kinking the clear tube will aect the reference pressure on all PSIG Series Transducers.

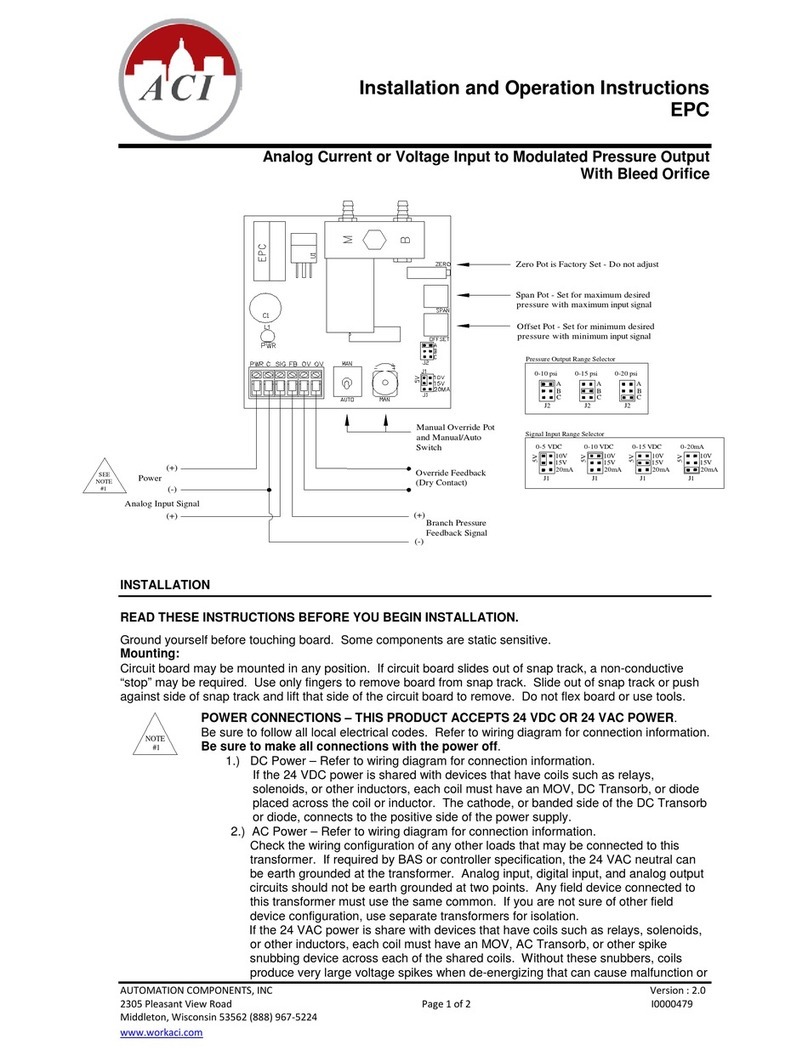

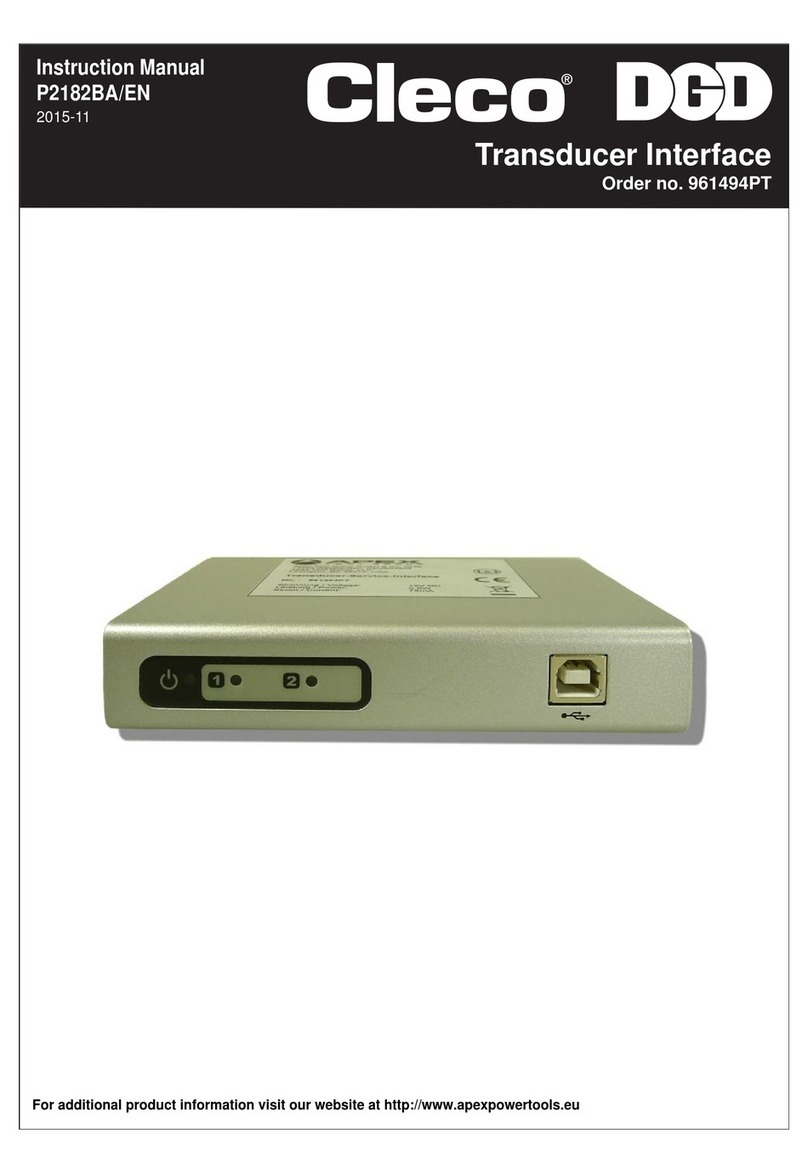

4-20 OUTPUT CONNECTIONS

Connect the Power lead (Red) to the plus terminal of the supply voltage. Connect the Return lead (White)

SHUT OFF VALVE

PRESSURE

TRANSDUCER

PRESSURE SNUBBER

(OPTIONAL)

SUPPLY LINE

Straight Thread w/O-Ring:

Recommended Torque

High Pressure >750 PSI (5171.1 kPa)

300 in lb (33.9 Nm)

All Other Ports Except Port Types U, Y

150 in lb (16.95 Nm)

Port Types U, Y

120 in lb (13.6 Nm)

WIRING INSTRUCTIONS (Continued)

to the plus terminal of the current measuring device (controller). Connect the minus terminal of the

current measuring device to the minus terminal of the supply voltage, and the Shield Wire (Green) should

be connected to the system or earth ground. See Figure 3, Current Wiring diagram.

Note: If the harness has a black wire, do not use it.

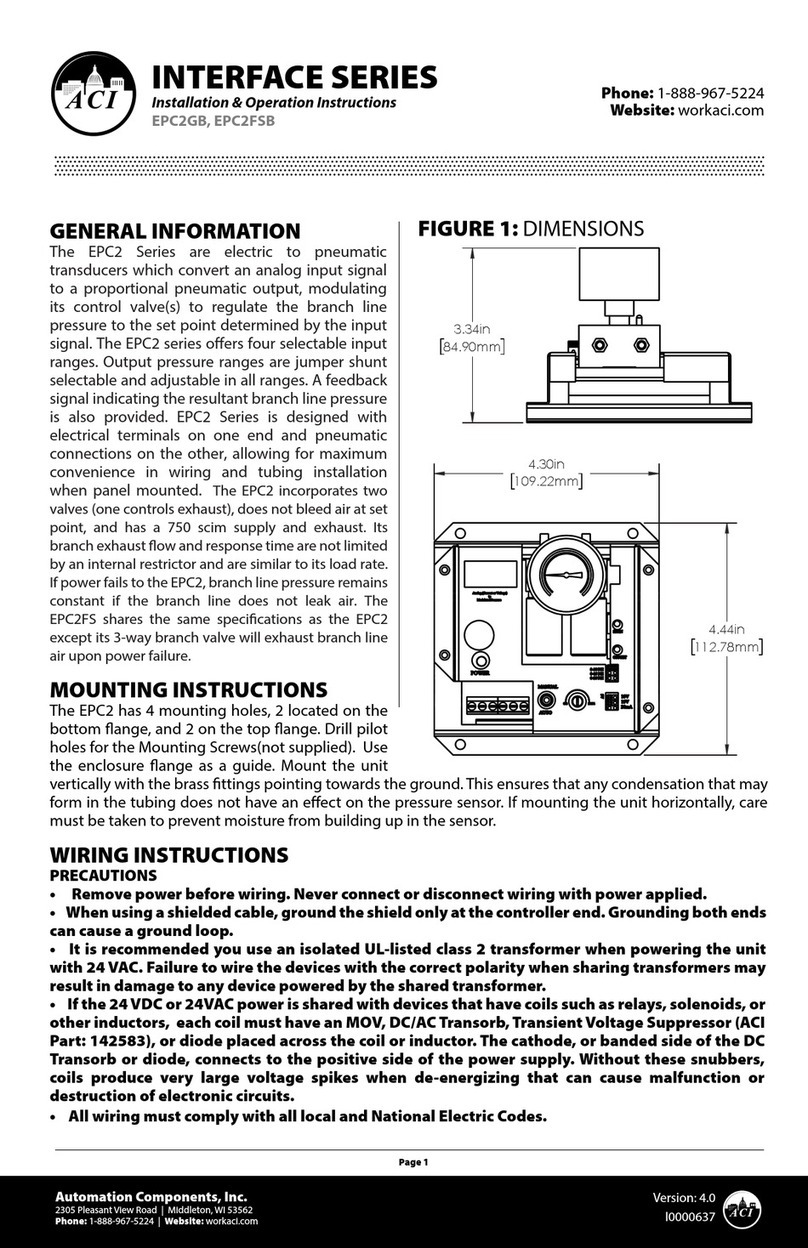

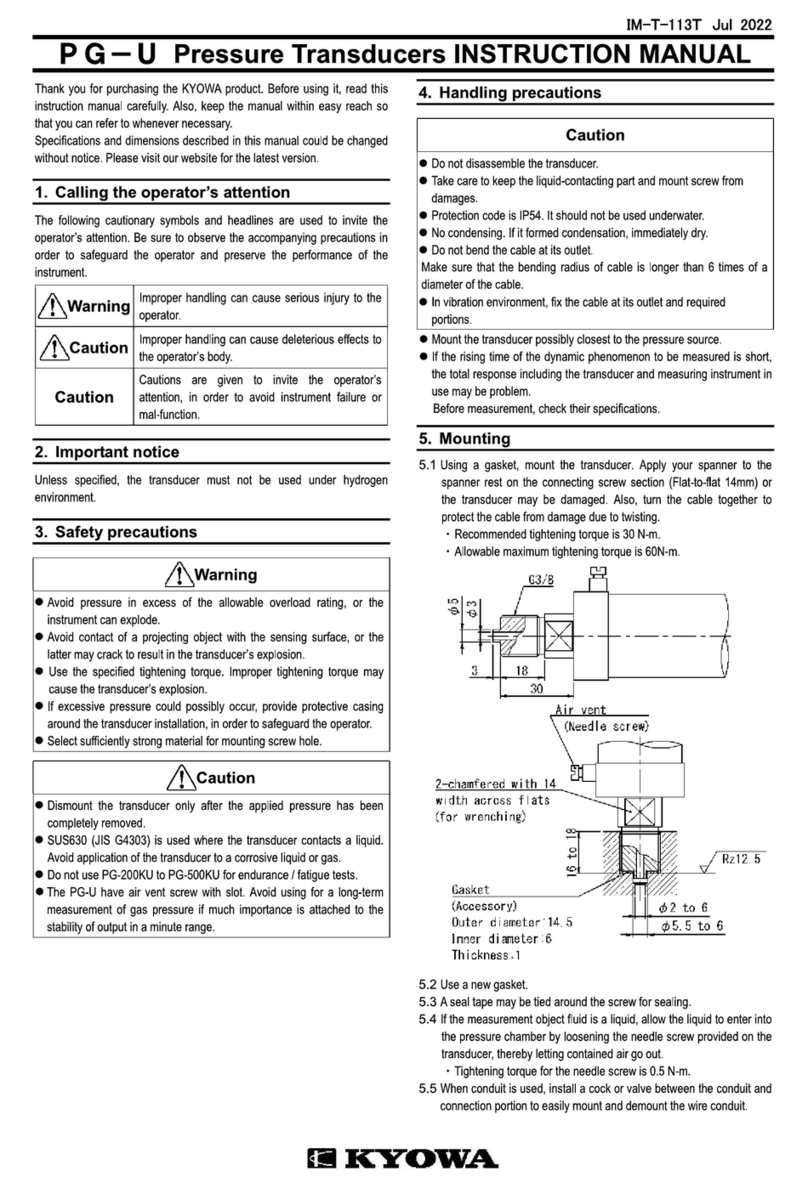

VOLTAGE OUTPUT CONNECTIONS

Connect the Power lead (Red) to the plus terminal of the supply voltage. Connect the Ground lead (Black)

and the minus terminal of the supply voltage to the minus input of your voltage measurement equipment.

Connect the Vout lead (White) to the plus input of your voltage measurement equipment, and the Shield

Wire should be connected to the system or earth ground. See Figure 4, Voltage Wiring diagram.

FIGURE 3: CURRENT WIRING

DIAGRAM

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 3

Version: 3.0

I0000792

MEDIA COMPATIBILITY

The bulk micro-machined transducer features a stainless steel diaphragm with welded construction that

contains no O-rings, which makes them compatible with any gas or liquid that’s compatible with 304L or

316L stainless steel. Some compatible gasses and liquids include refrigerants, glycol, motor oil, diesel,

hydraulic uid, brake uid, water, waste water, hydrogen, nitrogen and air.

Installation

LOCATION

Install the sensor in a location where it will not be exposed to extreme temperatures, vibration or shock.

Install the pressure sensor above or on the side of pipes, in a location where liquid will not drip on the unit.

Condensation can potentially build up and run down the harness; position the unit and harness so water

does not pool on the back of the sensor. Do not install the sensor at the end of a long run of pipe.

CONNECTION

The P51 series sensor is available with multiple

external thread sizes, see the Datasheet chart

for more details. Standard pipe ttings and

installation procedures should be used during

installation. Install pipe tape, thread sealant or

other suitable pipe compound when

connecting the sensor to the pressure source or

any of the accessories. For pressure ranges

more than 500 PSI (3447.4 kPa), we recommend

the use of a sealant such as Loctite Hydraulic

Sealant. Do not use excessive amounts of

sealant or you might block the pressure going

into the transducer. Install the device using a

wrench on the hex ats provided. Do not use a

strap wrench on the body. When installing the

sensor, the torque limit will vary, see the Torque

Limits Table for more detail. Do Not over

tighten. Overtightening metal ttings may

cause a slight zero shift. The use of plastic

ttings typically results in no noticeable zero

shift. The torquing eect does not appreciably

aect linearity or sensitivity. In liquid pressure

monitoring applications, air present in the lines

will cause erratic readings, use bleed ttings to

bleed o any air that has been trapped before

transducer installation.

WIRING INSTRUCTIONS

The supply voltage and current required will

vary per unit, see the General Specications

Table for more details. If you’ve selected a Packard connector make the proper connections to the harness,

then install the P51 Sensor onto the harness.

Note: Be careful not to kink the vent tube if cutting the 24” PVC wire down or removing all together.

Kinking the clear tube will aect the reference pressure on all PSIG Series Transducers.

4-20 OUTPUT CONNECTIONS

Connect the Power lead (Red) to the plus terminal of the supply voltage. Connect the Return lead (White)

WIRING INSTRUCTIONS (Continued)

to the plus terminal of the current measuring device (controller). Connect the minus terminal of the

current measuring device to the minus terminal of the supply voltage, and the Shield Wire (Green) should

be connected to the system or earth ground. See Figure 3, Current Wiring diagram.

Note: If the harness has a black wire, do not use it.

COM

RED WIRE

WHITE WIRE

CLEAR VENT TUBE

Clear Vent Tube on

I24 Lead Style Only Optional 250 Ohm or 500 Ohm

Load Resistor for a 1-5 VDC or

2-10 VDC Output

SHIELD

POWER SUPPLY

+13 TO 30 VDC

- +

AUTOMATION

PANEL

AI1

FIGURE 4: VOLTAGE WIRING

DIAGRAM

COM

RED WIRE

WHITE WIRE

BLACK WIRE Note: Clear Vent Tube on

I24 Lead Style Only

AI1/AI2 = VDC

Analog Input

CLEAR VENT TUBE

SHIELD

POWER SUPPLY

+5 TO 30 VDC

- +

AUTOMATION

PANEL

AI1

VOLTAGE OUTPUT CONNECTIONS

Connect the Power lead (Red) to the plus terminal of the supply voltage. Connect the Ground lead (Black)

and the minus terminal of the supply voltage to the minus input of your voltage measurement equipment.

Connect the Vout lead (White) to the plus input of your voltage measurement equipment, and the Shield

Wire should be connected to the system or earth ground. See Figure 4, Voltage Wiring diagram.

W.E.E.E. DIRECTIVE

At the end of their useful life the packaging and product should be disposed of via a suitable recycling

centre. Do not dispose of with household waste. Do not burn.

WARRANTY

The P51 Series Pressure transducers are covered by ACI's Two (2) Year Limited Warranty. The warranty can

be found in the front of ACI's Sensors & Transmitters catalog, as well as on ACI's website, www.workaci.com.

TROUBLESHOOTING

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 4

Version: 3.0

I0000792

PROBLEM

No Output or Output Signal Reading Low:

Output Signal is Inaccurate:

SOLUTION(S)

•Conrm the DC supply voltage is:

•0.5 to 4.5 VDC Output Only: 5.00 VDC +/- 0.500 VDC.

•4 to 20 mA and 1 to 5 VDC Outputs Only: +8 to 30 VDC (No

Load).

•4-20 mA Output: 250 Ohm Load: +13 to 30 VDC | 500 Ohm Load:

+18 to 30 VDC.

•Disconnect the sensor from the line to ensure No debris or sediment

is blocking the inlet port of the transducer.

•If a clear vent tube is present (I24 models only), conrm that the tube

is not kinked or has been removed.

•Determine that the proper output is being transmitted based on the

predetermined span. Measure the output of the transmitter with a

handheld multimeter and compare the measured output to calculate

output.

PRODUCT SPECIFICATIONS

0.5 to 4.5 VDC Output Only: 5.00 VDC +/- 0.500 VDC

4 to 20 mA and 1 to 5 VDC Outputs Only: +8 to 30 VDC (No Load)

4-20 mA Output: 250 Ohm Load: +13 to 30 VDC | 500 Ohm Load: +18 to

30 VDC

4 to 20 mA: 25 mA minimum | 0.5 to 4.5 VDC: < 3 mA | 1 to 5 VDC: < 5 mA

4 to 20 mA (2-Wire, Loop Powered); 0.5 to 4.5 VDC (3-Wires); 1 to 5 VDC

(3-Wires)

15 to 300 PSIG/PSIS: 3x FS | 15 to 300 PSIG/PSIS: 3x FS

15 to 3000 PSIA: 3x FS | 15 to 3000 PSIA: 10x FS or 15,000 PSI

(whichever is less)

500 to 750 PSIS: 3x FS | 500 to 750 PSIS: 3x FS

1000 to 3000 PSIS: 3x FS | 1000 to 3000 PSIS: 10x FS or 20,000 PSI

(whichever is less)

15 to 60 PSIG/PSIS: < +/- 1.0% FS; 75 to 300 PSIG/PSIS: < +/- 0.5% FS

500 to 750 PSIS:< +/- 0.5% FS; 1000 to 5000 PSIS: < +/- 1% FS

15 to 200 PSIA: < +/- 0.5% FS; 300 to 750 PSIA: < +/- 0.5% FS; 1000 to

3000 PSIA: < +/- 1% FS

15 to 60 PSIG/PSIS: < +/- 1.0% FS; 75 to 300 PSIG/PSIS: < +/- 0.5% FS

500 to 750 PSIS: < +/- 0.5% FS; 1000 to 3000 PSIS: < +/- 1% FS

15 to 200 PSIA: < +/- 0.5% FS; 300 to 750 PSIA: < +/- 0.5% FS; 1000 to

3000 PSIA: < +/- 1% FS

+/- 0.03% FS @ 0 PSIG; +/- 0.12% FS @ 1000 PSIG

-40 to 221ºF (-40 to 105ºC) | -40 to 176ºF (-40 to 80ºC)

304L or 316L Stainless Steel | See Datasheet for more details

0 to 95% RH, non-condensing

Any gas or liquid compatible with 304L or 316L Stainless Steel

All Ports except “U”and “Y”: 150 lbs-in (16.95 Nm); Ports “U” and “Y”: 120

lbs-in (13.56 Nm)

Packard Connector (Cables ordered separately per “Ordering Grid” on back

of data sheet)

“-124” (24 Lead Length): PVC Jacketed Cable 18 (0.823 mm2) or 24 AWG

(0.2047 mm2)

“-MD” Din 43650: Hirschman® Connector with 90º Mating Connector

SENSOR NON-SPECIFIC INFORMATION

Supple Voltage:

Supply Current:

Output Signal:

Proof Pressure | Burst Pressure:

Accuracy @ 22°C (71.6°F):

*Accuracy includes Hysteresis,

Repeatability, and Non-linearity (BFSL)

Thermal Error (-40° to 105°C):

*Additional error over temperature

range

Stability (250 Hours @ 225°F (125°C)):

Operating | Storage Temperature

Ranges:

Process Fitting Material | Thread Size:

Operating Humidity Range:

Media Types:

Recommended Torque Specications:

Wiring Connections:

Automation Components, Inc.

2305 Pleasant View Road | Middleton, WI 53562

Phone: 1-888-967-5224 | Website: workaci.com

Page 5

Version: 3.0

I0000792

Note 1: PSIS transducers are not vented to atmosphere, but are calibrated to have 0.5 VDC, 1 VDC or 4 mA at +14.5 PSIG

This manual suits for next models

12

Table of contents

Other aci Transducer manuals

Popular Transducer manuals by other brands

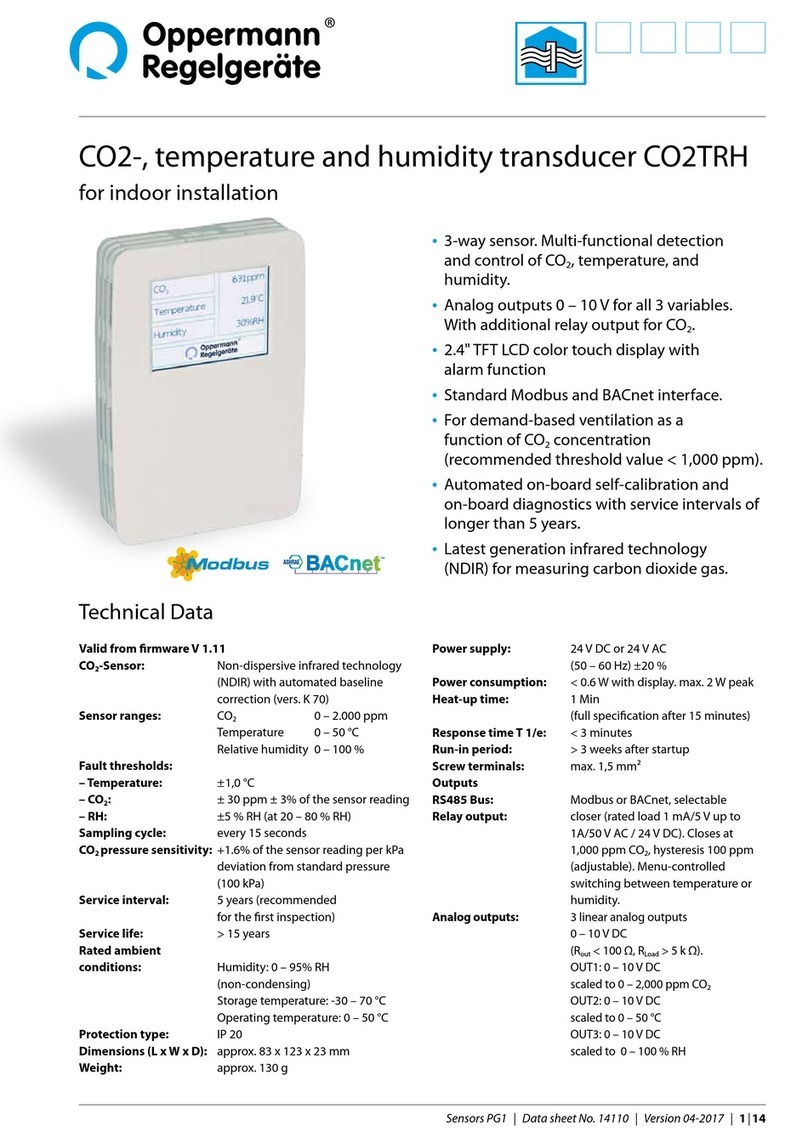

Oppermann Regelgeräte

Oppermann Regelgeräte CO2TRH manual

Soundmask

Soundmask SM-T-1200 operating manual

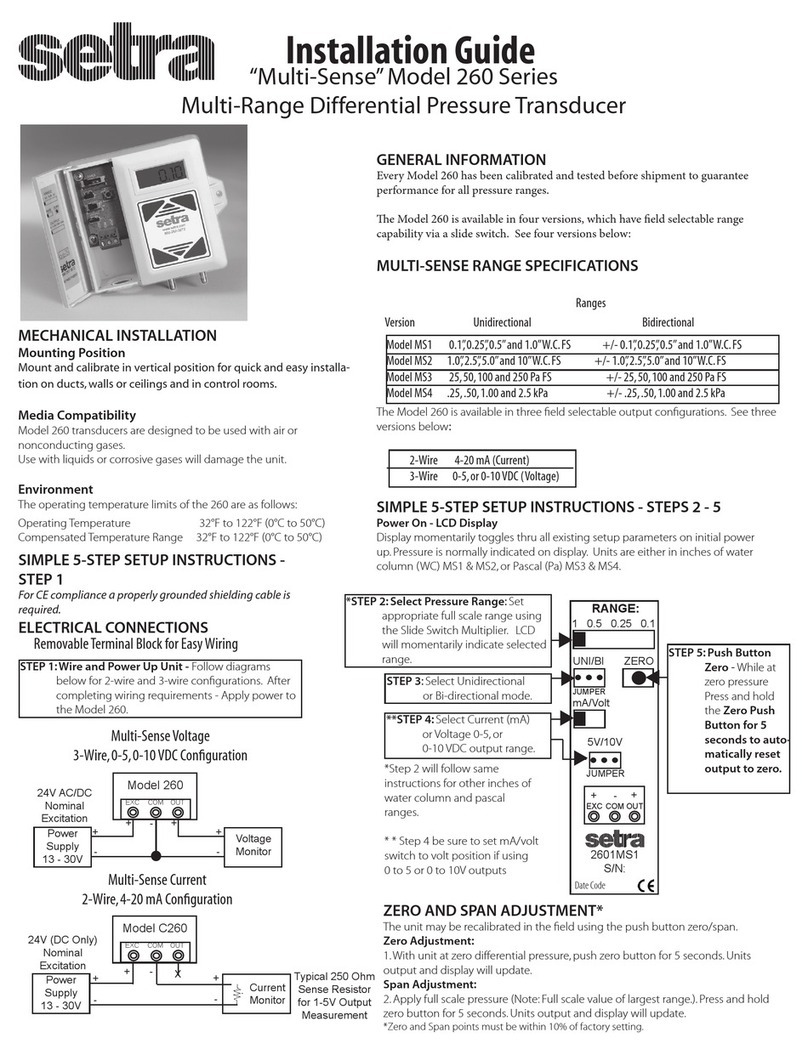

Setra Systems

Setra Systems Multi-Sense 260 Series installation guide

halstrup-walcher

halstrup-walcher PS11 instruction manual

novotechnik

novotechnik LS1 Series manual

Balluff

Balluff BTL7-A M Series user guide