actionair Smoke/Shield PTC User manual

August 2004 PTC Dampers

Actionair

Installation and Operating Instructions

Smoke/Shield PTC, Vent/Shield PTC,

Hot/Shield PTC, Smoke/Shield PTC, and

Hot/Shield Vent PTC are all trademarks

of Actionair.

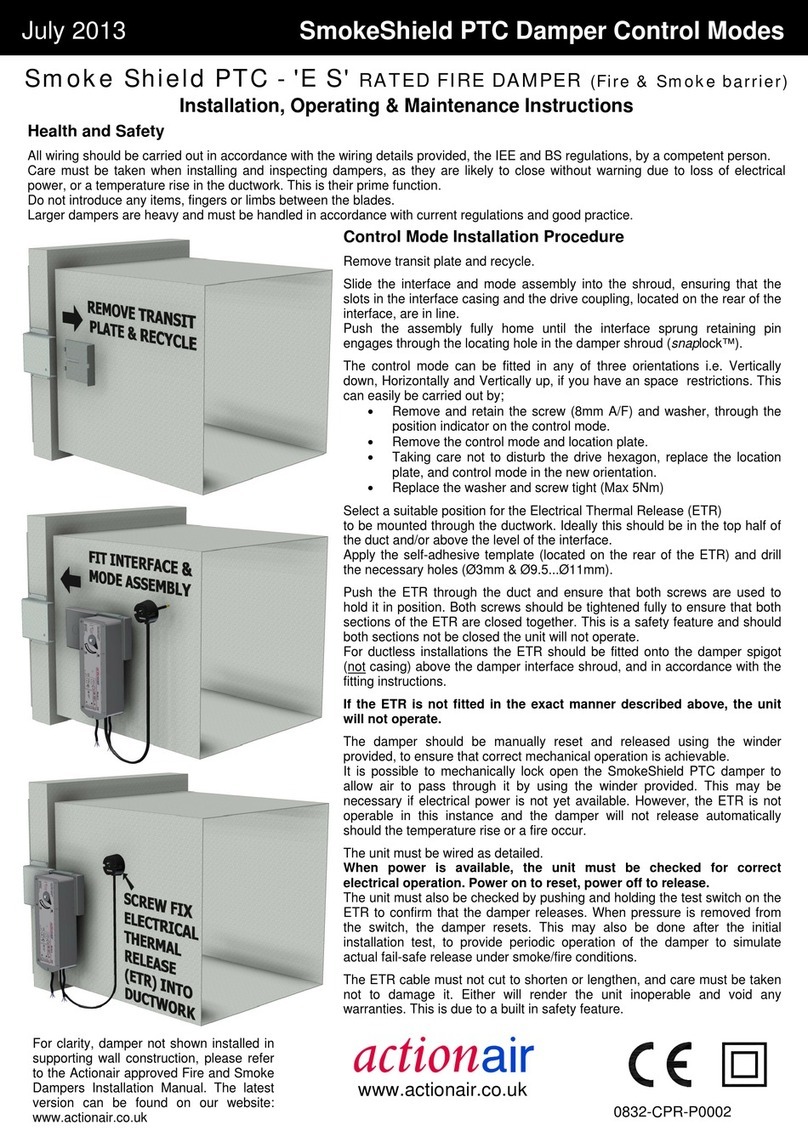

Smoke/Shield PTC

Modes 5 and 6 shown.

Hot/Shield PTC

Modes 5 and 6 shown.

Index

Heath and Safety.

General Information.

PTC Damper Installation. 2

Smoke/Shield PTC

Mode 1 Installation. 3

Smoke/Shield PTC and

Vent/Shield PTC

Modes 5 and 6 Installation. 3

Smoke/Shield PTC and

Vent/Shield PTC Control

Modes Dimensional Data. 4

Smoke/Shield PTC and

Vent/Shield PTC

Application and Wiring. 5

Hot/Shield PTC and

Hot/Shield Vent PTC

Damper Installation and

Dimensional Data.

Application and Wiring. 6

Hot/Shield PTC and

Hot/Shield Vent PTC

Dimensional Data. 7

Hot/Shield PTC and

Hot/Shield Vent PTC

Multiple Assembles 7

Smoke/Shield PTC,

Vent/Shield PTC,

Hot/Shield PTC and

Hot/Shield Vent PTC

Troubleshooting. 8

(Smoke/Shield PTC™ Modes 1,5 & 6

fail-safe spring close with manual or

electrical reset).

(Vent/Shield PTC™ Modes 5 & 6 fail-

safe spring open with manual or

electrical reset).

(Hot/Shield PTC™ Modes 5 & 6 are

operational up to 300 °C for 1 hour

with fail-safe spring closure).

(Hot/Shield Vent PTC™ are

operational up to 300 °C for 1 hour

with fail-safe spring opening).

Smoke/Shield PTC, Vent/Shield PTC,

Hot/Shield PTC, and Hot/Shield Vent PTC

2

All wiring should be carried out in

accordance with the wiring details

provided, the IEE and BS regulations,

by a competent person.

Care must be taken when installing

and inspecting dampers, as they may

close without warning due to a variety

of reasons. Particularly this may be in

the case of loss of electrical power, or

fire signal to temperature rise in the

ductwork. This is their prime function.

Do not introduce any items, fingers or

limbs between the blades.

Prior to handling, check the weight of

the unit and adopt suitable handling

techniques.

PTC Dampers

Health and

Safety

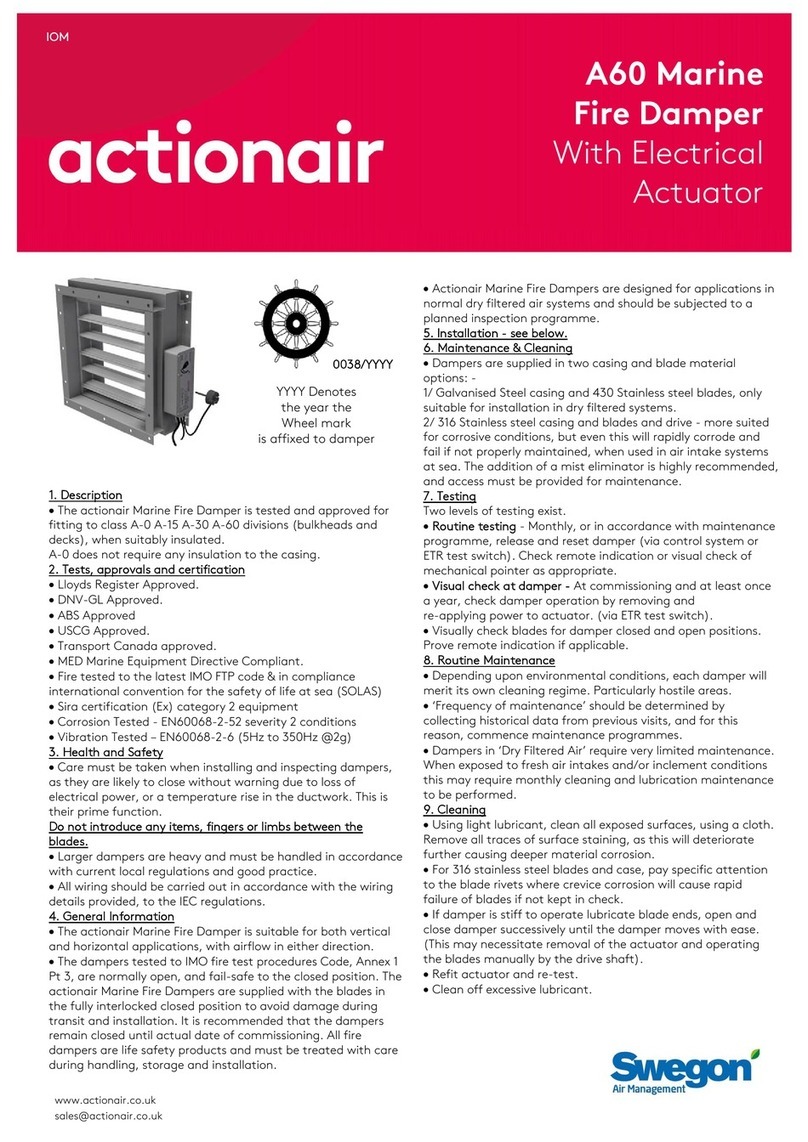

The PTC™range of dampers are

suitable for both horizontal and

vertical applications, for airflow in

either direction.

PTC™dampers to their maximum

width and height dimensions can be

used where the operating total

system pressure is up to 1500 Pa

and duct velocities to 15m/second.

All Smoke/Fire dampers are life safety

products and should be treated with

care during handling, storage and

installation.

PTC™dampers are designed for

applications in normal dry filtered air

systems and should be subject to a

planned inspection programme,

cleaning and light oil lubrication in

accordance with good industry

practice. When exposed to fresh air

intakes and/or inclement conditions

this may need to be performed more

regularly based on experience gained

from previous inspections.

Specialist or aggressive environments

may be unsuitable for this type of

damper. This should have been

checked with the Customer Service

department at the time of order. If

there are concerns this should be

addressed before installation.

For assistance with applications other

than those described please contact

our Customer Service Office.

Please note all installations must be

carried out in accordance with the

approval of the relevant local

authority.

General Information

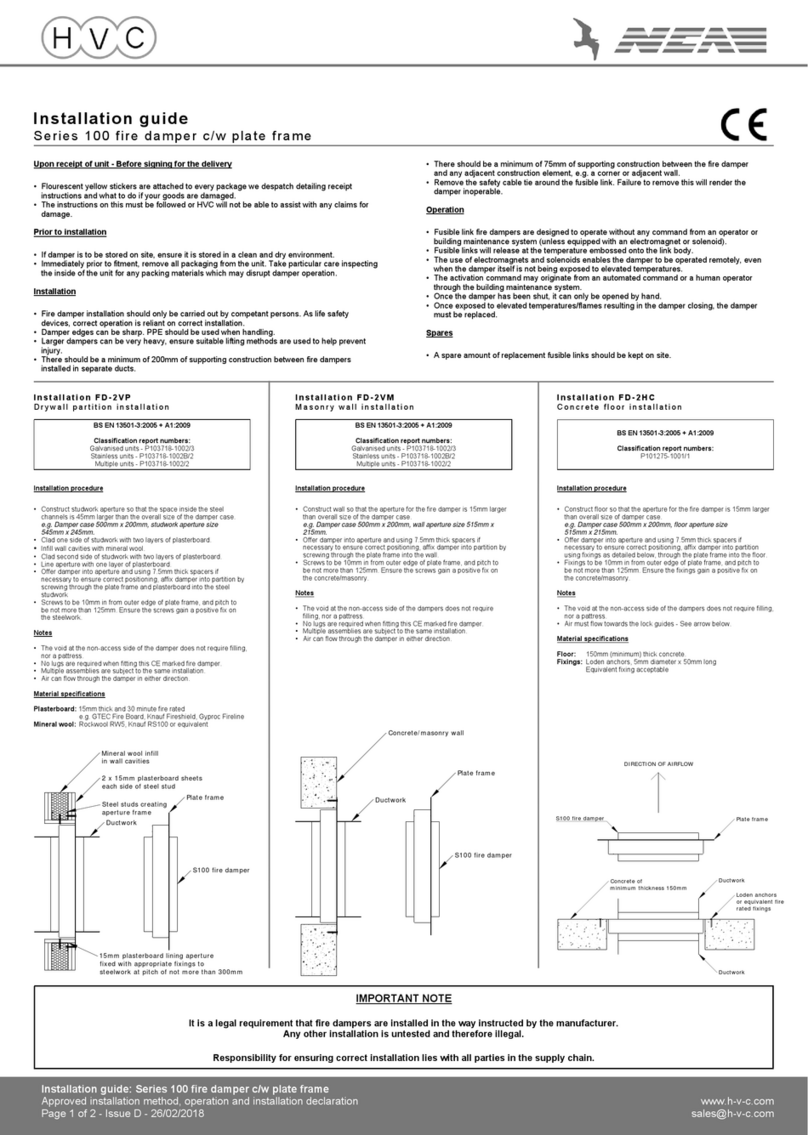

All installations must be made in

accordance with approval of the

relevant local authority and if

HEVAC/HVCA frames have been

supplied, also in accordance with

HEVAC specification HVC 6/5/83,

extracts of which are given below.

Installation frames are delivered to

site as a complete assembly with the

appropriate PTC™damper fitted

therein.

The damper shall be installed

centrally in the thickness of a

brickwork or concrete surrounding

wall or floor, or in the case of thick

walls or floors, so that the centre line

of the frame is at least 50mm, but

not more than 75mm, away from the

nearest face of the wall or floor, in

which the assembly is mounted.

Care must be taken not to backfill

past the line marked on the label

on the shroud. If this does occur

it will inhibit the fitting and

removal of the interface.

(See diagram on the right).

The four tabs (building ties) forming

each fixing point shall provide a

positive fixing into the structure.

In brickwork or blockwork walls the

tabs shall be bent out and solidly

built into the mortar joints between

the brickwork or blockwork.

In the cases of reinforced concrete

walls or floors, the tabs shall be bent

out and tied with wire to the

reinforcing bars, which will be

deliberately left protruding into the

opening.

The gap between the installation

frame and builders work shall be

backfilled with mortar or concrete on

both sides of the flange.

Adjacent frame assemblies must be

separated by builder’s work of a

minimum thickness of 225mm

(between installation frame upstand

flanges unless approval has been

previously obtained from the

appropriate Authority).

In no case shall the HEVAC/HVCA

frame and damper assembly be

held in position merely by the

adjacent ductwork, and it should be

noted that in reinforced concrete

structures (especially floors), it will

not be sufficient to only backfill

between the damper installation

frame and surrounding opening

with mortar or fine aggregate

concrete mix without provision for

tying in the frame to the

surrounding reinforced concrete

structure.

When fitting the ductwork care

must be taken to ensure that the

ductwork is independently

supported and not relying on the

damper as a structural anchor, all

in accordance with Ductwork

Specification DW144. Access

doors should also be fitted as

required by DW144.

For Hot/Shield PTC and

Hot/Shield Vent PTC dampers

fitted to thickened fire rated

ductwork, please refer to notes

on page 7.

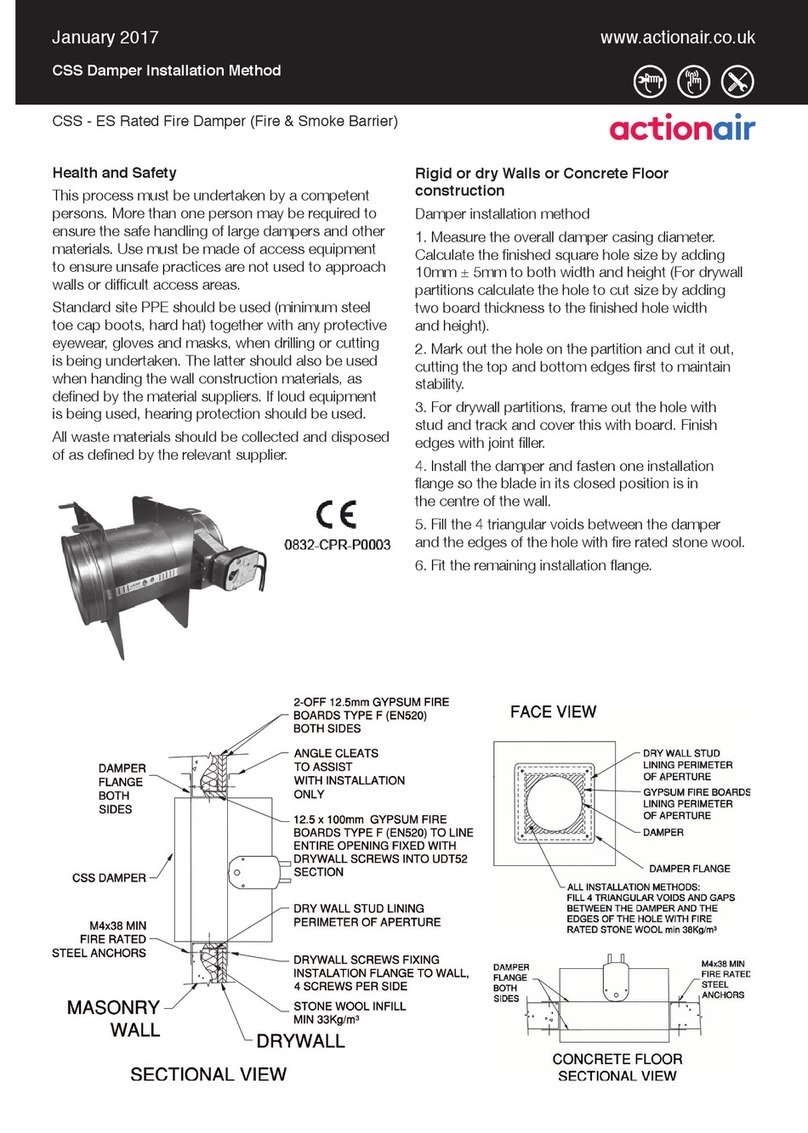

Damper Installation

Backfill

Limit Line

on Label

Damper Drive Shroud

3

Smoke/Shield PTC™

Mode 1 Installation Procedure

315 ±20mm

40 ±*75mm

5mm

130mm

135mm

108

130mm

TOP

*This dimension will vary on circular damper. Select

dimension to give smoothest radius on bowden cable.

1. Prepare ductwork

Prepare ductwork for Mechanical

fusible link as detailed below. (For

ductless installations, a suitable sized

plate or bracket must be fitted to the

installation, to allow the fusible link

fixing details to be achieved).

●Within the Mode 1 kit of parts, is a

self adhesive fusible link drilling

template label.

●This template should be positioned

on the duct in accordance with

the dimensions shown above.

●Using a 3.0mm dia bit, drill 2 fixing

holes.

●Using a 25mm dia hole cutter, drill

the central hole.

●Remove sharp edges.

248

28

56

84 260

100

112

12

108

70 25

130

108

130

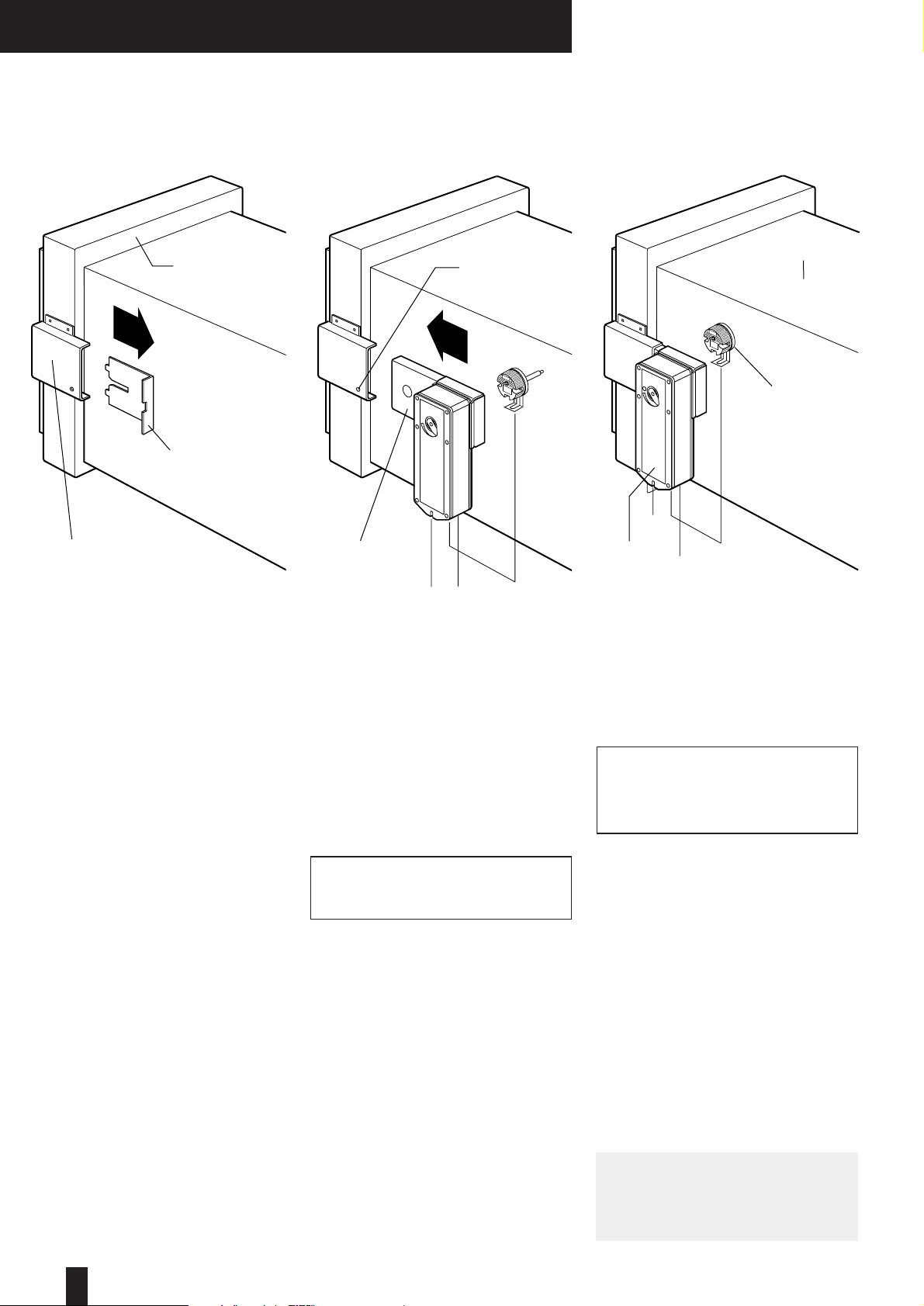

Smoke/Shield PTC™Control Modes

are located outside of the ductwork

for ease of access and installation.

Control Modes 5 and 6 can be fitted

in any one of three orientations i.e.

Vertically down (Position 1)

Horizontally (Position 2), or

Vertically up (Position 3).

This can be simply and easily carried

out on site, by repositioning the

Location Plate and Control Mode on

to the snaplock™Drive Interface.

This flexibility ensures that the

damper and control mode require the

minimal amount of room.

Mode 1 (Smoke/Shield only) Modes 5 and 6 Three position 180°(Pivotable Control Mode)

Control Mode Dimensional Data

2. Fit Control Mode

●Remove transit plate from damper

shroud, and discard.

●Slide the interface and mode

assembly into the shroud, having

ensured that the slots in the

interface case and the drive

coupling are in line.

●Push the assembly fully home until

the spring retaining pin engages

through the location hole in the

shroud (snaplock™).

●(The mode 1 option, unlike the

mode 5/6, does not have the

facility of alternative actuator fixing

positions).

3. Fit Mechanical Fusible Link

●Locate the fusible link assembly in

the prepared hole in duct.

●Using the 2 self tapping screws

provided, secure the assembly.

4. Electrical Connections

●Where use is to be made of the

integral microswitch for indication

purposes, this should be wired as

described in the section

‘Application and wiring’.

5. Reset and Test Unit

●If the mechanical fusible link is

not fitted to the ductwork, it will

not be possible to reset the

unit. – This is a safety feature.

●Using a 14mm A/F spanner, rotate

the input shaft clockwise to reset

the damper.

●NOTE: After resetting, never leave

the spanner attached to the reset

shaft.

●Test unit by simply unscrewing

wing nut of the fusible link

assembly. This will result in the

damper releasing. Check for

damper closure.

FUSIBLE LINK

●Re-tighten the wing nut.

●Using a 14mm A/F spanner, rotate

the input shaft clockwise to reset

the damper.

●Remove spanner.

Note: It will not be possible to reset

the control mode if the fusible link is

not correctly installed.

Control

Mode 5/6

Ductwork

Electrical

Thermal

Release (ETR)

4

Smoke/Shield PTC™Vent/Shield PTC™

Remove transit plate and discard.

Slide the interface and mode

assembly into the shroud, having

ensured that the slots in the interface

case and the drive coupling are in

line.

Push the assembly fully home until

the sprung retaining pin engages

through the location hole in the

shroud (snaplock™). If due to space

restrictions, it is necessary to rotate

the mode through 90°to alternative

position see page 3, this may be

achieved by doing the following:

●Remove the screw (8mm A/F)

through the position indicator on

the mode. Retain the screw and

washer.

●Remove the mode and location

plate.

●Taking care not to disturb the

drive hexagon, replace the location

plate in the new orientation.

●Replace the mode in the new

orientation.

●Replace the washer and screw

tight.

Select a suitable position for the

Electrical Thermal Release (ETR) to

be mounted through the ductwork.

Ideally this should be in the top half

of the duct and/or above the interface.

Apply the self-adhesive template and

drill the necessary holes.

Push the ETR through the duct and

ensure that both screws are used to

hold it into position. Both screws

should be tightened fully to ensure

that both sections of the ETR are

closed up together. This is a safety

feature and should both sections not

be closed the unit will not operate.

If the ETR is not fitted to the

ductwork, the unit will not

operate.

For ductless installations the ETR

should be fitted onto the damper

spigot (not casing) above the damper

shroud, and in accordance with

these fitting instructions.

The damper should be manually

reset and released, using the winder

provided, to ensure that correct

mechanical operation is achievable.

It is possible to mechanically lock

open the Smoke/Shield PTC damper

to allow air to pass through it by

using the winder provided. This may

be necessary if electrical power is not

available. However the ETR is not

operable in this instance and the

damper will not release automatically

should the temperature rise or a fire

occur.

The unit must be wired as described

in Section Application and Wiring

details.

When power is available the unit

must be checked for correct

electrical operation. Power on to

reset, power off to release.

The unit must also be checked by

pushing, and holding, the test switch

on the ETR to confirm that the

damper releases. When pressure is

removed from the switch the damper

will reset. This may also be done

after the initial installation test, to

provide periodic operation of the

damper to simulate actual fail-safe

release under smoke/fire conditions.

The cable connecting the mode and

the ETR must not be shortened and

care should be taken not to damage

it. Shortening and/or damaging the

cable will render the unit inoperable.

This is due to a built in safety feature.

Vent/Shield PTC™dampers and

associated control modes 5 and 6

are reverse acting with spring action

opening.

Mode 5 and 6 Installation Procedure

Snaplock™

Drive Interface

Snaplock™

Retaining Pin

Locating Hole

Transit Plate

Damper Drive

Shroud

Smoke/Vent/

Shield PTC™

Damper

BLACK

GREEN/

YELLOW

BROWN

BLUE

ELECTRICAL THERMAL RELEASE

(SPRING BIASED TEST SWITCH)

ELECTRICAL THERMAL RELEASE

(SPRING BIASED TEST SWITCH)

TF 72 °C

TF 72 °C

2

1

S2

S3

S4

S5

S6

S1

N

E

M

L

VOLT FREE CONTACT

CHANGES OVER WHEN

DAMPER RELEASED

RATED 24V 3A

VOLT FREE CONTACT

CHANGES OVER WHEN

DAMPER RESET

RATED 24V 3A

SUPPLY

24V A.C. OR D.C.

TYPICALLY 7W (MOTORING) 2W (RESET)

COMMON

NORMALLY CLOSED

NORMALLY OPEN

NORMALLY CLOSED

NORMALLY OPEN

COMMON

VOLT FREE CONTACT

CHANGES OVER WHEN

DAMPER RESET

RATED 240V 2A

COMMON

NORMALLY CLOSED

NORMALLY OPEN

2

1

S2

S3

S4

S5

S6

S1

N

M

L

VOLT FREE CONTACT

CHANGES OVER WHEN

DAMPER RELEASED

RATED 240V 3A

VOLT FREE CONTACT

CHANGES OVER WHEN

DAMPER RESET

RATED 240V 3A

SUPPLY

220 - 240V A.C. 50/60Hz

TYPICALLY 8W (MOTORING) 3W (RESET)

COMMON

NORMALLY CLOSED

NORMALLY OPEN

NORMALLY CLOSED

NORMALLY OPEN

COMMON

5

Smoke/Shield PTC™Vent/Shield PTC™

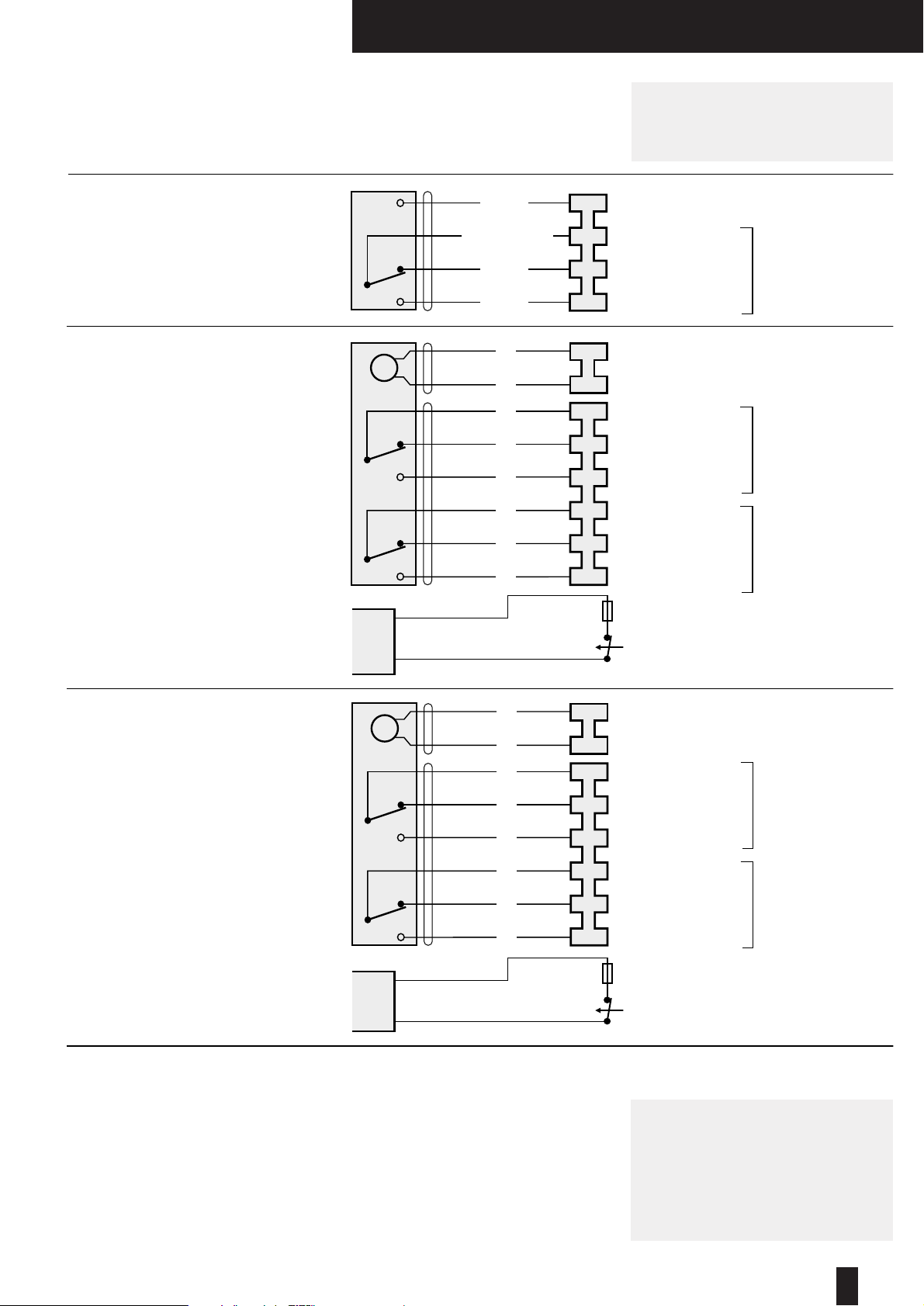

Smoke/Shield PTC

Application and

Wiring

Mode 1 (Manual System)

Manual opening.

Spring instant closure via mechanical

fusible link.

(Smoke/Shield version only, Vent/Shield not available.)

Mode 5 (24V System)

Power On –Damper motors open.

Power Off –Spring closure or via

Electrical Thermal Release.

External mechanical position indicator

with pointer.

Release Time ≈16 secs.

Reset Time ≈ 140 secs.

(Connect 24V via a safety isolating transformer.)

Vent/Shield PTC™dampers and

associated control modes 5 and 6

are reverse acting with spring action

opening.

Mode 6 (230V System)

Power On –Damper motors open.

Power Off –Spring closure or via

Electrical Thermal Release.

External mechanical position indicator

with pointer.

Release Time ≈16 secs.

Reset Time ≈ 1c secs.

(To isolate from main power supply, the system must

incorporate a device which disconnects the phase

conductors, with a least 3mm contact gap.)

General

One metre of halogen free low smoke

and fume electric cable is also

included with each control mode for

convenience of on site wiring. This

also provides the distinct safety

advantage of all electrics terminating

outside the duct, eliminating potential

in-duct fire hazards from wiring faults.

The Electrical Thermal Release is pre-

wired with 0.5m halogen free low

smoke and fume cabling to Control

Modes 5 and 6.

A Manual test switch fitted on the

ETR allows periodic operation of

damper simulating actual fail-safe

release under smoke/fire conditions.

Smoke/Shield and Vent/Shield

PTC™Dampers and associated

Control Modes 5 and 6 are

available without the ETR where

thermal operation is not required.

If integrating this unit with an Actionpac

damper control system (LNS or EM)

please refer to the relevant catalogue

and specific project details.

For non ETR applications refer to

specific product label on Mode, prior

to electrical connections.

BLUE N

L1

BROWN

1

2

3

4

VOLT FREE CONTACT

CLOSED WHEN

DAMPER RELEASED

VOLT FREE CONTACT

CLOSED WHEN

DAMPER RESET

SUPPLY

230V A.C 50/60 Hz

A.C. 230V

50 / 60 Hz

12.5 V A

8 / 3 W

–30...+50 °C

CONTINUOUS

A.C.

250V

6(3)A

M

6

Hot/Shield PTC™Hot/Shield Vent PTC™

Damper

Drive Shroud

Snaplock™

Retaining Pin

Transit

Plate

Ductwork Hot/Shield,

Hot/Shield Vent

Damper

Control Mode 5/6

housed in thermally

insulated enclosure

Dimensional Data

Install the Hot/Shield PTC™Damper

(complete with factory fitted damper

shroud and transit plate) into the

structure, connect and fit ductwork to

damper spigots. Remove transit plate

and discard. Slide the snaplock™

drive interface into the damper drive

shroud, snaplock™into position.

(See page 2.)

(Care must be taken when back filling

to ensure that the snaplock™

retaining pin location hole and the

entry slot of the damper drive shroud

is clear of builders work debris).

The above dimensional data is for

guide/general arrangement purposes.

Please contact our Customer

Service Office for details when

incorporating thickened fire rated

ductwork.

411

421

161

27

191

Damper Installation and Control

Mode Fitting

Series 2501

Hot/Shield PTC Application and Wiring

–

+

1

2

1

2

3

4

VOLT FREE CONTACT

CLOSED WHEN

DAMPER RELEASED

VOLT FREE CONTACT

CLOSED WHEN

DAMPER RESET

A.C./D.C.24V

50 / 60 Hz

10 V A

7/2 W

–30...+50 °C

CONTINUOUS

A.C.

250V

6(3)A

SUPPLY

24V A.C. or D.C.

M

Mode HM5 (24V System)

Power On –Damper motors open.

Power Off –Spring closure.

Cable specification:

Si HF Low Smoke and Fume,

Halogen Free, to IEC 754-1.

Conforming to 73/23/EEC directive.

Release Time ≈16 secs.

Reset Time ≈ 140 secs.

(Connect 24V via a safety isolating transformer.)

Mode HM6 (230V System)

Power On –Damper motors open.

Power Off –Spring closure.

Cable specification:

Si HF Low Smoke and Fume,

Halogen Free, to IEC 754-1.

Conforming to 73/23/EEC directive.

Release Time ≈16 secs.

Reset Time ≈ 140 secs.

(To isolate from main power supply, the system

must incorporate a device which disconnects the

phase conductors, with a least 3mm contact gap.)

Hot/Shield Vent PTC™Dampers and

associated Control Modes are reverse

action with spring operation

7

Hot/Shield PTC™Hot/Shield Vent PTC™

Dimensional Data

The following data is relevant to

square/rectangular dampers Series 2501

and 3501 when incorporating;

STD Standard 1.2mm (approx) sheet

steel ductwork.

THK Thickened fire rated ductwork up to

15mm thick.

(For dimensional data outside of these

parameters, refer to Customer Service

Office).

1. Transformation sections only required

when duct widths and/or heights is less

than 200mm, or if THK thickened fire

rated ductwork is greater than 15mm.

2. The following dampers with duct

widths and/or heights as listed will be

complete with transformation sections:

Duct widths and/or heights between

100mm –175mm, will have nominal

damper size of 200mm. Duct widths

and/or heights between 176mm –200mm,

please refer to Customer Service Office.

3. Dampers with duct widths and/or

heights of between 200mm –1000mm

are supplied as nominal damper sizes and

without transformation sections.

4. Always refer to Customer Service

Office for dimensional data when

incorporation THK thickened fire

rated ductwork, especially when

thicker than 16mm.

The following data is relevant to circular

dampers Series 2601 and 3601 when

incorporating;

STD (Standard 1.2mm (approx) sheet

steel ductwork).

THK (Thickened fire rated ductwork up to

35mm thick) (for dimensional data outside

of these parameters, refer to Customer

Service Office).

5. Transformation sections are always

included.

6. Dampers with duct diameters between

100mm diameter –150mm diameter, will

have nominal damper size of 200mm

diameter. Dampers with duct diameters

between 151mm diameter –982mm

diameter, will have nominal damper size

+50mm. Dampers with a nominal damper

size between 983mm diameter –

1000mm diameter, please refer to

Customer Service Office.

7. Always refer to Customer Service

Office for dimensional data when

incorporation THK thickened fire

rated ductwork, especially when

thicker than 35mm.

100 - 1000

DUCT WIDTH25

25

5025 * DUCT HEIGHT

3838 38

78

90

8357

Series 2501

Hot/Shield PTC™

Series 3501

Hot/Shield Vent PTC™

TRANSFORMATION

SECTION

SQUARE OR

RECTANGULAR

SQUARE OR

RECTANGULAR

100 - 1000

OVERALL WIDTH

OF INSTALLATION

FRAME IS DUCT

WIDTH + 114MM

* DUCT HEIGHT

DAMPER SPIGOTS 5MM

UNDER DUCT SIZE

100 - 1000

DUCT DIAMETER50 50

7550 DUCT DIAMETER

CIRCULAR

90

108

82

Series 2601

Hot/Shield PTC™

Series 3601

Hot/Shield

Vent PTC™

DAMPER CIRCULAR

SPIGOTS 3MM UNDER

DUCT SIZE

100 - 1000

2525

65383865 78

2525 CIRCULAR

OVERALL WIDTH

OF INSTALLATION

FRAME IS DUCT

DIA + 164MM

Series 2501 and 3501 Basic Damper (square/rectangular)

Series 2601 and 3601 Basic Damper (circular)

Multiple Assemblies

as provision for thermal expansion

(4mm/metre) should be allowed for

on multiple assemblies.

When fitted to fire rated

ductwork, please refer to

customer service office. Multiple

assemblies require installation

approval by the relevant local

authority.

Square and rectangular casings are

available in multiple module

arrangements, supplied complete

with blanking strips for site assembly

by others. Additional support as well

Interface Mode Assembly does

not fit into the shroud on the

damper.

SSM1, SSM5, SSM6, HSM5 & HSM6

•Check mode is in released position.

VSM5, VSM6, HSVM5 & HSVM6

•Check mode is in reset position.

•Check damper drive shaft is in line

to shroud, adjustment is made by

manually setting blades to fully

closed.

•The slots on the non-access side

of the shroud may be blocked (due

to removal of transit plate prior to

backfilling) - ensure adequate

clearance.

•Check alignment of drive coupling

slot in interface. If out of line, the

mode output drive is out of

synchronisation with the interface

drive. The mode will require to be

removed, and the refitted correctly

as follows:

SSM5, SSM6, HSM5 & HSM6

Remove mode. (Ensure released.)

Align interface coupling with slot on

interface. Refit mode with product

label uppermost. (Including location

plate and washer.)

VSM5, VSM6, HSVM5, & HSVM6

Remove mode. (Ensure reset.)

Align interface coupling with slot on

interface. Refit mode with product

label uppermost.(Including location

plate and washer.)

Produced by Graphic Partnership www.graphicpartnership.com

PTC Dampers

Troubleshooting

Below is a quick guide to problems that may be encountered. For detailed

actions, reference to the main document is necessary.

Please note modifications made to units will invalidate warranties etc.

Product Commissioning

and Maintenance

Available.

Control Mode (5 and 6) does

not operate electrically.

•The ETL is not correctly fitted to duct.

•The mode is incorrectly wired.

•The ETL cables have been

damaged or tampered with.

Control Mode operates, but

limited, or no movement of

damper blades is observed.

•The mode is not correctly

synchronised with the interface

•The damper is damaged or poorly

installed.

•The retaining pin in the interface is

not protruding through the location

hole in the shroud.

•Foreign matter is impeding blade

movement.

•Location plate omitted.

•Mode not screwed down correctly.

Interface assembly cannot be

removed.

•Mode is at incorrect position.

SSM5, SSM6, HSM5, HSM6 -

release position permits removal.

VSM5, VSM6, HSVM5, HSVM6 -

reset position permits removal.

•Interface coupling slot misaligned -

try carefully manually adjusting

blade slightly.

Smoke/Shield Control Mode 1

does not latch to reset position.

Control Mode 1 difficult to

install/remove from interface

shroud.

•Mechanical fusible link not fitted

correctly to duct.

•In released position, rotate the

shaft fractionally with 14mm A/F

spanner whilst installing/removing.

The wing nut on the fusible link is

not fully screwed clockwise to end

travel.

Key:–

SSM1 Smoke/Shield Mode 1

SSM5 Smoke/Shield Mode 5

SSM6 Smoke/Shield Mode 6

VSM5 Vent/Shield Mode 5

VSM6 Vent/Shield Mode 6

HSM5 Hot/Shield Mode 5

HSM6 Hot/Shield Mode 6

HSVM5 Hot/Shield Vent Mode 5

HSVM6 Hot/Shield Vent Mode 6

LNNN00162 8/04

NATIONAL

ACCREDITATION

OF CERTIFICATION

BODIES

Quality System Certificate No. 017 Assessed to

BS 5760 Part 2/ISO 9002/EN 29002

Actionair, South Street, Whitstable, Kent CT5 3DU England

Tel: (01227) 276100 Fax: (01227) 264262 International Code: +441227

Email: sales@actionair.co.uk Website: www.actionair.co.uk

Part of Ruskin Air Management Limited

This manual suits for next models

3

Table of contents

Other actionair Fire And Smoke Damper manuals

Popular Fire And Smoke Damper manuals by other brands

KOOLAIR

KOOLAIR SMLD Mounting instructions

Nailor

Nailor 0714 OPERATIONS AND MAINTENANCE PROCEDURES

VPro

VPro WT instruction manual

mercor

mercor mcr FID S Operation and maintenance manual

Greenheck

Greenheck FD150X Installation, operation and maintenance instructions

EKOVENT

EKOVENT EKO-RBG1 Installation and maintenance instructions