Assessed to ISO 9001:2008

LPCB Cert No. 17

LPS1162 Cert No. 017a

South Street, Whitstable,

Kent, CT5 3DU

Tel: +44 (0)1227 276100

Fax: +44 (0)1227 264262

Email: sales@actionair.co.uk

Website: www.actionair.co.uk

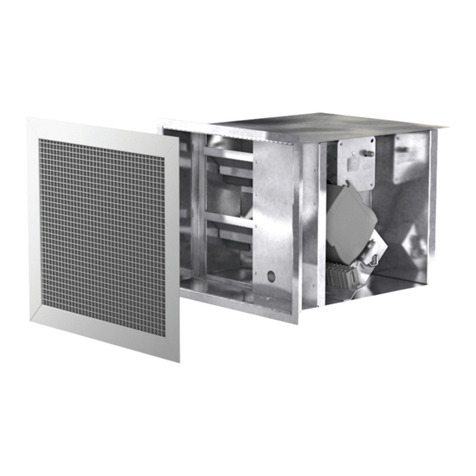

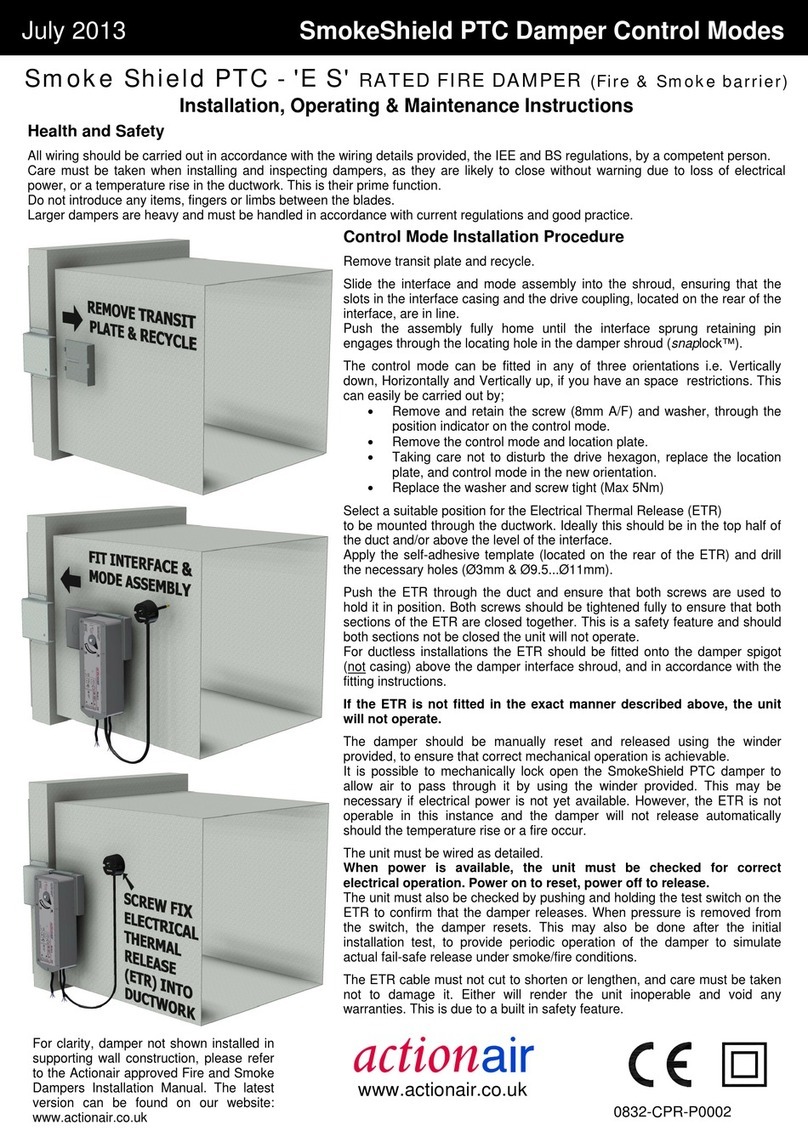

Replacement of Mode & ETR on CSS Dampers

Remove ETR

Undo the 2 self tapping screws with a No.1 Pozidriv

screwdriver and remove the ETR from the hole.

Undoing the 2 screws allows separation of the two

pieces of the ETR. Replace the old ETR with new.

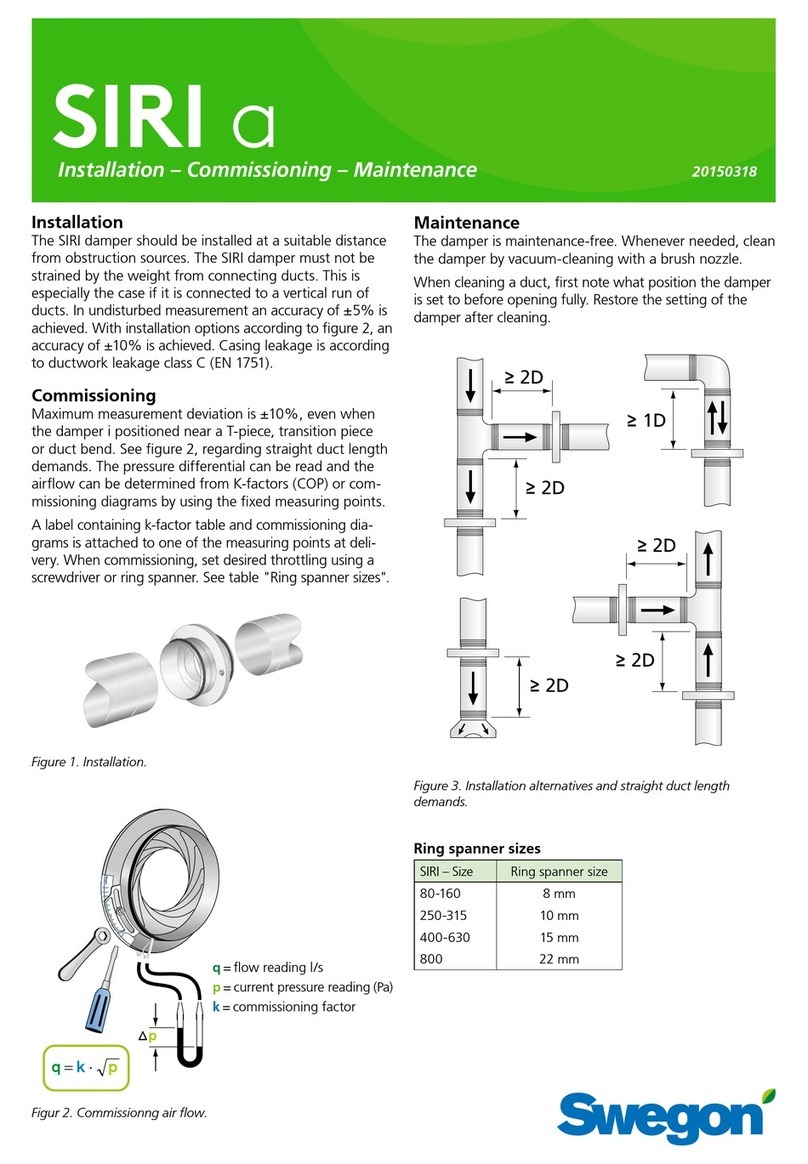

Aligning, tensioning and tting mode

The damper blade is designed to be pre-tensioned

with the mode tted. To ease mode tting the

following is necessary. Wind mode manually 1½ turns

clockwise and ½ turn anticlockwise quickly to lock

for fail-safe-closed position, to align the 2 xing screw

holes. Fit mode to bracket screws through mode

and into bracket then t nuts (they are embossed

to stop them coming loose). Fit screw supplied with

mode through mudguard washer and into the drive

shaft. Tighten screw into the shaft on the mode end

5Nm Max torque. Fully reset and release actuator by

manually winding to fully open, then release, noting

blade contacts both ‘blade stop’ positions using

manual reset key (3mm cranked allen key supplied).

Fit new ETR or replace ETR thermal probe

For damper sizes greater than Ø100mm t the ETR

into the pre-punched hole in the circular case using

a No.1 Pozidriv screwdriver to tighten the two self

tapping screws supplied with the ETR.

For damper size Ø100mm t to pre-punched hole

in the side of mode bracket and through a grommet

in case beneath. Tighten using a No.1 Pozidriv

screwdriver to tighten the two self tapping screws

supplied with the ETR. NOTE fully tighten the ETR

so that its two part case is completely together to

ensure electrical continuity inside.

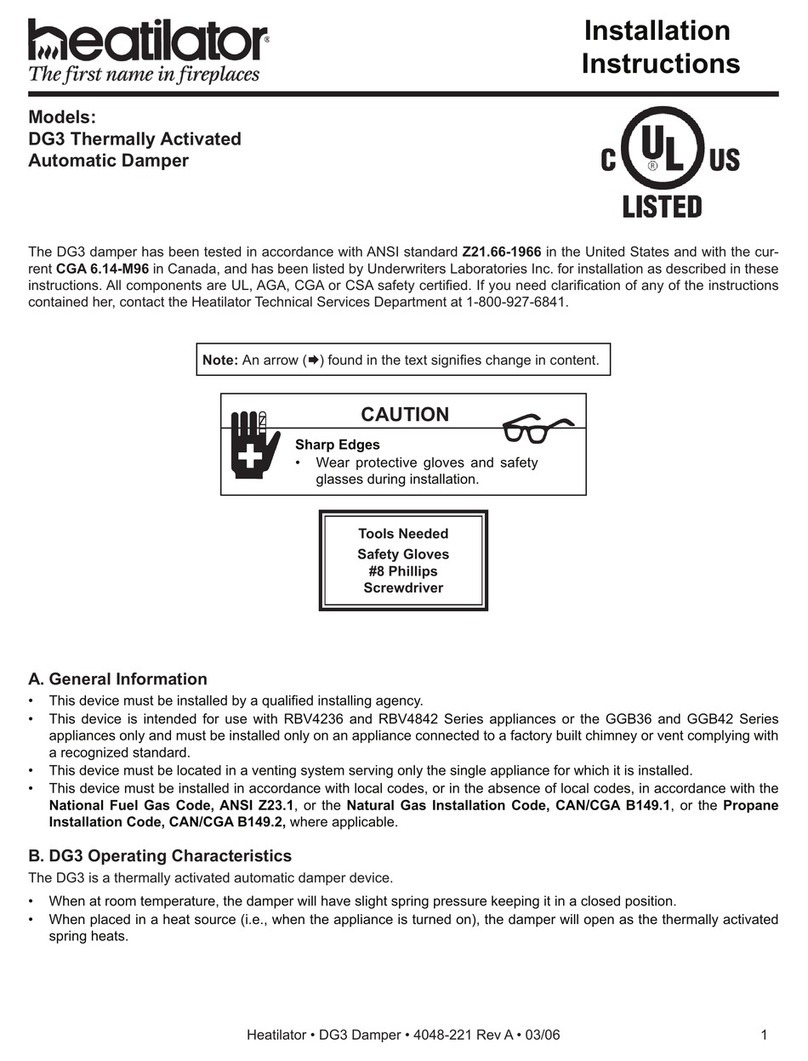

Electrical Connection and Final Operational Test

When power is available, the unit must be checked

for electrical operation. Power on to motor open,

power o to spring close (fail-safe-closed). The unit

must also be checked by pushing and holding the

test switch on the ETR to conrm that the damper

closes. When pressure is removed from the switch

the damper will reopen. This may be done after the

initial installation test to provide periodic operation of

the damper to simulate actual fail-safe-closure under

re conditions. Note: Supply voltage will automatically

override the manual locking mechanism.

Remove Mode Fasteners

Unscrew and remove the two bolts holding the

mode to the bracket using a 5mm allen key.

Unscrew and remove the bolt and washer holding

the mode to the shaft using an 8mm A/F spanner.

Do not to lose the xings these will be reused later.

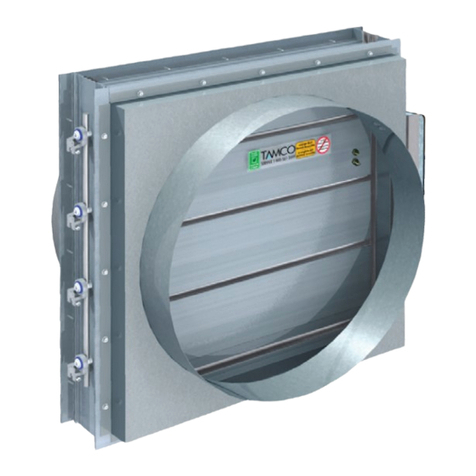

Check damper blade starting position

Damper blade in closed position for the ‘Fail-Safe-

Closed’. It is also a good opportunity to check the

condition of the white seal around the circumference

of the blade for any damage.

Orientation of mode

The mode can be tted in one of three positions

depending on preference this is the time to decide.

LNNN00356 (4.1)