Page 4 of 8 SB30X-XXX-X (en)

GENERAL DESCRIPTION

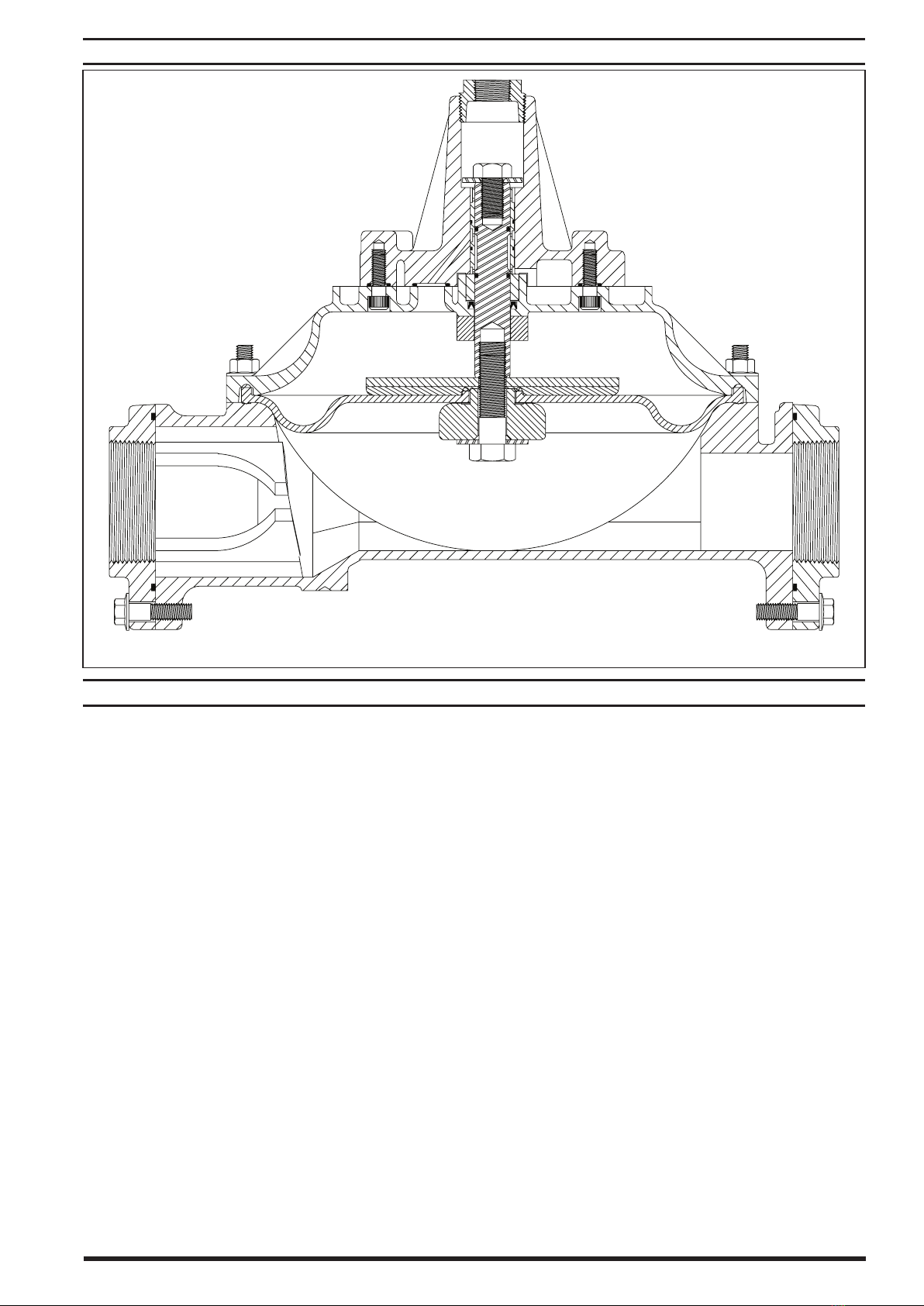

The ARO® shock blocker pulsation dampener is designed

to work with 1:1 ratio pumps having an outlet pressure not

exceeding 120 psi (8.3 bar). The shock blocker will eectively

reduce material pressure variations, surges and shock to pip-

ing and delivery in uid systems during pump reversal. It can

significantly contribute to pulse reduction in low pressure

spray applications.

Accurate selection of wetted material will assure longest ser-

vice life and minimize down time. Several material options

are available for the body and diaphragm materials. Fluid

section materials available include: aluminum, cast iron and

stainless steel. For specific fluid compatibility, consult the

chemical manufacturer.

The shock blocker uses a single air pressurized, flexible di-

aphragm working against the fluid line pressure. Several

diaphragm material options are available to allow custom

matching to the uid material for best compatibility (refer to

the model description chart).

Shock blocker units can also be added in series to provide

additional dampening on the material.

Pressure relief through the exhaust port is a normal compen-

sating function of the control valve in the shock blocker. It

will automatically adjust itself to the required operating pres-

sure once the material pressure has been applied. The pres-

sure supplied to the shock blocker needs to be equal to the

material pressure to provide the proper dampening eect.

AIR AND LUBE REQUIREMENTS

EXCESSIVE AIR PRESSURE. Can cause pulsa-

tion dampener damage, personal injury or property

damage.

yA filter capable of filtering out particles larger than 50

microns should be used on the air supply. There is no lu-

brication required other than the“O”ring lubricant which

is applied during assembly or repair.

yIf lubricated air is present, make sure that it is compatible

with the“O” rings and seals in the air motor section of the

pump.

OPERATION

DO NOT EXCEED 120 PSI (8.3 BAR). Operating

at higher pressure can cause explosion, resulting in prop-

erty damage or severe injury.

yPressure relief through the exhaust port is a normal

compensating function of the control valve in the shock

blocker. It will automatically adjust itself to the required

operating pressure once the material pressure has been

applied.

yOperate the system for a few minutes to equalize air and

uid chambers of the pulsation dampener.

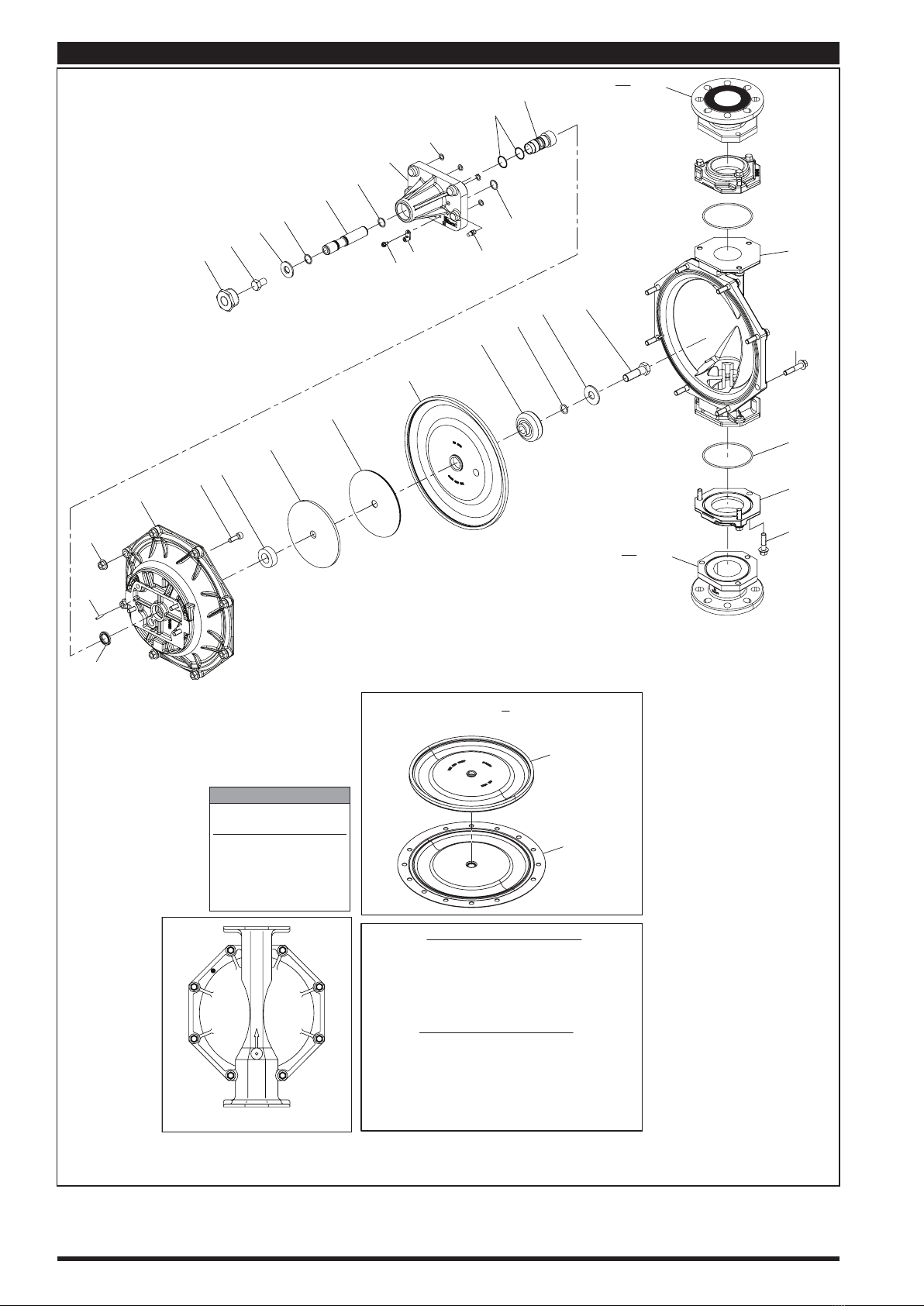

PARTS AND SERVICE KITS

Refer to the part views and descriptions as provided on pag-

es 5 and 6 for parts identication and Service Kit information.

yCertain ARO “Smart Parts” are indicated which should be

available for fast repair and reduction of down time.

MAINTENANCE

yProvide a clean work surface to protect sensitive internal

moving parts from contamination from dirt and foreign

matter during service disassembly and reassembly.

yKeep good records of service activity and include pump

in preventive maintenance program.

yBefore disassembling, empty captured material in the

uid cap by tipping the pulsation dampener on end.

FLUID SECTION DISASSEMBLY

1. Remove (107) reducing bushing.

2. Remove six (26) screws, releasing two (4) anges and (11)

“O”rings.

3. Remove eight (27) screws and (29) nuts, releasing (15)

uid cap.

4. Secure (14) screw in a vise, with (101) air valve body up-

ward.

5. Using a 15/16” socket on (186) screw, unthread and re-

move (186) screw and (9) washer.

6. Remove (68) air cap from (7) diaphragm and compo-

nents.

7. Remove (14) screw from the vise. Unthread and remove

(1) rod, releasing (2) stopper, (5) back-up washer, (7) or (7

and 8) diaphragms, (6) washer and (9) washer from (14)

screw.

8. Remove four (131) screws, releasing (101) air valve body

from the (68) air cap.

9. Remove (144)“U” cup from (68) air cap.

10. Remove (103) sleeve from (101) air valve body.

FLUID SECTION REASSEMBLY

yClean and inspect all parts. Replace worn or damaged

parts with new parts as required. Lubricate all replace-

ment parts and metallic moving parts with Lubriplate®

FML-2 grease upon reassembly.

1. Grease and assemble two (172)“O” rings to (103) sleeve.

2. Assemble (103) sleeve into the (101) air valve body.

3. Grease and assemble (70 and 173) “O” rings to (101) air

valve body.

4. Grease and assemble (144)“U”cup into (68) air cap.

5. Assemble (101) air valve body to (68) air cap.

6. Assemble four (131) screws, securing (68) air cap. NOTE:

Tighten (131) screws to 20 - 30 ft lbs (27.1 - 40.7 Nm).

7. Assemble (9) washer, (6) washer, (7) or (7 and 8) dia-

phragms, (5) back-up washer and (2) stopper to (14)

screw. NOTE: For models with PTFE diaphragms: Item (8)

Santoprene diaphragm is installed with the side marked

“AIR SIDE” towards the pump center body. Install the

PTFE diaphragm (7) with the side marked “FLUID SIDE”

towards the (15) uid cap.

8. Assemble (1) rod to (14) screw.

9. Grease and assemble two (173)“O” rings to (1) rod.

10. Place this assembly into (68) air cap.

11. Assemble (9) washer and (186) screw into (101) air valve

body and thread into (1) rod. Clamp (14) screw in a vise,

with (186) screw upward, and tighten (186) screw to 65 -

70 ft lbs (88.1 - 94.9 Nm).

12. Remove assembly from the vise and assemble to (15)

uid cap, securing with eight (27) screws and (29) nuts.

NOTE: Tighten (27) screws to 60 - 70 ft lbs (81.3 - 94.9

Nm).

13. Grease and assemble two (11)“O” rings to two (4) anges.

14. Assemble two (4) anges to (15) uid cap, securing with

four (26) screws. NOTE: Tighten (26) screws to 60 - 70 ft

lbs (81.3 - 94.9 Nm).

15. Apply Lubriplate FML-2 grease to threads of (101) air

valve body. Apply PTFE tape to threads of (107) reducing

bushing and assemble to (101) air valve body.