Acuity Controls GR2400 User manual

LC&D Operation,

Programming and

Maintenance Manual

Project Name:

Project Location:

Acuity Agency:

Order #:

PO #:

Project ID:

Date:

Controls TechSupport:

1-800-535-2465 - option 1: nLight; option 2: SSI; option 3: Fresco; option 4: Synergy; option 5: LC&D/Bluebox; option 6 ROAM

To preschedule a call with tech support (providing a 4 hour business lead time) go to the following

link: http://www.acuitybrands.com/resources/schedule-support-request

Additional TechnicalLiterature:

https://www.acuitybrands.com/products/controls/lcd

1

Table of Contents

GR2400 Installation and Operation Manual ............................................................................3

GR2400 Basic Programming Guide .......................................................................................71

Chelsea Digital Switch Programming Guide ..........................................................................83

Additional Resources (Product specific user guides, Programming documents, etc) ………103

2

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

NEWCO

High Voltage High Voltage

Low Voltage

120 vac

277 vac

120vCir cuit Breaker

277vTermal Fuse

Neutral

SCROLL

UP

SCROLL

DOWN

EXIT

DELETE HELP

TAB

UP

TAB

DOWN

ENTER

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

LINE

LOAD

120 OFF

277

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 H P

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1HP

277VAC/2 HP

LosAngeles, CA (800) 345-4448

GR2400 Series

Control Card

AUTO HAND

On Line

Assign

1

3

5

7

9

11

13

15

2

4

6

81

0

1

14

16

17

19

21

23

25

27

29

31

18

20

22

24

26

28

30

32

OnLine

Indicator

OnLine

Indicator

LosAngeles, CA

(800)345-4448

FactoryEntered

Address

PCC1

To

Photocell

Interfaceto Photocell

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

4

Off

3

Off

2

Off

1

Off

4

On

3

On

2

On

1

On

SnapLink

Relay

NO

20A

120VAC/1 HP

277VAC/2 HP

GR 2400

Manual

Installation & Operation

Lighting Control & Design, Inc. •Los, Angeles, CA •

support: 800-345-4448

•

fax: 323-226-1000

Pictorial

Quick Hook-Up

Pages 1- 6

Go to Appendix III

For Final Check Out

Page 66

www.lightingcontrols.com

GR2400 Complete Manual.pdf 1 8/6/2007 1:45:27 PM

3

GR2400 Complete Manual.pdf 3 8/6/2007 1:45:28 PM

4

The GR 2400 Manual Index

Quick Start Instructions

Hooking up the GR 2400 System Page 2

One Line Diagram Page 3

Telephone Connection Page 3

Typical Panel Schedule Page 4

Wire Labeling & Phone Hook Up Page 5

Connect & Terminate Bus Page 6

GR 2400 System in a bit more detail

Typical Hook Up 2 Panels 2 Switches Page 8

Long Distances between Switches Page 8

Single panel Lots of Switches Page 8

Too Many Switches on section of Bus Page 9

Things to Know about the bus Page 10

Too Long a Bus Page 11

Parts of the System

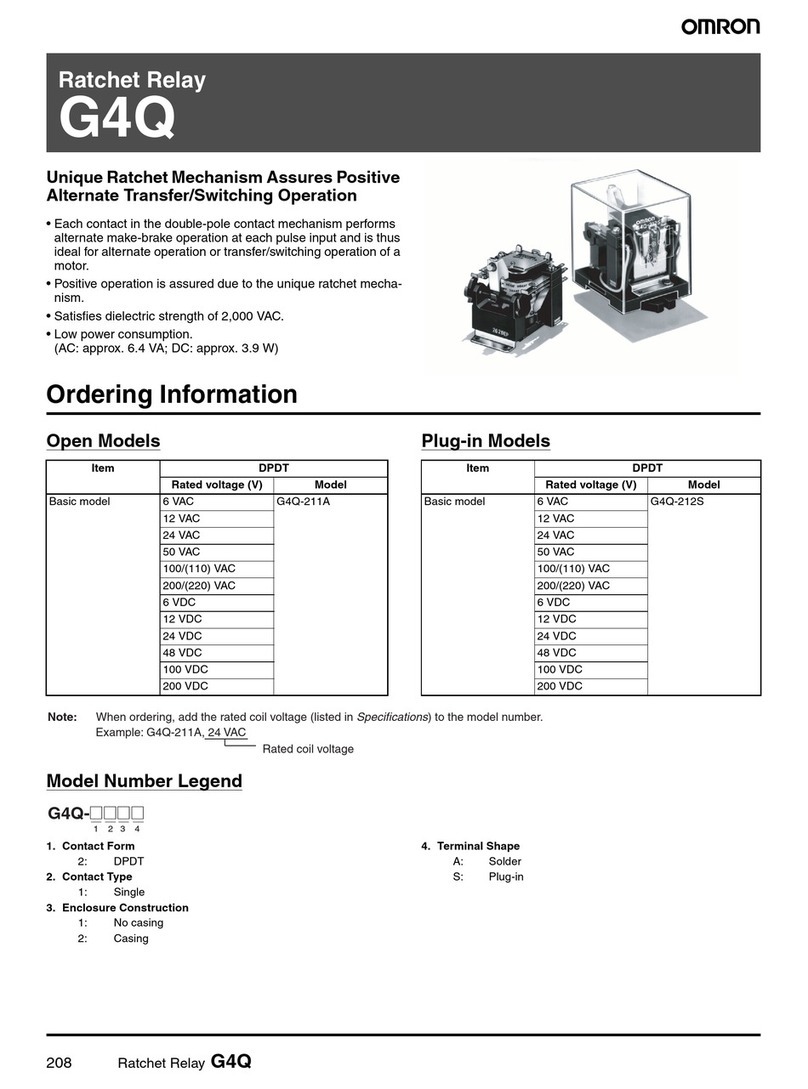

Relay (Types of) Page 12

Changing Relays Page 13

Dual Voltage Input Card Page 14

DigiLink Page 14

GR 2404 Page 16

GR 1416,2432 & 2448 cards Page 18

Board Addressing Page 18

Modes Page 18

8 & 16 Zone and Discrete Mode Page 19

GR 2416 Card Page 20

Checking the Mode Page 21

Assigning Relays to a Zone Page 21

Viewing which relays are in a zone Page 22

Sequence Speed Page 22

Flashing LEDs What they mean Page 23

Other Accessory Boards Page 24

Programming the GR 2400 System

Picture of Programmer Page 25

Navigating the Clock Page 26

The USER Menu Page 27

Review/Changing a Schedule Page 27

Mon to Fri Schedule Page 28

By Day Schedule Page 28

After Midnight Page 29

Schedules and Groups Page 30

Disabling a Schedule Page 30

Programming a Group Page 30

Group Properties Page 31

When to Set the Blink Warning Page 32

Manual Override Menu Page 32

Setup Menu Page 32

Contacting LC&D Page 33

Restricted Menu Page 33

System Setup Menu Page 33

Set Time & Date Page 33

Edit Holidays Page 33

System Option Page 35

Keyboard Lock Code Page 35

Select Location Page 35

Display Options Page 36

Naming Menu Page 36

What and When Menu Page 37

Scheduled Events Page 37

What Controls Groups Page 38

What Controls Relays Page 38

Relay Properties Menu Page 38

Changing the Time Delay between

relays Page 38

Specifying Normally Closed Relays Page 39

Sentry Switch Option Page 40

Other individual Relay Parameters Page 40

5

The GR 2400 Manual Index

(Cont)

Addressing Bus Scan Page 40

Auto Addressing Page 41

Read Address Page 41

Bus Diagnosis Page 41

Group Loads Menu Page 42

ON/OFFSequencing Page 42

Programming a Sequence Page 43

Programming Switches Page 43

Programming Buttons Page 43

Coying a Switch Page 44

Additional Features in Clock version 4.16 Page 45

Photocell Control Cards

Single Input Card Page 50

Three Input Card Page 51

Programming Photocells Page 51

Daylight Harvesting Page 52

Special Situations Page 52

Appendix I: The Restricted Menu

Appendix II: Start up Check List.

Pages 58through 62

Specifications Page 63

The Restricted Menu Page 53

Factory Set Up Menu Page 53

Addresing Bus Scan Page 53

Error Statistics Page 53

Panel Switch Types Page 54

Relay Properties Page 54

Remote System Menu Page 54

Remote Password Page 54

Dial Up Host Page 55

Owner Settings Menu Page 55

Erase Options Menu Page 55

Erase Clock Memory Page 56

Changing the Mode on a GR 2416 Card Page 57

6

G

G

GR

R

R2

2

24

4

40

0

00

0

0M

M

MA

A

AN

N

NU

U

UA

A

AL

L

L

How to install the Lighting Control & Design GR 2400 System

7

Quick Start Instructions

Hooking up the GR 2400 System

The GR 2400 system is very simple to put together.

The basic system consists of:

1)The Master Panel like the one on the left, it will have a

Clock Display and usually a modem.

2) A Switch or Switches like the Chelsea switch shown

above.

3) Sometimes there will be a Photocell.

4) Sometimes there will be additional slave relay panels.

They do not have the clock display or the modem in them.

5) Sometimes there will also be other accessories. These

are discussed later in the manual.

All these items are hooked together on a digital bus of

Category 5, four twisted pair data cable.

GR 2432 Relay Panel with 32 Relays Rated at 20 amps 277 Vac

Left barrier removed to show complete relay.

Outdoor Photocell

Chelsea 6 Digital Switch

C

Clock Display

MODEM

Page 2

8

Typical Hook Up

Breaker

Panel

LOAD

Neutral

Digital Switches

Locator Light Plus Pilot LEDs

on all buttons including "Off"

buttons.

Electronics

Relay

Slave

Relay

Panel(s)

4TwistedPair

Cat 5 Cable with

RJ45 Connectors at each end

Make sure there are

"terminators" at each

end of the bus.

Relay PCO

Outdoor Photocell

GR2400 PCI

Indoor Photocell

PCC-1

Single Input

Photocell Card

or

PCC-3, 3 Input

Photocell Card

could also be

mounted in the

nearest relay

panel.

2ea#18AWG

2ea#18AWG

MASTER

Relay

Panel

323

226-6615

Phone

Connection:

Contractor to

ensure it is

installed.

Write Phone #

on plate

One Line Diagram

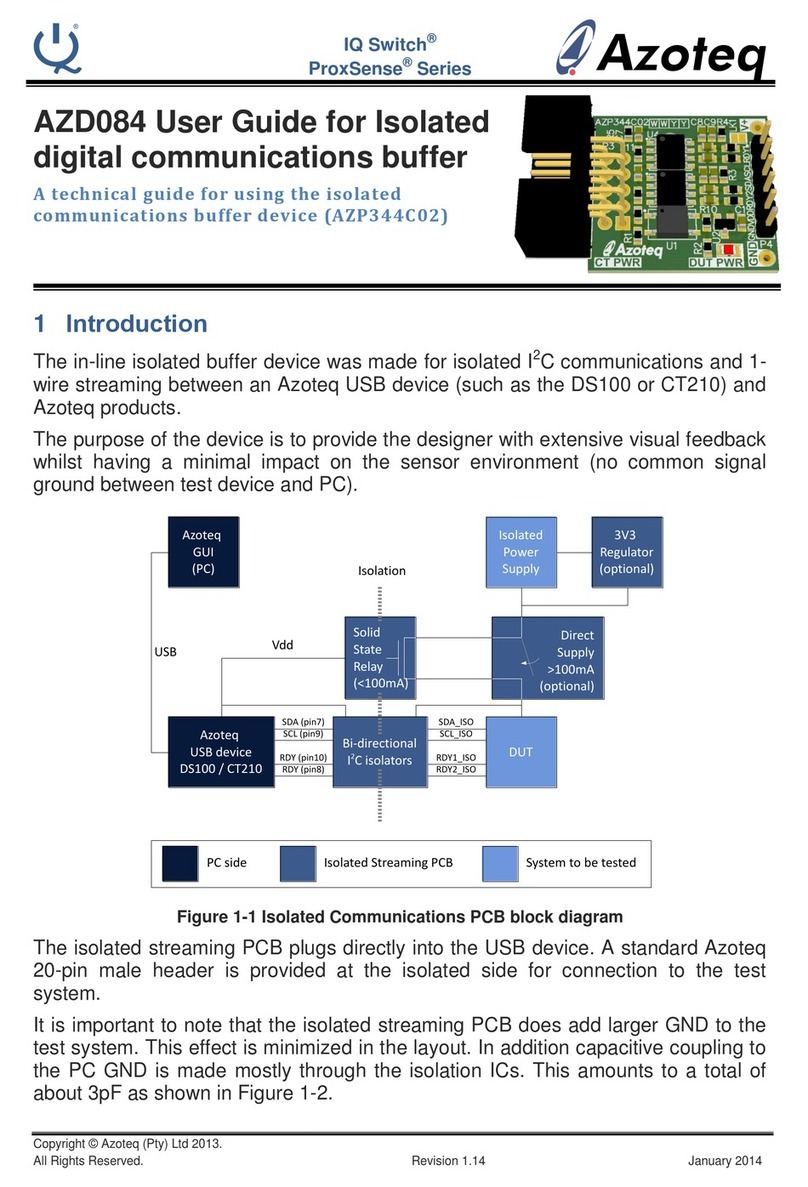

This one line diagram shows what

types of low voltage wires are

used to connect the parts of the

system together.

The Cat 5 cable must be looped

through each item on the bus with

NO SPURS!

The items on the bus (switches,

panels, photocell cards, etc.) may

be arranged on the bus in any

order, its not important. The only

point to be careful of in large sys-

tems is getting enough voltage to

the switches. There are several

pages of the manual that cover

this point later.

Telephone Connection

LC & D systems come pre pro-

grammed from the factory with

the data on hand when we ship it.

However at start up there are

usually some minor changes and

some trouble shooting to be done.

If the telephone hook up is avail-

able a factory tech can check out

the system rapidly over the phone.

Not having the phone line in can

slow project completion.

PLAN AHEAD! Get the phone line installed in

timeforstartup!Call LC&Dbeforeinstallation

forquicktips.CallLC&Dagainbeforestartup

for help with final programming. (800) 345-4448.

Page 3

9

Page 4 Typical Connection

Most jobs are pre programmed at the

factory. You must land the wires from the

breakers to the designated relays and

connect them to the correct loads for the

programming to work!

Note: If you use a gutter the neutrals do

not need to be sent through or landed in

the panel.

The panel schedules should be at the

beginning of this manual and also in a

pocket on the door of each panel.

Please follow the panel schedule and

you will save everyone a lot of work.

GUTTER

Circuit Breakers

Relay Panel

Typical Panel Schedule

10

Page 5

Label the line feed wire with the number of the breaker.

Use a separate breaker for powering the electronics.

This prevents a problem circuit from disabling the whole

system.

Note that the 120 Vac feed is protected by a circuit

breaker mounted to be accessible when the door is on

the panel while the 277VAC feed is protected by self

resetting thermal fuses. The rotary switch also has a

position for OFF if the system needs to be de-powered.

Did we mention it is a good idea to get the phone line

installed early! It may not get used much so it could be

placed in parallel with a fax machine and plugged in as

necessary.

1

120 Vac

Circuit

Breaker

277Vac

Thermal

Fuses

INPUT Selector

Switch

Label Wires

Connect Phone Line

Write Phone #

on Phone Plate

11

Page 6

Connect and Terminate the Bus

The “Bus Connectors” are all wired in parallel. Use Cat 5, 4 twisted pair wire.

1= (Nominal Ground or Common of System) The Green Pair wired together

2= (Data Wire “A”) The Orange wire of the Orange White Pair

3= (Data Wire “B”) The White wire of the Orange White Pair

4= (+12 Volt dc to power switches) The Blue White Pair wired together.

Note: In earlier manuals a different color code was used. If adding to an older

system make sure your color code is exactly the same as the old system.

On panel control cards there are two connectors. These are in parallel. It is a

good idea to have one cable come in and one out so that the bus can be “op-

ened” for trouble shooting.

Blue End of bus

Terminator Installed

Location of Terminator pins

on the back of a switch

Make sure the numbered

switches are connected at

the correct locations as per

the switch schedules or the

programming will be incor-

rect.

Back View of a Digital Switch

Showing the Bus Connector

Hook up.

Close Up of a Relay Panel control card

showing the four Bus Connectors. Two

RJ 45s and two “1-2-3-4 connectors.”

Cat 5 Cable

Note the HAND/AUTO switch. Use

this to keep the relays ON while

testing the system. All LEDs on the

control cards and switches will

still indicate even with the relays

locked ON.

12

Page 7

Connecting up the GR 2400 System.

Lighting Control & Design recommends the use of pre-

made and pre-tested Ethernet style cables. These can

even be pulled through conduit with little difficulty. In

most cases the cabling does not have to be in conduit

though plenum rated cable may be required.

The Wiring diagram shown is from www.lanshack.com.

They are also a good supply house for off the shelf pre-

made and tested cables at a cost that is way less than

one can make them oneself.

Cable Testers

A vital tool to have is a cable tester.

This ensures that cables are verified

in the field as being hooked up cor-

rectly. (90% of field problems are

caused by incorrectly installed

cables.) If each cable is tested just

before plugging it in these problems

go away. The cable tester and

crimper kit is available from LC &D

at cost. Call 800 345 4448 and ask

for Tech support.

Cable tester and crimper

kit available from LC & D

Inspect your crimps! A damaged or Old crimper will not seat each of

the contacts evenly. Though the cable may pass the tester any tug-

ging or mechanical stress can cause problems later.

Note: The cable tester will NOT work if any of the wires are

plugged into any card since 3 of the wires are shorted together to

carry 12 volts and 3 are shorted to carry ground.

Pair #

1-

White/Blue

2-

White/Green

3-

White/Orange

4-

White/Brown

Wire Pin

#

5

4

3

6

1

2

7

8

White/Blue

Blue/White

White/Green

Green/White

White/Orange

Orange/White

White/Brown

Brown/White

Wiring Scheme 568B

While the wiring scheme above is the most

commonly used wiring some jobs may have a

standard that more closely follows Telephone

company conventions Data hook up of 568A.

(which transposes the Green and Orange pairs)

This can also be used as long as both ends of

the cable are ALWAYS the same.

13

Single Panel with 10 switches will be OK with a wire length

of up to 200ft.

Panel A LCP 1

GND

+12V

DC

AB

4

3

2

1

GND

+12V

DC

4

3

2

1

AB

4

3

2

1

GND

+12V

DC

AB

GND

AB

+12V

DC

4

3

2

1

Blue White Pair

Orange/White

White/Orange

Panel A LCP 1

Switch 1 Switch 2

Panel B LCP 2

GR 2404 -DIM

Typical Hook up of a 2 Panel system with two Switches using

“1234" Connectors:

Panel A LCP 1

A panel at each end of the run increases the number of

switches and length of wire.

Panel B LCP 2

Switches with Long Distances Between Them and Multiple

Switches with only One Panel.

Cat 5 cable is 24 AWG and will carry 1 amp of current over 200 ft.

After that the resistance of the wire becomes too great and there will

not be enough voltage to run the electronics of the switches.

A system with a lot of switches or long distances between the panel

and the switches may require additional wire to handle the voltage

drop.

The calculations for this are a bit tricky and it is always better to be

safe than sorry. Here are some rules of thumb.

Each Switch takes about 100ma of current. Thus 10 switches equals about 1

amp. Cat 5 wire with RJ45s used three conductors for the power which aver-

ages out to about 1 ohm per 100ft.Per Ohms LAW V=IR , I=1amp R =2 Ohms

soVoltagedropwillbe2Volts)

There is also a limit to the amount of current a panel can provide to

drive switches.

Page 8

Green White Pair

Using the “1234" Connectors

Older systems have “1234" Connectors. These

are wired as shown on the left. New systems

use RJ 45 connectors only and the “1234" con-

nectors are being phased out. Note that the

1234 connectors use the Orange pair as the

Data pair while the RJ45s use the Blue pair as

the data pair. Should there be a situation that

needs a 1234 at one end and an RJ 45 at the

other make sure the connection is carefully

checked before it is connected.

Each 48 relay panel can drive 12 switches. For each

relaynotbeingdrivenanextraswitchcanbeadded

up to a maximum of 20.Thus a 32 relay panel can

have up to 20 switches. A panel at each end of the

line is better than having two panels at the beginning

of the line to drive all the switches.

14

Page 9

$LV

$LV

$LV $LV

$LV

$LV $LV

$LV

$LV

$LV

$LV

$LV $LV

$LV

$LV $LV

$LV

$LV

$LV

$LV

$LV

$LV

$LV

$LV

Example of a Tenant Improvement High Rise Core and Shell.

LCP 1 LCP 2

The booster wire can be 2 number 18s or just a short section

of Cat 5 with two pairs twisted together for +12 and two pairs

twisted together for Gnd.

Another solution is to get a “BUS BOOSTER” from LC & D

which is just a 12 volt power supply with RJ45 connectors on it

used to boost the voltage in the middle of the bus.

Also note: Never connect the bus “ground” to the actual “Earth”

ground. It is supposed to be a “floating” ground.

300 ft

$LV

$LV $LV$LV $LV

$LV

Add Gnd

&+12VONLY

Add Gnd

&+12VONLY

Getting out of trouble

Too Many Switches on a section of Bus

In this example the cat 5 Bus was wired before the equip-

ment and the manual were received. Though the electrician

knew what to do from a previous job he did not have this

number of switches on that job so had not run into this prob-

lem before.

By adding two sections of booster wire to boost the Ground

and +12 Volt connection he fixed his problem with voltage

drop to the switches.

15

Page 10

Terminator Terminator

The beginning and the end of the bus should be "terminated" even in systems with just a panel and a single switch. Terminators dampen reflections that could otherwise

cause data to get corrupted.

One might liken the bus to a rope with knots in it at every item on the bus. A termination could be considered to be the binding at the end of the rope to preventfraying.

SPUR

Items on the bus should be connected in sequence (no particular order needed) with no "SPURS." A Spur is any branch from the bus of more than a few (3) feet.

4000 ft

The bus may be up to 4000 ft long. Items must be connected in sequence. No Star Topologies allowed.

Note the way the bus has been drawn with an angle in and vertical out. This is the standard way to represent an RS 485 type data bus.

RS 485 is a Standard that describes the voltages associated with transmitting data on this type of bus.

NEVER run the bus close to current carrying conductors even if they are in conduit. 2ft away is good. NEVER EVER run the bus in the same conduit as

high voltage wires.(Even in cases where it is allowed by code.) In places with a very high Radio Frequency Field (ie near a Radio Station Antenna and

sometimes even high frequency ballasts can cause a problem)it may be necessary to use a shielded Cat 5 or run it in conduit.

Things to know about the BUS

16

Page 11

$LV

$LV

$LV

$LV

$LV

$LV

$LV

$LV

$LV

$LV

$LV

$LV

School Gym and Associated Rooms

Bus Length 3500 ft without

adding switch in Scorekeeper Sky Box

Score Keeper Sky Box

400Ft wire

Getting Out of Trouble

Too Long a Bus

In this example of a school Gym the switches and panels

were as shown in a concrete building with limited conduits.

There was no way to put everything on a straight line bus

and keep under 4000ft. The main problem was the Score

Keep’s switch which would have added close to 800 ft to the

bus. (Out and Back.)

The solution was to order an analog switch with a DigiLink

dry Contract input card instead of a digital switch for that

one location. The Analog switch requires two wires plus one

wire per button. (8 Wires for a 6 button switch.) For under

200 ft one can use Cat 5 and for longer use # 18 wire.

Change to Analog Switch and

home run wires to a “DigiLink”

17

Page 12

SnapLink Relays are rated at 277Vac 20Amps. Standard panels are

shipped with Normally Closed relays so that the relay will be on during

hook up and will default to ON when power is lost. This is especially nec-

essary for emergency circuits but is also very useful on normal circuits

during maintenance. Normally Open relays are also available.

SoftStart relays can be identified by a small box next to the terminal

block. Soft Start relays are only rated for use on 120Volt incandescent

lamp circuits. Please make sure that they are correctly connected and that

any changes made in the field uses them on incandescent loads. They will

not be damaged by switching Fluorescent loads or being run at 277 but

the extra money spent on the relay will give no benefit.

@Zero relays may be used on any type of load. They have a solid state

section that turns ON and OFF the relay at the zero cross point to reduce

contact burn. They should be used for loads that require frequent cycling.

They have a life of at least 250,000 throws and should last for close to a

million throws.

600 Volt 2 Pole Relay

Parts of the System:

Relays

Standard SnapLinkTM Relay

600 Volt 2 pole relays. These take up two

single pole relay spaces and are mechanically

linked 2 pole relays. They are used for dual

277Vac circuits that require a higher rating

(480Vac) than the standard 277 Vac relays.

These relays will be mounted in a special sec-

tion since they do not fit under the usual barri-

er.

2 Pole relays are driven by alternate outputs

from the control card. Thus if output 1 is driv-

ing a 2 pole, output 3 would be unused.

18

Page 13

L

O

A

D

L

I

N

E

I

N

L

O

A

D

L

I

N

E

Screwdriver

Blade

Changing Relays

Relays are mounted in "Snap Track." This is an insulating

holder that allows relays to be "Snapped" in and out.

First loosen the mounting screws for the barrier that both

acts a clamp and a cooling fin for the relays.

Remove the high voltage connections and unplug the low

voltage connections. Place a flat bladed screwdriver in the

notch at the front of the relay and twist and lift to pop the

relay out.

Put the replacement relay into the same location with the

back side of it engaged in the track. Place the flat bladed

screw driver blade on the front of the relay and give the end

of the screwdriver a sharp tap to snap the relay into the

track. Now reconnect the low and high voltage

connections.

I

N

Snaplink Latching Relay.

Introduced at the end of 2005 the Snaplink Latching

relay is a heavy duty 347 volt relay. It is designated

Normally Closed since it will snap to closed upon loss

of power.

The heavy construction ensures that any dead short

on the output is passed along to the circuit breaker

with minimal damage to the relay. The extra large ter-

minals can take 2 number 8 wires for loads at long

distances from the cabinet.

The Snaplink Latching relay is not a Zero Cross relay

yet is rated to switch 20 amps of High Output

Flourecent ballasts loads for 100,000 operations.

(Most smaller relays require a zero cross circuit to

handle High Output ballasts which have extremely

high inrush currents.)

19

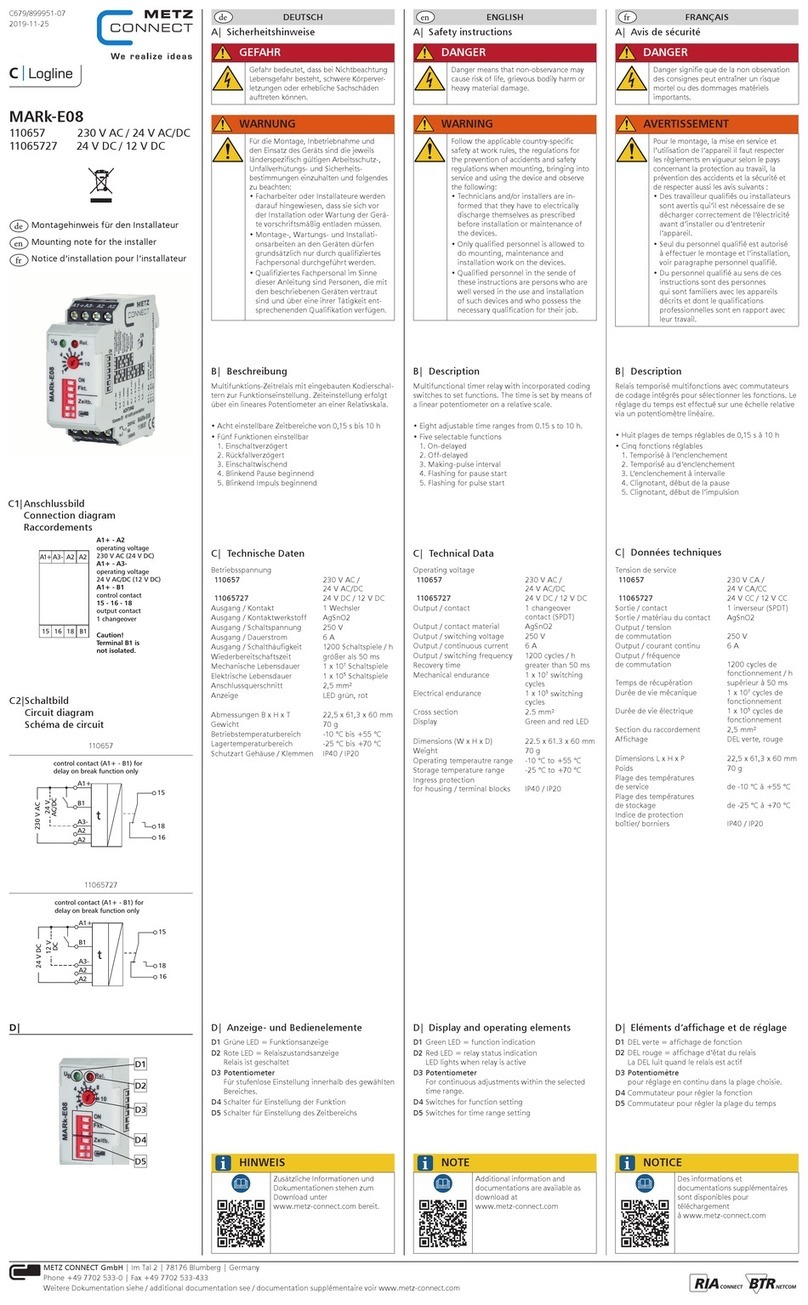

Dual Voltage Input Card

Most systems are shipped with dual voltage input cards.

These have a rotary switch that selects OFF, 120 VAC or

277 VAC.

When 277Vac is connected there will be no voltage on the

120 Volt terminal and similarly when 120 Volts is selected

there will be no voltage on the 277Vac connector.

In the OFF position both the 120 and 277 volt inputs are dis-

connected.

The 277 Vac primary is protected with a thermal fuse, the

120 Vac primary is protected with a 1amp circuit breaker.

Page 14

B

BREAKER

DigiLink

The DigiLink Dry Contact Input Card is used to interface to

non LC & D equipment.

The DigiLink card is connected to the GR 2400 bus in the

usual way through the RJ 45 Connectors or the“1234” bus

connector.

It is most usually mounted inside one of the relay panels but

may also be mounted in a 6" by 4" by 4" box in any conve-

nient location.

When used with an Occupancy Sensor an additional power

supply may be needed to provide the auxiliary voltage

needed by that brand of sensor.

For the hook up diagrams below only some inputs are illus-

trated in order to conserve diagram space. The additional

inputs are wired the same way.

Note that a DigiLink appears in the clock programming win-

dows as a 14 button switch. Each input is programmed in

the exact same way as a switch button.

20

Table of contents

Other Acuity Controls Relay manuals

Popular Relay manuals by other brands

Rockwell Automation

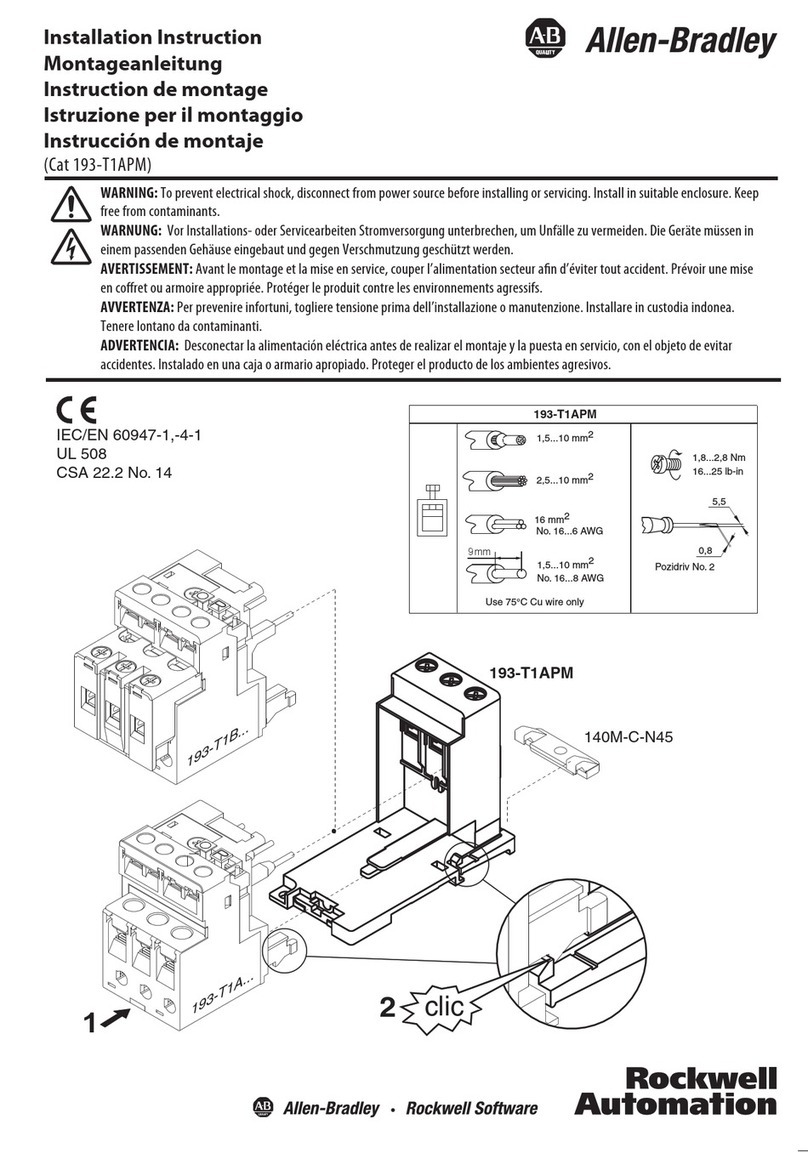

Rockwell Automation Allen-Bradley 193-T1APM Installation instruction

Emirel

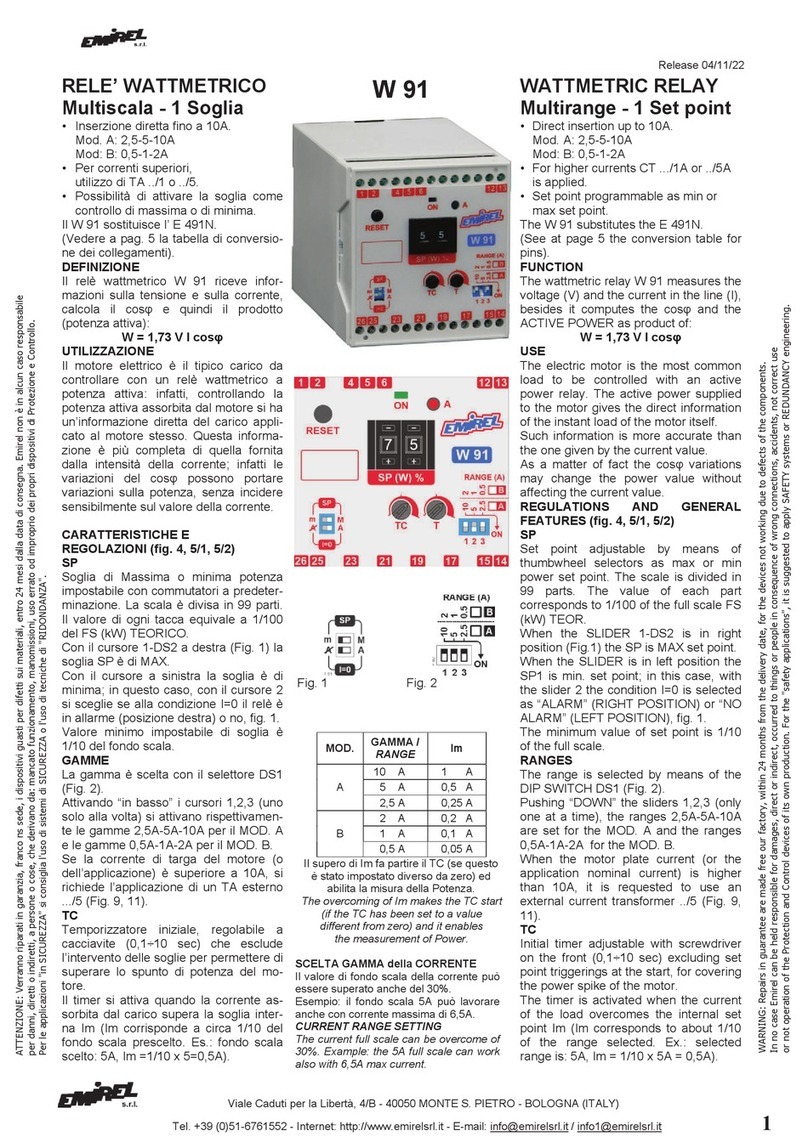

Emirel W 91 quick start guide

LS

LS META MEC Series instruction manual

ABB

ABB Relion 615 series installation manual

TSURUGA ELECTRIC

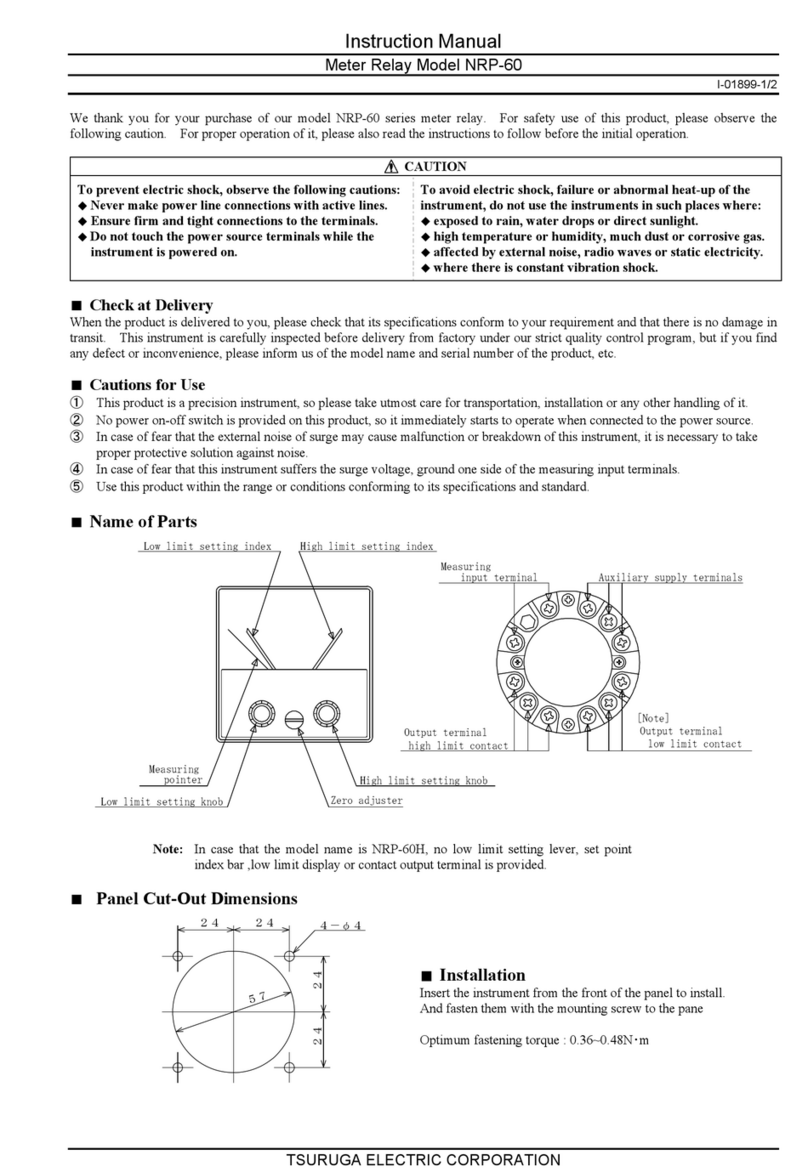

TSURUGA ELECTRIC NRP-60 instruction manual

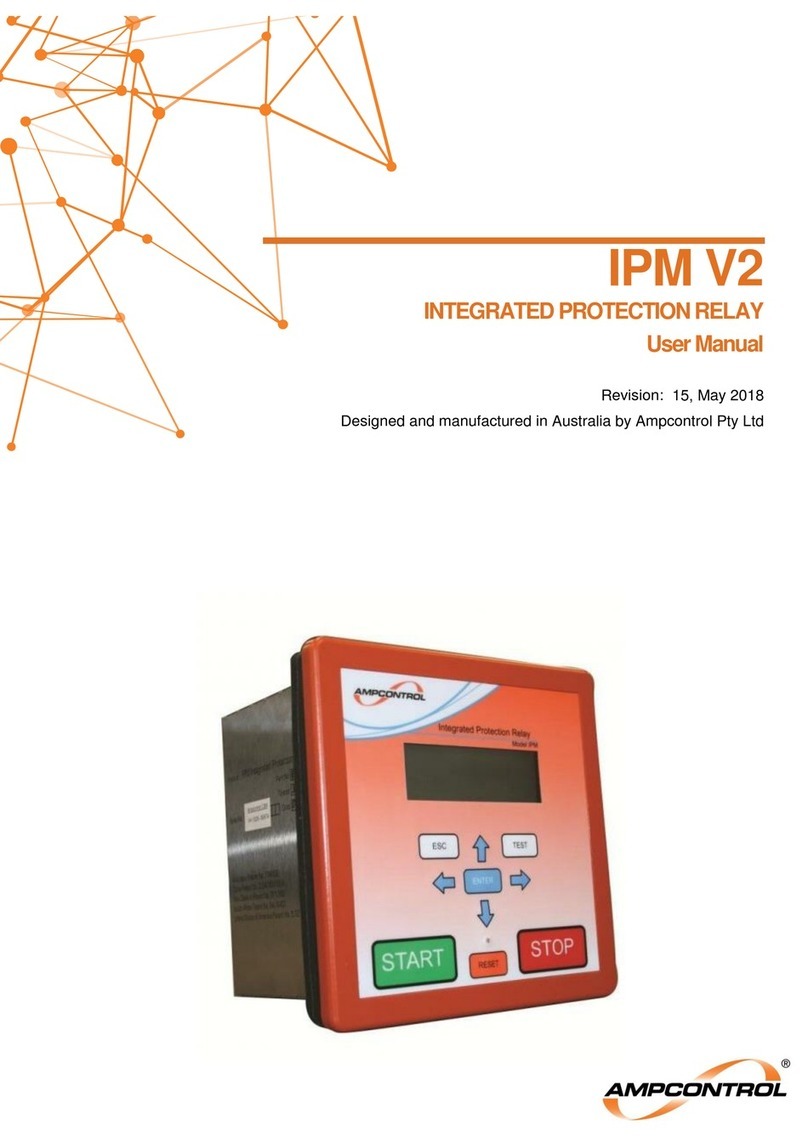

Ampcontrol

Ampcontrol IPM V2 user manual