1-1

!"#$%&'()

GENERAL INFORMATION

DESCRIPTION

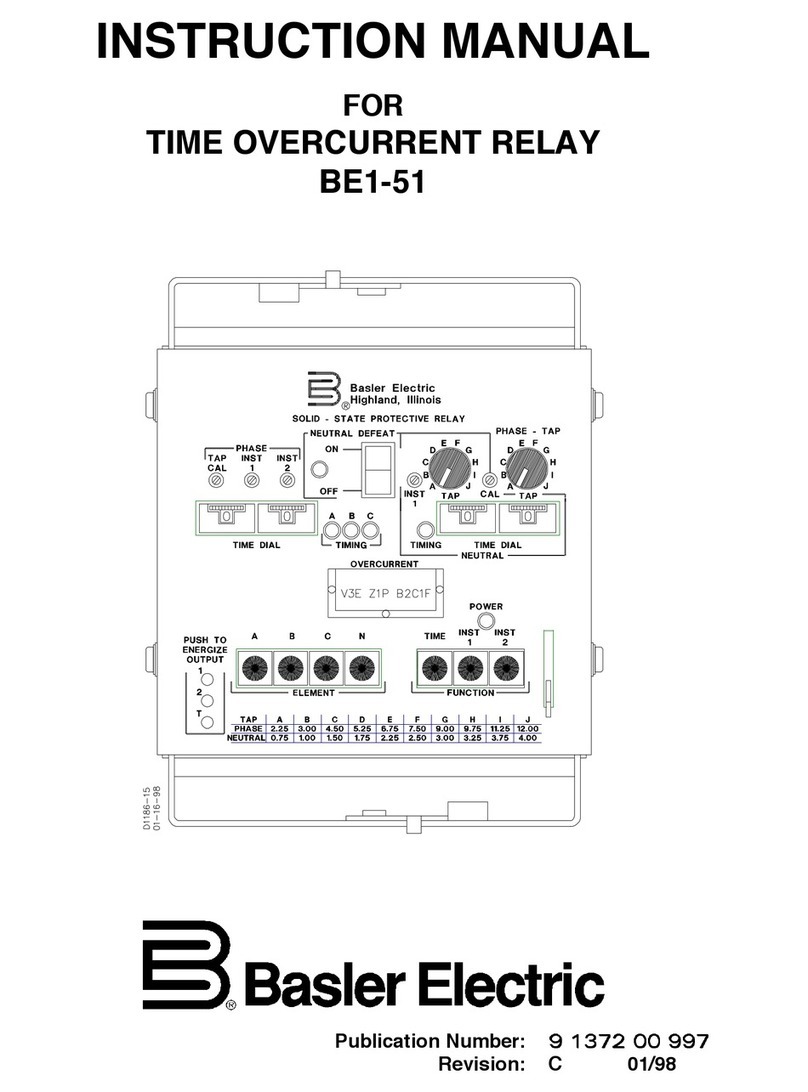

BE1-51/27C Time Overcurrent Relays are microprocessor-based devices that monitor the magnitude of line

current to provide accurate time-overcurrent protection with undervoltage control (when the voltage drops

below the set point, the timing circuit is enabled). Instantaneous overcurrent element(s) and the neutral time

overcurrent element, when supplied, operate independently of the undervoltage function. Each relay is

available with one, three, or four time overcurrent elements.

Basler BE1-51/27C relays provide backup protection for generators or transformers. Voltage control

provides discrimination between load and fault conditions by allowing the time overcurrent pickup to be set

below the maximum load (or swing) current. For sustained fault conditions, the synchronous reactance,

Xd(unsat), is typically larger than for normal load, Xd(sat). As a result, if the regulator is not in service, the three-

phase fault current will be less than the normal maximum load current. The relay pickup should be set below

rated maximum load current (e.g., 50 percent of rated) to ensure dependable backup. The BE1-51/27C

relay may also be used to provide primary phase fault protection for small generators or backup protection

for transformers.

When the BE1-51/27C is used to protect for faults on either side of a delta-wye power transformer, phase

overcurrent units should be supplied on all three phases (either three single-phase relays or one three-phase

relay). For this application, each phase time overcurrent element should be controlled by the phase-to-

ground voltage on its phase, rather than by the phase-phase voltage.

Because the time overcurrent pickup of the phase element(s) does not vary with voltage level (the element

is either enabled or not, depending upon voltage level), conventional time coordination techniques apply.

A neutral (ground) overcurrent element can be applied and connected residually to a set of three current

transformers on solidly grounded applications or on impedance grounded systems that provide ground fault

current approximating the generator rated current level. The neutral element can also be connected to a

10:1 ampere, zero-sequence window current transformer to provide protection on systems producing a

minimum of about 20 amperes primary current. Still another alternative would be connecting this device to

a current transformer in the neutral of a generator or power transformer.

Instantaneous elements can be used for transformer back-up applications when connected on the source

side of the power transformer. Because the pickup of these elements can be set above the relay current

flowing in the low-side fault, coordination can be achieved. Instantaneous overcurrent elements would not

ordinarily be used for a generator back-up function, because they would not operate correctly for faults

external to the generator zone.

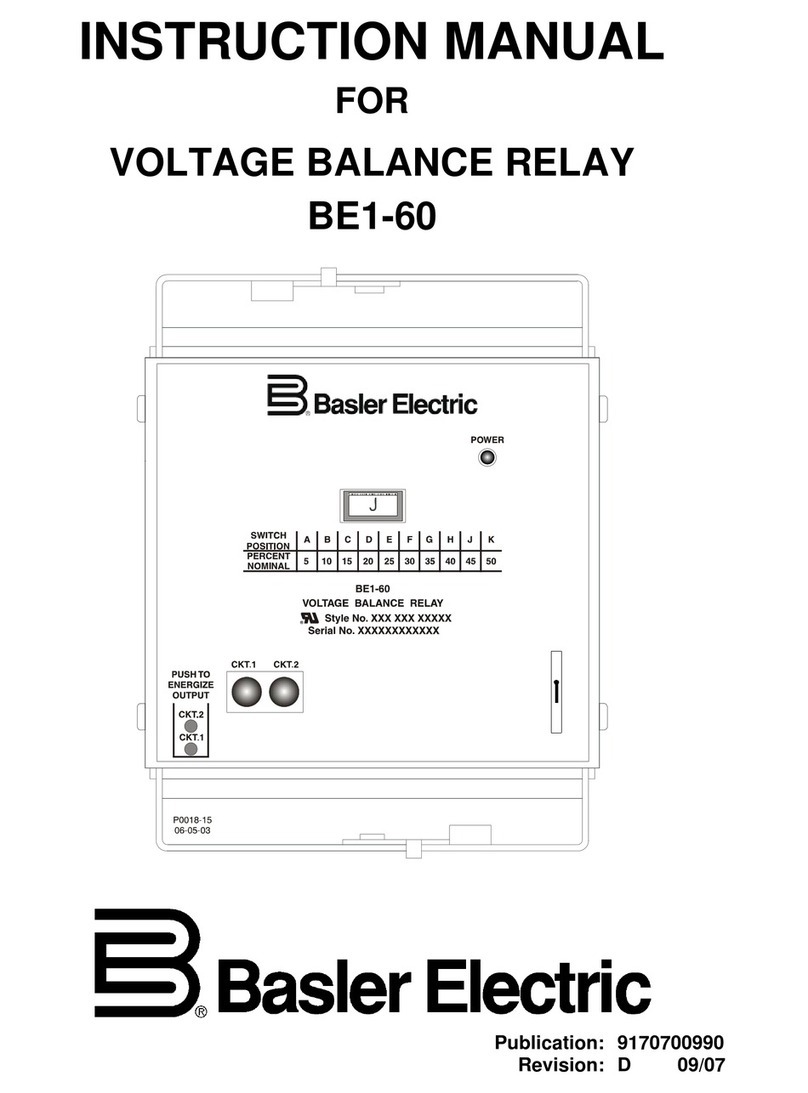

Under normal operating conditions, the phase time overcurrent pickup will be less than the maximum load

or non-fault current. As long as the rated voltage is applied to the relay, no operation will occur. However,

if a fuse opens on the voltage transformer and interrupts the signal, the relay will see this as a fault condition

(i.e., current level above pickup and voltage level below minimum set point) and operate accordingly. The

Basler Electric BE1-60 Voltage Balance relay can prevent such a misoperation where two sources of signal

voltage are available. This relay compares the output of two signal sources, to detect an anomaly in one

of these sources and block the operation of those devices connected to that signal source. Therefore, for

generator applications, the Basler BE1-60 Voltage Balance relay should be used in conjunction with the

BE1-51/27C to prevent misoperations due to loss of the voltage source.