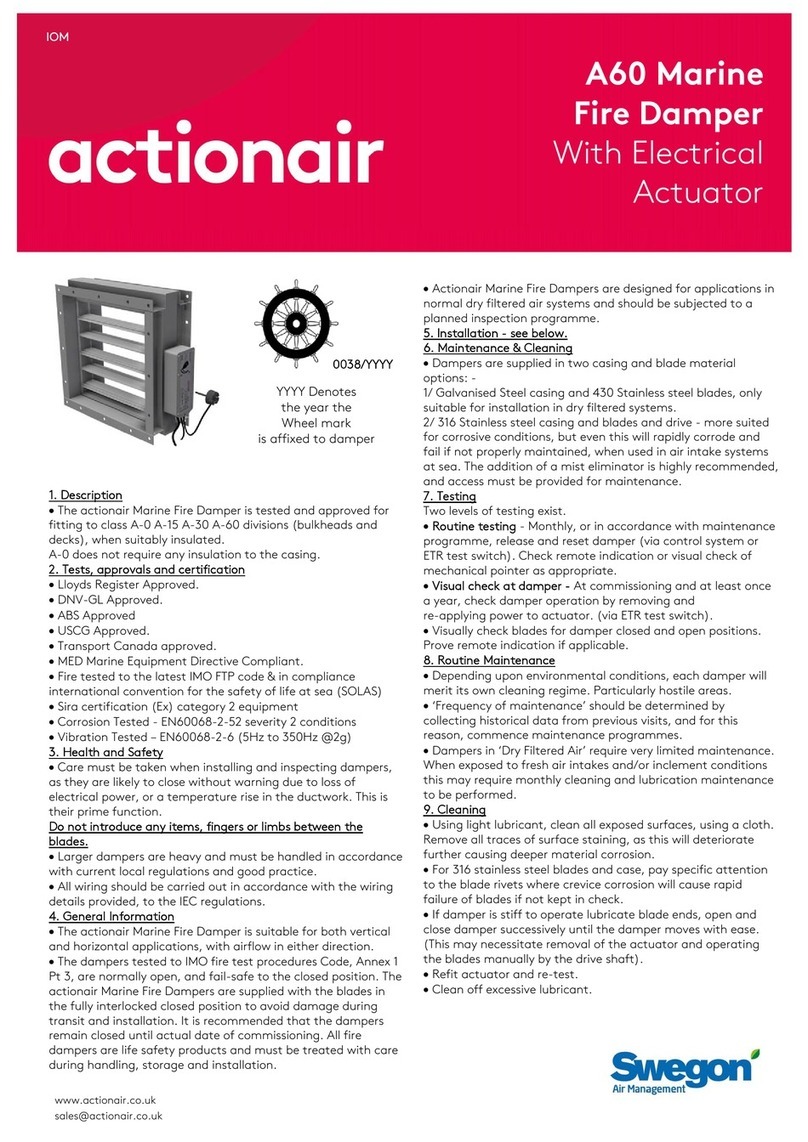

actionair SmokeShield PTC Assembly instructions

Smoke Shield PTC - 'E S' RATED FIRE DAMPER (Fire & Smoke barrier)

Installation, Operating & Maintenance Instructions

www.actionair.co.uk

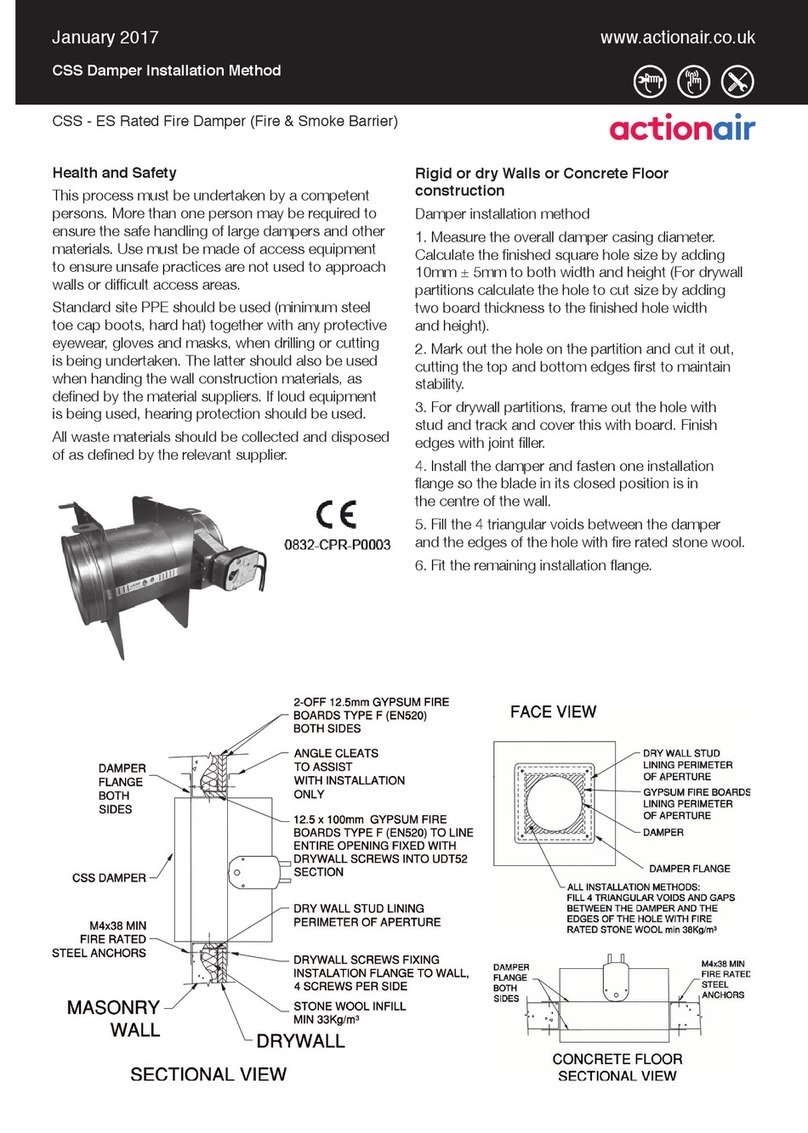

For clarity, damper not shown installed in

supporting wall construction, please refer

to the Actionair approved Fire and Smoke

Dampers Installation Manual. The latest

version can be found on our website:

www.actionair.co.uk

Health and Safety

All wiring should be carried out in accordance with the wiring details provided, the IEE and BS regulations, by a competent person.

Care must be taken when installing and inspecting dampers, as they are likely to close without warning due to loss of electrical

power, or a temperature rise in the ductwork. This is their prime function.

Do not introduce any items, fingers or limbs between the blades.

Larger dampers are heavy and must be handled in accordance with current regulations and good practice.

July 2013 SmokeShield PTC Damper Control Modes

Control Mode Installation Procedure

Remove transit plate and recycle.

Slide the interface and mode assembly into the shroud, ensuring that the

slots in the interface casing and the drive coupling, located on the rear of the

interface, are in line.

Push the assembly fully home until the interface sprung retaining pin

engages through the locating hole in the damper shroud (snaplock™).

The control mode can be fitted in any of three orientations i.e. Vertically

down, Horizontally and Vertically up, if you have an space restrictions. This

can easily be carried out by;

Remove and retain the screw (8mm A/F) and washer, through the

position indicator on the control mode.

Remove the control mode and location plate.

Taking care not to disturb the drive hexagon, replace the location

plate, and control mode in the new orientation.

Replace the washer and screw tight (Max 5Nm)

Select a suitable position for the Electrical Thermal Release (ETR)

to be mounted through the ductwork. Ideally this should be in the top half of

the duct and/or above the level of the interface.

Apply the self-adhesive template (located on the rear of the ETR) and drill

the necessary holes (Ø3mm & Ø9.5...Ø11mm).

Push the ETR through the duct and ensure that both screws are used to

hold it in position. Both screws should be tightened fully to ensure that both

sections of the ETR are closed together. This is a safety feature and should

both sections not be closed the unit will not operate.

For ductless installations the ETR should be fitted onto the damper spigot

(not casing) above the damper interface shroud, and in accordance with the

fitting instructions.

If the ETR is not fitted in the exact manner described above, the unit

will not operate.

The damper should be manually reset and released using the winder

provided, to ensure that correct mechanical operation is achievable.

It is possible to mechanically lock open the SmokeShield PTC damper to

allow air to pass through it by using the winder provided. This may be

necessary if electrical power is not yet available. However, the ETR is not

operable in this instance and the damper will not release automatically

should the temperature rise or a fire occur.

The unit must be wired as detailed.

When power is available, the unit must be checked for correct

electrical operation. Power on to reset, power off to release.

The unit must also be checked by pushing and holding the test switch on the

ETR to confirm that the damper releases. When pressure is removed from

the switch, the damper resets. This may also be done after the initial

installation test, to provide periodic operation of the damper to simulate

actual fail-safe release under smoke/fire conditions.

The ETR cable must not cut to shorten or lengthen, and care must be taken

not to damage it. Either will render the unit inoperable and void any

warranties. This is due to a built in safety feature.

0832-CPR-P0002

General

One metre of halogen free low smoke and fume electric cable is fitted to each control mode for convenience of onsite wiring. This provides

the distinct safety advantage of all electrics terminating outside the duct, eliminating potential in-duct fire hazards from wiring faults. The

Electrical Thermal Release is prewired with 0.5m halogen free low smoke and fume cabling to Control Modes 5 and 6.

A Manual test switch fitted on the ETR allows

p

eriodic o

p

eration of dam

p

er

,

simulatin

g

actual fail-safe release under smoke/fire conditions.

Control Mode Wiring Procedure

If integrating this unit with an Actionpac damper control system (LNS, EMS or EMB) please refer to the relevant catalogue and specific

project details.

WHITE (2)

BLACK (1)

1

2

3

4

5

6

_

+

SUPPLY 24V A.C. or D.C.

TYPICALLY 10W (MOTORING

2W (RESET)

COMMON

CONTINUITY WITH 'COMMON'

WHEN DAMPER CLOSED

COMMON

VOLT FREE CONTACT

MADE BETWEEN 1 & 2

WHEN DAMPER

FULLY RELEASED

VOLT FREE CONTACT

MADE BETWEEN 4 & 6

WHEN DAMPER

FULLY RESET

M

AC/DC 24V

50 / 60 Hz

12.5 VA

10 / 2 W

Imax

8.3A @ 5ms

-30°C...+50°C

CONTINUOUS

Smoke Shield Mode 5 PTC

(24V System)

Supply on - Damper motors open

Supply off - Damper spring close

Electrical thermal release (ETR)

(Must be fitted to ducting for

damper operation)

Spring close time ˜ 22 seconds

Motor open time ˜ 60 seconds

(Connect 24V via a safety

isolating transformer.)

IP54 rated

Smoke Shield Mode 6 PTC

(230V System)

Supply on - Damper motors open

Supply off - Damper spring close

Electrical thermal release (ETR)

(Must be fitted to ducting for

damper operation)

Spring close time ˜ 22 seconds

Motor open time ˜ 60 seconds

(To isolate from main power

supply, the system must

incorporate a devise which

disconnects the phase

conductors, with at least 3mm

contact gap)

120V A.C. version available

IP54 rated

ELECTRICAL THERMAL RELEASE (ETR)

(MUST BE FITTED TO DUCTING FOR

DAMPER OPERATION).

(SPRING BIASED TEST SWITCH)

TF 72°C

AC

250V

6(3)A

BROWN

BLUE

1

2

3

4

5

6

L1

SUPPLY 230V AC 50/60Hz

TYPICALLY 12W (MOTORING

4W (RESET)

COMMON

COMMON

VOLT FREE CONTACT

MADE BETWEEN 1 & 2

WHEN DAMPER

FULLY RELEASED

VOLT FREE CONTACT

MADE BETWEEN 4 & 6

WHEN DAMPER

FULLY RESET

M

AC/DC 24V

50 / 60 Hz

14 VA

12 / 4 W

-30°C...+50°C

CONTINUOUS ELECTRICAL THERMAL RELEASE (ETR)

(MUST BE FITTED TO DUCTING FOR

DAMPER OPERATION).

(SPRING BIASED TEST SWITCH)

TF 72°C

AC

250V

6(3)A

N

CONTINUITY WITH 'COMMON'

WHEN DAMPER OPEN

CONTINUITY WITH 'COMMON'

WHEN DAMPER CLOSED

CONTINUITY WITH 'COMMON'

WHEN DAMPER OPEN

CONTINUITY WITH 'COMMON'

WHEN DAMPER CLOSED

CONTINUITY WITH 'COMMON'

WHEN DAMPER OPEN

CONTINUITY WITH 'COMMON'

WHEN DAMPER CLOSED

CONTINUITY WITH 'COMMON'

WHEN DAMPER OPEN

Smoke Shield Mode 5-3P PTC

(24V System)

Supply on - Damper motors open

Supply off - Damper spring close

The M5-3P-1 is controlled by a

standard 0...10V control signal.

The actuator motors to the

position specified by the control

signal. If the ETR is activated,

power supply lost or removed the

device springs the damper to the

fail-safe position.

Electrical thermal release (ETR)

(Must be fitted to ducting for

damper operation)

Spring close time ˜ 16 seconds

Motor open time ˜ 120 seconds

The SiHF connecting cable

needs to be protected from sharp

edges.

(Connect 24V via a safety

isolating transformer.)

IP54 rated

1

2

3

4

5

6

COMMON

COMMON

VOLT FREE CONTACT

MADE BETWEEN 1 & 2

WHEN DAMPER

FULLY RELEASED

VOLT FREE CONTACT

MADE BETWEEN 4 & 6

WHEN DAMPER

FULLY RESET

ELECTRICAL THERMAL RELEASE (ETR)

(MUST BE FITTED TO DUCTING FOR

DAMPER OPERATION).

(SPRING BIASED TEST SWITCH)

TF 72°C

AC

250V

6(3)A

CONTINUITY WITH 'COMMON'

WHEN DAMPER CLOSED

CONTINUITY WITH 'COMMON'

WHEN DAMPER OPEN

CONTINUITY WITH 'COMMON'

WHEN DAMPER CLOSED

CONTINUITY WITH 'COMMON'

WHEN DAMPER OPEN

WHITE (5)

WHITE (3) Y DC 0...10V

U DC 2...10V

AC/DC 24V

50 / 60 Hz

9.5 VA

7 / 2.5 W

Imax

8.3A @ 5ms

-30°C...+50°C

CONTINUOUS

MRED (2)

BLACK (1) _

+

SUPPLY 24V A.C. or D.C.

TYPICALLY 6W (MOTORING

2W (HOLDING)

~

T

DIAGRAMS SHOWS ACTUATOR IN FULLY CLOSED STATE

NOTE THAT THE FOR INTERMEDIATE

POSITIONS, NEITHER OF THE

CONDITIONS BELOW WILL BE TRUE.

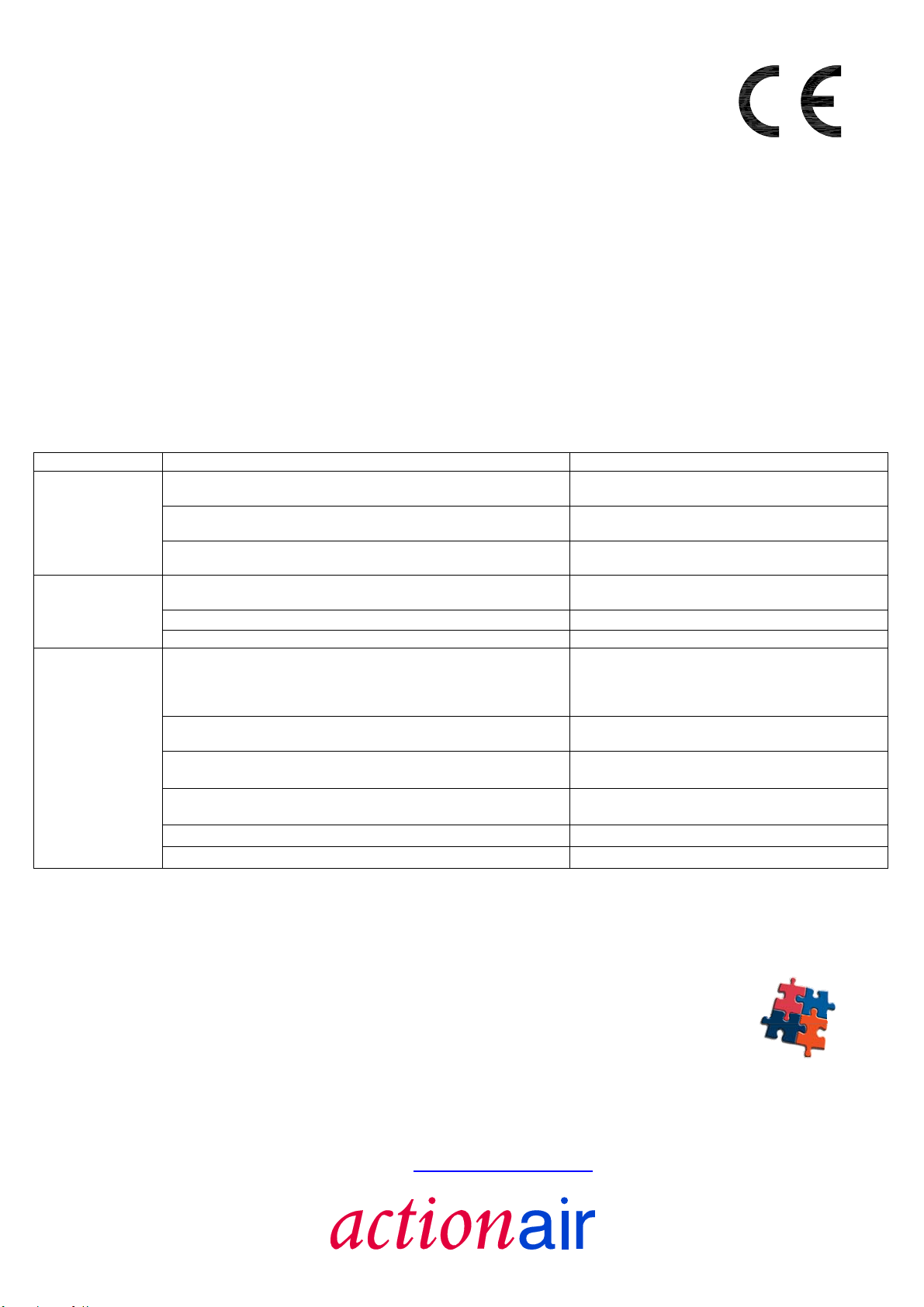

Assessed to ISO 9001:2008

LPCB Cert No. 17

LPS1162 Cert No. 017a

Smoke Shield PTC

product brochure

Please scan

QR code for

smart phone

version.

Ruskin Air Management LTD

Actionair, Whitstable,

Kent CT5 3DU

12

RAM-F-024 A

EN 15650:2010

SMOKE SHIELD PTC

LEAKAGE RATED

SS I/F

E120 (ve ho io)S

SS DWFX-C

SS DWFX-F

SS OSW

E120 (ve io)S

SS S&A

E120 (ve io)S

E120 (ho io)

E90 (ho io)S

Sensing element:

Response temperature: 72°C

Load Bearing capacity: N/A

Closure times

M5 & 6: ~22s (@ tamb = 20°C)

M5-3P: ~16s (@ tamb = 20°C)

Corrosion tested to En 60068-2-52: Pass

Operational reliability:

20,000 cycles: Pass

Ambient leakage test: Pass

LPS 1162: Issue 4

Cert No : 017a / 04

LPCB

0832-CPR-P0002

Troubleshooting

Product Commissioning & Maintenance Available

Below is a quick guide to problems that may be encountered. Please note modifications made to units will invalidate warranties etc

Fault Possible problem Recommended action

Interface Mode

Assembly does

not fit into the

shroud on the

damper.

Damper drive shaft not in line with shroud. Gentle adjustment made by manually setting

blades to fully closed.

Mode not in released position. Release clutch on motor using manual key.

Check the slot on rear of interface.

Slots on the non-access side of the shroud may be blocked

(due to removal of transit plate prior to backfilling). Ensure adequate clearance.

Control mode

does not

operate

electrically.

The ETR is not correctly fitted to duct. Screw fix to duct ensuring both parts of the

ETR are fully together. Do not over tighten.

The mode is incorrectly wired. Check wiring in accordance with procedures.

The ETR cables have been damaged or tampered with. Replace with new mode.

Control Mode

operates, but

limited, or no

movement of

damper blades

is observed.

The mode is not correctly

synchronised with the interface. Remove motor from interface. Check motor in

fully released state. Set position of interface,

and refit motor with label upmost, include

motor location pointer and washer.

The damper is damaged or poorly

installed. New damper or re-install.

Interface not fitted correctly to damper Fit interface correctly, ensure retaining pin

protrudes through location hole in the shroud.

Foreign matter is impeding blade

movement. Check and remove.

Motor location pointer omitted. Fit new pointer.

Mode not screwed down correctly. Check and tighten.

Ruskin Air Management Limited

South Street, Whitstable, Kent

CT5 3DU England.

Tel: 01227 276100

Fax: 01227 264262

Website: www.actionair.co.uk

LNNN00357

(

B

)

0832-CPR-P0002

This manual suits for next models

3

Other actionair Fire And Smoke Damper manuals

Popular Fire And Smoke Damper manuals by other brands

System air

System air fantech bathfan Select SC50-80-110 installation instructions

Greenheck

Greenheck FSD Series Installation instruction supplement

BLAUBERG Ventilatoren

BLAUBERG Ventilatoren BSK quick start guide

Mandik

Mandik SEDM-L manual

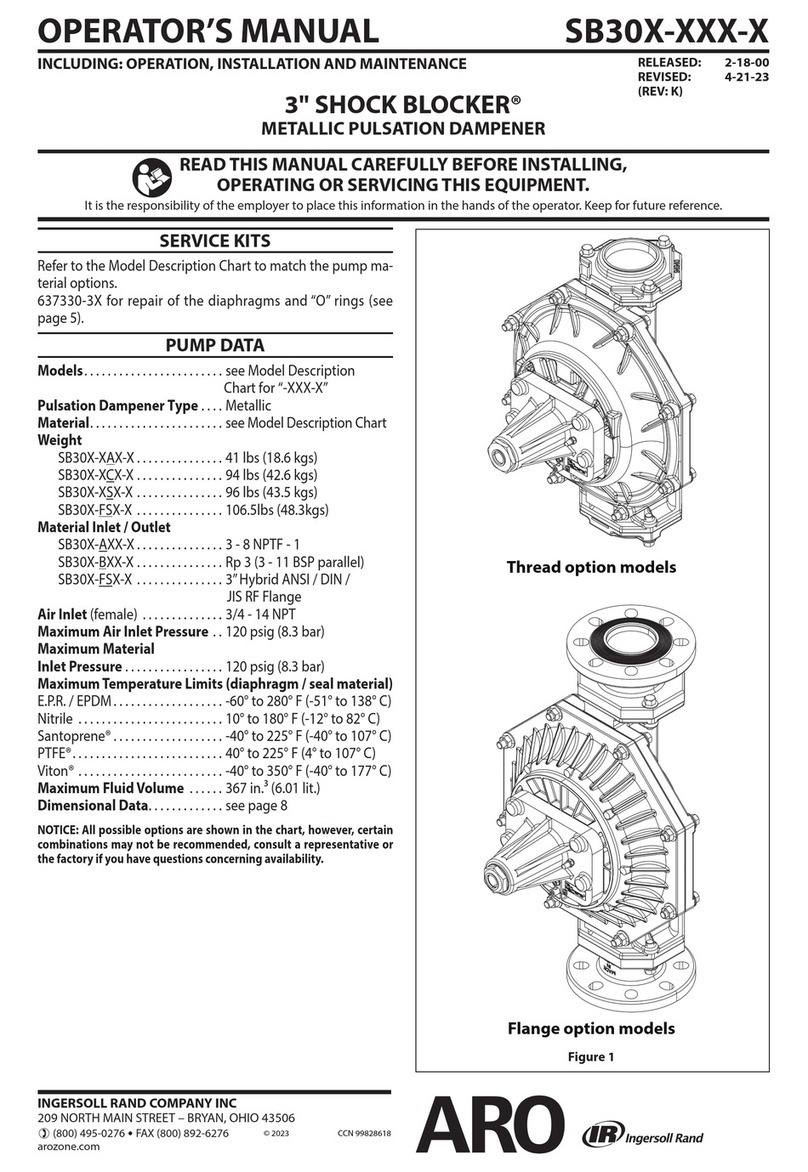

Ingersoll-Rand

Ingersoll-Rand ARO SB30 Series Operator's manual

Wildeboer

Wildeboer FR90 user manual