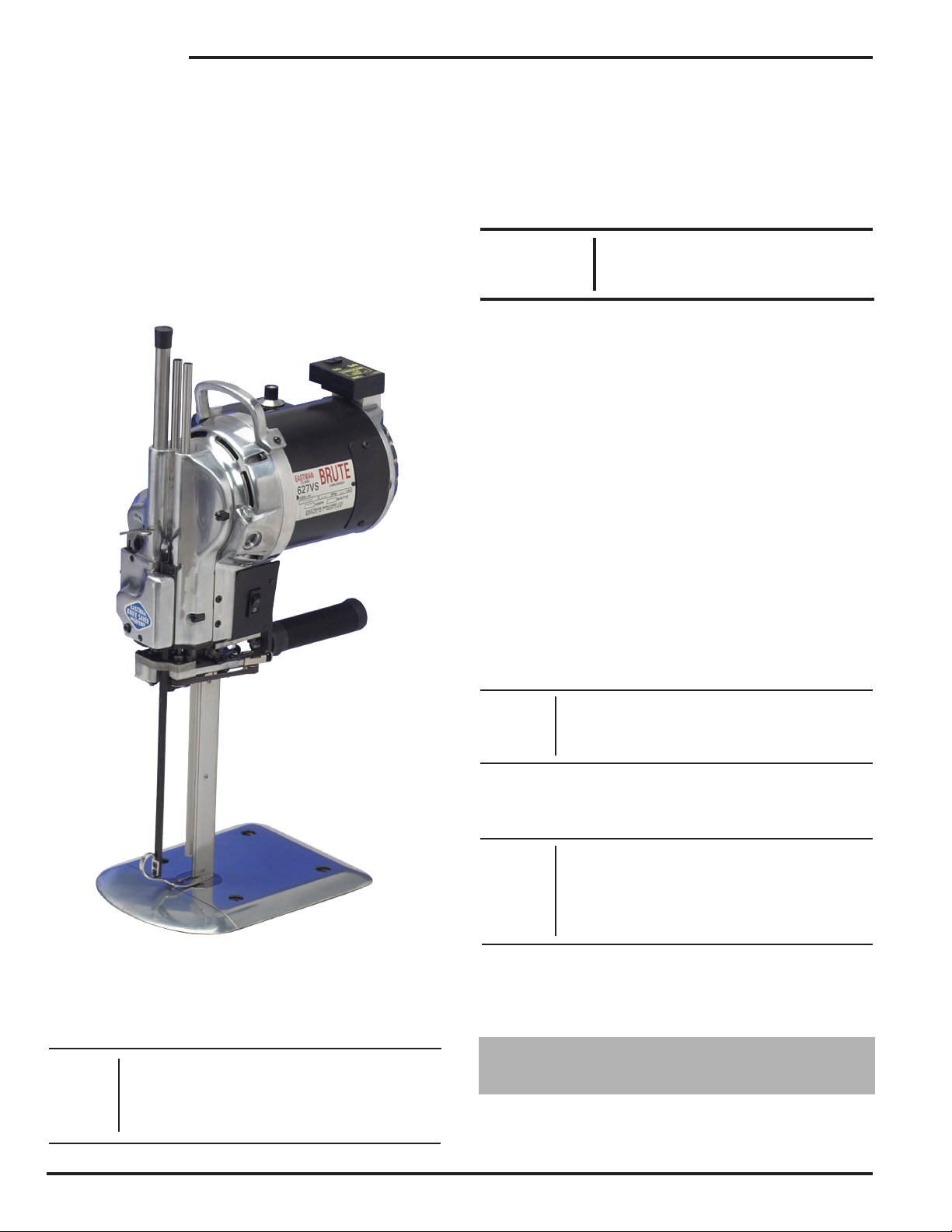

EASTMAN

2

This machine is equipped with a sharp knife.

Keep hands away from the knife area at all

times. Use control levers and handles only

when operating or handling machine. When

machine is not in operation the KNIFE

GUARD/PRESSURE FOOT should be kept

lowered (by depressing lever B) to the base

plate at all times, except when changing

the knife or performing similar maintenance.

When making a cut the KNIFE GUARD/

PRESSURE FOOT should be raised by

handle G only enough to clear the material

being cut. When this equipment is not be-

ing utilized, the power supply should be

disconnected from the machine.

WARNING:

The purchaser must instruct all operators on the proper use of

the equipment. All standard industrial safety measures and

equipment should be provided to protect the operator. Opera-

tors must be cautioned that improper use of this equipment can

cause bodily injury. If you do not have qualied operators to

instruct new persons, contact your Eastman sales representative

or write to Eastman Machine factory direct.

Before starting the motor, be sure that electric supply voltage

and current are the same as stamped on the nameplate.

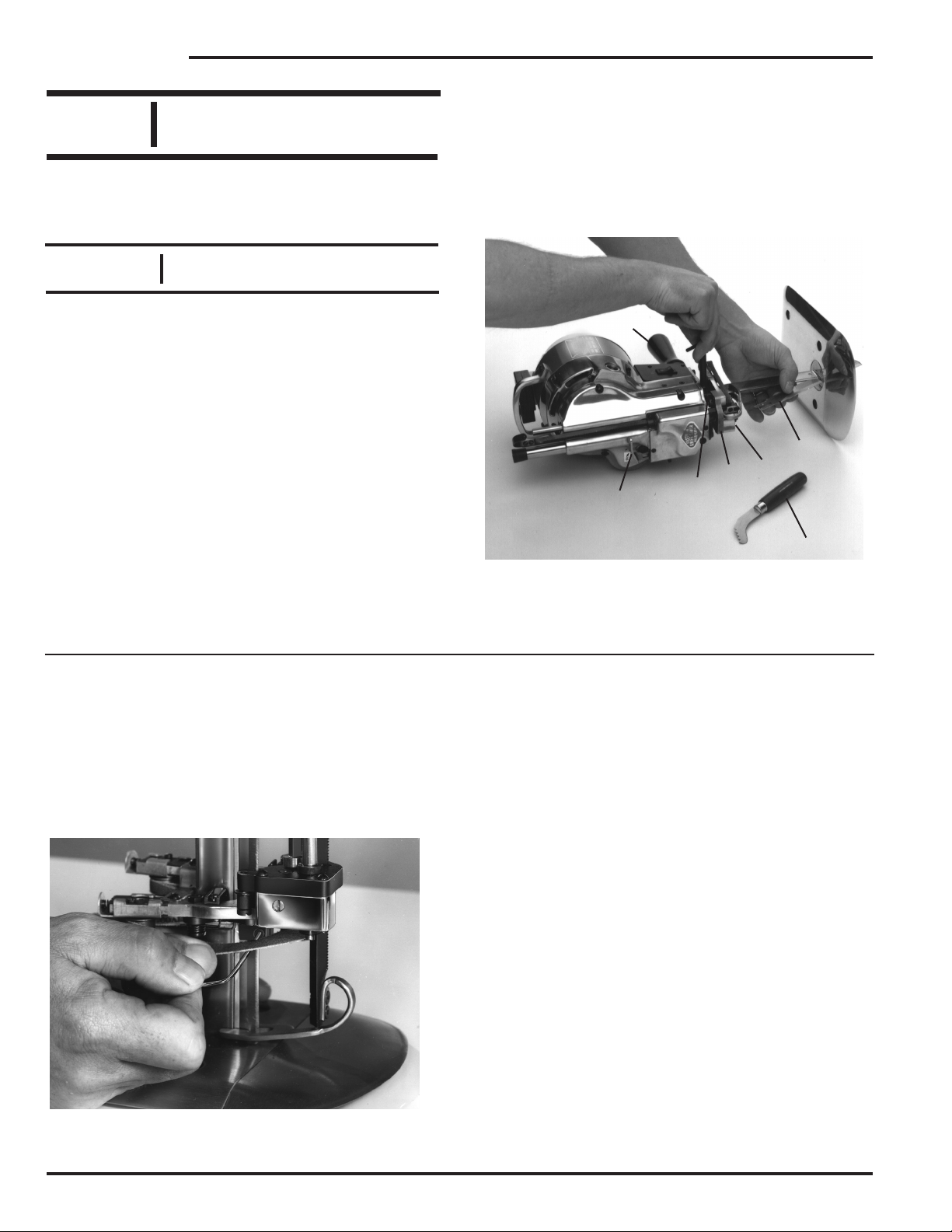

Fill oil cup F (see illustration page 3). Make sure the sharpener is

in locked position. Push in turning knob A and turn the machine

over a few revolutions by hand to see if the knife moves easily.

If the knife does not move easily, sharpener is probably in an

unlocked position. Use bell crank release lever N to return

sharpener to locked position.

Proceed as follows: Check to see that motor switch is in off

position. Connect attachment plug to terminal block on machine.

With left hand straddle front of sharpener with ngers and

thumb. Press in release lever N to dis-engage sharpener

mechanism from motor. With right hand turn on motor switch,

allow motor to gather full speed and then release lever N. This

will automatically return sharpener to locked position. Knife

must be in machine.

The variable speed straight knife ranges in speeds of 1,200 to

4,000 RPM depending on the control setting. The setting, de-

pending on operator preference, can be decreased by turning

the speed control knob "1" counter-clockwise to a lower number

(0=1,200 rpm) or increase by turning clockwise to a higher number

(10=4,000 rpm).

For the rst week or two, or after the machine has been idle for

any length of time, the motor should be turned on and off a few

times before running continuously. This permits the oil to warm

up and ow easily into the closely t moving parts. IN COLD

WEATHER, PLEASE KEEP MACHINE IN WARM PLACE.

Before performing any of the following

procedures, make sure that the attach-

ment plug has been disconnected from

power source.

Operation,

Lubrication

And Care

Before operating machine, read

these instructions carefully.

Familiarize yourself with all

functions and adjustments of this

equipment.

Do not operate sharpener without

knife in machine or the sharpener

will be damaged. Do not shut off

motor while sharpener is in motion.

IMPORTANT:

Depress bell crank 584C3-16

release lever to return sharpener to

locked position before starting.

WARNING:

WARNING:

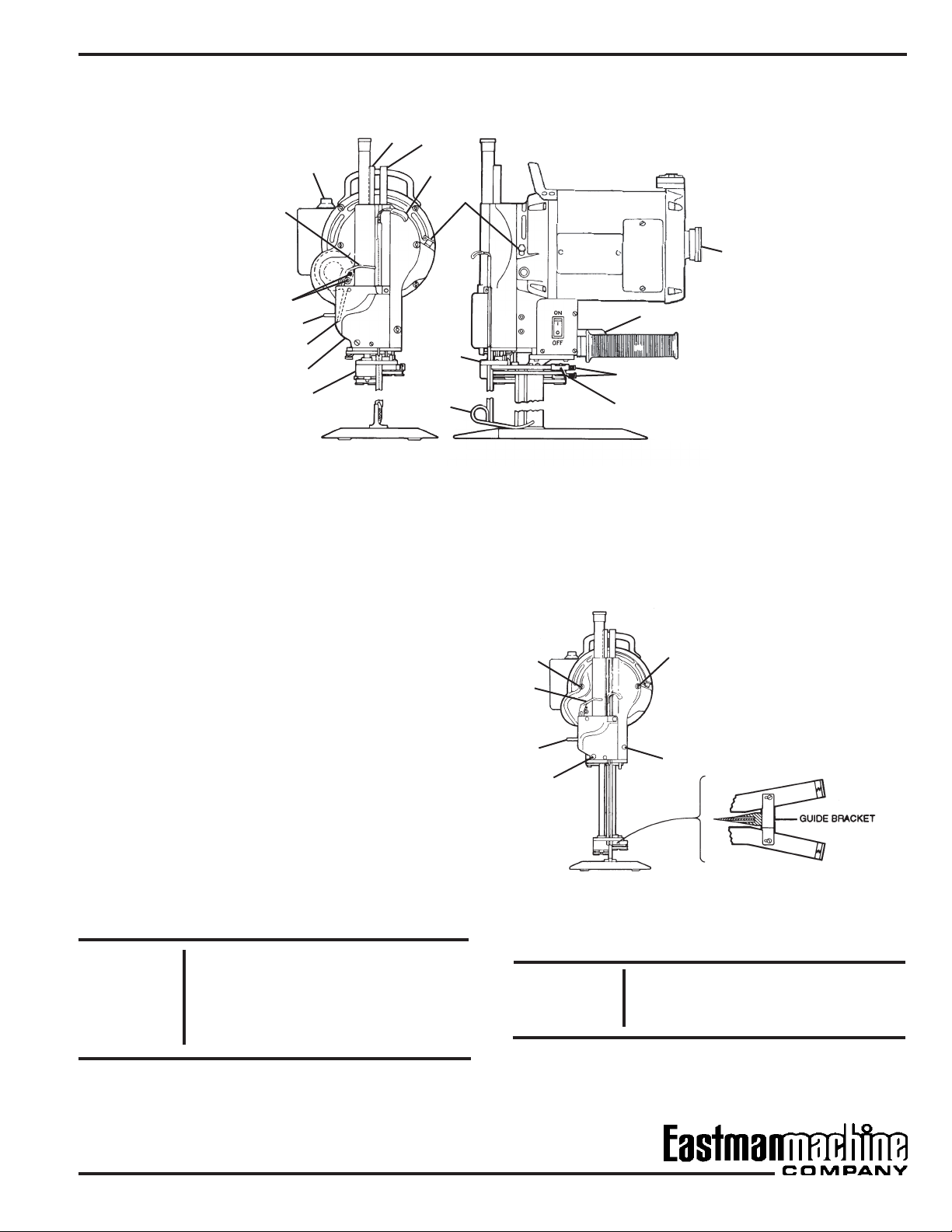

Operating

Handle

Knife Guard-

Pressure Foot

Carrying Handle