ActSafe ACX User manual

Introduction A

Product safety

& system description B

Rope C

Lifting systems &

equipment setup D

Battery care E

How to use the Ascender F

Service & maintenance G

Warranty terms H

Technical data I

Rev 4 - 2021 ENG MASTER

AC X

DISCLAIMER

WARNING

Training and experience are required to lower the risk

of serious bodily injury or death.

This user’s manual provides general information about safe

operation and risks associated with the use of the ActSafe ACX

Power Ascender. It also gives details of maintenance procedures.

Never use the equipment unless you have read and understood

this manual and completed an ActSafe approved training in the

use of the power Ascender system. ActSafe AB, our partners and

subsidiaries, disclaim any liability for damages, injuries or death

resulting from the use of the equipment which is not in compliance

with this manual.

This manual may be updated without notice.

For more information about updates and safety warnings,

visit www.actsafe.se

Failure to read and follow

the instructions within

this manual may result

in fire, damage to property,

personal injury or death.

4

A

INTRODUCTION

About ActSafe A.01

About this manual A.02

Definitions A.03

FOREWORD

Thank you for choosing the ActSafe ACX

Ascender from ActSafe.

This Ascender has been designed as

an ultra-portable and versatile lifting tool

for lifting people or equipment in a safe

and effective way. It revolutionises working

in a vertical environment.

BE AWARE:

A Power Ascender is a hi-tech tool

and should be treated with care.

5

AA.01 ABOUT ACTSAFE

ActSafe is a pioneer in developing powered

Rope Ascenders and has been delivering

high-performance equipment since 1997.

ActSafe has a worldwide distribution

network of dedicated experts selling our

innovative products to a wide variety of

users. Our Power Ascenders have been

successfully used for installing fireworks at

the top of the Eiffel Tower, hostage rescue

from pirates at sea and providing essential

logistical support in offshore wind turbines.

ActSafe products are redefining the

possibilities for work in vertical environments.

We are completely committed

to our customers and do our

utmost to deliver top quality

products and service.

6

i

A.02 ABOUT THIS MANUAL

This manual gives detailed information on

features and safety. However, this manual

cannot replace the need for training and

experience. The Ascender must only be

used by operators who have undergone

the ActSafe-approved training.

Safety messages of extra importance

are highlighted throughout this manual

using the signals ‘danger’, ‘caution’,

’note’ and ’recommendation’.

RECOMMENDATION

Instructions and tips on how best

to use the Ascender.

DANGER

CAUTION

Not following instructions or training

methods may result in SERIOUS

BODILY INJURY or DEATH.

Not following instructions or training

methods may result in BODILY INJURY,

or DAMAGE TO PROPERTY.

Note

Important information on the use of the

equipment used with the Ascender.

7

A.03 DEFINITIONS

Active/loaded rope

Loaded end of the work-positioning

rope system.

Anchor

Attachment point for rope or Ascender.

Ascending

Moving up the rope.

Backup system

A rope system which captures the

load in case of primary rope failure.

Approved according to backup

system requirements.

Competent Person

Operator with adequate training,

experience and certification.

Descending

Moving down the rope.

Passive/dead rope

Unloaded end of the work-positioning

rope system.

Primary rope

Work rope system used with Ascender.

Rope must be 11 mm (7/16”) and

approved according to EN 1891 A

or be an ActSafe Equipment Lifting

Rope depending on the application.

User/operator

Operator of the Ascender, either by

the Throttle or by the Remote Control.

Secondary rope

See ‘Backup sytem’.

SWL

Safe Working Load. The maximum load

(as certified by a competent person) that an

item of lifting equipment may raise, lower or

suspend under particular service conditions.

WLL

Working Load Limit. The maximum

load that an item of lifting equipment

is designed to raise, lower or suspend.

8

B

PRODUCT SAFETY

& SYSTEM DESCRIPTION

Product safety B.01

Usage exclusions B.02

System description B.03

Rope mechanism B.04

9

B

B.01 PRODUCT SAFETY

ActSafe Ascender operators must, before first use, have undergone

training in the safe use of the Ascender by either ActSafe AB or by an

ActSafe-approved training partner or ActSafe distributor.

The ActSafe Ascender must be checked before every use by

a Competent Person and must undergo a minimum of one inspection

per year by ActSafe AB or an ActSafe-authorised person.

More frequent inspections may be required by your national regulations.

10

»For any purpose other than that

for which it has been designed

»In an explosive environment

»If modified in any way by anyone

other than ActSafe

»After a free fall from a height of

more than 0.5 m (2 ft) or any other

severe impact onto a hard surface

»If subjected to misuse in any

way so that parts or components

might have been damaged

»The Ascender system should not

be exposed to high impact forces

caused by people or loads falling

into the system

»With any Battery other than

original ActSafe ACX Batteries

»With any other battery charger

than an original ActSafe ACX

Battery Charger

»With a damaged or modified ActSafe

ACX Battery and/or ACX Charger

»If the operator is unsure of how

to use the Ascender safely

»If you are tired, ill, using prescription

medication that prevents you from

using machinery, or under the

influence of alcohol and/or drugs

»Without having performed

a pre-use check

B.02 THE ASCENDER MUST NOT BE USED:

11

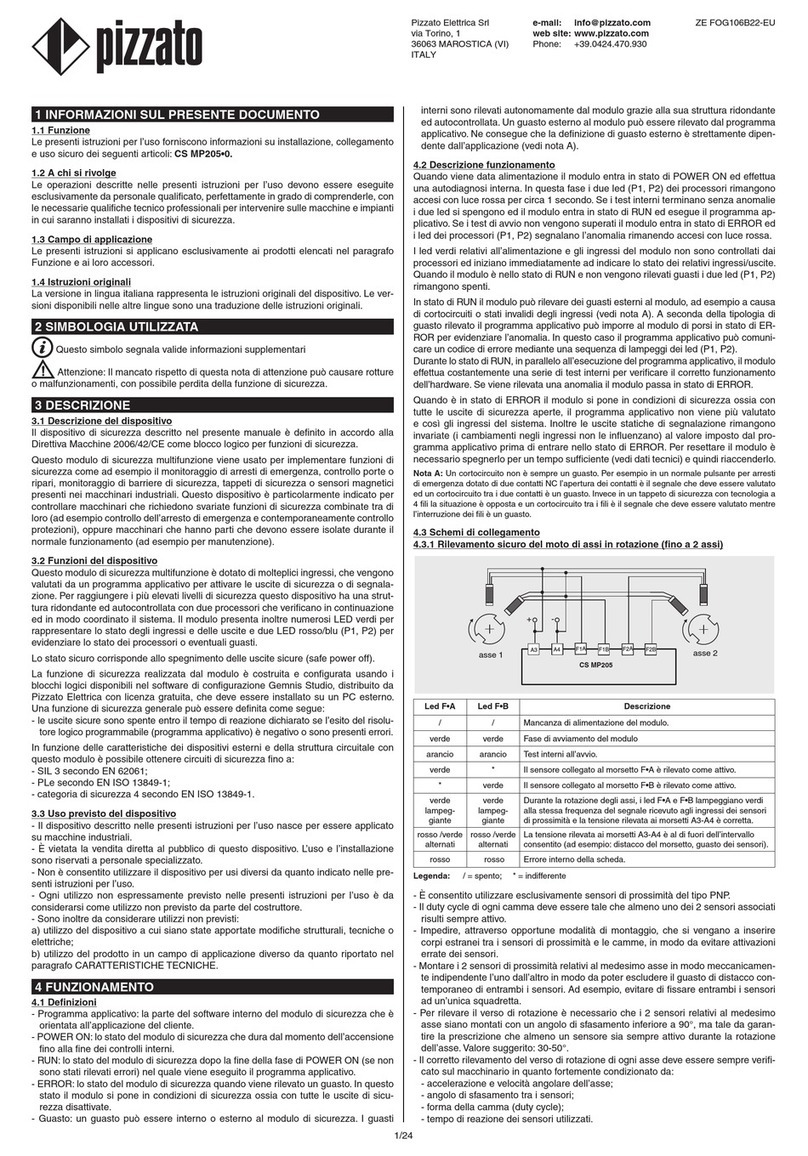

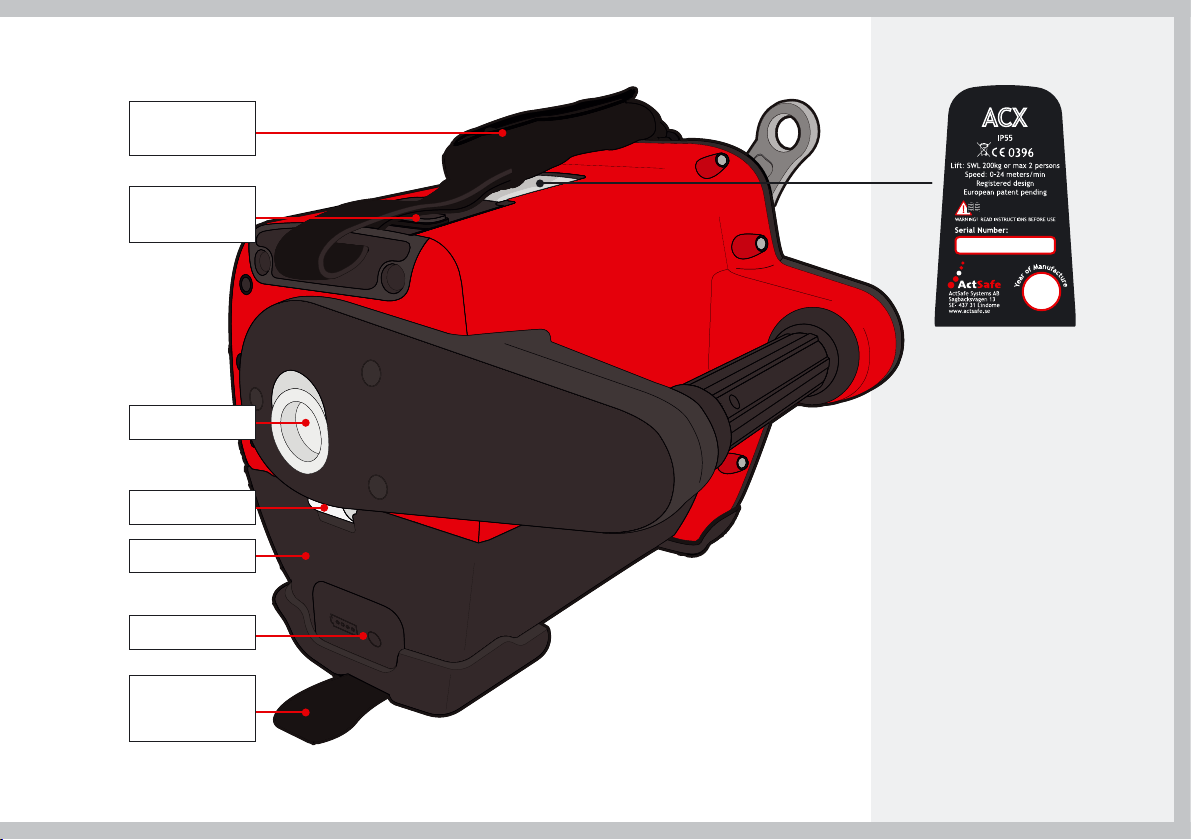

BB.03 SYSTEM DESCRIPTION

CAUTION

The Connection Sling is the only point

for connecting the Ascender to a Person,

Anchor or Load.

Rope Guide

Rope Cover Lock

Ascender

Positioning Point.

See D.04

Rope Cover

Karabiner

Emergency Stop

Connection Sling

Titanium Sling Bolt

Power Button & Indication LED

Bi-directional

Throttle

12

Battery Release

Emergency

Descent Lever

Battery

Battery Lock

Battery Indicator

Battery Strap

(Not for Loads)

Carrying Handle

(Not for Loads)

Machine Rating label

The Ascender is supplied

with a machine label

attached to the housing.

This label must not

be removed!

The ACX Ascender

is approved under

the machinery directive

2006/42/EC for lifting

both people and

equipment with a

Working Load (WLL/

SWL) of 200 kg (440 lb).

13

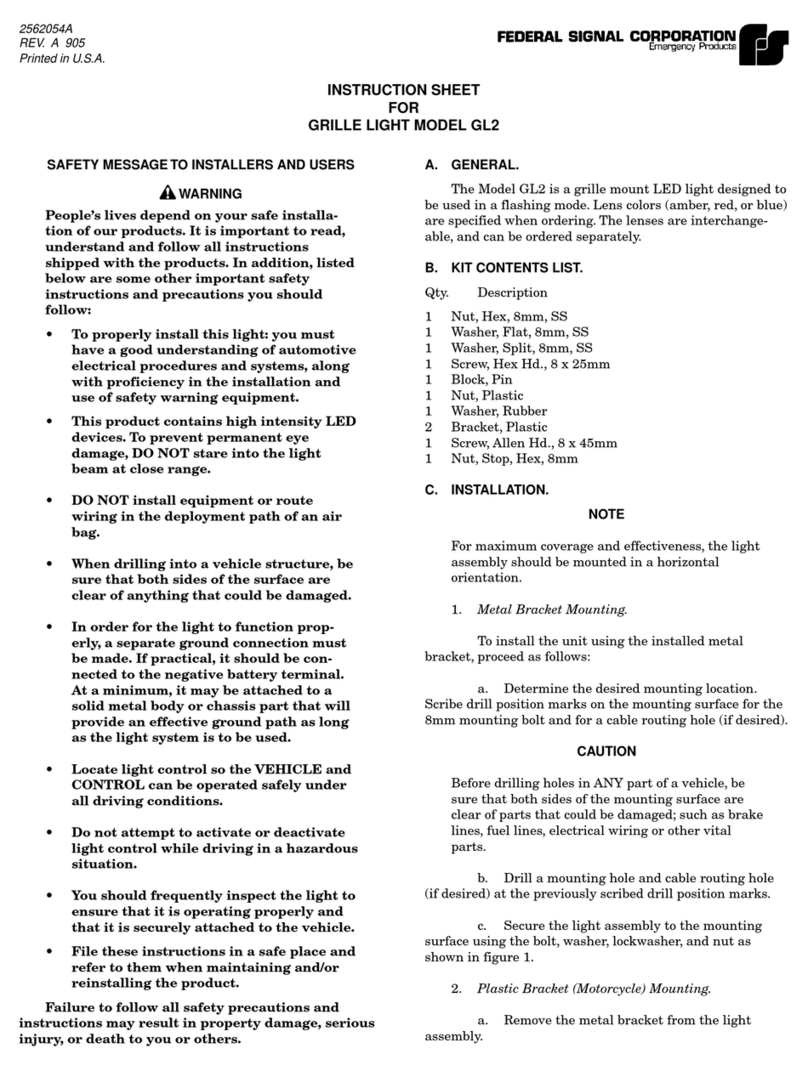

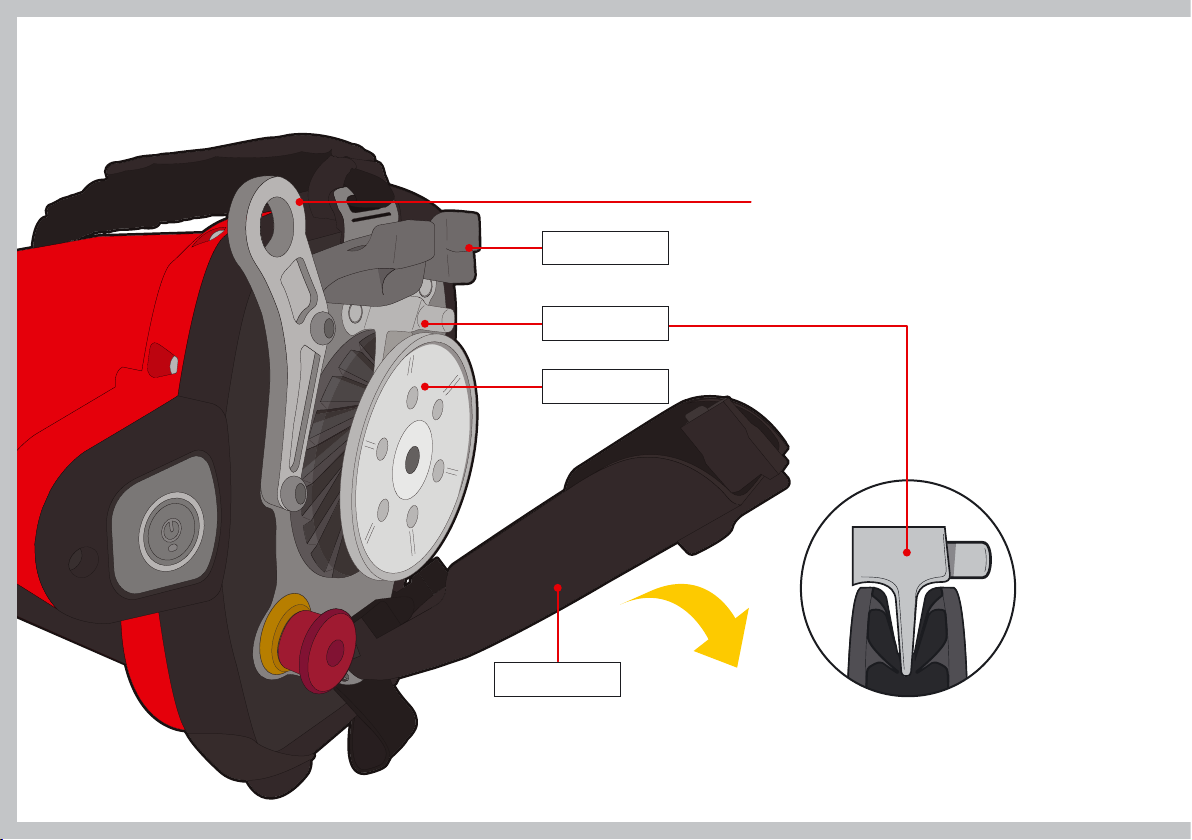

B.04 ROPE MECHANISM

The Ascender Positioning Point may

be removed by the user if desired but

can only be mounted by ActSafe or

an ActSafe approved service center.

Rope Guide

Rope Wedge

Rope Grab

Rope Cover

14

C

ROPE

Rope type

and preparation C.01

15

C

Rope recommendations

Rope recommendations for the ACX

Ascender depend on the type of

application, whether personnel

or equipment lifting.

Equipment lifting

The ActSafe Equipment Lifting Rope

(ELR) is the only approved rope

to be used in the equipment lifting

system and can be ordered at

ActSafe or your ActSafe distributor.

Personnel lifting

The ActSafe Personal Lifting Rope

(PLR) is available in several colours

from your ActSafe distributor. All ropes

that are used for personnel lifting must

meet EN 1891 A with a diameter of 11

mm (7/16”) and should be of a solid

construction. A list of the rope testing

procedure can be found at our website

should you wish to perform your own

tests. For further information please

contact your ActSafe distributor.

Softer ropes are unsuitable for the use

in ActSafe Ascenders. Softer ropes

should be avoided because they

deform under load, grip is poor and can

potentially jam the Rope Grab system.

Pre-Soaking (applies only

to Polyamid ropes)

It is recommended that only pre-

soaked ropes are used with ActSafe

Ascenders. New ropes should be

put in cold water <40°C (104°F) for

24 hours and dried slowly afterwards.

This will make ropes more suitable

for use in ActSafe Ascenders for

two reasons:

1. Rope density

Pre-soaking makes ropes denser.

The fibres will absorb the water

The correct choice of rope

type depends on whether

the Ascender is being

used to lift or lower

equipment or personnel.

Check with your ActSafe

supplier for suitable ropes.

C.01 ROPE TYPE

AND PREPARATION

16

i

and will shrink when drying.

The result is that all fibres become

more densely aligned and the sheath

sits tighter around the core of the rope.

This will make the rope more solid and

will consequently result in less mantle

slippage and deformation and thereby

lead to better grip in the Ascender.

2. Oil dissolution

During the production process some

oil is added to the rope fibres in order

to reduce the friction between the

individual fibres. When soaking the

rope in cold water some surface oil

in the sheath of the rope will dissolve.

This will contribute further to a better

grip. Do not soak ropes in warm water,

this will lead to greater dissolution of

oil, which will have a negative impact

on the rope properties.

A new rope will get an increased service life if it is soaked in cold

water before the first use.

Avoid getting sand or dirt onto/into the ropes since it will wear the

Rope Grab and Rope Guide. Use a rope mat, rope bag or similar.

Always make sure that the rope is in good condition.

CAUTION

RECOMMENDATION

17

D

GENERAL SAFETY

GUIDELINES AND

LIFTING SYSTEMS

General safety guidelines D.01

Personnel lifting D.02

Personnel safety checklist D.03

Personnel lifting setup D.04

Equipment, material

and tool lifting D.05

Basic lifting safety rules D.06

Lifting setup D.07

ActSafe Training Network D.08

19

D

DANGER

DO NOT USE the Ascender if you

are tired, ill, using prescription

medication that prevents you from

using machinery, or under the

influence of alcohol and/or drugs.

DO NOT hold the loaded rope

when ascending as there is

a risk of pinching.

CAUTION

»Operate the Ascender according

to the advice contained within this

user manual and pre-planned work

instructions (lift plan, access plan)

»Only trained and competent

operators should operate

the ACX Ascender and its

ancillary equipment

»Plan and evaluate your work

carefully. A rescue plan should

be in place

»Plan for appropriate supervision

of work

»Perform a toolbox talk before

starting the work

»Use only approved and

inspected equipment. This

goes for the Ascender, PPE

and/or lifting equipment

»Inspection of equipment must

be carried out in accordance with

local regulations. The Ascender

should undergo a documented

inspection at least once every year

»Pre-use check of the Ascender

should be carried out in

accordance with the inspection

guidance provided (see F.11)

»Use PPE (Personal Protective

Equipment) such as helmet,

gloves and protective eye

wear when required

»Keep your hands, hair and

clothing away from moving parts

»Keep a constant eye on the

Rope Guide to ensure that

the rope is running smoothly

through the rope mechansim

D.01 GENERAL SAFETY GUIDELINES

The ACX Ascender is

designed for both personnel

and equipment lifting. These

applications have different

system requirements

that are described in the

following pages.

20

Other manuals for ACX

2

Table of contents

Other ActSafe Safety Equipment manuals