ACO DMMS User manual

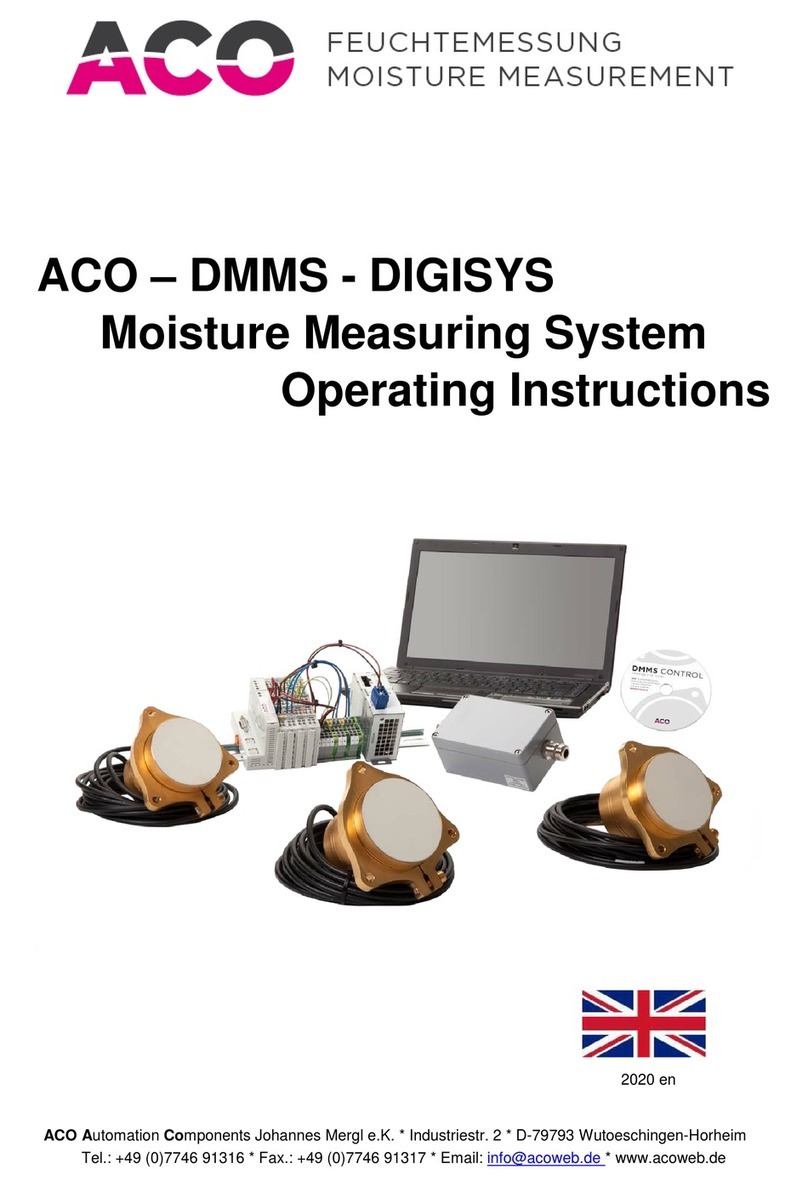

ACO - DMMS - DIGISYS

Moisture Measuring System

Operating Instructions

ACO-DMMS- Moisture Measuring System (2008)

ACO AUTOMATION COMPONENTS

Table of Contents

1. FOREWORD .............................................................................................................. 3

2. NOTES ON SAFETY.................................................................................................. 4

3. TECHNICAL DATA.................................................................................................... 6

3.1 DMMS sensor .....................................................................................................................................6

3.2 Bus connection socket......................................................................................................................7

3.3 Interchange and evaluation unit.......................................................................................................8

3.4 Power pack (DIN rail mounting)........................................................................................................9

3.5 Profibus DP measured value transmission...................................................................................10

3.6 PC-Software......................................................................................................................................10

4. SYSTEM SUMMARY ...............................................................................................11

5. MOISTURE SENSOR................................................................................................12

6. DIGISYS BUS CONNECTION SOCKET...................................................................14

7. DIGISYS INTERCHANGE AND EVALUATION UNIT...............................................15

7.1 Measuring operation........................................................................................................................15

7.2 Configuration and programming interface....................................................................................15

7.3 LED-signalisation...........................................................................................................................156

7.4 Profibus...........................................................................................................................................157

7.5 Connection / wiring..........................................................................................................................18

8. PC-SOFTWARE DMMS/DIGISYS ............................................................................20

8.1 Installation ........................................................................................................................................20

8.2 General notes on operation ............................................................................................................21

8.3 Extras / Settings...............................................................................................................................22

8.4 info.....................................................................................................................................................22

8.5 Moisture / Temperture-Image..........................................................................................................23

8.6 Service ..............................................................................................................................................23

8.7 Configuration....................................................................................................................................23

8.8 Test image ........................................................................................................................................25

8.9 Take Sample .....................................................................................................................................26

8.10 Curves ...............................................................................................................................................27

8.11 System ..............................................................................................................................................29

8.12 Example - install a measuring channel..........................................................................................30

8.13 Error reports .....................................................................................................................................32

8.14 Software versions ............................................................................................................................32

9. SPARE-PARTS LIST ................................................................................................33

1

ACO AUTOMATION COMPONENTS

1. Foreword

These operating instructions relay important information regarding safety, operation, maintenance and

repair.

Every person involved with utilisation, assembly, start-up, operation and maintenance, must have read and

understood these operating instructions and must retain them within their immediate proximity at all times.

In order that a safe, fault-free and cost-effective operation can be guaranteed, it is absolutely imperative that

the notes on safety, operation and maintenance are strictly adhered to.

The operating instructions are to be supplemented with any existing national guidelines concerning accident-

prevention and environmental protection.

The valid, relative regulations for accident-prevention in the country of utilisation, as well as on the applica-

tion site and the recognised, specialist-technical laws for safe and professional operation are to be noted.

The operating instructions must be available at the application site of the measuring system at all times.

Acknowledgements

We would like to thank the company, WAGO Kontakttechnik GmbH, Minden, for the documentation material

which was so kindly submitted by them.

Registered trademarks

MS-WINDOWS (95/98/ME, NT4, 2000, XP), MS-EXCEL are registered trademarks of the Microsoft Corpora-

tion.

PROFIBUS s a registered trademark of the PROFIBUS User Organisation PNO.

Copyright and company address

© Copyright 2005

ACO AUTOMATION COMPONENTS

Johannes Mergl e.k.

Industriestrasse 2

79793 Wutöschingen-Horheim /Germany

Tel.: +49 7746 91316

Fax.:+49 7746 91317

ACO AUTOMATION COMPONENTS have taken all necessary care to ensure utmost correctness during compilation of these operating

instructions. The data specified serves the product description only and should not be interpreted as guaranteed properties in a legal

sense. We refuse to accept liability for errors, omissions or the data included herein as regards utilisation.

All rights, particularly those rights regarding reproduction and distribution, as well as translations, are reserved. Under no circumstances

should any part of this work be reproduced or stored within an electrical system, modified or distributed in any way or form (printing,

photocopying, microfilm or reprinted) without expressed written permission from ACO/LMT.

As errors may never be completely ruled out, despite every endeavour on our behalf, we are always appreciative of any comments

submitted.

3

ACO AUTOMATION COMPONENTS

2. Notes on safety

Warning information and symbols

Tasks and operating phases which represent an increased danger to persons or the system are indicated

with special symbols.

In these operating instructions, the symbols carry the following meanings:

DANGER indicates a particularly dangerous situation.

Possible causes:

DANGER

•Serious injuries or death.

•Serious consequential damage to the plant.

WARNING indicates a very dangerous situation.

Possible causes:

•Very serious injuries, possibly fatal.

•Serious consequential damage to the plant.

WARNING

CAUTION indicates a possibly dangerous situation.

Possible causes:

•Serious injuries. CAUTION

•Damage to the plant.

INFO

Important note or important information.

Operation and maintenance of the plant becomes considerably easier if this information is observed

Use as directed

•The measuring system has been designed around state-of-the-art technology and all recognised regula-

tions regarding technical safety. Nevertheless, even if these standards are observed, there is a possibil-

ity that the life of the user or a third party could be put at risk, or that the plant or other equipment could

sustain damage.

•Only use the measuring system as directed i.e conscientious of safety and dangers which may occur,

and only if it can be guaranteed that the system is in a technically sound condition! In particular, faults

which may impeded safety must be remedied immediately.

•The measuring system is to be used exclusively for measuring the water content in the bulk material and

liquids or in the dry matter in water. It is not permissible to measure the water content in flammable or

explosive liquids. Any other use, as well as exaggerated use, is not considered use as directed. The

manufacturer or supplier can not be held responsible for any damage which occurs as a result of this.

The user is solely responsible. Use as directed also includes observation of the operating instructions

and adherence to the maintenance and inspection guidelines.

4

ACO AUTOMATION COMPONENTS

General operational safety

•Ensure that the operating instructions are on-hand in the switch cabinet, within which the Interchange

and evaluation unit is installed, at all times!

•Observe and apply any supplements to the operating instructions, general valid, legal and other obliga-

tory regulations regarding accident-prevention (e.g. providing or wearing of personal protective equip-

ment, road traffic regulations) and environmental protection (e.g. handling of dangerous substances)!

•Supplement the operating instructions with all necessary information including duty of supervision and

reporting obligations for the observance of operational particulars (e.g. work organisation, working pro-

cedures, hiring of personnel).

•Refrain from all working procedures which appear dubious as regards safety!

•Ensure that personnel are familiar with the location of fire extinguishers and how to use them! Observe

all fire alarms and firefighting possibilities!

•Ensure safe and environmentally-friendly disposal of all fuels and lubricants, as well as replacement

parts!

Personnel and supervision

•Personnel which are actively involved with the measuring system must have read the operating instruc-

tions before beginning work, in particular the chapter concerning the notes on safety. During operation is

too late. This applies in particular to personnel working opportunely on the sensor (e.g. when carrying

out maintenance).

•Carry out regular checks as to whether the personnel are working conscientiously as regards safety, and

are observing the operating instructions!

•Ensure that only contracted personnel are actively involved with the measuring system

•Employ trained or instructed personnel only. Explain responsibilities regarding operation, maintenance

and repair clearly to all personnel! Observe the legal minimum age!

•Before commencing work, inform all operating personnel of repair tasks which may be required! Nomi-

nate supervisors! Only allow repair tasks to be carried out by specialist personnel.

•Tasks to the electrical equipment of the measuring system may only be carried out by electrical special-

ists or by trained personnel under the instruction and supervision of an electrical specialist in accordance

with electro-technical regulations.

•Always wear personal protective equipment when necessary or when otherwise required by the safety

guidelines!

Operation and maintenance

•Prescribed times or intervals specified in the operating instructions or for repeated inspections must be

adhered to!

•For all tasks which concern operation or adjustment of the measuring system, as well as the safety-

relevant devices, observe the activation and deactivation procedures, as well as control displays in ac-

cordance with the operating instructions and notes for repair tasks!

•All screw connections loosened for maintenance and repair tasks must be retightened!

•Spare-parts must meet the technical requirements determined by the manufacturer. This can always be

guaranteed by using original spare-parts.

Assembly and repair

•Before commencing work, inform all operating personnel of repair tasks which may be required! Nomi-

nate supervisors! Only allow repair tasks to be carried out by specialist personnel.

•If not expressly otherwise specified, only carry out tasks to the measuring system when the voltage sup-

ply for the system has been disconnected. Always disengage the power supply prior to carrying out work

on the measuring system.

5

ACO AUTOMATION COMPONENTS Technical data

3. Technical data

3.1 DMMS sensor

Technical data sheet:

Physical principal Determination of capacity in the high-frequency stray field

frequency

Measuring location Outside of the silo, within the silo, via deflection plate, on a

belt with guide shoe slides, pipes, conveyor screws

Measuring frequency 0.016 ..0.022 GHz

Measuring range 0 %M - 100 %M (adjustable measuring window)

Capacity dissolution 10 fF

Actualisation cycle 32.64 ms

Sampling rate mean value calculator 16 × 106- 25 × 106

Maximum attainable measuring precision ± 0.05 %F 1.)

Measured value transmission digital: RS-485{XE "RS-485"}, multiprocessor protocol

Max. number of sensors at the bus 16

Maximum bus length 1.2 km

Microprocessor AT89C51ED2

Power supply 8..30V, 0.4 VA

Measuring range, temperature measurement -10°C - 90°C

Measuring precision, temperature measurement ± 0.5°C

Operational ambient temperature 5°C - 72°C

Operating temperature, electronic -20°C - 80°C

Storage temperature -25°C - 80°C

Protection device IP68

Connection line, type LiYD11Y 6 x 0.14mm2

Connection line, length 6m

Wear protection ZrO2 Al2O3

Material housing / flange V4A 1.4571

Dimension: ∅/ height 78 / 57 mm

Weight without cable 500 g

Weight of tensioning flange 300 g

1.) Representative of the batch or of the time window with the continuous process ,in connection with the respective

evaluation unit DIGISYS, material-dependent, with ideal flow properties and with sound calibration

Dimensions illustration Master gauge

Ø

76

70

60 mm var

6

ACO AUTOMATION COMPONENTS

3.2 Bus connection socket

Technical data sheet:

Housing material Aluminium

Weight 200 g

Colour Grey

Height [mm] 57.5 mm

Height [inches] 2.26 in

Width [mm] 125 mm

Width [inches] 4.92 in

Depth [mm] 80 mm

Depth [inches] 3.15 in

Operating temperature -25 °C ... +85 °C

Storage temperature -25 °C ... +85 °C

Relative moisture (without condensation) 95 %

Identification of conformity CE

Vibration resistance in accordance with IEC 60068-2-6

Shock resistance in accordance with IEC 60068-2-27

Protection device IP 66

EMC interference immunity in accordance with EN 50082-2 (96)

EMC interference emission in accordance with EN 50081-2 (94)

Cable glands 4 x Pg 11 or M16 stainless steel

Shield clamps 4 x CAGE-CLAMP 2.5 mm²

Bus clamps 18 x CAGE-CLAMP 0.5 mm²

Cross-section from [mm²] 0.08 mm²

Cross-section up to [mm²] 0.5 mm²

Cross-section from [AWG] 28 AWG

Cross-section up to [AWG] 20 AWG

Stripping length [mm] 5 -6 mm

Stripping length [inches] 0.236 in

Dimension illustration:

113.00

125.00

52.00

57.50

80.00

ø8.00

ø4.00

7

ACO AUTOMATION COMPONENTS Technical data

3.3 Interchange and evaluation unit

These technical data sheets can be obtained directly from WAGO Kontakttechnik GmbH, Minden, or by

way of the internet site: http://www.wago.com

WAGO 750-833 WAGO 750-550

Field bus controller 2-channel

PROFIBUS DP/V1 analogue output terminal

with ACO/LMT Firmware 0..10 V

WAGO 750-513

WAGO 750-402

Relay output terminal 250V

AC, 30V DC,

4-channel digital

input terminal 3ms 2A AC/DC

WAGO 750-504 WAGO 750-653/000-020

4-channel digital Serial interface RS485

output terminal

WAGO 750-554

2-channel WAGO 750-600

analogue output terminal End terminal

4..20mA

HAMA 00049262

USB / RS-232 - adapter

http://www.hama.de

Dimension illustration:

12.0

ADDRESS

35.0

100.0

48.2

35.0

X10

X1

DIA

USR

BUS

RUN

I/O

BF

PROFIBUS

25.0

25.0

12.0 10.0

8

ACO AUTOMATION COMPONENTS

3.4 Power pack (DIN rail mounting)

Technical data sheet:

Type PH15-2406

Manufacturer: MGV Stromversorgungen (Internet: www.mgv.de)

Weight 0.130kg

Dimensions (B x H x D) 25 x 76 x 74 mm

Operating temperature 0...70°C, with free convection

Overtemperature protection yes

Input

Mains voltage range Ue AC 94 – 264 V, 50/60 Hz

Efficiency 77 – 87%

current limitation = 20 A peak in cold conditions

Derating 2.5% / K from +50°C

Mains buffering > 40 ms (with Ue = 187 VAC)

Interbal fuse 2.5 A flink

Output

Nominal voltage tolerance +2% / -1%, at 5V + 3%

Residual ripple < 50 mVss

Interference voltage < 150 mVss

Temperature coefficient 0.025% / K

Switch on / switch off performance No overshooting of Ua (soft-start)

Rise-delay time 0.8 s

Run-up time 30 ms

Overvoltage protection < 130% from Ua nominal

Current limitation 105 – 200% / 250% I nominal,

Continious short circuit proof yes

Operation indicator Green LED

Protection IEC 60950 / EN 60950 / VDE 0805 safety classification I

UL508 listed, UL 60950, CSA 22.2 - 60950

Dimension illustration:

25.0mm

75.0mm

N

L

PE

-

+

9

ACO AUTOMATION COMPONENTS Technical data

3.5 PROFIBUS DP measured value transmission

Technical data sheet:

Hardware WAGO 750-833/000-002 field bus controller

Transmission medium Cu-cable EN50170

Bus segment length 100..1200m

Baud rate 9600.. 12M bit/s

Bus connector 9-pin Sub-D male

Protocol DP / DPVI

GSD - file WAGOB756.GSD download: www.wago.com

Measuring channels 1..16

1.) input data / measuring channel(s) (n*2+2) byte

2.) Output data / measuring channel(s) (n*6+4) byte

1.) This regards output variables where the PROFIBUS-Master is concerned.

2.) This regards input variables where the PROFIBUS-Master is concerned.

3.6 PC-software

Technical data sheet:

Channels visualisation moisture 16 of 16

Number of channels for simultaneous visualisation moisture 16 of 16

Manual/automatic changeover 16 of 16

Graphic measured value representation 1 of 16

Parameterisation 1 of 16

Calibration 1 of 16

Material curve changeover yes

Service and diagnosis yes

Software system requirement

Microsoft Windows ® WIN 95/98/ME,

NT4.0, 2000, XP

Operating systems

Documentation Acrobat Reader

Hardware system requirement:

CPU Pentium min133MHz

RAM – memory 32MB

Harddisk free 10MB

Installation drive CD-ROM

Interface RS232B or USB / RS-232 adapter

if necessary, LAN connection Ethernet 10/100 Mbit/s

10

ACO AUTOMATION COMPONENTS

4. System summary

The DIGISYS with intelligent bus sensors is an independently operating moisture-measuring system, without

the necessity of installing indication and operating units. It is thus ideally suited for controls featuring a visu-

alisation system. The Interchange and evaluation unit can be installed compactly in a switch cabinet. A multi-

tude of interfaces can be realised for the overriding systems. An easy-to-use PC-software allows a quick and

precise calibration of the measuring channel.

1.. 16

Moisture sensors

on the bus

Sensor bus

Bus length

max. 1200m

Bus connection socket-

for 1..2 sensors

DIGISYS Interchange and

evaluation unit

modular upgradable

Power pack

24V DC

PROFIBUS-DP

Measured value transmission-

Material curve chan

g

e-ove

r

DIGISYS/DMMS PC software

Measured value display, cali-

bration,set-up, material curves,

recording

Analogue measured value out-

put 0-10V, 4-20mA digital in-

puts for Start/Stop control

RS-232

and material curve change-over, digital

outputs for limit signalisation

USB

11

ACO AUTOMATION COMPONENTS DMMS moisture sensor

5. DMMS moisture sensor

The DMMS sensor is a so-called "intelligent sensor", thus, the installed µ-processor allows complete solving

of the problem in one component, as well as an expanded functionality.

•Direct digital measuring procedure

•Calibration data memory

•Linearisation

•Inspection of thresholds

•Start / Stop control

•Mean value calculation

•Temperature measurement

•Temperature compensation

•Material-specific adjustment

•Digital interface / networking

•Error report

A precise calibration at the factory allows complete reproducibility over a wide temperature range. The costly

material-specific adjustment therefore is also possible for wider measuring channels and no readjustment is

necessary, in the case the sensor is replaced.

The sensor receives a measuring task from the DIGISYS Interchange and evaluation unit and makes avail-

able the ready-processed measuring result available at the precise required time. The data transfer is re-

duced to a minimum and the resources of controls which have a higher priority are less burdened.

Sensor assembly

The sensor can be installed in a container, guide shoe carriage, batching table or in a material chute using

the mounting flange. The sensor can be installed flush on wall thicknesses of 1 to 25 mm by shifting in the

flange.

•Open up a mounting hole in the wall partition - see master gauge

•Loosen the straining screw (E)

•Fix the mounting flange (C) with 3 countersunk screws (a) on the rear side of the wall partition, leav-

ing the nuts (d) loose

•Adjust the sensor in the flange until it is flush with the wall partition.

•Tighten the straining screw (E) first, and then the fastening (B)

•Clamp the sensor cable to the bus connection socket and tighten the cable gland

Master gauge:

Assembly:

a: Countersunk

screw M5 with

Allen head

E

D

C

B

Ac

d

a

b

ø10.0

120°

R55

ø5.2

R39.1

b: Washer:

c: Snap ring

d: Nut M5

A: Wall partition

C: Mounting flange

D: Sensor

E: Straining screw

B: Fastening

12

ACO AUTOMATION COMPONENTS

CAUTION Damage to the system.

•Do not open the cable clamp on the sensor.

•Do not strike the ceramic wear shield directly with a hammer.

•Install the sensor flush to prevent material encrustations or premature wear.

•Hot water from evaporation in the silo damages the sensor or leads to measuring discrepancies.

•The temperature inside the sensor housing may not exceed 80°C.

•The sensor may not be installed in immediate proximity to vibratory discharge aids (vibrators).

•When replacing sensors, do not cut away the connecting cable of the old sensor.

•When filling the silo for the first time, ensure that the sensor is protected against falling rocks.

•A mounting flange installed at a tilt in the sensor can fall out if it becomes overloaded.

•The 3 fastening screws (a) and the straining screw (E) must be made of stainless steel.

Maintenance

•Correct functioning of the measuring channel (s) must undergo a daily inspection.

•The wear shield made of ceramic must be examined for damage and wear

•Remove any material which adheres to the ceramic wear shield.

•An even flow of material with sufficient over-layer (>50mm) must be present.

•The moisture measuring value must be verified via a laboratory test. A sufficient quantity of material,

representative of the mix, is extracted and at the same time the moisture measuring value or the digit

value is recorded. If the deviations prove too great, the calibration curves can be adjusted. (see PC soft-

ware or indication and parameterisation module)

Replacing the sensor

Electric shock!

Connection of the plant and all tasks to the electrical equip-

ment may only be carried out by an electrical specialist.

DANGER Moving machine parts!

The sensor can be fitted in the immediate proximity of mov-

ing machine parts. Switch off the machine!

1. Cut the voltage supply to the measuring system.

2. Open the bus connection socket, loosen the cable clamp and unclamp the sensor cable.

3. First loosen the fastening (B) and then loosen the straining screw (E) until the mounting flange releases

the sensor.

4. Install a new sensor in the mounting flange, adjust. and tighten the straining screw (E).

5. Tighten the fastening (B).

6. Clamp the sensor cable, tighten the cable clamp and connect the bus connection socket.

7. Clean and dry the surface of the sensor.

8. Start up the measuring system once again

9. Read off the digit value for the air and carry out an offset. A recalibration of the measuring channel is

then not necessary. (see PC software or APM)

13

ACO AUTOMATION COMPONENTS Bus connection socket

14

6. Bus connection socket

The ACO bus connection socket facilitates installation of the sensor bus:

•Protection type IP66

•Connection of 1 or 2 moisture sensors

•Connection of 1 or 2 bus lines

•Bus termination

•Allocation of sensor address

•Fine protection against lightning

•CAGE CLAMP connection technology

•4 cable clamps

Assembly of the bus connection socket

1. Fasten the socket using suitable screws

through the holes B.

2. Connect 1 or 2 sensors, the white and grey

wires serve to determine the sensor address.

3. Connect the cable from the sensor bus, at the

last socket attach clamps A and B as bus con-

nection instead of 120 Ohm resistance.

4. All shieldings on shield clamp

5. Tighten the cable glands.

6. Connection socket - mount the cover

Sensor

+-

ABKanal Nr.

gr

ws

gn

ge

rs

bn

B

Sensorbus

+-

AB

BUS

C1

V1

Sensor

R7

+-

AB

BUS

R8

R1

R2

R3

R4

Schirm

+-

ABKanal Nr.

gr

ws

gn

ge

rs

bn

R5

R6

Sensorbus

B

V2

Sensor Sensor cable connection

address + -

A

B Channel no.

1 bn rs ge gn ws gr

2 bn rs ge gn ws gr

3 bn rs ge gn ws gr

4 bn rs ge gn ws gr

5 bn rs ge gn ws gr

6 bn rs ge gn ws o----o gr

7 bn rs ge gn ws gr

Do not set any double

sensor addresses!

Sensor cable length is a

maximum 6m!

8 bn rs ge gn ws gr

Wire colours

{

XE 9 bn rs ge gn ws gr

bn brown 10 bn rs ge gn ws o-------o gr

rs pink 11 bn rs ge gn ws o----o gr

BUS

120

-

AB

+

ge yellow 12

bn rs ge gn ws o----o gr

gn green 13 bn rs ge gn ws gr

For the last connection socket, set a resistance

with 120 ohms between clam

p

s A and B . ws white 14

bn rs ge gn ws o----o gr

gr grey 15 bn rs ge gn ws gr

Circuit diagram:

o----o Bridge 16 bn rs ge gn ws gr

Schirm / shield

Sensorbus

+-AAB+-B

rs

gn

ge

ws

bn

gr

Sensor

R22k

R11k

R48k

R34k

V110N391K

C110n

gr

AB+-

rs

gn

ge

ws

bn

Sensor

R51k

R62k

R74k

R88k

A+- B

Sensorbus

V210N391K

ACO AUTOMATION COMPONENTS

7. DIGISYS interchange and evaluation unit

The ACO_DIGISYS interchange and evaluation unit is comprised of a WAGO - I/O - SYSTEM 750. A de-

tailed description of all components can be obtained from the company, WAGO Kontakttechnik GmbH, Min-

den, or alternatively, from the internet site from WAGO Kontakttechnik GmbH: http://www.wago.com.

The field bus controller 750-833000-002 includes a ACO-specific Firmware, comprising the complete ACO-

DIGISYS - approach:

•Communication with overriding system (PROFIBUS)

•Issue of measured values via diverse interfaces

•Start-Stop control mean value calculator

•Distribute measuring orders

•Storage of measuring channel configuration, curves, thresh-

olds etc.

•Summarisation of measured values from several sensors

•Material curve changeover

•Error report

7.1 Measuring operation

Moisture measuring is initiated automatically following activation of the DIGISYS.

No operation is necessary in this operating mode.

This operation is not discontinued, even within the service functions, thus the measurement continues to run

in the background.

7.2 Configuration and programming interface

The configuration and programming interface is located behind the cover flap. It is

used for communication with the PC-software, the indication and parameterisation

module and for transmission of the Firmware. The communication cable is con-

nected to the 4-pin port (1).

The switch for the operation mode (2) is also located behind the cover flap. The

switch (2) is a push-slide switch featuring three positions and a key function.

Functions of the operation mode switch

Operation mode switch (2) Function

From the middle to the upper

position Activate program processing (RUN)

From the upper to the middle

position Stop program processing (STOP)

Lower position Bootstrap for booting the Firmware, not necessary for the user.

Hardware-Reset

Press down (using a screwdriver,

for example) All outputs and flags are reset; Variables are set to 0 or to FALSE or to an initial

value. The Hardware - Reset can be initiated with STOP, as well as with RUN in

each position of the operation mode switch!

A change in operation mode occurs internally at the end of a PFC-cycle.

15

ACO AUTOMATION COMPONENTS DIGISYS interchange and evaluation unit

7.3 PROFIBUS DP

Moisture and temperature values, status and error reports from all 16 channels can be read from the control-

ler via the PROFIBUS DP, and all control signals such as Start, Fine and Manual can be set.

Detailed description 750-121 and a supplement for 750-333/-833 PROFIBUScan be ob-

tained from the WAGO Kontakttechnik GmbH company in Minden, or on their internet

site:http://www.wago.com

.

All documentation regarding the PROFIBUS is available on the PROFIBUS user organisation internet page:

www.PROFIBUS.com.

16

ACO AUTOMATION COMPONENTS

7.4 LED-signalisation

Explanation

LED Colour

A B C D green Operating voltage available

RUN green The field bus was efficiently initialised.

BF (flashing) red Communication via the PROFIBUS is not functioning.

DIA red An external diagnosis is being performed.

BUS Flashing code Projection error

Data cycle unavailable on the nodeFaulty operation of the

PROFIBUS nodeNormal operation of the PROFIBUS

node.Flash-access of the equipment-Firmware

Offflashing

redgreenorange

I/O

red Initiate system start

off Boot

flashing

green/orange

Sensors on the sensor bus are being searched for or occur-

rence, interchange and evaluation unit

green System running

USR

orange System running with indication and parameterisation module

red flashing

code

DIGISYS -error, see error - flashing code

Error - flashing code error signalisation

First wait until the LED begins to flicker red, then sequence flashes 4 times. e.g. error code = 2 5 1 4 :

flickering code 2 code 5 code 1 code4

The most important codes and their meaning:

Code Description Remedy

2 3 # $

2 4 # $

Measuring channel: # S-Adr.: $ - overrun mean value

calculator Start signal too long, adapt CMW-pause

Measuring channel: # S-Adr.: $ - TO measuring value

processing

2 5 # $ Eliminate sensor error (sequence error)

3 1 $ 1 Sensor S-Adr.: $ - used, however, not found Check cabling and addressing

3 2 $ 1 Sensor S-Adr.: $ - not used, however, found Check addressing, register sensor $

3 3 # $ Sensor channel: # S-Adr.: $ - data transfer error

3 4 # $ Sensor channel: # S-Adr.: $ - no answer

3 5 # $ Sensor channel: # S-Adr.: $ - incorrect answer Cabling, check power supply

3 6 # $ Sensor channel: # S-Adr.: $ - error report

3 11 $ 1 Sensor S-Adr.: $ - found twice Cabling, check addressing

7 6 1 1 WAGO RS-485 module unavailable

7 7 1 1 WAGO digital input module unavailable

7 8 1 1 WAGO digital output module unavailable

7 9 1 1 WAGO relay module unavailable

7 10 1 1 WAGO analogue output module unavailable

7 11 1 1 WAGO incorrect amount digital-input modules

Install WAGO I/O module or remove mod-

ule from the configuration

7 12 1 1 WAGO incorrect amount digital-output modules

7 13 1 1 WAGO incorrect amount relay modules

7 14 1 1 WAGO incorrect amount digital-input modules

# = Channel number 1..16 $= Sensor address 1..16

17

ACO AUTOMATION COMPONENTS DIGISYS interchange and evaluation unit

7.5 Connection / wiring

The I/O modules must be inserted in a determined sequence on a carrier rail (35x7.5 mm):

WAGO Module type

Amount

Field bus controller PROFIBUS DP / V1 with ACO/LMT soft-

ware

1750-833

0 to 4 750-402 4-channel digital input terminal 3ms

0 to 4 750-504 4-channel digital output terminal

2-channel analogue output terminal 4..20mA or2-channel ana-

logue output terminal 0..10 V

0 to 8 750-554750-550

0 to 8 750-513 Relay output terminal 250V AC, 30V DC, 2A AC/DC

1750-653 000-020 Serial interface RS-485 with sensor bus

1750-600 End terminal

Electric shock!

DANGER Connection of the plant and all tasks to the electrical equip-

ment may only be carried out by an electrical specialist.

Examples of wiring:

6

X10

2

4

S

3

8

S

ADDRESS

X1 3

M

7

M

+-AB

GPROFIBUS A H

1

2

USR

I/O

RxD

+

6

RxD

-

TxD

BF

DIA

BUS

24V 0V

+

1

RUN

-

5

TxD

+ -

J5

4

PROFIBUS-DP

A controller PROFIBUS DP

G RS485 interface

H end terminal

J terminal block

1 PROFIBUS cable/plug

2 PROFIBUS address

3 configuration interfaces

4 connection power pack 24V DC

5 terminating resistor120 ohm

6 bus cable sensor bus

+ - power supply sensors

A B data signal

shield

18

Other manuals for DMMS

1

This manual suits for next models

1

Table of contents

Other ACO Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Shodex

Shodex RSpak DC-613 Operation manual

IDEAL

IDEAL 61-737 Operation and safety manual

Hanna Instruments

Hanna Instruments HI 8424NEW instruction manual

Agilent Technologies

Agilent Technologies OmniBER 720 user guide

SCHALT

SCHALT E9MF manual

Agilent Technologies

Agilent Technologies FieldFox N9913A user guide