1. INTRODUCTION

This publication contains all necessary information for the installation, operation and maintenance of the kitchen

cutter.

The purpose of this publication, hereinafter also referred to as the “manual”, is to inform the user in a clear and

easily understandable form in order to ensure a long service life and a fault-free operation of the machine.

The machine has been developed and manufactured to shred foods such as meat, fish, vegetables, cheese,

nuts, etc. into small pieces in the commercial sector.

Kitchen cutters are subject to continuous improvements, but this in no way affects the instructions and details

in this manual.

This manual must be read carefully before putting the kitchen cutter into operation.

If this manual becomes worn out or gets lost over time, immediately request a copy of the manual from the

manufacturer.

The majority of accidents and injuries that occur when using the machine is due to insufficient knowledge of its

functions and safety devices. Therefore, the instructions and information contained in this manual should be

read carefully before starting work with the machine.

1.1 Introduction

The Rotomat series kitchen cutters are designed according to the applicable safety standards. For this reason,

on each device you will find the “CE” identification label that certifies conformity with the requirements.

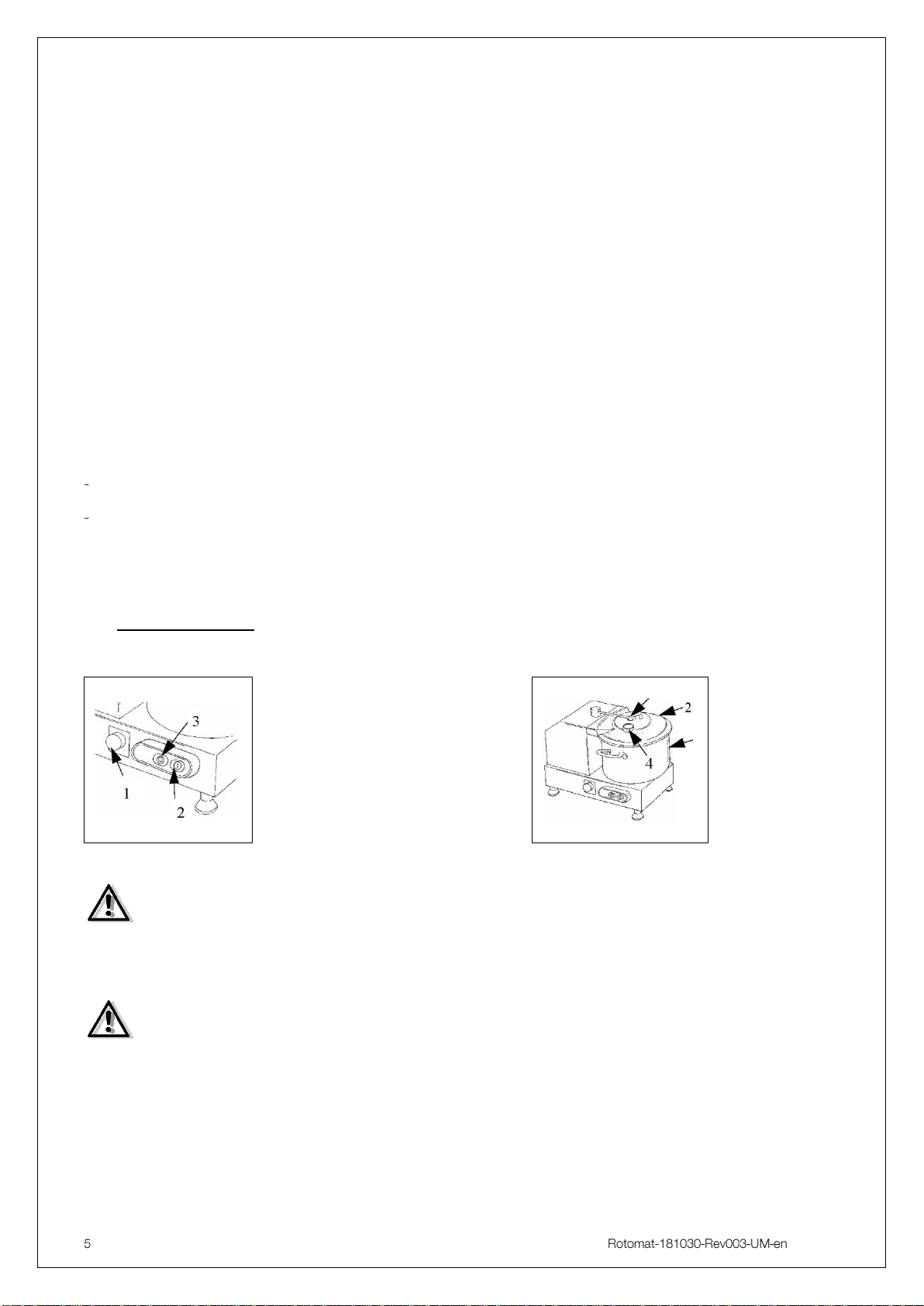

The machine consists of a base that carries a pot, with two rotating blades screwed to a spindle inside the pot.

The products can be shredded or processed into mash depending on the working time of the two blades.

All machine components are made of chrome steel (AISI 430; housing) or stainless steel (AISI 304; pot). This

material guarantees hygiene during contact with foods, as well as great resistance to acid salts and oxidation.

The hardened and polished blades are made of blade holder stainless steel (AISI 420). This allows foods to be

cut, crumbled, beaten and kneaded without having to change the blades. The pot is made of stainless steel

(18/10 stainless steel) with heat spreading bottom. The pot is equipped with handles that provide maximum

handiness and easy removal.

The blades are driven by an electric motor. Start-up and stopping are triggered by buttons connected to an

auxiliary control circuit that prevents unintentional start-up after a possible power outage.

1.2 Use

The Rotomat series kitchen cutters are designed for shredding, cutting and crumbling into small pieces, as well

as for beating and kneading of foods such as meat, fish, vegetables, cheese, nuts, etc. Foods to be processed

should already be pre-portioned into pieces so that they fit easily through the feed opening on the lid.

Two horizontally rotating sickle blades ensure perfect cutting.

The user is advised to fill the pot only partially to achieve the best possible cutting results.

The continuous operating time of the shredding machine should be limited to 24 minutes (duty cycle = 40% per

hour) in order to avoid overheating of the motor. The operation can be resumed after appropriate rest period,

during which the motor cools down. If you process a very tough material, the intervals should correspondingly

be kept shorter.