© Copyright 2014 KE2 Therm Solutions, Inc., Washington, Missouri 63090

Q.1.23 November 2014

Page 2

KE2 ControlledEnvironment

Quick Start Guide

degrees for low temperature, and 8-10 degrees for medium tempera-

ture applications.

Subcooling - There should be a solid column of liquid at the inlet of

the valve. This can be veried by looking at the sight glass, however,

the proper method requires measuring the subcooling of the liquid

entering the valve.

Verify Temperature Dierence

A typical Temperature Dierence (TD) between the coil tempera-

ture and the air temperature is between 5 and 15°F. An insucient

TD, between the coil and air temperature, indicates a system issue

that needs to be addressed before installing the KE2 Controlled

Environment.

Understanding Frost

The air exiting side of the evaporator is often the coldest spot on the

coil due to the load eecting the temperature. As air travels through

the ns of the evaporator, the Relative Humidity will reach 100%.

Moisture will begin to drop out of the air and deposit on the coil

surfaces to form frost. Although frost typically has a negative con-

notation when discussed in refrigeration, initial frost formation has

a positive eect. Some may even say “frost is our friend.” It is not un-

common to see a small amount of frost on the coils that have KE2

Controlled Environment controllers installed. The KE2 Controlled

Environment is continually measuring, monitoring, and managing

the frost to assist in maximum energy eciency. When the ecien-

cy of the coil is reduced due to excessive frost, the KE2 Controlled

Environment will initiate a defrost.

Liquid/Vapor Mix

Restrictor,

TEV or EEV

Warm Liquid

Cold Vapor

Hot Vapor

Warm Air

Cold Air

Evaporator

Compressor

Condenser

Saturation Temp °F

(from receiver pressure)

Liquid Temp at Valve °F

Subcooling °

Suction Pressure PSI

Suction Temp °F

(evaporator outlet)

Saturation Temp °F

(calculated from Suct. Pressure)

Superheat °

Temp Dierence (TD) °F

(return air minus coil temp)

Coldest point in evap °F

AMPS

Trouble Shooting Diagram

Discharge Pressure PSI

Refrigerant

Arriving at the Jobsite

When arriving at any jobsite, it is good practice to verify the correct

operation of the system. Even systems running for a considerable

amount of time without requiring a service call may not be running

properly.

Inspect the coil to see the current frost pattern. If the unit has not

recently performed a defrost, look for the heaviest area of frost. This

will be used to locate the coil sensor.

Installers should account for a full system diagnostic in the installa-

tion estimate for the controller.

Although it may seem unnecessary, identifying system issues before

the controller is installed will save time overall. It will also allow the

controller to provide the highest energy savings.

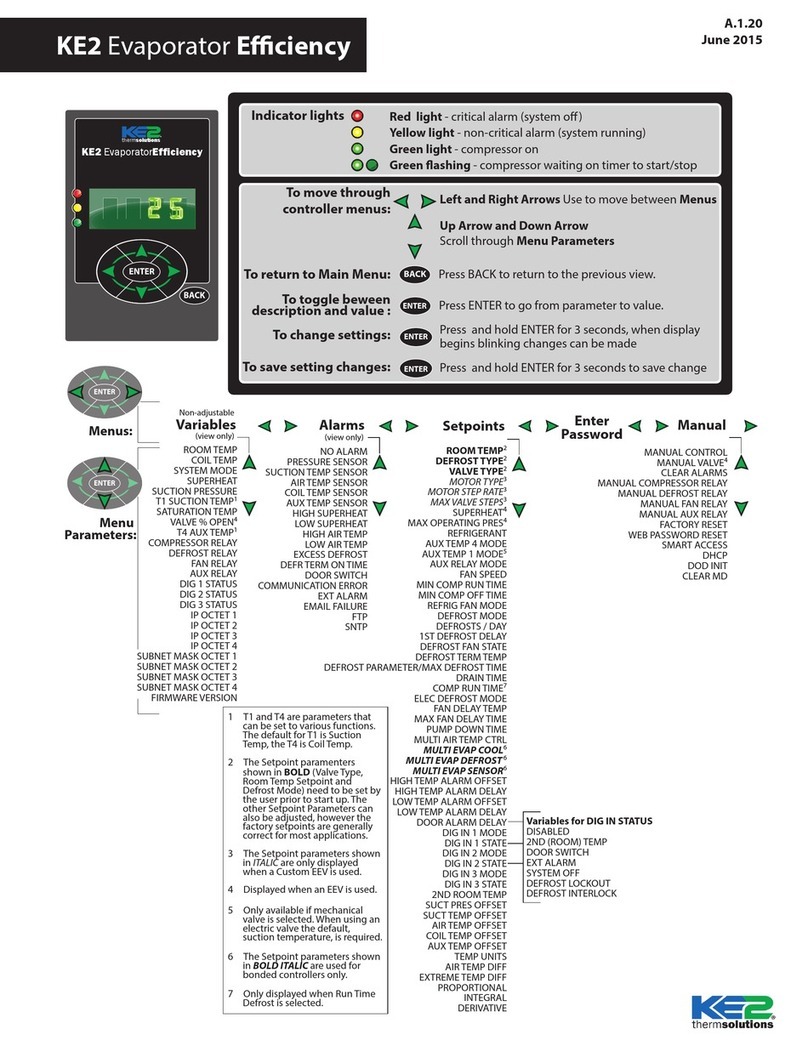

Verify the system is running correctly. Taking several measurements

will help determine the current health of the system. Using the dia-

gram below, ll in the necessary information.

Two of the most critical indicators of system health are the super-

heat and subcooling.

Superheat - Superheat is the most overlooked ineciency in exist-

ing systems. Typically the superheat on a TEV is set when there is not

product in the controlled space, if it is set at all.

When applying the controller to an existing system, it should include

an electronic expansion valve, the superheat should be between 6-8