Prosody X Installation guide

3 of 25

CONTENTS

1Getting started ........................................................................................................................ 5

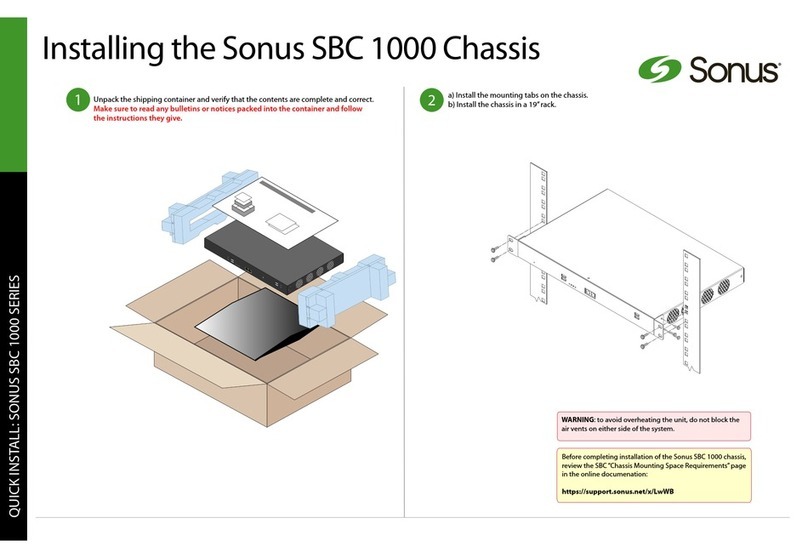

1.1 Unpacking and assembly ............................................................................................................ 5

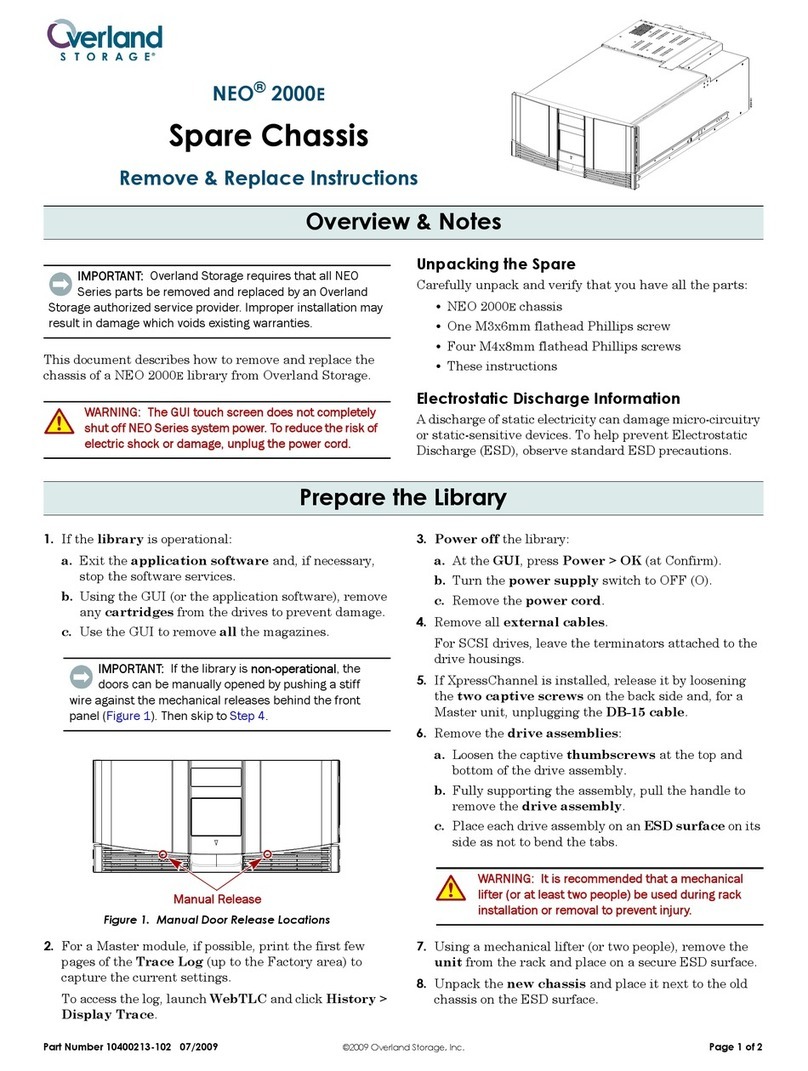

1.1.1 Chassis packaging .................................................................................5

1.1.2 Prosody X 1U HA Location.....................................................................5

1.1.3 Rack mounting 19 inch equipment..........................................................5

1.1.4 Free standing .........................................................................................5

1.1.5 Airflow and cooling .................................................................................5

1.1.6 Power connection AC option ..................................................................6

1.1.7 Power connection DC option ..................................................................6

1.1.8 Earth connection.....................................................................................6

1.1.9 Electrostatic discharge precautions ........................................................6

1.1.10 Prosody-X 1U HA chassis physical details..............................................7

1.2 Powering the Prosody X HA 1U on............................................................................................. 8

1.3 Powering the Prosody X 1U HA chassis off............................................................................... 9

1.4 E1/T1 trunk numbering................................................................................................................ 9

1.5 Ethernet connections................................................................................................................... 9

1.5.1 Ethernet LEDs......................................................................................10

1.6 Cabling........................................................................................................................................ 10

1.6.1 Cable pin-outs......................................................................................11

1.6.2 75 Ohm E1 trunk connection ................................................................11

1.6.3 Cable lengths .......................................................................................12

1.7 Ethernet equipment legacy compatibility ................................................................................ 12

1.8 System initialisation................................................................................................................... 13

1.9 Initial hardware checks.............................................................................................................. 13

1.10 Multiple Prosody X 1U HA configurations ............................................................................... 13

1.11 Common setup problems.......................................................................................................... 13

1.11.1 System TDM clock not configured........................................................13

1.11.2 Ethernet IP address out of range..........................................................13

2Hardware maintenance......................................................................................................... 14

2.1 Servicing..................................................................................................................................... 14

2.1.1 Battery replacement .............................................................................14

2.2 Cooling fan failure...................................................................................................................... 14

2.3 Power Module Failure ................................................................................................................ 15

2.4 Moving an installed Prosody X 1U HA chassis ....................................................................... 16

2.5 Basic fault finding ...................................................................................................................... 16

Appendix A: USA/Canada approval details ............................................................................. 17

USA federal communication commission warnings........................................................................ 18

Appendix B: Approval details for UK and other EU countries............................................... 19

Appendix C: Approval details for Australia............................................................................. 20

Appendix D: Warranty and support.......................................................................................... 21

D.1 Warranty...................................................................................................................................... 21

D.2 Returns procedure ..................................................................................................................... 21

D.3 Accessories................................................................................................................................ 21

D.4 Contact information ................................................................................................................... 21

D.5 Prosody X 1U HA chassis technical support........................................................................... 21

Appendix E: Safety information................................................................................................ 22

E.1 AC Power requirements............................................................................................................. 22