Acson ACC-D Series User manual

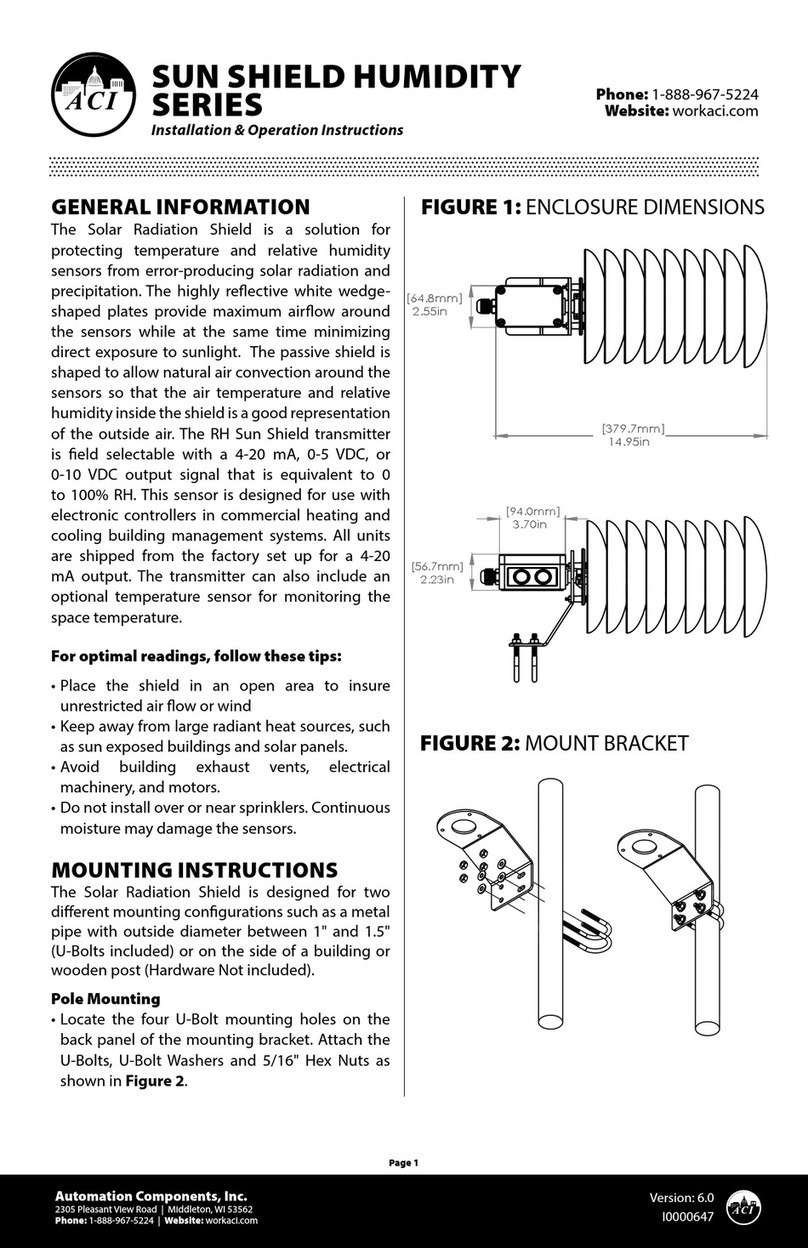

Ceiling Concealed

D Series

ACC-D2-2007

ACC 75 D/DR

ACC100 D/DR

Models:

1. NOMENCLATURE..........................................................................................................3

- PRODUCT LINE-UP

2. FEATURES.....................................................................................................................6

3 . APPLICATION INFORMATION.......................................................................................7

- OPERATING RANGE

- REFRIGERANT CIRCUIT DIAGRAMS

- CONTROLLERS

- PRECAUTION AND INSTALLATION

4. SOUND DATA...............................................................................................................24

5. SELECTION PROCESS...............................................................................................26

- FAN PERFORMANCE CHART

6. ENGINEERING & PHYSICAL DATA...........................................................................28

- GENERAL DATA

- COMPONENTS DATA

- SAFETY DEVICES

7. PERFORMANCE DATA...............................................................................................37

- PERFORMANCE TABLE

8. DIMENSIONAL DATA...................................................................................................47

9. ELECTRICAL DATA.....................................................................................................49

10. WIRING DIAGRAMS.....................................................................................................51

11. SERVICING AND MAINTENANCE...............................................................................53

12. TROUBLESHOOTING..................................................................................................55

13. EXPLODED VIEW & PART LIST.................................................................................61

TABLE OF CONTENTS

1

A CC 75 D R - A B A A

Series

D: D series

Model Type

R: Heatpump

Omitted if cooling only

Capacity

75: 75,000 Btu/h

Model Name

CC: Ceiling Concealed

Refrigerant

Blank: R22

4: R407C

Brand

A: Acson

Electrical Characteristic

A: 50Hz / 1Ph / 220-240V

Type of connection

B: For Brazed

A: First Issue

Production spec variation

1. NOMENCLATURE

2

A 4 MC 75 E R - F B A A

Series

E: E Series

D: D series

Model Type

R: Heatpump

Omitted if cooling only

Capacity

75: 75,000 Btu/h

Model Name

MC: Single Split

Condensing Unit

Refrigerant

Blank: R22

4: R407C

Brand

A: ACSON

Electrical Characteristic

F: 50Hz / 3Ph / 380-415V

P: 60Hz / 3Ph / 208-230V

Q: 60Hz / 3Ph / 460V

Type of connection

B: For Brazed

A: First Issue

3

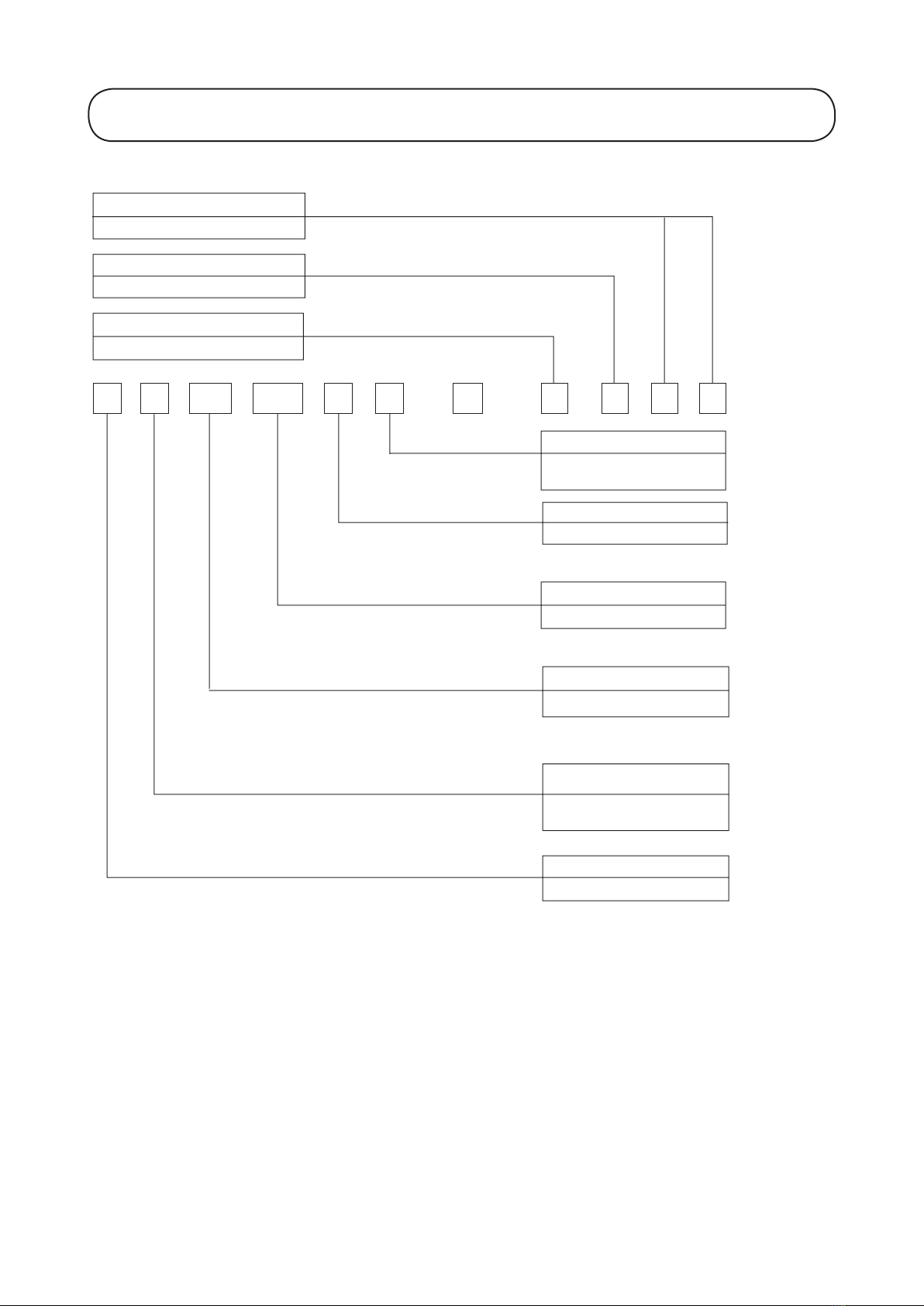

Indoor Unit ACC-D Series

Control

Handset

Marking

NETWARE 3

L2

CE Mark

Cap. Tube

TXV

75D ABAA XXX X XXX

100D ABAA XXX X XXX

75DR ABAA XXX X XXX

100DR ABAA XXX X XXX

Cooling

Model

Heat Pump

Model

With Air Filter

X

X

Fin

ALUMINIUM

(CORR.)

X

X

Level Switch

Classification

Refrigerant

Control

ACC

NONMENCLATURE

Built-in Filter Rail

Product Line-up

4

Compressor

With Contactor

Without Contactor

With 24Vac Control Circuit

With Auto HP/LP

With Manual HP/LP

CE Mark

ETL

Without Marking

Scroll-Copeland

TXV

Without Expansion Device

Rivet "Made In Malaysia"

With Accumulator

With Type Brazed Ball Valve

Phase Protector

Gold Fin (NA549)

FBAF X X X X X X

FBAG X X X X X X

FBAH X X X X X X

FCAA X X X X X X

FCAB X X X X X X X

PBAB X X X X X

PBAC X X X X X X X

PCAA X X X X X X

QBAB X X X X X

QBAC X X X X X X X

QCAB X X X X X X X X

FBAF X X X X X X

FBAG X X X X X X

FBAH X X X X X X

FCAA X X X X X X

FCAB X X X X X X X

PBAB X X X X X

PBAC X X X X X X X

PCAA X X X X X X

QBAB X X X X X

QBAC X X X X X X X

QCAB X X X X X X X X

A4MC-D Series Product Line Up

Marking

Compressor

With Contactor

Auto HP/LP

CE Mark

Scroll-Copeland

TXV

Without Expansion Device

For Sequential Controller

With Accumulator

With Type Brazed Ball Valve

Gold Fin (NA549)

FBAA XXXX XX

FBAA XXXX XXX

FCAA XXXX XX X

FCAB XXXX XXXXX

FBAA XXXX XX

FBAA XXXX XXX

FCAA XXXX XX X

FCAB XXXX XXXXX

1-1/8

Others

Liquid Pipe Size (in)

Gas pipe size (in)

1

Cooling Only Model

75D 1/2 1

100D 5/8 1-1/8

Cooling Only Model

75D 1/2

A4MC

Nomenclature

Controller

Refrigerant

Control

100D 5/8

Classification

Classification

AMC

Nomenclature

Controller Marking

Refrigerant

Control

Others

Liquid Pipe Size (in)

Gas Pipe Size (in)

Outdoor Unit

AMC-D Series Product Line Up

5

Outdoor Unit

AMC-ER Series Product Line Up

Marking

Compressor

With Contactor

With Auto HP/LP

CE Mark

Scroll-Copeland

TXV

Without Expansion Device

For Sequential Controller

Gold Fin (NA549)

Rivet "Made In Malaysia"

With Brazed Type Ball Valve

Check valve

Phase Sequencer

FBAA XXXXX X

FBAB XXXXX XX

FBAC X X X X X X X

FCAA XXXXX X X

FBAA XXXXX X

FBAB XXXXX XX

FBAC X X X X X X X

FCAA XXXXX X X

FBAA XXXXX X

FBAB XXXXX XX

FBAC X X X X X X X X

FCAA XXXXX X X

FBAA XXXXX X

FBAB X X X X X X X X

FCAA XXXXX X X

A4MC-ER Series Product Line Up

Marking

Compressor

With Contactor

With Auto HP/LP

CE Mark

Scroll-Copeland

TXV

Without Expansion Device

For Sequential Controller

Gold Fin (NA549)

With Accumulator

With Brazed Type Ball Valve

FBAA XXXXX X

FCAA XXXXX X X

FBAA XXXXX X

FCAA XXXXX X X

FBAA XXXXX X

FCAA XXXXX X X

FBAA XXXXX X

FCAA XXXXX X X

125ER 5/8 1-3/8

150ER 5/8 1-3/8

Others

Liquid Pipe Size (in)

Gas Pipe Size (in)

Heatpump Models

75ER 1/2 1

100ER 5/8 1-1/8

A4MC

Nomenclature

Controller

Refrigerant

Control

150ER 5/8 1-3/8

Classification

HEATPUMP MODLES

75ER 1/2 1

100ER 5/8 1-1/8

125ER 5/8 1-3/8

Classification

AMC

Nomenclature

Controller

Refrigerant

Control

Others

Liquid Pipe Size (in)

Gas Pipe Size (in)

6

Invisible Operation

The unit is installed concealed above the ceiling. ACC-D is designed to intelligently create a comfortable and

healthy indoor air climate, while remaining invisible. This allows user to enjoy conditioned air without sacricing

room space or interior design creativity.

Flexibility In System Design

The unit offers fan motor that can operate up to 4 speeds, thus provide choices of external static pressure for

designing ducting system.

Easy Serviceability

With the concept of easy serviceability in mind, ACC-D series is designed for easy access to internal components.

The internal components, such as fan motor or blower, can be easily accessed for servicing through both sides

or bottom of the unit.

High Level Of Protection

The unit is incorporated with a unique safety feature, i.e. a oat switch, to provide an additional protection from

possible problems of condensate water over ow inside the unit. Once the condensate water reaches critical level,

the level switch will be activated and signal will be sent to the microprocessor controller to stop the compressor

as well as sending an error message to the wired controller, alerting the user, for further action.

Wired Remote Controller

The standard unit comes with the Netware III controller, which offers wide range of control features that, includes

7 days and 24 hours timer setting and more. The ACC-D series is able to communicate with the versatile NIM

network control module and offers the opportunity of one centralized control for a system of multiple indoor

units in a building.

Auto Random Restart

Auto random restart function allows the unit to automatic restart as the last setting condition when the power

supply is resumed after power failure. However, the compressor will restart randomly if more than one unit is

installed and sharing the same phase of power.

Self Diagnosis

The microprocessor provides the possibility to detect and diagnose any fault or malfunction that occurs in the

system. The error will be reected by the wired remote controller with a series of error code.

2. FEATURES

7

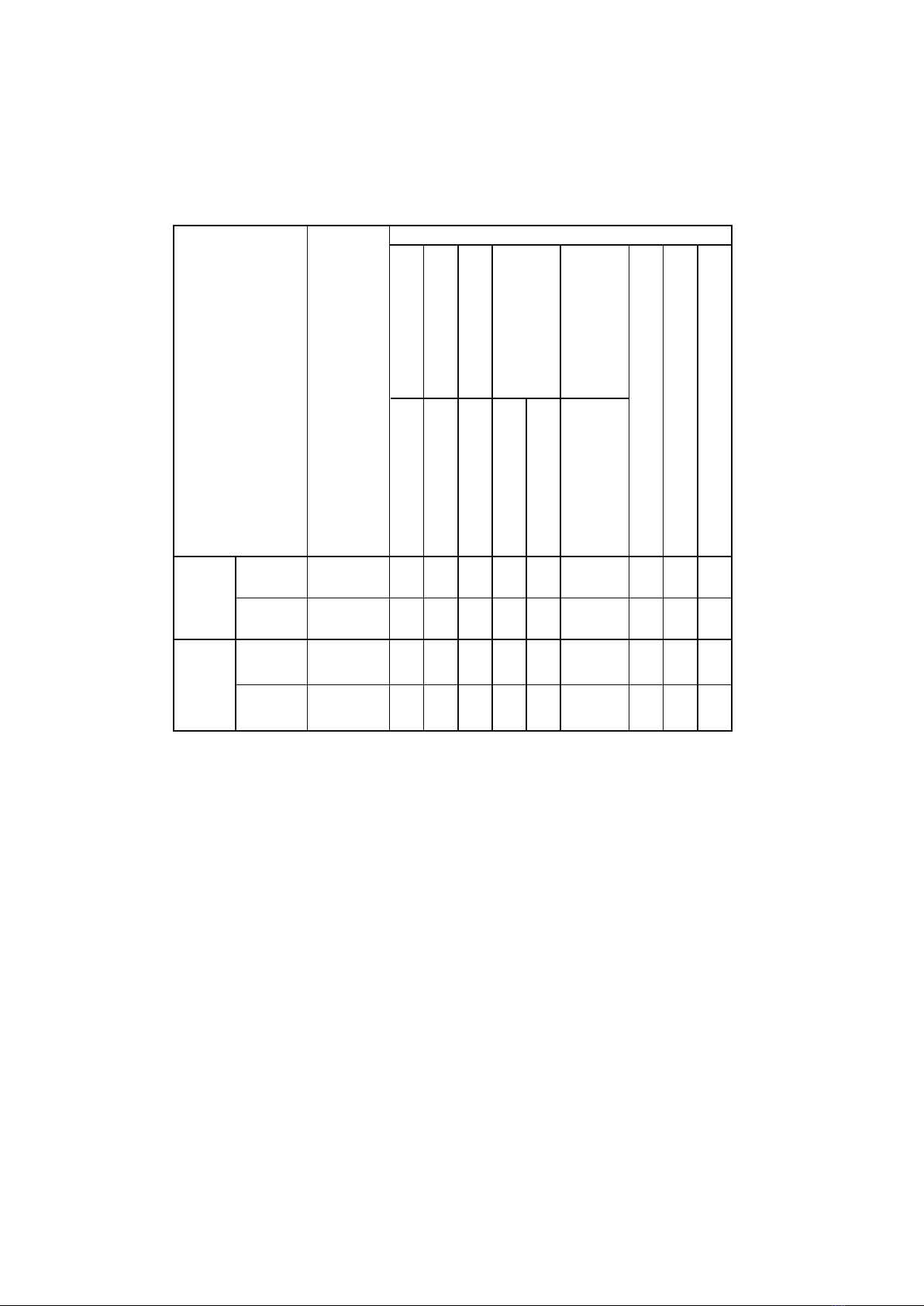

Operating Range

Ensure the operating temperature is in allowable range.

Cooling only

Heat pump

Outdoor temp. (°CDB)

Indoor temp. (°CWB)

Heating

Outdoor temp. (°CWB)

Indoor temp. (°CDB)

Cooling

Outdoor temp. (°CDB)

Indoor temp. (°CWB)

-9

15 21

6

27

-5

19

35

15

46

24

54

Standard

point

High ambient unit

Low ambient kit

18

-5

19

35

15

46

24

54 High ambient

unit

Low ambient kit

Standard

point

Standard

point

Caution :

The use of your air conditioner

outside the range of working

temperature and humidity can result

in serious failure.

Note :

Standard operating range.

With High ambient unit. (Optional item)

Please refer to local dealer for unit of this specification.

With Low ambient kit. (Optional item)

Please refer to local dealer for unit of this specification.

3. APPLICATION INFORMATION

8

Refrigerant Circuit Diagrams

Model: ACC 75D – AMC 75D ACC 100D – AMC 100D

ACC 75D – A4MC 75D ACC 100D – A4MC 100D

Model: ACC 75DR – AMC 75ER ACC 100DR – AMC 100ER

ACC 75DR – A4MC 75ER ACC 100DR – A4MC 100ER

9

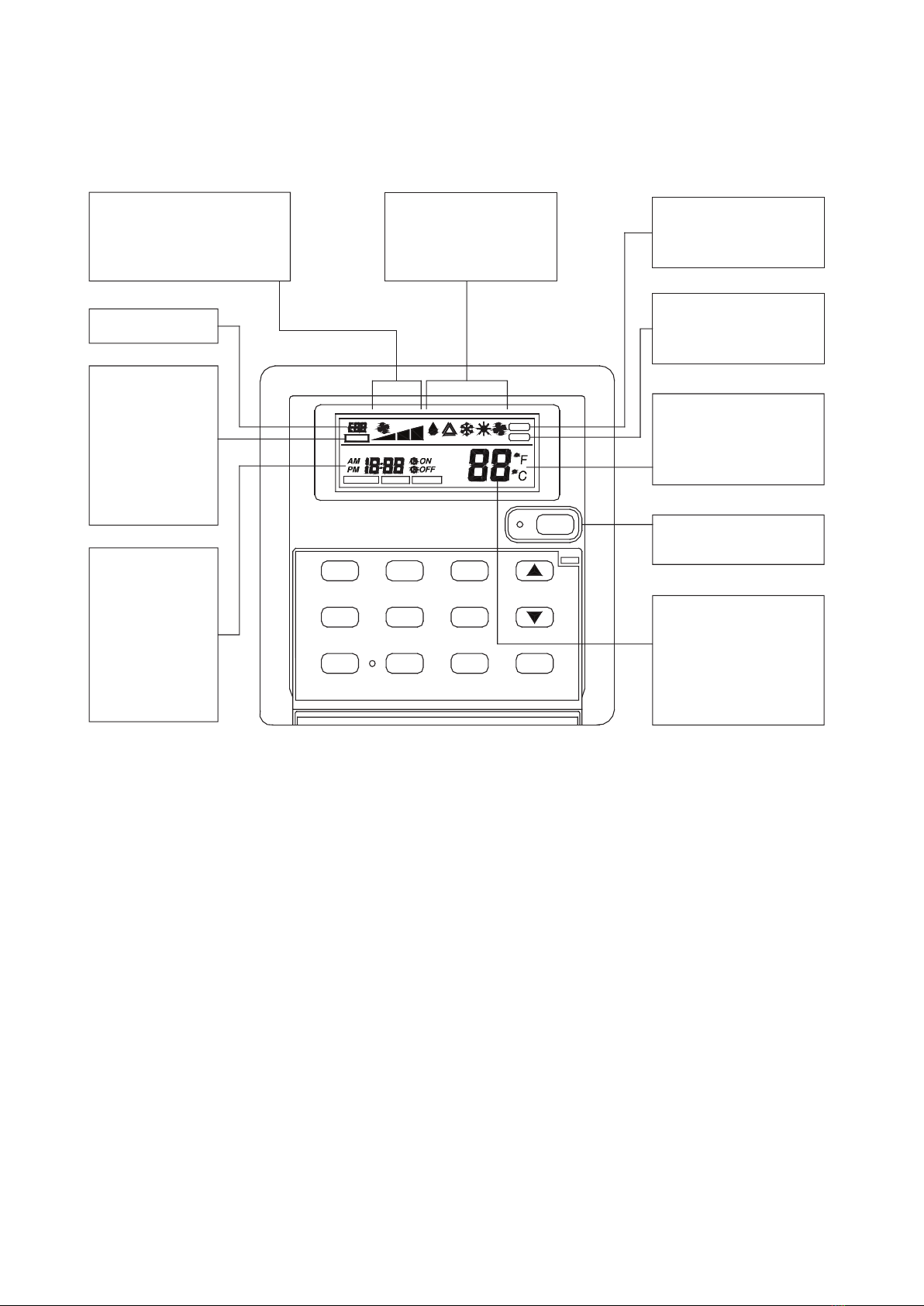

Controllers

°C or °F Display

Display the

temperature in °C

or °F.

HEAT

TEMP.

Key Lock

Display

Display

indicates when

key lock

function is

activated.

FAN

SET TIMER

ON TIMER

DAY

Current Time,

Start / Stop

Time Display

Display the

current time as

well as the start

and stop time

programmed.

CLOCK

HOLD

SWING

SLEEP

TIMER ACTIVE

Set Temperature

or Room

Temperature

Display

Display the set or

room temperature.

MINUTE

HOUR

OFF TIMER

SET TEMP

MODE

ROOM

TEMP.

SET C LOCK

ON / OFF

On/Off Status Lamp

Display

Operation Mode

Display

Displays the current

mode of operation.

AUTO

MON TUE WED THU FRI SAT SUN

Error Display

KEY LOCK

Fan Speed Display

Displays the fan speed

setting.

(Auto/High/Medium/Low)

SLEEP

SWING

COOL

TEMP.

COOLAUTODRY FANHEAT

Swing Display

Display the air swing

status.

Sleep Display

Display the sleep /

energy saving status.

Netware III

10

DAYHOLD

CLOCK

HOUR

ON TIMERSWING

SLEEP

OFF TIMER

MODE

MINUTE

SET TEMP

ON / OFF

FAN

MON TUE WED THU FRI SAT SUN

SET TIMER

AUTO

TIMER ACTIVE

KEY LOCK

ROOM

TEMP.

HEAT

TEMP.

COOL

TEMP.

AUTO

SET CLOCK

DRY HEATCOOL SWING

SLEEP

On / Off

Starting operation:

When the unit is off, press

the ON/OFF button. The

operation LED lights and

the unit will be turned on.

Stopping operation:

When the unit is on, press

the ON/OFF button. The

operation LED is

extinguished and controls

are turned off.

Set Temperature

Press this button to set

the temperature. By

pressing up or down once,

temperature changes by

1°C (or 1°F).

The temperature range is

16°C to 30°F (60°F to

85°F).

In FAN mode,

temperature cannot be

set.

Pressing up and down

buttons simultaneously

will toggle the temperature

unit between °C and °F.

When set temperature

button is pressed, the set

temperature will be

displayed for 5 seconds.

After that, room

temperature will be

displayed.

Operating Lamp

Mode

Press MODE button to

select operation mode from

Cool, Heat, Auto, Dry and

Fan. The display will show

the selected mode.

Swing

Press SWING button to

activate the air sweep

function.

Sleep

Press SLEEP button to

activate the sleep or

energy saving mode.

Fan

Press FAN button to

select Auto, High,

Medium or Low fan

speed.

FAN

11

DAY

CLOCK

HOUR

ON TIMERSWING

SLEEP

OFF TIMER

MODE

MINUTE

SET TEMP

ON / OFF

FAN

MON TUE WED THU FRI SAT SUN

SET TIMER

AUTO

TIMER ACTIVE

KEY LOCK

ROOM

TEMP.

HEAT

TEMP.

COOL

TEMP.

AUTO

SET CLOCK

DRY HEATCOOL SWING

SLEEP

Key Lock

Operating Lamp

FAN

Current Time DisplayTimer Active Display

– This feature protects the

controls from being

tempered with by children or

unauthorized persons.

– To activate, press MINUTE

button three times consecu-

tively, “KEY LOCK” symbol

will appear on the LCD

display.

– During this time, ON/OFF

button and FAN button can

be used.

– To cancel this feature, press

the MINUTE button again

three times consecutively.

When the control is in set clock

or set timer mode, pressing the

MINUTE button will change the

set minute.

Minute

When the control is in set clock

or set timer mode, pressing the

HOUR button will change the

set hour.

Hour

When the control is in set clock

or set timer mode, pressing the

DAY button will change the set

hour.

– Press button once to set the clock mode.

– Press button again to disable the clock mode.

– When the clock mode is activated, the time and date can be

set or changed by pressing ther DAY, HOUR & MINUTE button.

Day

Clock

– Press button until “TIMER ACTIVE” appears to activate the timer.

– The symbol will indicate Event 1, Event 2 and/or Event 3 timers

are active.

– To clear the timer setting, press and hold TIMER ACTIVE button

for 2 to 3 second until the word “TIMER ACTIVE” is no longer

display.

–To resume the timer setting after the timer has been deactivated,

press and hold TIMER ACTIVE button again for 2 to 3 seconds

until the word “TIMER ACTIVE” is displayed.

Timer Active

TIMER ACTIVE

12

Operating State and Fault Table

Wired Handset – Netware III

Cooling / Heat Pump Model

Phase Sequencer

The unit with Scroll Compressor can only rotate in one direction. For this reason, a protective device (phase

sequencer) is fitted to prevent incorrect wiring of the electrical phases. When the three phases are not

connected correctly, the phase sequencer operates, and the unit will not start. This devise is located in the

control box of the outdoor unit.

The following table shows the LED indicator light for phase sequencer under normal operation and fault

conditions.

Room sensor open or short

Indoor coil sensor open

Outdoor coil sensor open

Compressor overload / Indoor or

outdoor coil sensor short

Error Code

Event

Blink E1

Blink E2

Blink E3

Blink E4

Notes: 1. “-“ means LED off.

2. When R phase missing, no LED or buzzer will indicate the error, but relay 71

(Common) and 81 (NO) will cut off.

3. The unit will check the discharge sensor availability only during power up.

4. All errors can only recover through manually reset.

Normal Operation On - - -

Reverse Phase Blink Blink Blink Blink

S & T Phase Missing Blink - Blink Blink

T Phase Missing Blink - - Blink

S Phase Missing Blink - Blink -

R Phase Missing - - - -

Overload Blink - - -

Sensor Missing Blink On On On

LED-P

(Red)

LED-R

(Yellow)

LED-S

(Yellow)

LED-T

(Yellow)

13

Installation

Caution

Sharp edges and coil surfaces are potential injury hazard. Avoid from contact with them.

(1) Installation of Indoor Unit

Preliminary Site Survey

• Electrical supply and installation is to confirm to local authority’s (e.g. National Electrical Board) codes and

regulations.

• Voltage supply fluctuation must not exceed ± 10% of rated voltage. Electricity supply lines must be inde-

pendent of welding transformers which can cause high supply fluctuation.

• Ensure that the location is convenient for wiring, piping and drainage.

Standard Mounting

Ensure that the overhead supports are strong enough to hold the weight of the unit. Position the hanger

rods and check for its alignment with the unit. Also, check that the hangers are secured and the base of the

fan coil unit is leveled in both horizontal directions, taking into account the gradient for drainage flow as

recommended in Figure A.

10.0

The indoor unit must be installed such that there is no short circuit of the cool discharge. Comply with the

installation clearance recommended as shown in Figure B. Do not put the indoor unit where there is direct

sunlight on the unit. Make sure the location is suitable for piping and drainage.

Figure B

Figure A

800.0 800.0

800.0

14

Pipings

Do not use contaminated or damaged copper tubings. If pipings, evaporator or condenser is exposed or had

been opened for 15 seconds or more, vacuum and purge with eld supplied refrigerant. Generally, do not

remove plastic, rubber plugs or caps from ttings, tubings and coils until ready to connect suction or liquid

line into ttings.

For ACC 75/100D/DR, the piping connections are brazing type. If any brazing work is required, ensure that

nitrogen gas is passed through coil and joints while brazing work is being done. This will eliminate soot

formation on the inside walls of copper tubings.

Electrical Connection

As wiring regulations differ from each country, please refer to your LOCAL ELECTRICAL CODES for eld

wiring regulations and ensure that they are complied with. Besides, take note of the following general

precautions:

1. Ensure that the rated voltage of the unit correspond to the name plate before commencing wiring work.

2. Provide a power outlet to be used exclusively for each unit and a power supply disconnect and a circuit

breaker for over-current protection should be provided in the exclusive line.

3. The unit must be EARTHED to prevent possible hazards due to insulation failure.

4. All wiring must be rmly connected.

5. Electrical wiring must not touch the refrigerant piping, compressor and any moving parts of the fan motor.

Operational Check

After all wiring is completed and system is charged with refrigerant, make sure unit is operating properly.

Check that:

1. Condenser fans are running with warm air blowing off the condenser coil.

2. Evaporator fans are running and discharging cool air.

3. Suction line pressures and condensing pressures are in the range of 60 – 75 psig. and 260 – 300 psig.

respectively in cooling cycle or 45 – 60 psig. and 245 – 285 psig. respectively in heating cycle.

4. Microprocessor electronic thermostats as used in the remote controls incorporate a 3 minutes delay in

their circuit. Thus it requires about 3 minutes upon start-up before the outdoor unit is activated.

15

(2) Installation of Outdoor Unit

AMC Series

As condensing temperature rises, evaporating temperature rises and cooling capacity drops. In order to achieve

maximum cooling capacity, the location selected for outdoor unit should fulll the following requirements:

• Install the condensing (outdoor) unit in a way such that hot air distributed by the outdoor condensing unit

cannot be drawn in again (as in the case of short circuit of hot discharge air). Allow sufcient space for main-

tenance around the unit

• Ensure that there is no obstruction of air ow into or out of the unit. Remove obstacles which block air intake

or discharge.

• The location must be well ventilated, so that the unit can draw and distribute plenty of air thus lowering the

condensing temperature.

• A place capable of bearing the weight of the outdoor unit and isolating noise and vibration.

• A place protected from direct sunlight. Otherwise use an awning for protection, if necessary.

• A place where the hot air discharge and operating sound level will not annoy the neighbours.

• The location must not be susceptible to dust or oil mist.

Installation Clearance

• Outdoor units must be installed such that there is no short circuit of the hot discharge air or obstruction to

smooth air ow.

CAUTION : If the condensing unit is operated in an atmosphere containing oils (including machine

oils), salt (coastal area), sulphide gas (near hot spring, oil renery plant), such substances may lead

to failure of the unit.

2000mm

1000mm

300mm

300mm

300mm

16

(3) Refrigerant Piping

Field Piping

To ensure satisfactory operation and performance, the following points should be noted for the eld piping

arrangements of the complete refrigerant cycle.

a) Liquid loops or oil traps must be provided according to the position of the outdoor and indoor units (depend-

ing on whether the indoor unit is above or below the outdoor unit).

b) Field supplied lter dryer should be provided as close to the expansion valve(s) of the indoor unit

(evaporator) as possible.

c) Field supplied sight glass must be assembled and mounted next to lter dryer.

Maximum Piping Length and Maximum Number of Bends

When the pipe length becomes too long, both the capacity and reliability drop. As the number of bends

increases, system piping resistance to the refrigerant ow increases, thus lowering the cooling capacity,

and as the result the compressor may become defective. Always choose the shortest path and follow the

recommendation as tabulated below:

Model

Indoor

Outdoor

ACC 75/100 D/DR

AMC/A4MC

75/100 D/DE

Maximum Length, m 35

Maximum Elevation, m 20

Maximum No. of Bends 8

CAUTION:

1) Our guarantee on the performance of our air-conditioners is strictly revoked if the height, length

and/or the number of bends of the refrigerant piping system installed is beyond the limit above.

2) Bendings must be carefully made so as not to crush the pipe. Use a pipe bender to bend a pipe as

far possible.

(4) Vacuuming and Charging

The pre-charged outdoor unit does not need any vacuuming or charging. However once it is connected, the

connecting pipe line and the indoor unit need to be vacuumed before releasing the R22/R407C from the out-

door unit.

1. Open the service port core cap.

2. Connect pressure gauge to the service port.

3. Connect the line to vacuum pump. Open the charging manifold valve and turn the pump on. Vacuum to -0.1

MPa (-760mmHg) or lower. (Evacuation time varies by the pump but averagely in 1 hour).

CAUTION FOR R407C

Do not top-up when servicing leak, as this will reduce the unit performance. Vacuum the unit

thoroughly and then charge the unit with fresh R407C according to the amount recommended

in the specication.

17

Guidelines Of Field-charging Air Conditioning Systems With Scroll Compressors

These guidelines are intended for use with Scroll compressors only with R22, R407C, R134a, R404A, R507,

and R410A refrigerants. They do not apply to reciprocating compressors or competitive Scroll compressors.

Field-charging - Some Precaution Points

Scroll compressors have a very high volumetric efciency and quickly pump a deep vacuum if there is

insufcient refrigerant in the system or if refrigerant is added too slowly. Operation with low suction pressure

will quickly lead to very high discharge temperatures. While this process is happening, the scrolls are not being

well lubricated - scrolls depend on the oil mist in the refrigerant for lubrication. A lack of lubrication leads to high

friction between the scroll anks and tips and generates additional heat. The combination of heat of compres-

sion and heat from increased friction is concentrated in a small localized discharge area where temperatures

can quickly rise to more than 300°C. These extreme temperatures damage the Scroll spirals and the orbiting

Scroll bearing. This damage can occur in less than one minute especially on larger compressors. Failure may

occur in the rst few hours or the damage done during eld charging may show up some time later.

Other typical eld charging problems include undercharging, overcharging, moisture or air in the system etc.

In time each one of these problems can cause compressor failure.

Equipment

Minimal equipment is required for eld charging. The minimum equipment required to do a satisfactory job is:-

Set of service gauges

Hoses

Vacuum pump

Vacuum gauge

Scales

Thermometer

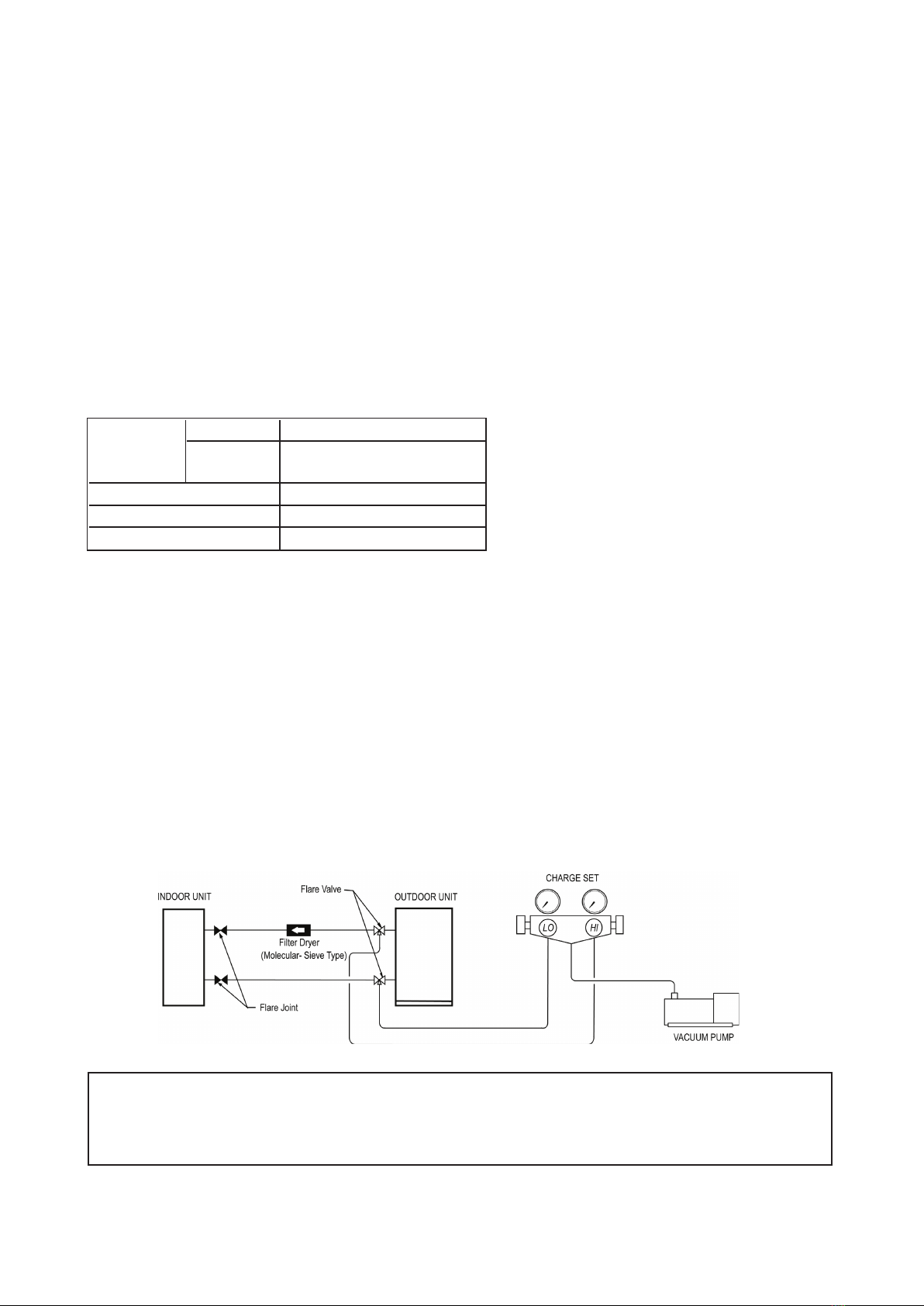

Charging Hoses

Most eld-charging is done using standard service hoses. Hoses are made in different colors with

different working pressures and with different leak rates but the most important point is the presence or

absence of Shredder valve depressors. Shredder valve depressors severely restrict the ow through the

service hoses. This slows evacuation and vapor charging dramatically. In most cases the Shredder depressor

can be removed but it is simpler to have one set of hoses with and one set without Shredder depressors.

Hose with Shredder valve Depressor Hose without Shredder valve Depressor

Hose selection is important depending whether the system is being evacuated or charged. Charging liquid

from the cylinder into the liquid line should be carried out using an open hose connected to an unrestricted

tting. This will reduce charging time.

18

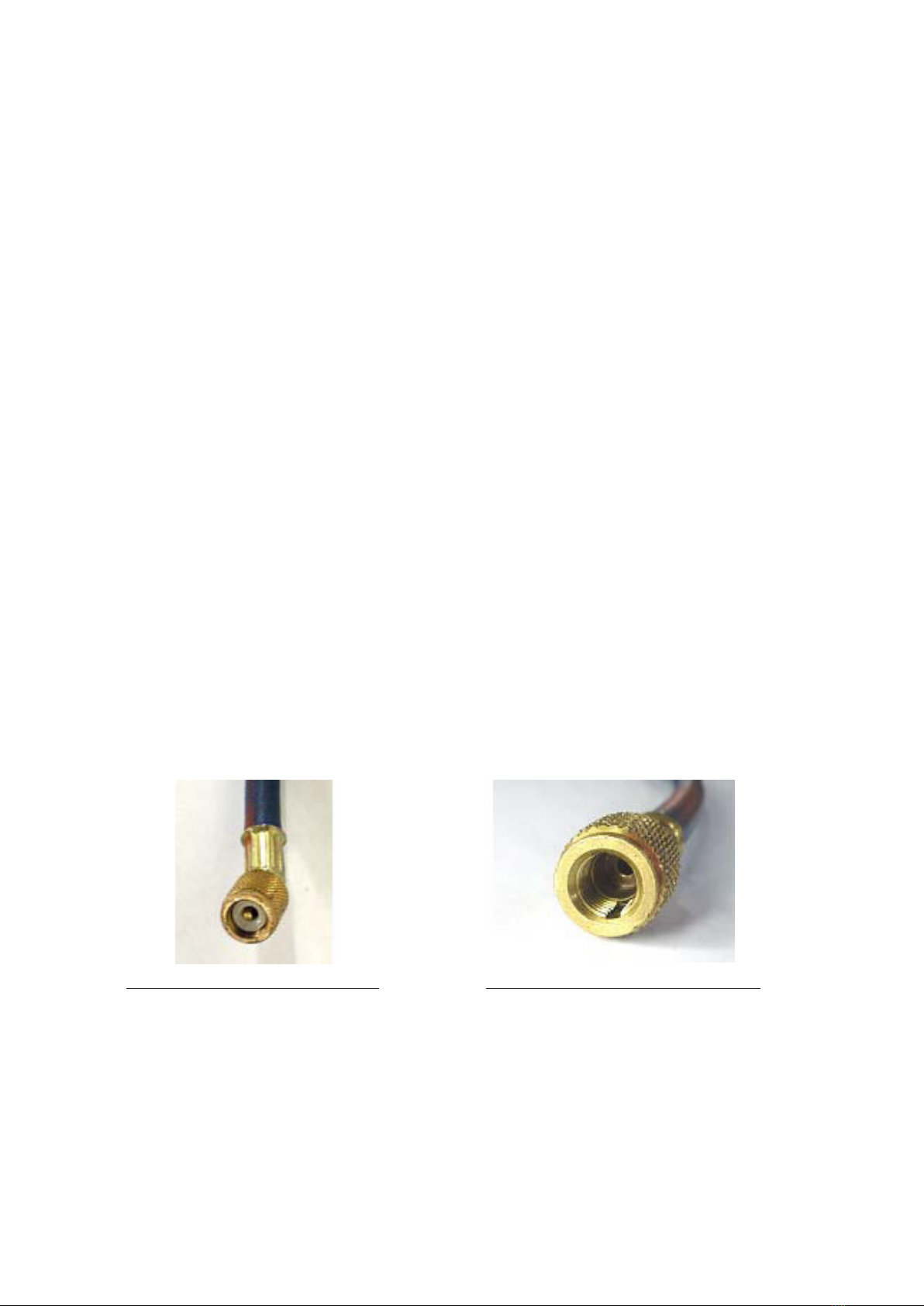

Typical service valves

Found on the outdoor unit

Most split systems have a suitable connection on the outdoor unit

Shredder valves provide easy system access for pressure reading and addition of refrigerant. On small sys-

tems, they provide a reasonable connection for evacuation also. However, Shredder valves and the hoses

connected to them can cause very severe pressure drops and can multiply evacuation time by a factor of 4

or 5.

On the positive side, Shredder valves provide a restriction that slows the speed of liquid charging into the

suction side. When a pressure drop is desirable (charging liquid into suction), connect via a Shredder valve.

When a pressure drop is detrimental (evacuation), connect via an open tting.

How Much Refrigerant?

The proper refrigerant charge should follow the volume as recommended by manufacturer and

recommendation should be followed by the installer. Refer to the table of Refrigerant Charge Level.

If the installer cannot nd the correct charge but the system must be started, refrigerant should be

carefully added to the system until reasonable sub-cooling is measured in the liquid line and reasonable

suction superheat is measured at the compressor suction. Suction and discharge pressures must be moni-

tored carefully during the charging process.

Charge Limits

Copeland Scroll compressors have the different charge limits for different compressor models as shown in

table below. If the total charge exceeds these limits, the system should have a crankcase heater and/or pump

down cycle and/or accumulator to prevent liquid damage to the compressor. Some systems may require ac-

cumulators to limit liquid oodback even though the charge is lower than the published limit.

Shredder core

Shredder valves

Shredder valve

with core in place

Shredder valve with core removed

Compressor Range Model Ibs. kg.

Quest ZR46 to ZR81 10 4.5

Summit ZR84 to ZR144 16 7.3

Specter ZR90 to ZR19M 17 7.7

This manual suits for next models

14

Table of contents

Other Acson Inverter manuals