ActSafe RIGGING FRAME User manual

Introduction A

Assembly B

Application C

Pivoting Frame D

Fixed Rigging Frame E

Tramway Frame F

Rigging Frame Warranty Terms G

Technical Data H

RIGGING

FRAME

Rev 1-2018 ENG MASTER

DISCLAIMER

Failure to read and follow

the instructions within

this manual may result

in damage to property,

personal injury or death.

WARNING

Adequate Training and experience are required to

reduce the risk of serious bodily injury or death.

This user manual provides general information about

the safe operation and risks associated with the use

of the ActSafe Rigging Frame. It also gives details

of maintenance procedures.

Never use the equipment unless you have read

and understood this manual and completed ActSafe-

approved training in the use of the Rigging Frame.

ActSafe Systems AB, our partners and subsidiaries,

disclaim any liability for damages, injuries or death

resulting from the use of the equipment which

is not in compliance with this manual.

This manual may be updated without notice.

For more information about updates and safety

warnings, visit www.actsafe.se

INTRODUCTION

A

About ActSafe A.01

About this manual A.02

Denitions A.03

FOREWORD

Thank you for choosing the Rigging Frame from

ActSafe Systems.

The Rigging Frame is a lightweight and portable edge

management system for the deviation of ropes over edges,

for rope rescue, and rope access.

The main benet of this frame is to pass casualties,

operators and loads, in a controlled way, over any edges in

both lowering and lifting operations. The Frame has been

successfully used in both urban and outdoor environments

for rope rescue and industrial rope access applications all

over the world.

DANGER

The Rigging Frame is designed purely to deviate ropes

over edges. The Rigging Frame is NOT approved as

an anchor point and should not be not used as such,

neither as standalone anchor construction or anchor

point extension. Always use a backup system that is not

rigged via the Rigging Frame.

A.01 ABOUT ACTSAFE

A

ActSafe is a pioneer in developing powered

Rope Ascenders and has been delivering

high-performance equipment since 1997.

ActSafe has a worldwide distribution

network of dedicated experts selling our

innovative products to a wide variety

of users.

ActSafe products are redening the

possibilities for work in vertical environments.

We are completely committed

to our customers and do our

utmost to deliver top quality

products and service.

A.02 ABOUT THIS MANUAL

This manual gives detailed information on

features and safety. However, this manual

cannot replace the need for training and

experience. The Rigging Frame must only

be used by operators who have undergone

the ActSafe approved training.

Safety messages of extra importance

are highlighted throughout this manual

using the signals ‘danger’, ‘caution’,

’note’ and ’recommendation’.

DANGER

CAUTION

Not following instructions or training

methods may result in SERIOUS

BODILY INJURY or DEATH.

Not following instructions or training

methods may result in BODILY INJURY,

or DAMAGE TO PROPERTY.

RECOMMENDATION

Instructions and tips on how best

to use the Rigging Frame.

i

Note

Important information on the use of the

equipment used with the Rigging Frame.

A.03 DEFINITIONS

Anchor

Attachment point for rope, rope adjustment

devices or Ascender.

Backup system

A rope system which captures the load in

case of primary rope failure or if any other

components in the work system should fail.

Approved according to backup

system requirements.

Guying line

A tensioned rope that is used to stabilise

the Rigging Frame in its desired position.

Lifting system

The main rope system that is used to lift or lower

any persons or loads with an ascender.

Resultant force

An object may have several different forces

acting on it, which can have different strengths

and directions. But they can be added together

to give the resultant force. This is a single force

that has the same effect on the object as all the

individual forces acting together.

User/operator

Person that operates the Rigging Frame,

Backup system or Ascender and/or is

suspended on the lifting system.

SWL

Safe Working Load. The maximum load

(as certied by a competent person) that an

item of lifting equipment may raise, lower or

suspend under particular service conditions.

ASSEMBLY

B

Assembly B.01

Pre-use inspection B.02

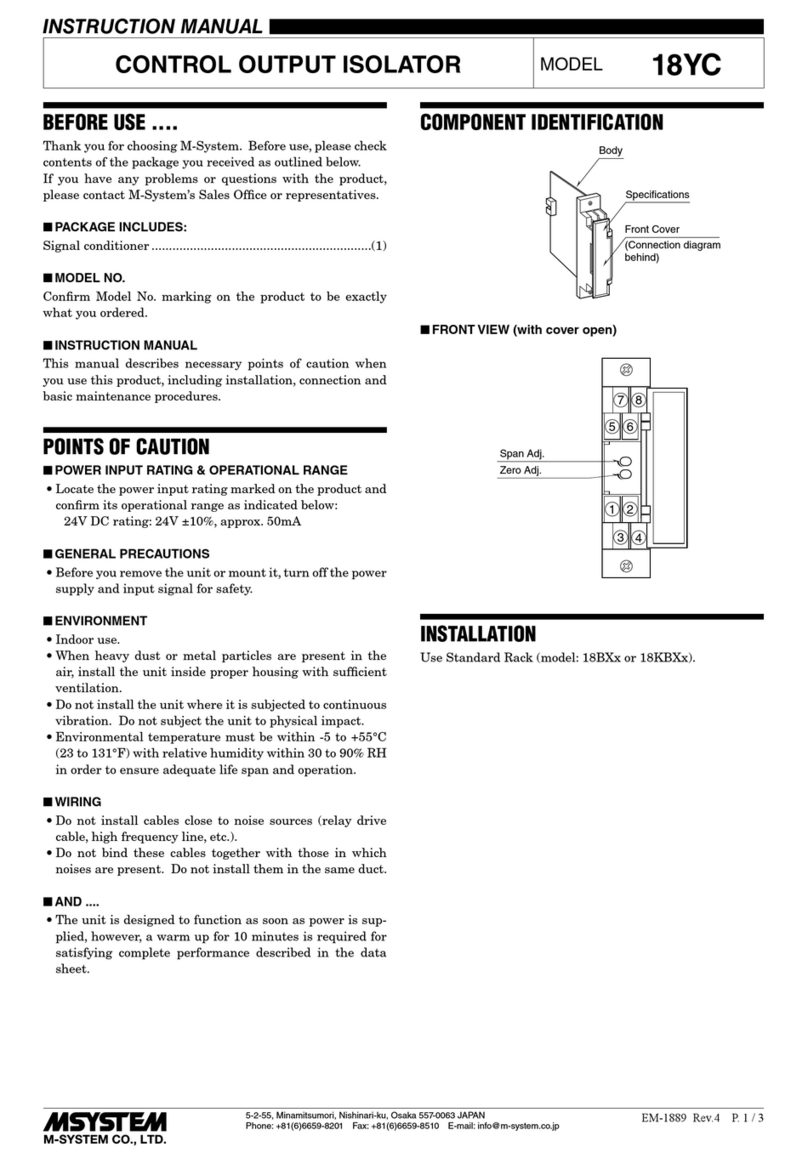

BB.01 ASSEMBLY

B

The Rigging Frame is made

up of two sets of aluminium

poles. Each set is a group

of three distinct tube types

which, when connected,

form a triangle structure.

When combined, the two

triangle forms create the

Rigging Frame.

x2

B

1. Lay the two pole sets out on the oor. Place the end of

the U-sections over the top of the red tubes and align

the bolt holes.

2. Secure the fastening by scewing together both parts

of the eyelet bolts through the bolt holes.

Rear view – fastening completeSide view

1

2

3. Fasten the two red ties around the two

U-sections tubes. Pull them tight to give

more stability.

Cross-section view

CAUTION

Only use original feet

to extend the frame.

The use of any other

feet could affect the

structural integrity.

4. The frame can be raised if required. Extend the legs by pulling the steel

clip at the base of the red section sliding into the desired hole. Secure

the feet at the desired height by putting the clip back in.

B.02 PRE-USE INSPECTION

Check the Rigging Frame thoroughly

in accordance with your training

and this manual.

If you are in any doubt about the

condition of the Rigging Frame, do

not use it and contact yourActSafe

distributor orActSafe directly.

Structure (tubes)

Check that the tubes are not damaged

in a way that it could compromise the

static strength of the frame.

»No cracks or holes

»No bending of tubes

»No indentations more

than 5mm deep

»Tubes must be round

Bolts

»Check that all bolts and eyes

are original

»Remove top bolts and check

thoroughly

»No cracks or deformations

on bolts or eyes

»Closely check the bolts

threading to ensure there is

no bending

Feet

»Check that feet are not bent,

and pivot freely

»Rubber should be present

under both feet

»No damage to tubes

»Check that both locking pins

are present and connected

to the frame

»Both feet can be easily adjusted

in height after removing pins

»Other components such as

pulleys, connector rings etc.

(see respective user manuals for

these parts)

»Annual documented inspection

APPLICATION

C

Overview and Pivoting Frame C.01

Fixed Frame C.02

Tramway Frame C.03

v

In this section, three basic

Rigging Frame applications

are shown. For more detailed

information about these

applications and the exact

setups, see the respective

sections in the manual.

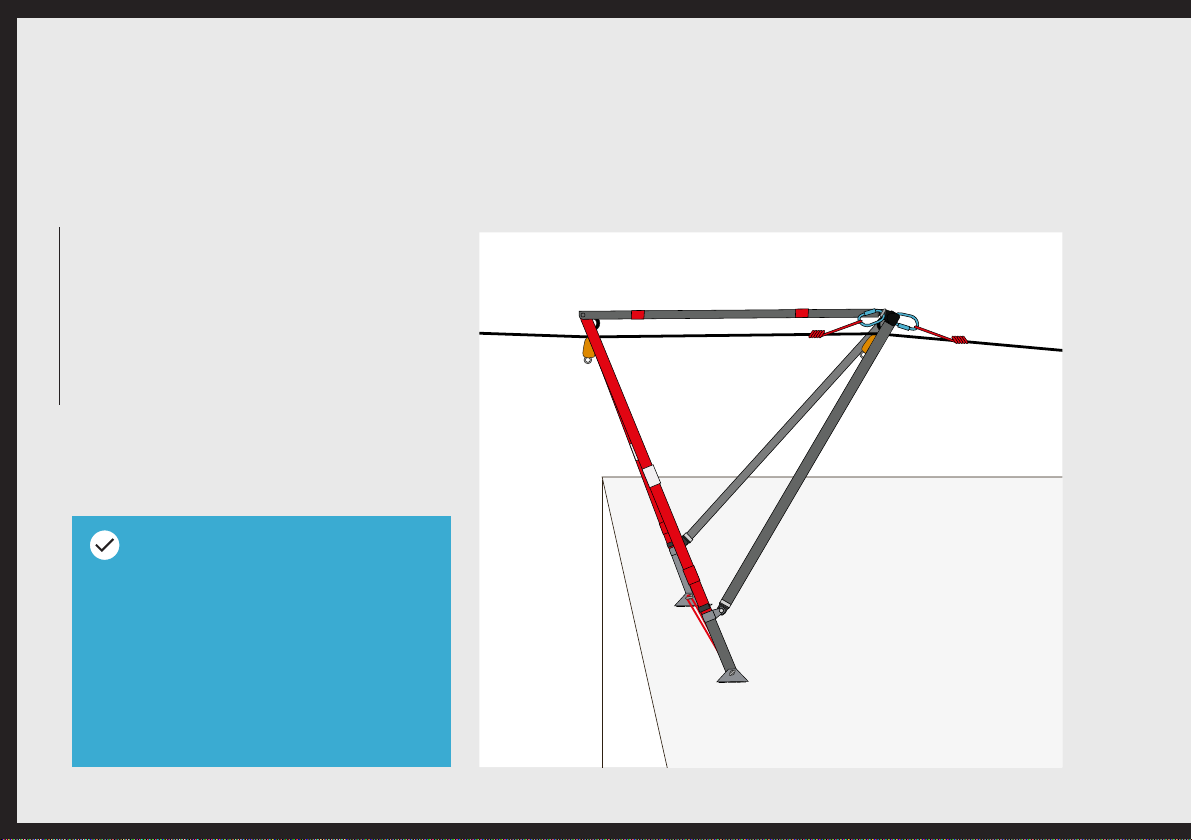

CC.01 OVERVIEW AND PIVOTING FRAME

Pivoting Frame

The Pivoting Frame setup, with its inwards/

outwards pivot, is ideal for lifting a casualty

over an edge in a controlled manner.

Allow enough space for positioning and

maneuvering the frame properly in order to

benet fully from the pivoting principle.

The Frame will hold its nal, balanced,

position on the equalisation of forces alone,

with the resultant force pushing onto the

right-angle towards the feet.

C

Fixed Frame

The Rigging Frame can also be used in a xed

position with multiple guying lines. The Fixed

Frame setup allows edges to be cleared in

situations where there is little space to manage

the frame, or where the frame cannot stand on

a level surface. This setup does not have the

advantage of moving a controlled load over

the edge with the frame (as per the Pivoting

Frame setup).

C.02 FIXED FRAME

Note

Displayed are the 3 basic setups

as recommended by ActSafe, other

setups are possible but should only be

used by expert user who can ensure

the safe operation of and take the full

responsibility for that particular use.

»ww

Tramway Frame

The Rigging Frame can also be used as a

support frame for Tramway guidelines, to

facilitate further ground clearance for easier

access and exit on the Tramway. The frame

can be xed on the Tramway ropes for

improved stability.

Note

It is recommended to use the Rigging

Frame with the red side facing towards

the edge for optimal balance and

function, especially when used in the

pivoting frame setup. However, the

structural integrity of the frame is not

affected if the frame is used with the

black tubes facing towards the edge.

C.03 TRAMWAY FRAME

PIVOTING FRAME

D

Working principle,

angles and resultant forces D.01

Setup position D.02

Rigging D.03

Outward edge transition D.04

Inward edge transition D.05

Balance position

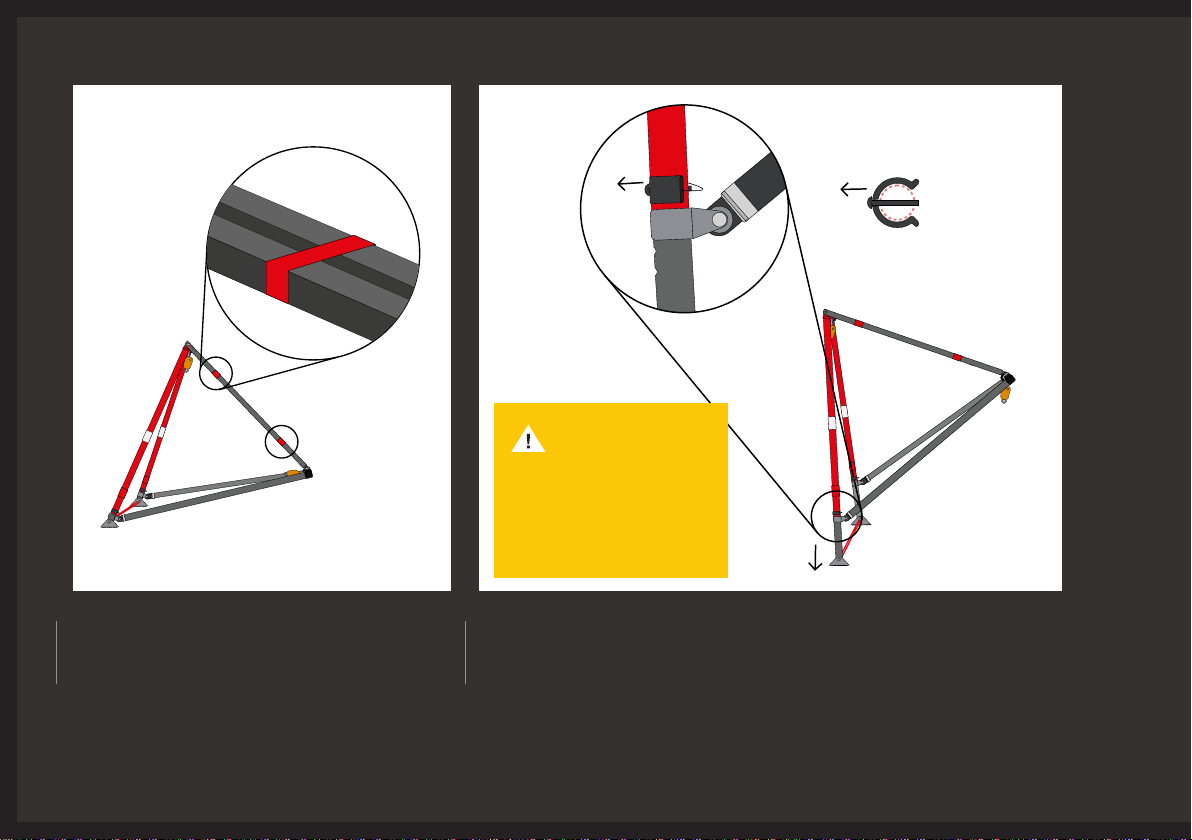

The pivoting frame will stand in

balance in its outward position,

when the angles of the ingoing

and outgoing rope are equal.

As a result, the forces that are

working will stabilise the frame

and the resultant forces point

towards the area around feet and

therefore the feet do not slip away.

D

The basic principle of the

pivoting frame is that it can

be ipped outwards/inwards

under load and will stand

in balance in its outwards

position. This working

principle is ideal for passing

edges with people or loads

with reduced effort.

D.01 WORKING PRINCIPLE, ANGLES & RESULTANT FORCES

CAUTION

Secure the feet of the

rigging frame to avoid

them slipping away.

Table of contents

Other ActSafe Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Petzl

Petzl DJINN STEEL AXESS manual

Roger Technology

Roger Technology R85 Series Instruction and warnings for the installer

Dupont

Dupont ProShield 20 SFR Cat. III Instructions for use

Sabre

Sabre MK-60 Fill and Pressurization Instructions

LAS

LAS 10334 operating instructions

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

CMC

CMC HELITACK AIRBAG quick start guide

Elysee

Elysee 23415 Product information

Tractel

Tractel blocfor AES Series Operating and maintenance instructions

Tractel

Tractel FABA-Klassik A11 Operating and maintenance instructions

Protekt

Protekt P-16 instruction manual

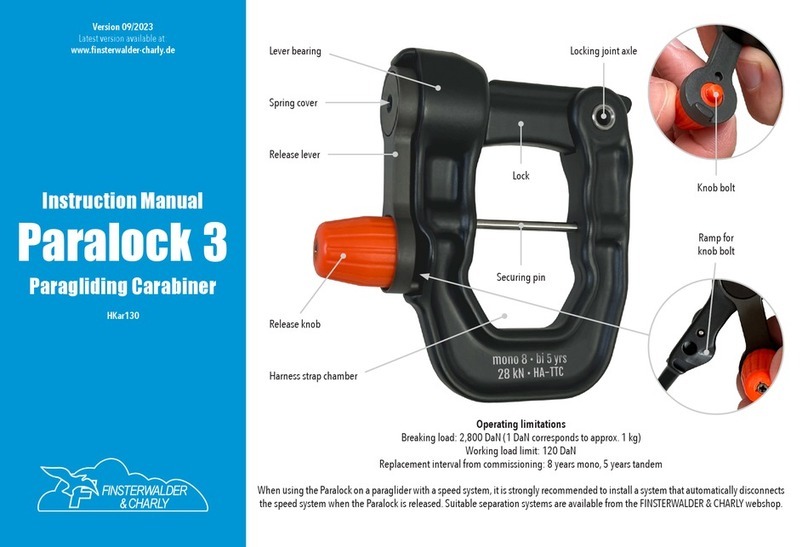

Finsterwalder

Finsterwalder Paralock 3 instruction manual