MULTISPAN VPR-22 Instruction sheet

Other MULTISPAN Relay manuals

MULTISPAN

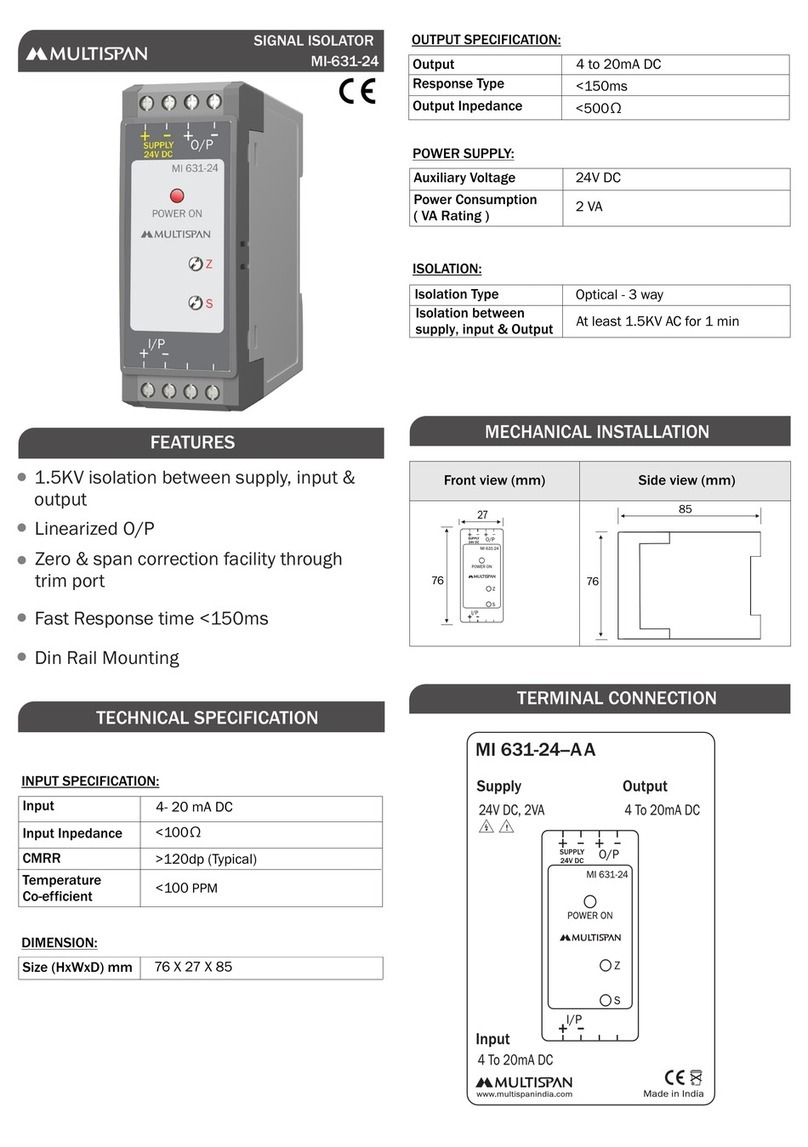

MULTISPAN MI-631-24 Instruction sheet

MULTISPAN

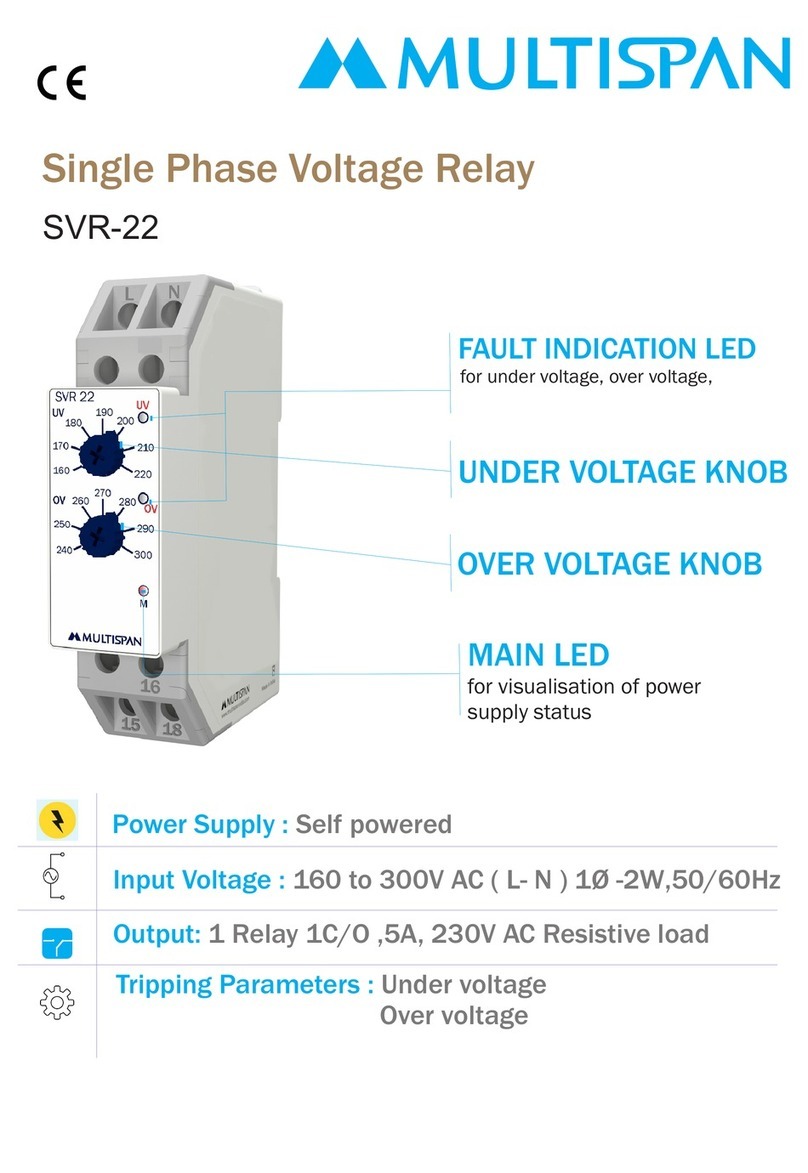

MULTISPAN SVR-22 Instruction sheet

MULTISPAN

MULTISPAN VPR-126-2R User manual

MULTISPAN

MULTISPAN CPR 126-1C User manual

MULTISPAN

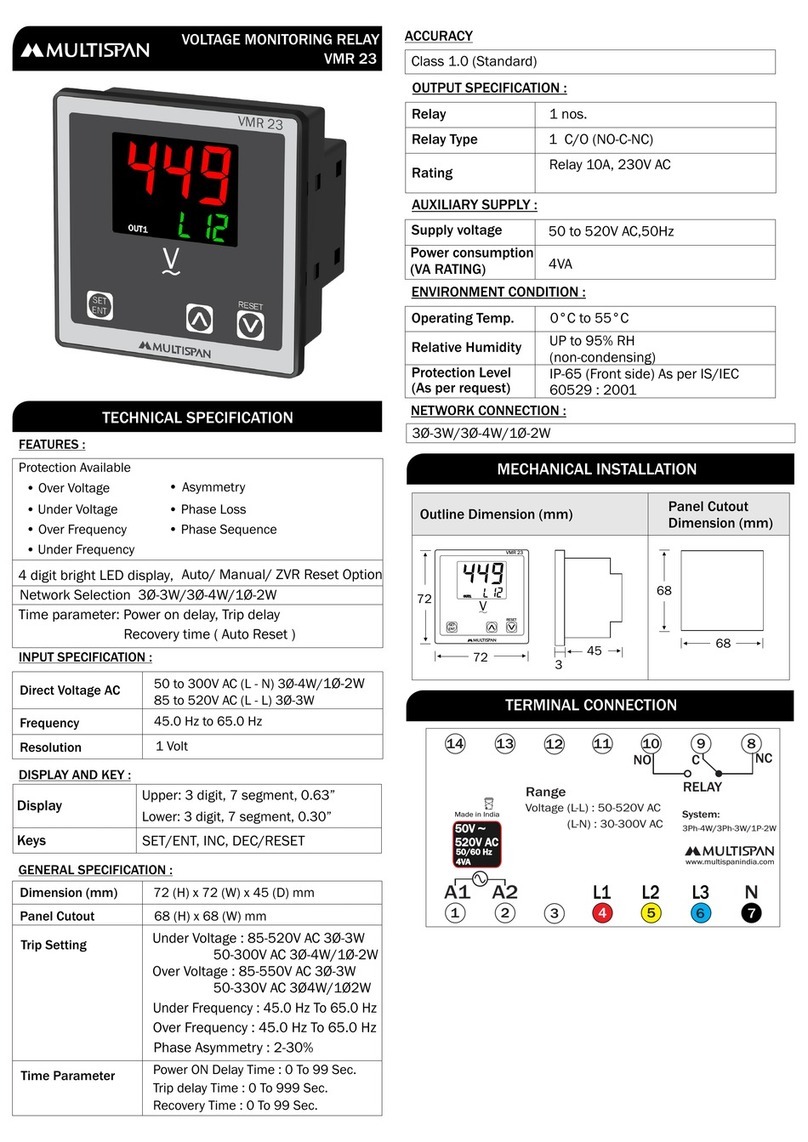

MULTISPAN VMR 23 Instruction sheet

MULTISPAN

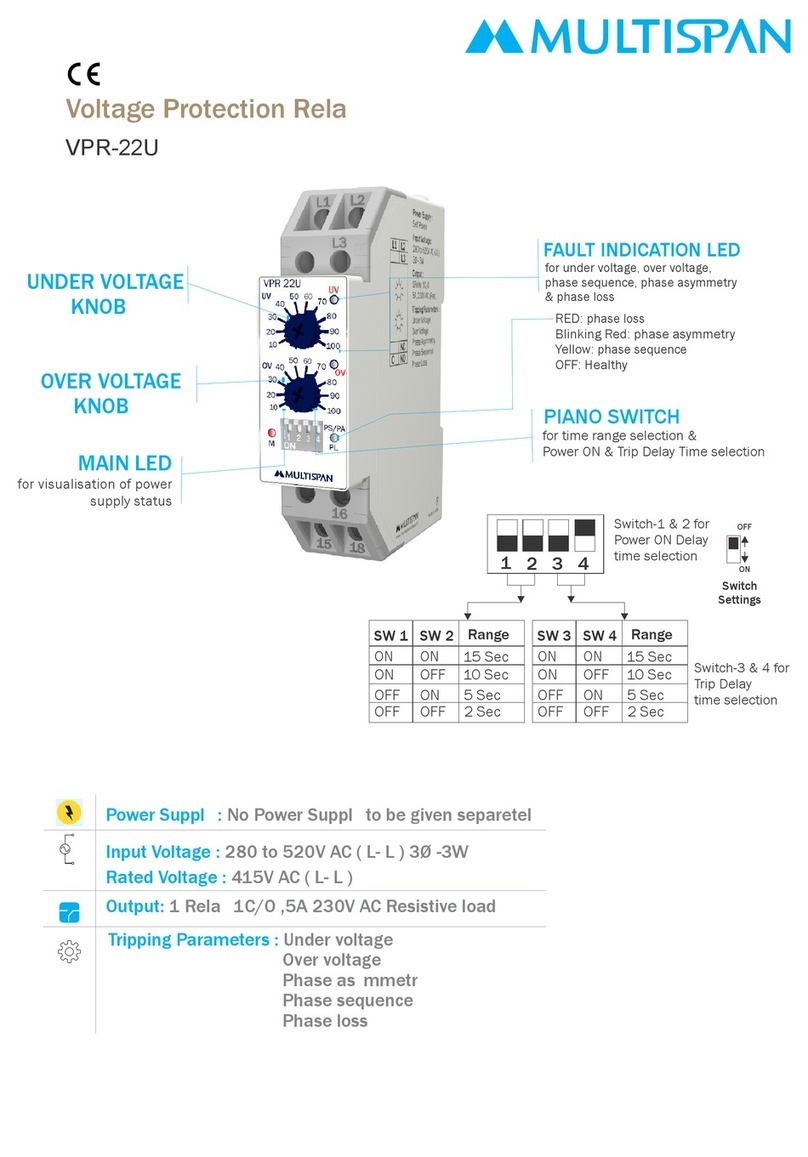

MULTISPAN VPR-22U User manual

MULTISPAN

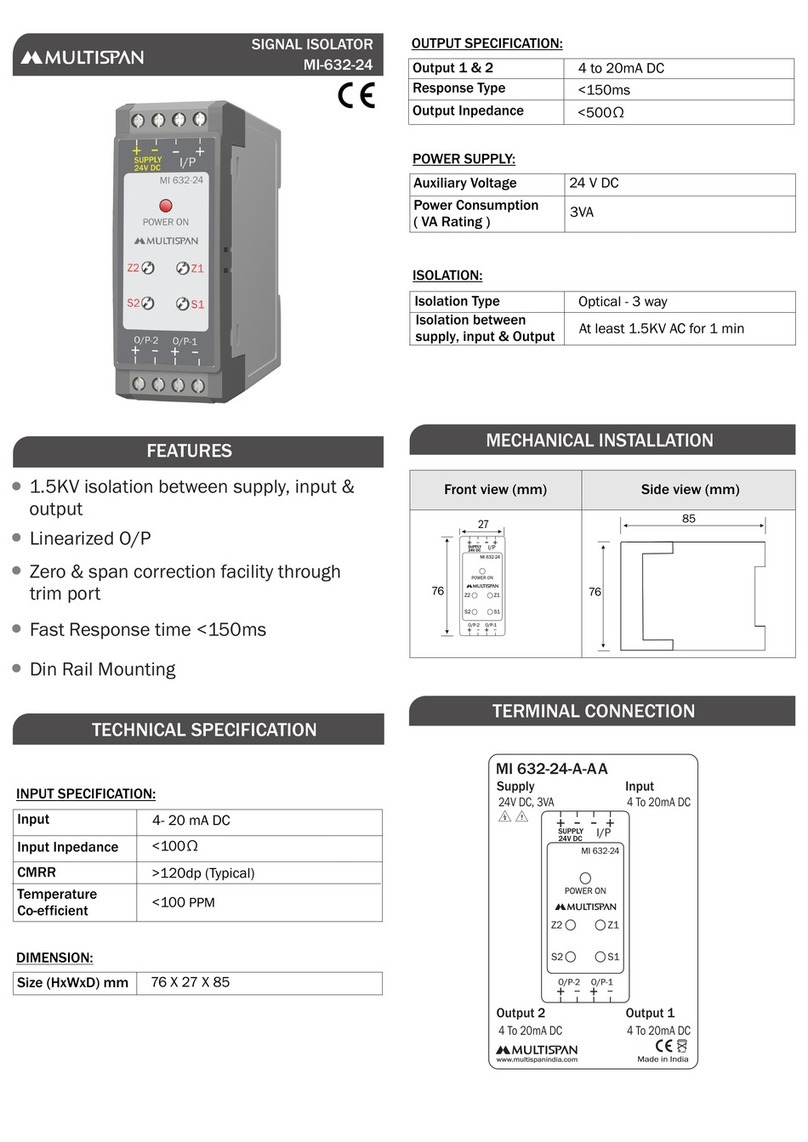

MULTISPAN MI-632-24 User manual

MULTISPAN

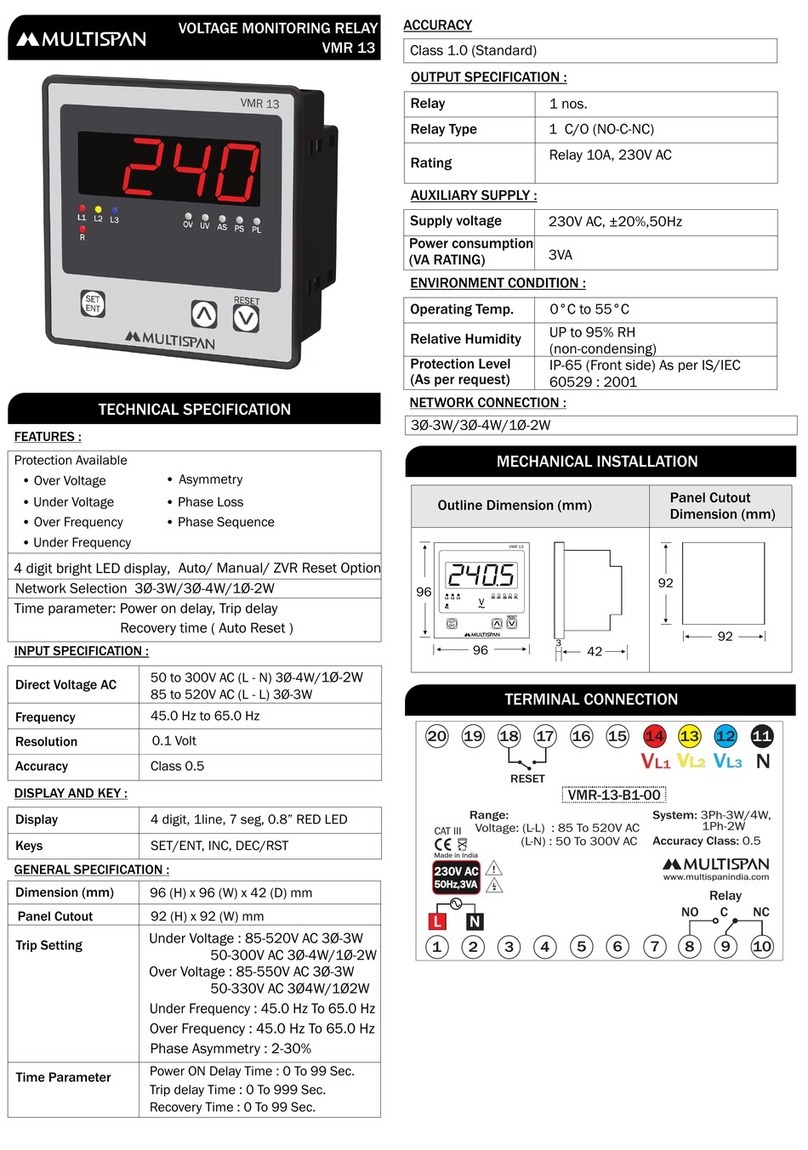

MULTISPAN VMR 13 User manual

MULTISPAN

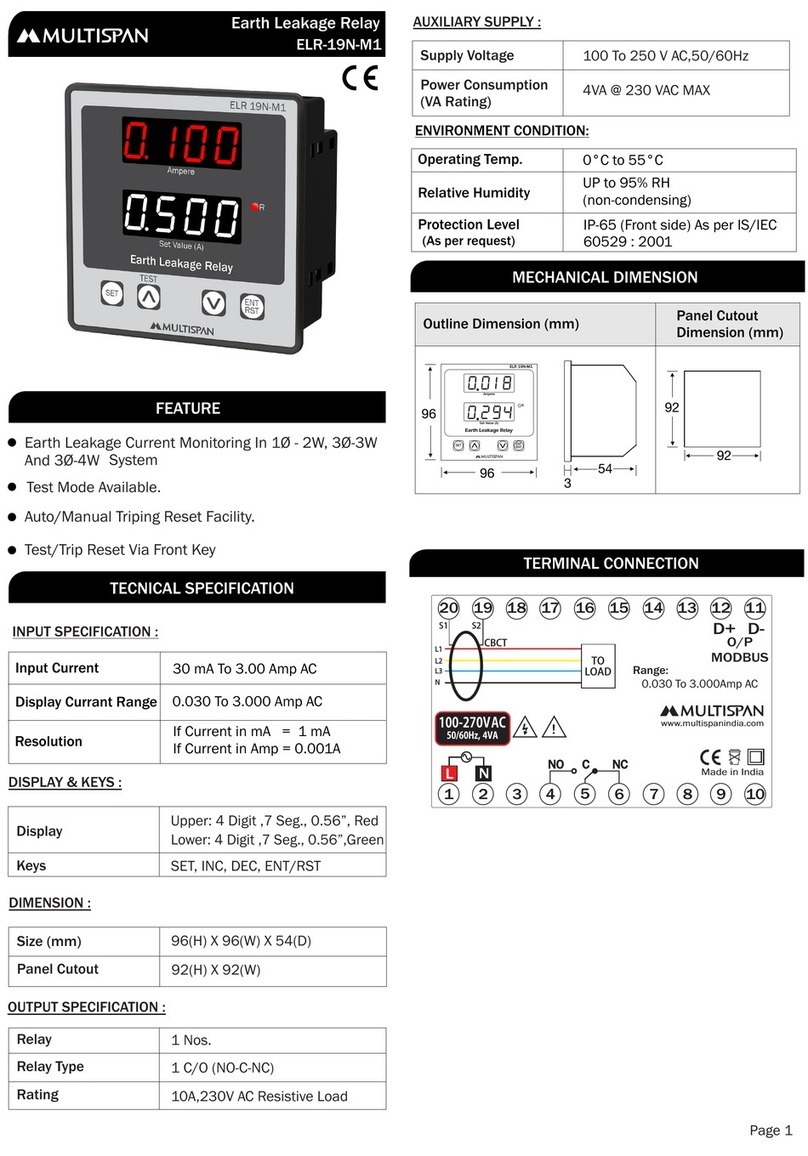

MULTISPAN ELR 19N-M1 User manual

MULTISPAN

MULTISPAN VPR 126 User manual

MULTISPAN

MULTISPAN ELR-19N-M1 Instruction sheet

MULTISPAN

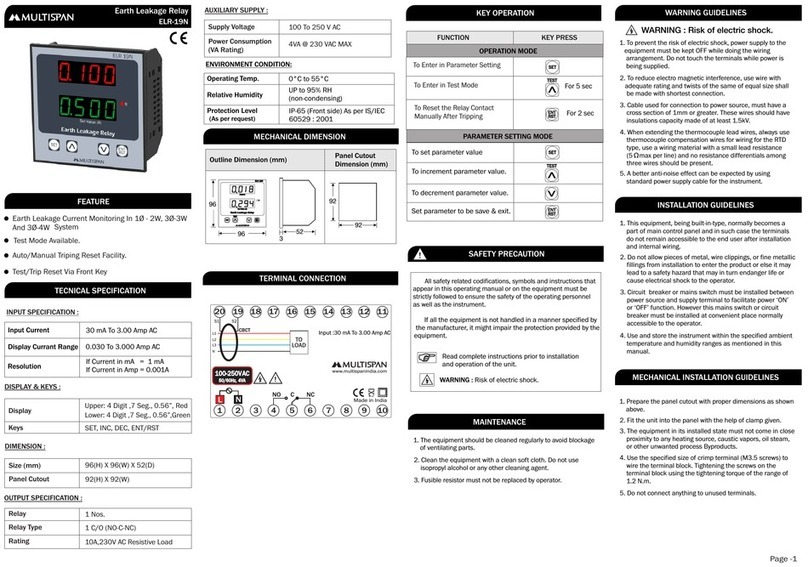

MULTISPAN ELR-19N User manual

MULTISPAN

MULTISPAN VPR 3P User manual

MULTISPAN

MULTISPAN ELR-19N User manual

MULTISPAN

MULTISPAN VPR 3P User manual

MULTISPAN

MULTISPAN ELR-63 User manual

MULTISPAN

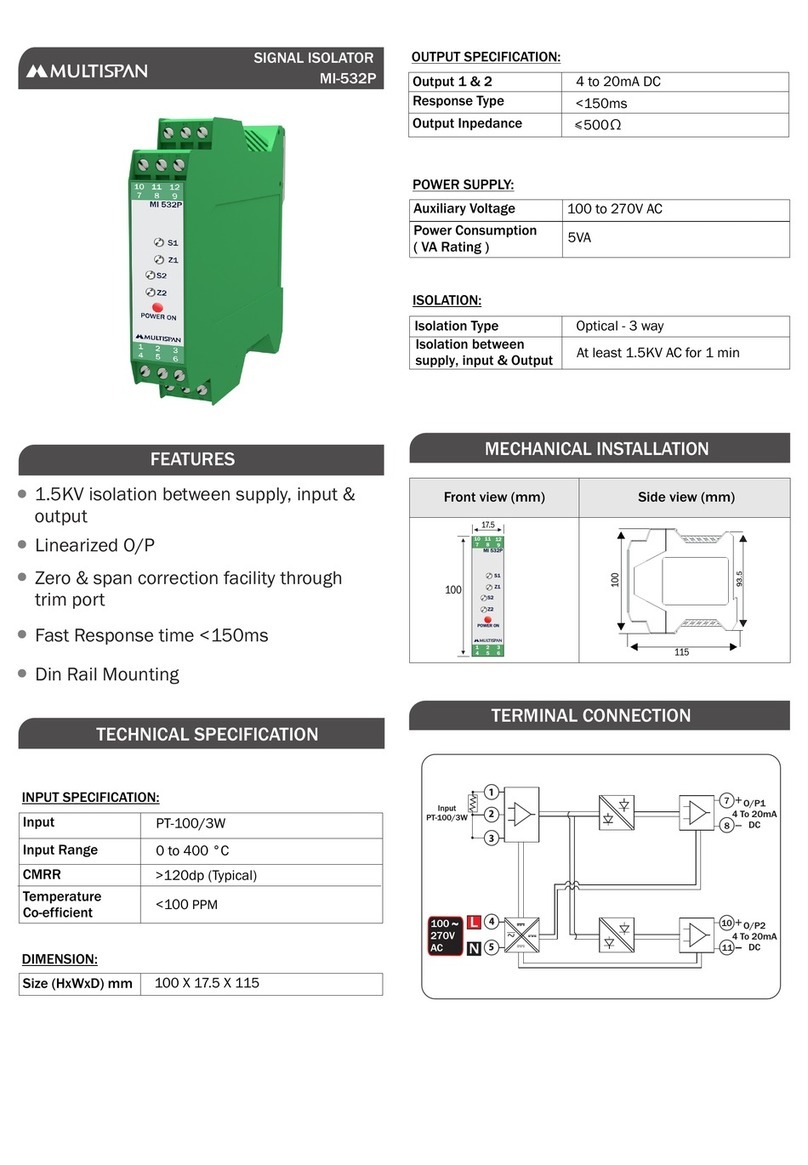

MULTISPAN MI-532P User manual

MULTISPAN

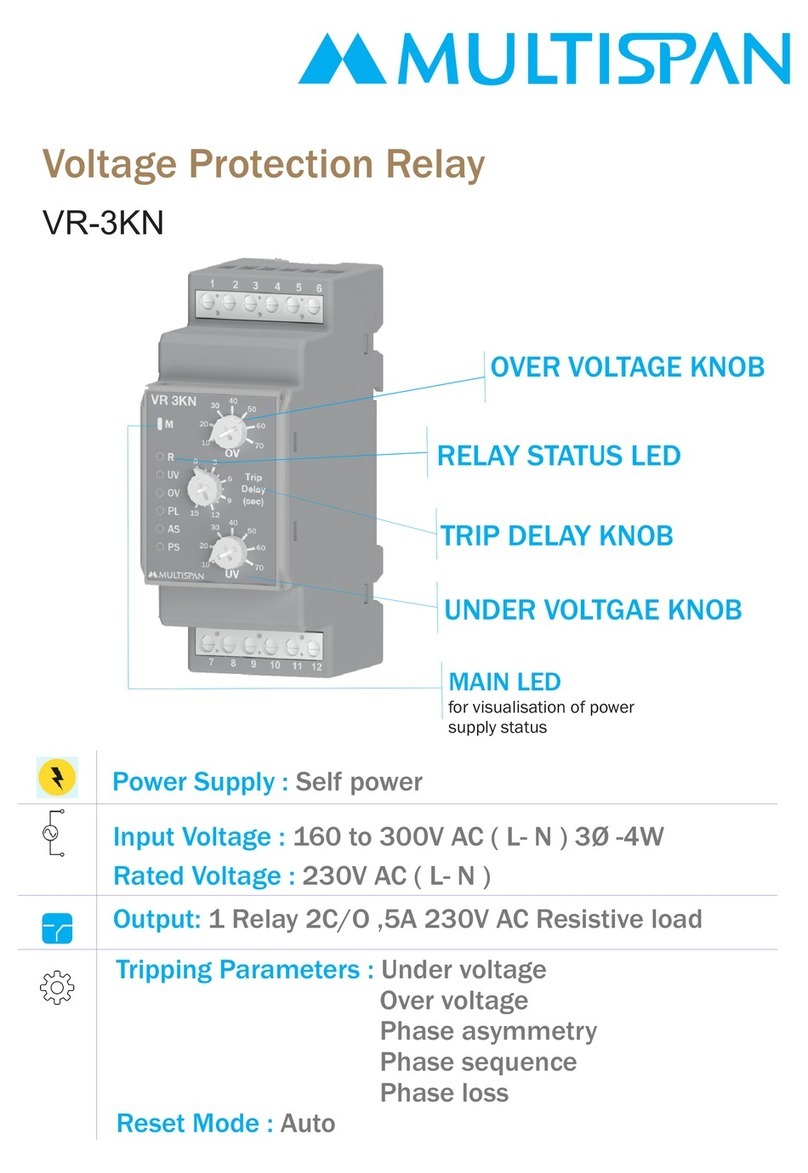

MULTISPAN VR-3KN User manual

MULTISPAN

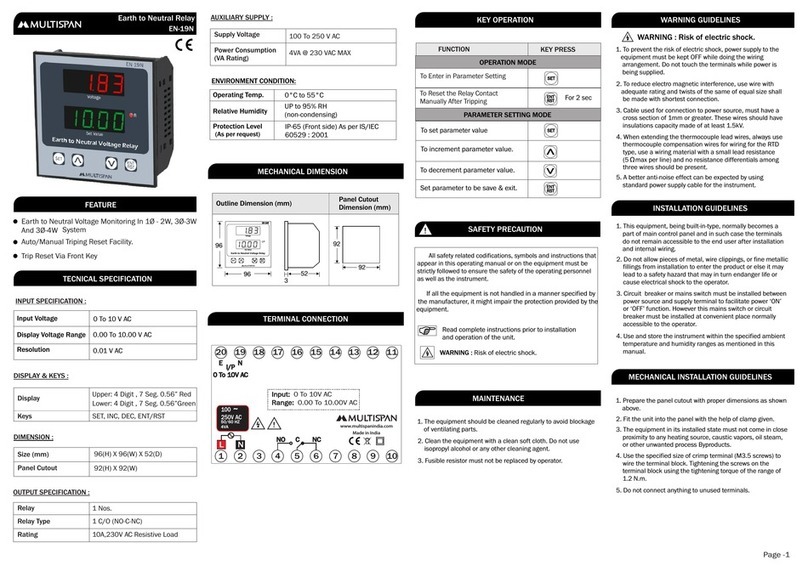

MULTISPAN EN-19N User manual

MULTISPAN

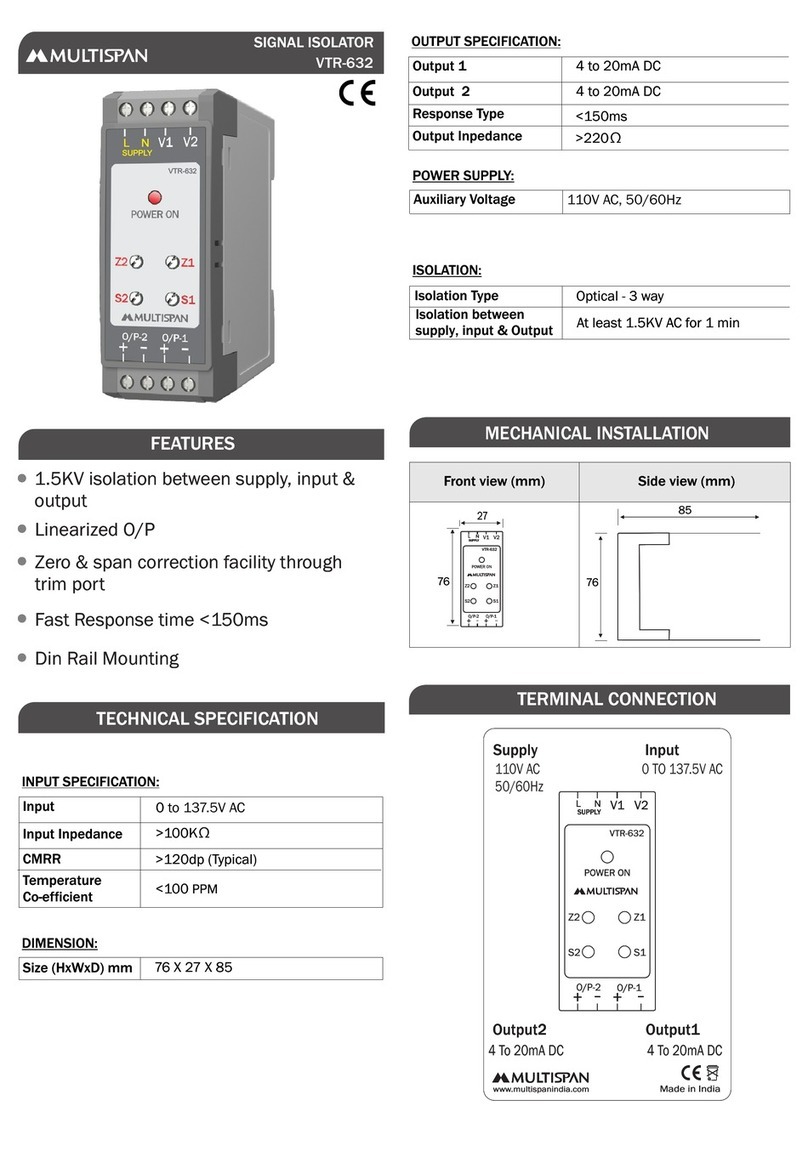

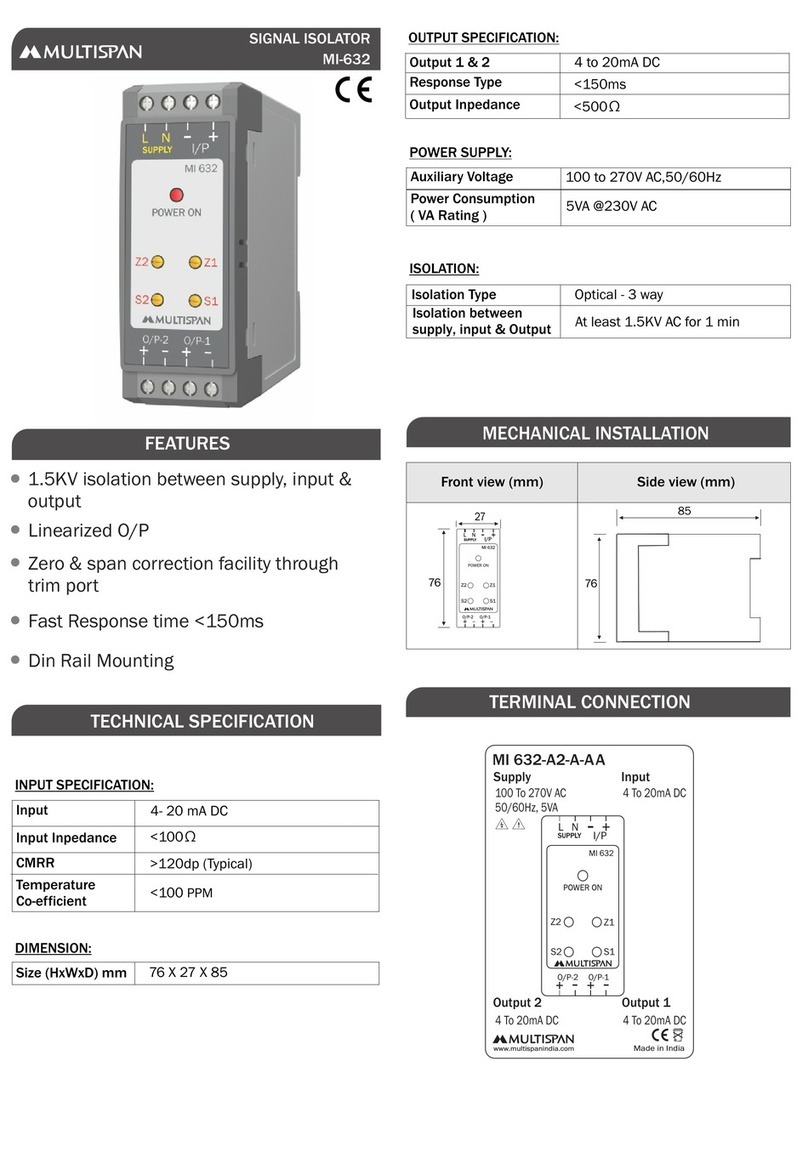

MULTISPAN MI-632 Instruction sheet