Adec 500 User manual

-DEC

500"

Owner's

Guide

MODEL

551

ASSISTANT

S

INSTRUMENTATION

A

A

aídec

A-dec

500

Assistant's

Instrumentation

Quick

Start

Guide

A-dec's

standard

assistant's

package

includes

syringe,

HVE,

and

saliva

and

Saliva

Ejector

About

the

ejector.

Optional

instruments

may

include

an

additional

HVE.

The

Assistant's

assistant's

vacuum

instruments

are

fully

autoclavable

and

have

quick

Instrumentation

disconnect

attachments

that

remove

easily

for

cleaning.

_

Left-Right

The

HVE

and

saliva

ejector

can

be

easily

Conversion

of

the

converted

for

opposite-hand

operation.

Autoclavable

HVE

To

convert

the

HVE

or

saliva

ejector

for

opposite-hand

use,

push

the

control

valve

out

of

the

HVE

body,

by

pressing

on

the

small

diameter

side.

Rotate

the

control

valve

180°,

then

press

it

back

into

place.

1

-

Cannula

opening

(for

tip);

2

-

Valve

body;

3

-

Control

valve;

4

-

Tailpiece

Autoclavable

HVE

and

Saliva

Ejector

Asepsis

The

table

shows

the

steps

for

HVE

and

saliva

ejector

asepsis.

Step|

Action

Remove

the

tip

from

the

valve

body.

T

|

NOTE:

Turn

off

the

central

vacuum

before

disconnecting

the

HVE

or

saliva

ejector.

To

remove

the

HVE

or

saliva ejector

body,

separate

the

body

from

2

|

the

tubing

by

pullingit

apart

at

the

tailpiece,

and

removing

the

control

valve.

Clean

and

rinse

the

valve

body

and

control

valve

using

a

mild

4

|

detergent,

water,

and

the

brushes

that

have

been

provide.

Allow

the

instrumenis

to

dry

completely.

Heat

sterilize

the

valve

body

and

control

valve

for

six

minutes

using

5

either

of

these

methods:

steam

autoclave,

or

chemical

vapor

(275°F

[135°C]

maximum

temperature).

Apply

a

light

coat

of

A-dec

silicone

lubricant

on

the

O-ring

seals

of

the

control

valve.

©

6

|

CAUTION:

Use

only

silicone

lubricant

when

lubricating

instrumentation

O-rings.

Petroleum

products

will

cause

permanent

damage

to

the

O-rings.

7

|

Reinstall

.the

control

valve

in

the

valve

body,

and

the

tubing

tailpiece.

8

Operate

the

HVE

and

the

saliva

ejector

valves

several

times

to

verify

that

they

rotate

smoothly.

Copyright

©

2004

A-dec

Inc.

All

Rights

Reserved.

À.

sê

86.0603.00

2003-12

Rev.

A

(04123.13)

Sterilizing

the

HVE

Tip

adec’

It

is

recommended

that

the

stainless

steel

tips

used

on

the

HVE

be

heat

sterilized

between

patients

using

either

of

the

following

methods:

steam

autoclave,

or

chemical

vapor

(275°F

[135°C]

maximum

temperature;

four

minutes

at

temperature).

If

you

are

using

disposable

HVE

tips,

be

sure

to

replace

them

with

new

tips

between

patients.

The

table

shows

the

steps

for

sterilizing

the

HVE

tip.

Step

|

Action

1

|

Remove

the

HVE

tip

from

the

HVE

valve

body.

>

Clean

and

rinse

the

HVE

tip

using

a

mild

detergent

and

water,

then

allow

the

tip

to

completely

dry.

3

|

Sterilize

the

HVE

tip

using

one

of

the

recommended

methods.

NOTE:

A-dec

HVE

Cannula

Opening:

Standard

A-dec

HVE

—

0.435"

+

0.006"

(11.05

+

0.15

mm).

A-dec

15

mm

HVE

-

.592"

(14.8

mm).

If

not

using

A-dec

HVE

tips,

select

a

tip

that

is

compatible

with

your

HVE

cannula

opening.

A-dec

Saliva

Ejector

Cannula

Opening:

A-dec

Saliva

Ejector

—

0.265

+

0.006"

(6.73

+

0.15

mm)

Select

a

tip

that

is

compatible

with

your

saliva

ejector

cannula

opening.

Solids

Collector

The

solids

collector

aids

in

preventing

solids

from

entering

the

central

vacuum

system.

At

least

twice

a

week,

discard

and

replace

the

solids

collector

screen.

This

is

necessary

to

ensure

proper

suction

from

the

central

vacuum,

and

to

maintain

proper

treatment

room

asepsis.

The

table

shows

the

steps

for

sterilizing

the

HVE

tip.

Step

|

Action

Turn

off

vacuum,

if

vacuum

is

on,

open

the

HVE

control

valve

to

1

,

,

facilitate

removal

of

the

solids

collector

cap.

Remove

the

screen

from

the

collector.

The

solids

collector

screen

is

disposable.

Discard

following

your

local

regulations.

CAUTION:

Do

not

empty

the

screen

into

your

cuspidor.

Doing

so

could

plug

the

drain.

3

|

Insert

a

new

screen

in

the

solids

collector

and

install the

cap.

Limit

Switch

If

activated,

the

support

link

limit

switch

will

interrupt

the

base

down

motion

and

reverse

the

chair

to

prevent

damage.

Copyright

©

2004

A-dec

Inc.

All

Rights

Reserved.

86.0603.00

2003-12

Rev.

A

(04123.13)

A-dec

500

Assistant’s

Instrumentation

Owner’s

Guide

Я

Copyright

Copyright

©

2004

A-dec

Inc.

All

Rights

Reserved.

2601

Crestview

Drive,

Newberg,

OR

97132

USA

Printed

in

USA.

A-dec

Inc.

makes

no

warranty

of

any

kind

with

regard

to

the

content

of

this

document,

including

but

not

limited

to,

the

implied

warranties

of

merchantability

and

fitness

for

a

particular

purpose.

A-dec

Inc.

shall

not

be

held

liable

for

any

errors

contained

herein

or

any

consequential

or

other

damages

concerning

the

furnishing,

performance,

or

use

of

this

material.

The

information

in

this

document

is

subject

to

change

without

notice.

If

you

find

any

problems

with

this

document,

please

report

them

to

us

in

writing.

A-dec

Inc.

does

not

warrant

that

this

document

is

error-free.

All

other

non

A-dec

products

or

services

mentioned

in

this

document

are

covered

by

the

trademarks,

service

marks,

or

product

names

designated

by

the

companies

marketing

those

products.

Trademarks

A-dec

500,

A-dec

logo,

Cascade,

Cascade

Master

Series,

Century

Plus,

Continental,

Decade,

Performer,

Preference,

Preference

Collection,

and

Radius

are

A-dec

trademarks

registered

in

the

U.S.

Patent

and

Trademark

office.

A-dec,

A-dec

500

and

ICX

are

also

trademarks

of

A-dec

Inc.

www.a-dec.com

a

=.

A-dec

500

Assistant's

Instrumentation

Warranty

Use

this

box

to

log

your

equipment

information.

Warranty

Information

Serial

number

Model

number

Date

purchased

A-dec”

warrants

all

products

against

defects

in

material

or

workmanship

for

one

year

from

time

of

delivery.

A-dec's

sole

obligation

under

the

warranty

is

to

provide

parts

for

the

repair,

or

at

its

option,

to

provide

the

replacement

product

(exclud-

ing labor).

The

buyer

shall

have

no

other

remedy.

(All

special,

incidental,

and

coincidental

damages

are

excluded.)

Written

notice

of

breach

of

warranty

must

be

given

to

A-dec

within

the

warranty

period.

The

warranty

does

not

cover

damage

resulting

from

improper

installation

or

maintenance,

accident

or

misuse.

The

warranty

does

not

cover

damage

resulting

from

the

use

of

cleaning,

disinfecting

or

sterilization

chemicals

and

processes.

The

warranty

also

does

not

cover

light

bulbs.

Failure

to

follow

instructions

provided

in

A-dec's

Owner's

Guide

(operation

and

maintenance

instructions)

may

void

the

warranty.

A-dec

warrants

A-dec

dental

chair

cylinders,

both

lift

and

tilt,

for

ten

years

from

the

date

of

purchase

of

the

chair

or

the

cylinder.

This

warranty

is

retroactive

to

A-dec

chair

cylinders

already

in

the

field.

The

warranty

covers

chair

cylinders

A-dec

finds

to

have

manufacturing

related

irregularities.

Stool

cylinders

are

covered

under

A-dec's

one-year

warranty.

No

other

warranties

as

to

merchantability

or

otherwise

are

made.

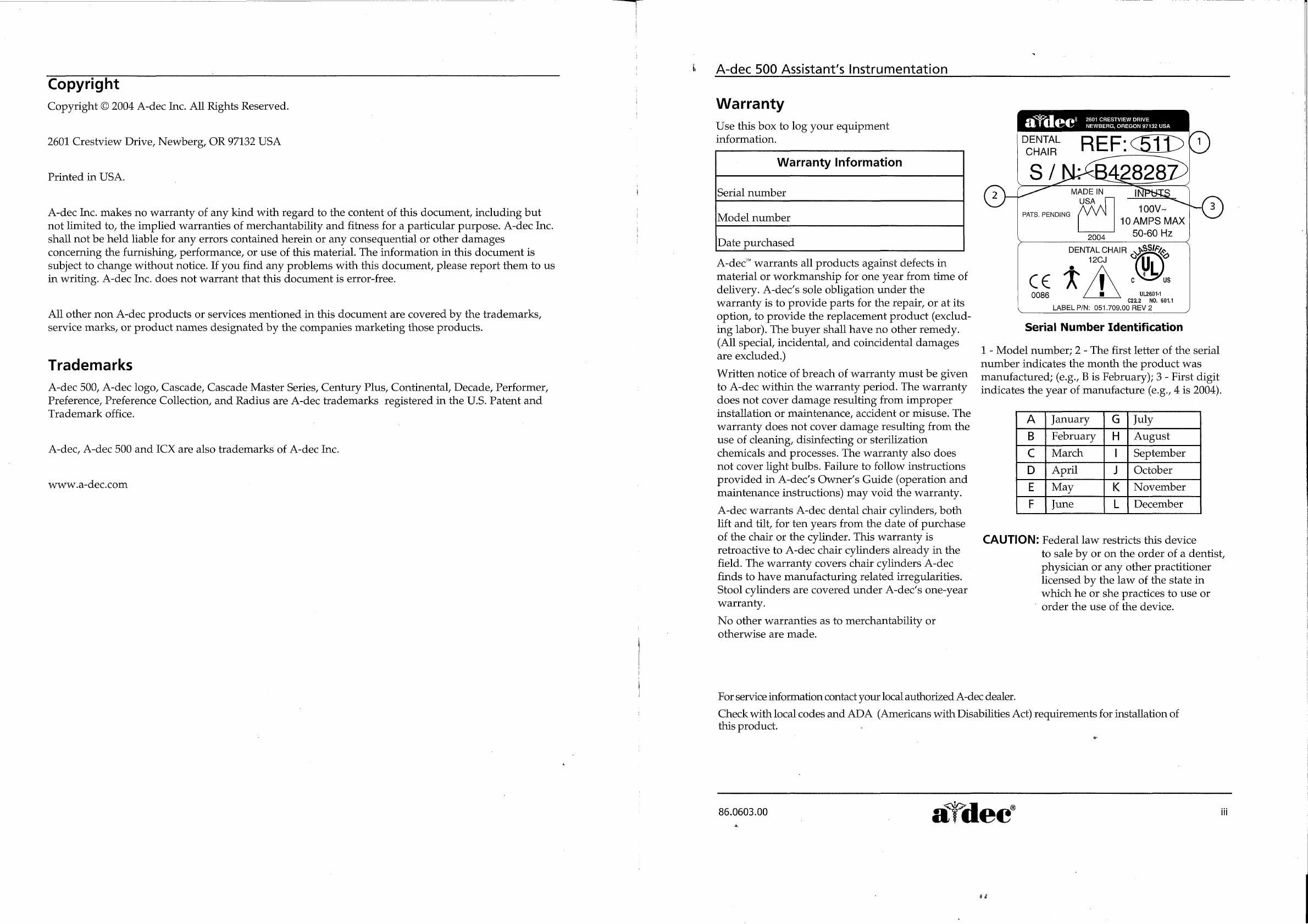

atde

oa

REF:

GIP

©

S

/

N:<B42828

§

2601

CRESTVIEW

DRIVE

|

NEWBERG,

OREGON

97132

USA

>

MADE

IN

AT

USA

PATS.

100V~

10

AMPS

MAX

PENDING

12CJ

©

C €

J

c

US

0086

UL2601-1

C22.2

NO.

601.1

し

LABEL

P/N:

051.709.00

REV

2

)

SSIE,

DENTAL

CHAIR

OX

^

Serial

Number

Identification

1

-

Model

number;

2

-

The

first

letter

of

the

serial

number

indicates

the

month

the

product

was

manufactured;

(e.g.,

B

is

February);

3

-

First

digit

‘ov

ο

indicates

the

year

of

manufacture

(e.g.,

4

is

2004).

A

|

January

G

|

July

B

|

February

|

H

|

August

C

|

March

|

|

September

D

|

April

J

|

October

E

|

May

K

|

November

F

|

June

L

|

December

CAUTION:

Federal

law

restricts

this

device

to

sale

by

or

on

the

order

of

a

dentist,

physician

or

any

other

practitioner

licensed

by

the

law

of

the

state

in

which

he

or

she

practices

to

use

or

‘

order

the

use

of

the

device.

For service

information

contact

your

local

authorized

A-dec

dealer.

Check

with

local

codes

and

ADA

(Americans

with

Disabilities

Act)

requirements

for

installation

of

this

product.

tor

A

86.0603.00

。

|

al

dec

я.

e

A-dec

500

Assistant’s

Instrumentation

Identification

of

Symbols

Recognized

by

Underwriters

Laboratories

Conforms

to

European

Inc.®

with respect

to

electric

shock,

fire

С

€

Directives

(refer

to

~

개

and

mechanical

hazards

only

in

accor-

Declaration

Statement)

“ee

dance

with

UL

2601-1.

Recognized

with

respect

to

electric

shock,

fire,

mechanical

and

other

specified

hazards

only

in

accor-

©

Protective

earth

(ground)

dance

with

CAN/CSA

C22.2,

No.

601.1

o

=

Functional

earth

(ground)

c

US

UL

listed

to

US

(UL

544)

and

Canadian

LISTED

(CAN/CSA

C22.2,

No.

125)

safety

standards

.

A

Attention,

consult

|

accompanying

documents

SRE

:

(UL)

Classified

by

Underwriters

Laboratories

e

|

KOL)

us

Inc.

with

respect

to

electric

shock,

fire

x

Type

B

applied

part

UL

2601-1

and

mechanical

hazards

only

in

accor-

-

6011

dance

with

UL

2601-1.

Classified

with

respect

to

electric

shock,

fire,

mechanical

and

other

specified

hazards

only

in

accor-

Г]

Class

II

equipment

dance

with

CAN/CSA

C22.2,

No.

601.1

Classification

of

Eguipment

(EN

60601-1)

Types

of

shock

protection:

CLASS

|

EQUIPMENT

(Dental

Chairs,

Dental

Lights,

&

Power

Supplies)

CLASS

IT

EQUIPMENT

(Chair,

Wall,

&

Cart-Mounted

Delivery

Systems)

Degree

of

shock

protection:

TYPE

B

APPLIED

PART

(Delivery

Systems

Only)

Degree

of

protection

against

water

ingress:

ORDINARY

EQUIPMENT

(All

products)

Mode

of

operation:

CONTINUOUS

OPERATION

(All

models

except

Dental

Chairs)

5%

Duty

Cycle

Mode

of

operation:

CONTINUOUS

OPERATION

WITH

INTERMITTENT

LOADING

(Dental

Chairs)

Environmental

-40°C

to

70°C

(-40°F

to

158°F)

Relative

Humidity:

95%

maximum

Operating

Temperature:

10°C

to

40°C

(50°F

to

104°F)

Relative

Humidity:

95%

maximum

Storage

Temperature:

Electromagnetic

Compatibility

This

equipment

has

been

tested

and

found

to

comply

with

the

limits

for

medical

devices

in

EN60601-1-2.

These

limits

are

designed

to

provide

reasonable

protection

against

harmful

interference

in

a

typical

medical

installation.

Contact A-dec

Customer

Service

if

you

have

any

questions.

Flammable

Gasses

Not

suitable

for

use

in

the

presence

of

a

flammable

anesthetic

mixture

with

air,

oxygen,

or

nitrous

oxide.

NE

®

dec

86.0603.00

A-dec

500

Assistant's

Instrumentation

Table

of

Contents

Welcome

eee

eee

due

eee

eue

1

Intended

Audience

eee

eee

eee.

1

About

TIhis

Document

..

e

erra

a

1

Conventions

........................................,.....

aaa

1

How

to

Use

This

Guide

ân

1

About

Your

Assistant's

Instrumentation

.........................................

2

How

to

Operate

Your

Assistant's

Instrumentation

................................

2

On/OffSwithh

......................

ea

2

Instruments

eee

ων

3

How

to

Maintain

the

Sohiids

Collector

eee

ee

een

eee

5

LimitSwitches

.......................

ea

ーーー

κ

κ

ων

5

How

to

Position

Your

Assistant's

Instrumentation

................................

6

Short

Assistant's

Arm

.....................

K

νο

ον

6

Long

Assistant's

Arm

................

ce

cette

tent

e

ees

6

HolderAssembiy

..............................

еее

нии

иначе

еек

6

AdjustableHolderss

...................................

an

7

Оиа!

Но4ег

АззетЬПез

........

неа

н

요

ㅇ

요

요

이

ㅇ

교

요

ㅇ

교

ㅇ

교

요요

요요

교

요 요

요요

이

요

요

요 이

이 이

이 이

이 이 이

7

ElectricHolders

..........................

ερ

ρω

εν

ον

νοκ

ρω

εννοω

ε

ερ

ον

νε

νε ρε

ο

νο

ων

7

Assistant's

Touchpad

.

7

ГеН/

Е1эТЕ

Сопуег10п

.......

иен

ини

eee

renerne

7

How

to

Operate

Your

Standard

Touchpad

................................,......

8

ManualChairControls

..................................

.....8

Program

Button

.......................

R

rrenee

8

Position

O

(Entry

/Exit)

...................

ea

8

Positionsland2...............................

eee

„8

Position

3

K

нанени

9

Cup

Fill

esse

died

eee

9

Bowl

Rinse

idée

eee

ο

ρε

εν

ον

9

AT/A2

Buttons

.......

υἷυἶἷ

e

9

Light

K

K

reen

rere

10

Care

_InmnstrucHong

,,

erere

11

Touch

and

Transfer

Surfaces

..

нение

ине

nenee

11

Heat

Sterilization.

,

eee

rnvsree

11

Specificatlons

.................

eee

11

86.0603.00

i'dec

する

A-dec

500

Assistant's

Instrumentation

Tables

Table

1

—

Steps

for

HVE

and

Saliva

Ejector

Asepsis

....................,..................

4

Tabple2-

9teps

for

Sterilizing

theHVETIip

rr

4

Illustrations

Figure

1

—

Parts

of

the

Assistant’s

Instrumentation

.....................,..................

2

Figure2-

Solids

Collector

ее

нина

нии

ини

е

нии

тененни

я

2

Figure

3

—

Left/Right-Hand

Conversion

of

the

Autoclavable

HVE

and

Saliva

Ejector

.........

3

Figure

4

—

Removing

the

Solids

Collector

Screen

cence

tenes

6

Figure

5

—

Rotation

of

the

Holder

Assembly

............................................

6

Figure

6

—

Positioning

Individual

Holders

....................................,.........

7

Figure

7ーFHunctions

ot

Standard

Touchpad

ων

8

vi

adec

86.0603.00

A-dec

500

Assistant’s

Instrumentation

About

This

Document

About

this

Document

Welcome

Welcome

to

the

A-dec

500

Assistant’s

Instrumentation

Owner's

Guide.

This

guide

provides

an

easy

to

use

source

of

technical

information

for

servicing

and

maintaining

your

assistant’s

instrumentation.

Intended

Audience

This

guide

is

intended

for

doctors

and

dental

staff

to

use

when

operating

and

maintaining

A-dec

500

assistant’s

instrumentation.

About

this

Document

This

document

contains

*

instructions

on

left/right

conversion

of

a

HVE

and

saliva

ejector

*

maintenance

procedures

for

the

solid

collector

.

detail

on

the

functions

of

the

touchpad,

and

.

product

specifications.

Conventions

A

number

of

items

and

instructions

appear

throughout

this

document.

The

formatting

conventions

are

designed

to

make

it

quick

and

easy

to

find

and

understand

information.

e

References

to

sections,

or

reference

documentation

appear

in

italic

type,

e.g.,

How

to

Operate

the

Delivery

System.

e

Important

supplemental

information

about

the

covered

topic

appears

as

a

note,

e.g.,

NOTE:

The

foot

control

also

has....

¢

Bubble

numbers,

callouts,

and

tables

identify

key

components

in

an

illustration.

How

to

Use

this

Guide

This

guide

provides

detailed

descriptions

and

operation

instructions

for

the

use

of

the

A-dec

500

assistant’s

instrumentation.

Before

using

the

assistant’s

instrumentation,

review

this

document

to

get

a

feel

for

the

capabilities

of

the

assistant’s

instrumentation

and

its

to

operation.

Make

note

of

all

cautions

and.

warnings.

86.0603.00

ο

σα

Page

1

$e

Operation

A-dec

500

Assistant's

Instrumentation

About

Your

Assistant’s

Instrumentation

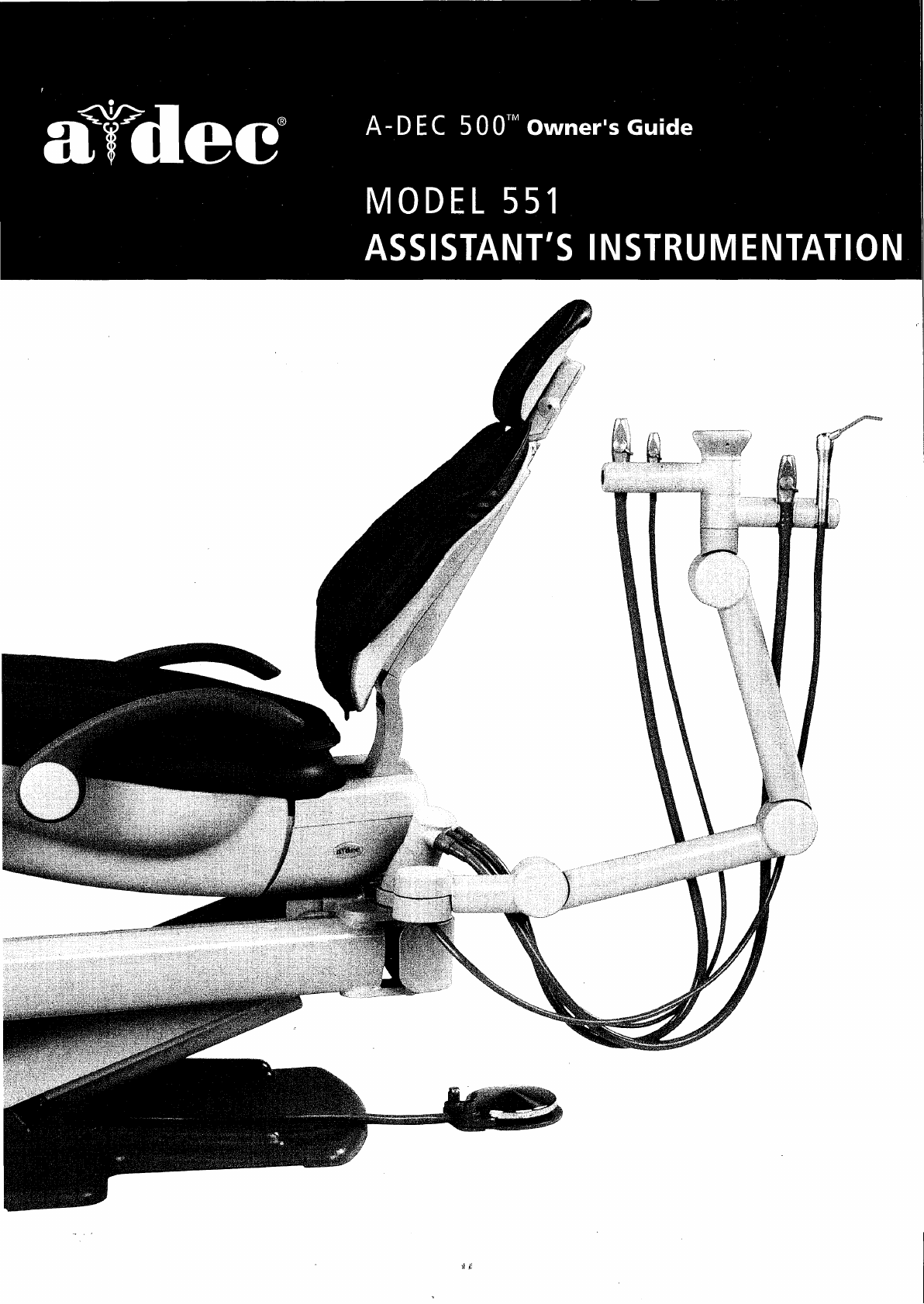

A-dec’s

standard

assistant’s

instrumentation.

package

includes

autoclavable

syringe,

HVE,

and

saliva

ejector.

Optional

instruments

may

include

an

additional

HVE.

The

solids

collector

is

also

a

part

of

the

assistant’s

instrumentation,

located

at

the

end

of

the

assistant’s

instrumentation

arm.

The

assistant’s

vacuum

instruments

are

fully

autoclavable

and

have

quick

disconnect

attachments

that

are

easily

removed

for

cleaning.

How

to

Operate

Your

Assistant’s

Instrumentation

On/Off

Switch

There

are

two

power

source

locations

for

the

assistant's

instrumentation,

the

Power

On/Off

button

on

the

chair

and

the

delivery

system

master

On/Off

toggle.

Figure

1

Parts

of

the

Assistant's

Instrumentation.

Power

On/Off

Button

The

Power

On/Off

button

is

located

on

the

base

of

the

chair.

This

function

allows

you

to

engage

power

or

disengage

power

to

the

entire

system

at

the

touch

of

a

button.

When

the

button

is

pressed

in,

the

system

has

power.

When

the

button

is

out,

the

system

has

no

power.

Figure

2.

Solids

Collector.

Delivery

System

Master

On/Off

Toggle

The

master

On/Off

toggle,

located

on

the

right

1

-

Autoclavable

HVE;

2

-

Autoclavable

syringe;

side

of

the

control

head,

controls

the

utilities

for

the

>"

Autoclavable

saliva

ejector;

4

-

Holder

assembly;

delivery

system

as

well

as

other

modules

mounted

5

-

Touchpad;

6

-

Solids

collector

to

the

chair.

CAUTION:

For

prolonged

life

of

your

equipment,

turn

power

OFF

when

not

in

use.

86.0603.00

Page

2

_

dec

A-dec

500

Assistant's

Instrumentation

Instruments

Autoclavable

Syringe

For

information

on

the

operation,

care,

and

maintenance

of

A-dec's

autoclavable

syringe,

refer

to

your

Autoclavable

Syringe

Owner's

Guide

(P/N

85.0680.00).

Autoclavable

HVE

and

Saliva

Ejector

The

autoclavable

HVE

and

saliva

ejector

are

equipped

with

a

quick

disconnect

to

remove

the

valve

body

from

the

tubing

for

cleaning

and

autoclaving.

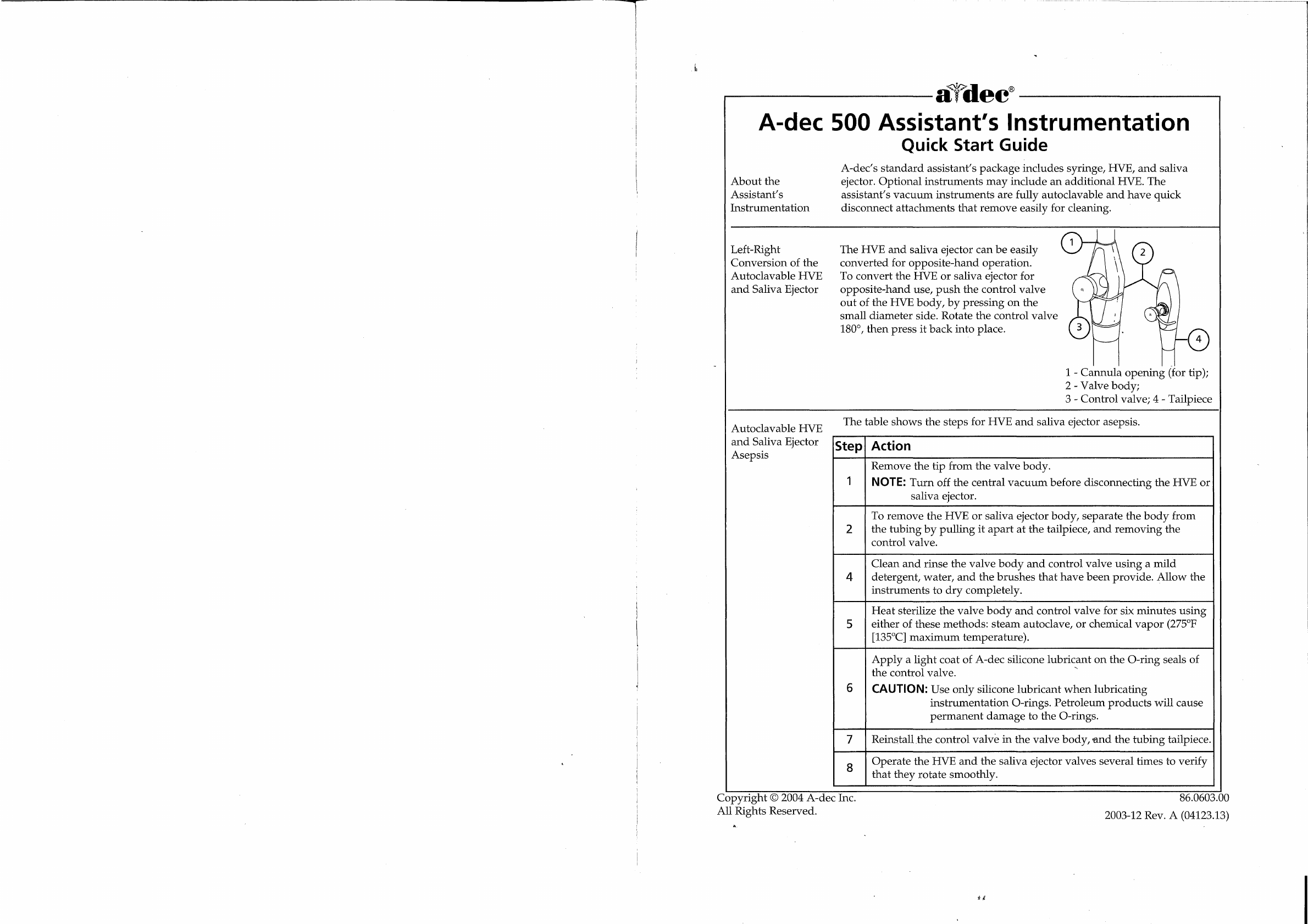

Left/Right-Hand

Conversion

of

the

Autoclavable

HVE

and

Saliva

Ejector

the

Autoclavable

HVE

and

The

HVE

and

saliva

ejector

can

be

easily

converted

Saliva

Ejector

for

operation

from

either

side

of

the

chair.

1

-

Cannula

opening

(for

tip);

2

-Valve

body;

To

convert

the

HVE

or

saliva

ejector

to

one

side

or

3

-

Control

valve;

4

-

Tailpiece

the

other,

push

the

control

valve

out

of

the

HVE

body,

by

pressing

on

the

small

diameter

side.

Rotate

the

control

valve

180°,

then

push

it

back

into

place.

Figure

3

Left/Right-Hand

Conversion

of

Operation

|

|

86.0603.00

a

dec

À.

Page

3

Operation

A-dec

500

Assistant's

Instrumentation

Autoclavable

HVE

and

Saliva

Ejector

Asepsis

The

table

shows

the

steps

for

HVE

and

saliva

ejector

asepsis.

Table

1

Steps

for

HVE

and

Saliva

Ejector

Asepsis

Step

|Action

1

Remove

the

tip

from

the

valve

body.

NOTE:

Turn

OFF

the

central

vacuum

before

disconnecting

the

HVE

or

saliva

ejector.

>

To

remove

the

HVE

or

saliva

ejector

body,

separate

the

body:

from

the

tubing

by

pulling

it

apart

at

the

tailpiece.

3.

[Remove

the

control

valve

by

pushing

it

out

of

the

HVE

or

saliva

ejector

valve

body.

A

Clean

and

rinse

the

valve

body

and

control

valve

using

a

mild

detergent,

water,

and

the

brushes

that

have

been

provided.

Allow

the

instruments

to

dry

completely.

5

Heat

sterilize

the

valve

body

and

control

valve

for

6

minutes

using

either

of

the

following

methods:

steam

autoclave,

or

chemical

vapor

(275°F

[135°C]

maximum

temperature).

Apply

a

light

coat

of

A-dec

silicone

lubricant

on

the

O-ring

seals

of

the

control

valve.

6

|CAUTION:

Use

only

silicone

lubricant

when

lubricating

instrumentation

O-rings.

Petroleum

products

will

cause

permanent

damage

to

the

O-rings.

7

|Reinstall

the

control

valve

in

the

valve

body,

and

the

body

on

the

tubing

tailpiece.

8

|Operate

the

HVE

and

the

saliva

ejector

valves

several

times

to

verify

that

they

rotate

smoothly.

How

to

Sterilize

the

HVE

Tip

It is

recommended

that

the

stainless

steel

tips

used

on

the

HVE

be

heat

sterilized

between

patients

using

either

of

the

following

methods:

steam

autoclave,

or

chemical

vapor

(275°F

[135°C]

maximum

tempera-

ture;

four

minutes

at

temperature).

If

you

are

using

disposable

HVE

tips,

be

sure

to

replace

them

with

new

tips

between

patients.

The

table

shows

the

steps

for

sterilizing

the

HVE

tip.

Table

2

Steps

for

Sterilizing

the

HVE

Tip

Step

|Action

1

[Remove

the

HVE

tip

from

the

HVE

valve

body.

>

Clean

and

rinse

the

HVE

tip

using

a

mild

detergent

and

water,

then

allow

the

tip

to

completely

dry.

3

|Sterilize

the

HVE

tip

using

one

of

the

recommended

methods.

NOTE:

A-dec

HVE

Cannula

Opening:

Standard

A-dec

HVE

—

0.435"

+

0.006"

(11.05

+

0.15

mm).

A-dec

15

mm

HVE

—

.592"

(14.8

mm).

If

not

using

A-dec

HVE

Tips,

select

a

tip

that

is

compatible

with

your

HVE

cannula

opening.

A-dec

Saliva

Ejector

Cannula

Opening:

A-dec

Saliva

Ejector

—

0.265

+

0.006"

(6.73

+

0.15

mm)

Select

a

tip

that

is

compatible

with

your

saliva

ejector

cannula

opening.

Page

4

a

dec

86.0603.00

A-dec

500

Assistant’s

Instrumentation

How

to

Maintain

the

Solids

Collector

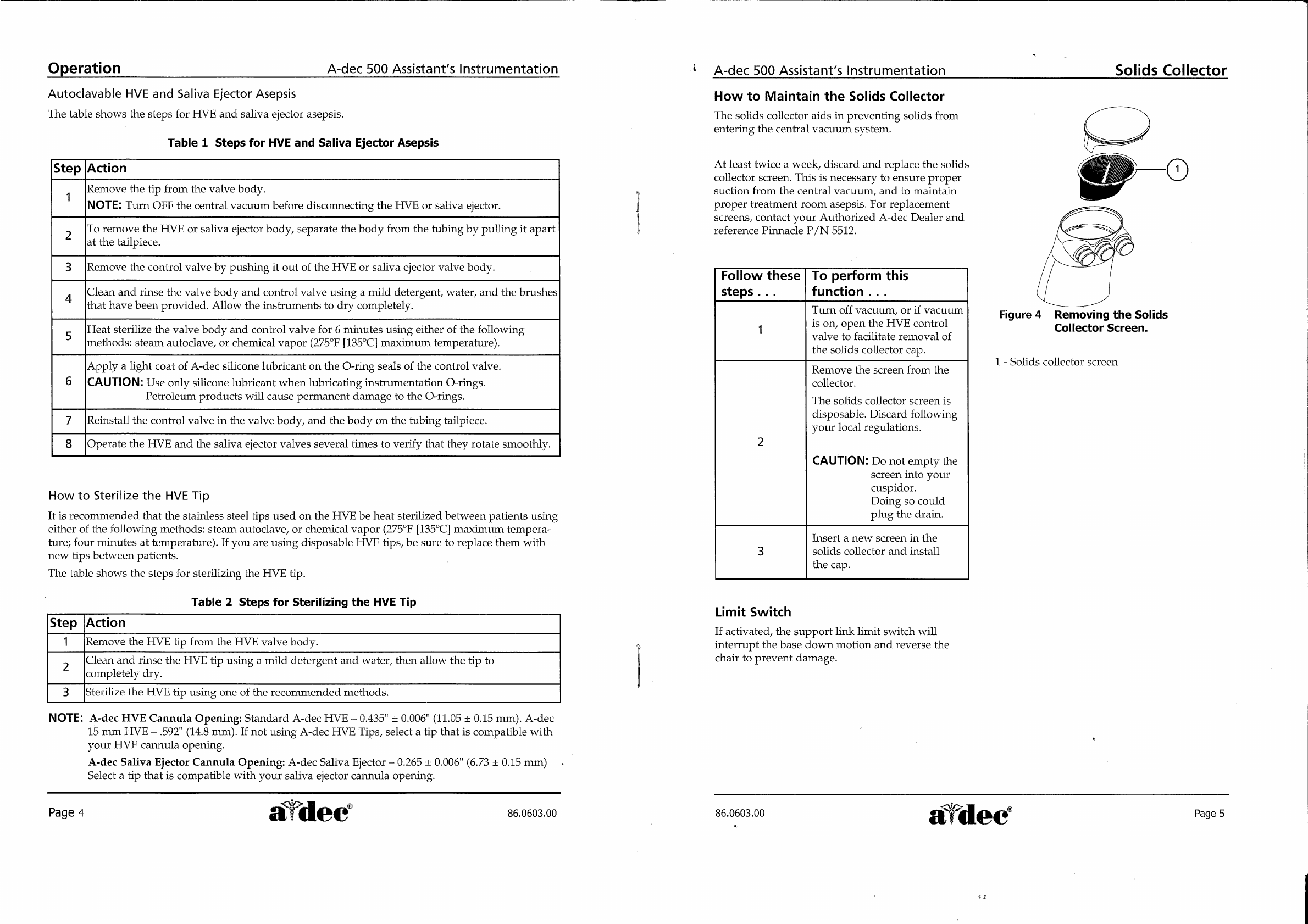

The

solids

collector

aids

in

preventing

solids

from

entering

the

central

vacuum

system.

At

least

twice

a

week,

discard

and

replace

the

solids

collector

screen.

This

is

necessary

to

ensure

proper

suction

from

the

central

vacuum,

and

to

maintain

proper

treatment

room

asepsis.

For

replacement

screens,

contact

your

Authorized

A-dec

Dealer

and

reference

Pinnacle

P/N

5512.

Follow

these

|

To

perform

this

steps...

function...

Turn

off

vacuum,

or

if

vacuum

is

on,

open

the

HVE

control

valve

to

facilitate

removal

of

the

solids

collector

cap.

Remove

the

screen

from

the

collector.

The

solids

collector

screen

is

disposable.

Discard

following

your

local

regulations.

CAUTION:

Do

not

empty

the

screen

into

your

cuspidor.

Doing

so

could

plug

the

drain.

Insert

a

new

screen

in

the

3

solids

collector

and

install

the

cap.

Limit

Switch

If

activated,

the

support

link

limit

switch

will

interrupt

the

base

down

motion

and

reverse

the

chair

to

prevent

damage.

Solids

Collector

Figure

4

Removing

the

Solids

Collector

Screen.

1

-

Solids

collector

screen

86.0603.00

ide

a,

Page

5

Positioning

A-dec

500

Assistant's

Instrumentation

How

to

Position

Your

Assistant's

Instrumentation

The

A-dec

500

assistant’s

instrumentation

is

equipped

with

either

a

short

or

long

assistant’s

arm

for

easy

positioning

of

instrumentation.

Both

arms

are

equipped

with

a

touchpad

and

holder

assemblies

with

individual

holders

for

added

positioning.

Short

Assistant’s

Arm

The

short

assistant’s

arm

positions

near

the

cuspidor

or

along

side

the

chair

back.

It

adjusts

in

a

forward,

backward,

and

side-to-side

movement

for

easy

positioning

and

access

to

the

instrumentation.

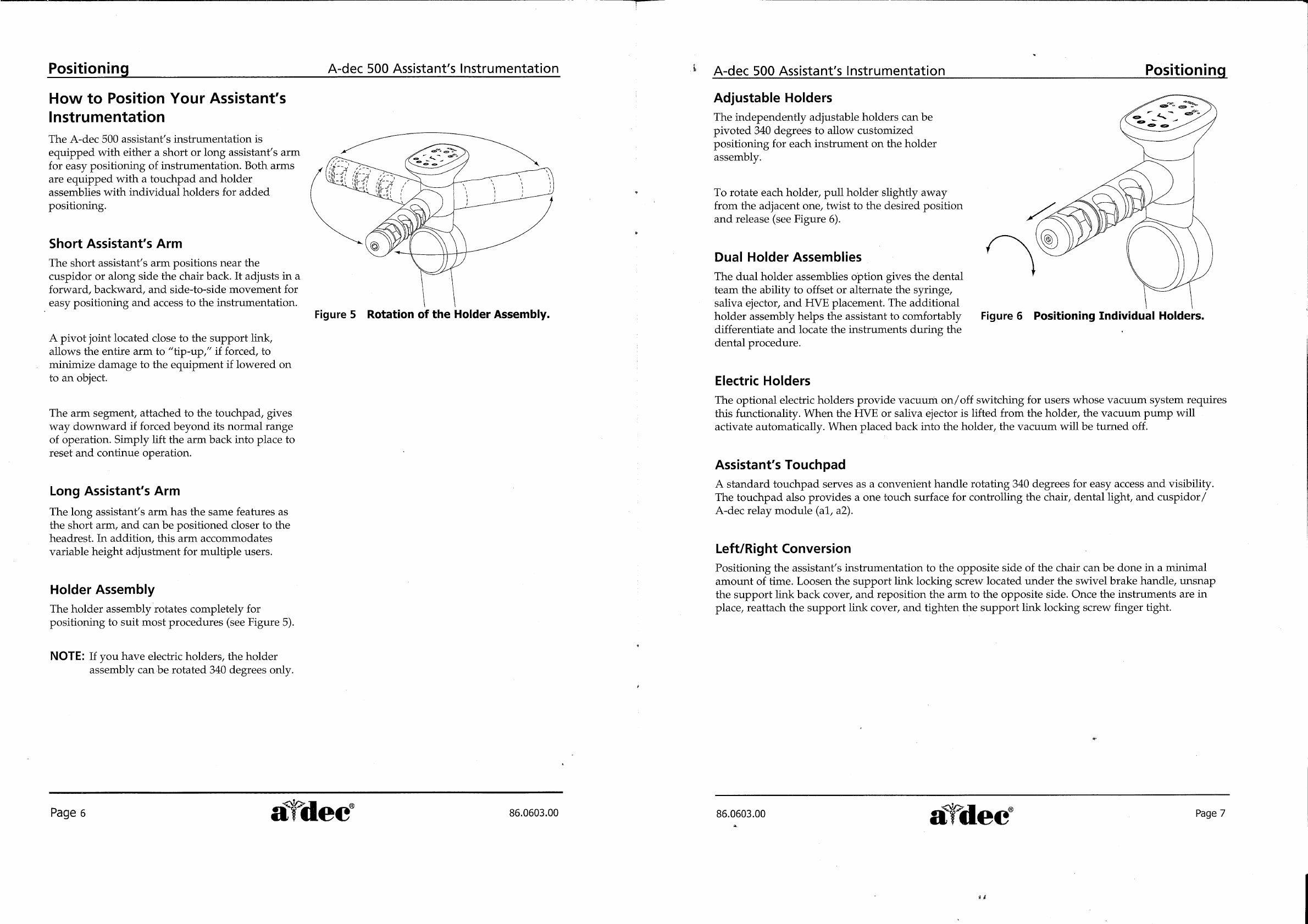

Figure

5

Rotation

of

the

Holder

Assembly.

A

pivot

joint

located

close

to

the

support

link,

allows

the

entire

arm

to

“tip-up,”

if

forced,

to

minimize

damage

to

the

equipment

if

lowered

on

to

an

object.

The

arm

segment,

attached

to

the

touchpad,

gives

way

downward

if

forced

beyond

its

normal

range

of

operation.

Simply

lift

the

arm

back

into

place

to

reset

and

continue

operation.

Long

Assistant's

Arm

The

long

assistant’s

arm

has

the

same

features

as

the

short

arm,

and

can

be

positioned

closer

to

the

headrest.

In

addition,

this

arm

accommodates

variable

height

adjustment

for

multiple

users.

Holder

Assembly

The

holder

assembly

rotates

completely

for

positioning

to

suit

most

procedures

(see

Figure

5).

NOTE:

If

you

have

electric

holders,

the

holder

assembly

can

be

rotated

340

degrees

only.

A-dec

500

Assistant’s

Instrumentation

Positioning

i

Page

6

sa

dec

86.0603.00

Adjustable

Holders

The

independently

adjustable

holders

can

be

pivoted

340

degrees

to

allow

customized

positioning

for

each

instrument

on

the

holder

assembly.

To

rotate

each

holder,

pull

holder

slightly

away

from

the

adjacent

one,

twist

to

the

desired

position

and

release

(see

Figure

6).

Dual

Holder

Assemblies

The

dual

holder

assemblies

option

gives

the

dental

team

the

ability

to

offset

or

alternate

the

syringe,

saliva

ejector,

and

HVE

placement.

The

additional

holder

assembly

helps

the

assistant

to

comfortably

Figure

6

Positioning

Individual

Holders.

differentiate

and

locate

the

instruments

during

the

dental

procedure.

Electric

Holders

The

optional

electric

holders

provide

vacuum

on/off

switching

for

users

whose

vacuum

system

requires

this

functionality.

When

the

HVE

or

saliva

ejector

is

lifted

from

the

holder,

the

vacuum

pump

will

activate

automatically.

When

placed back

into

the

holder,

the

vacuum

will

be

turned

off.

Assistant's

Touchpad

A

standard

touchpad

serves

as

a

convenient

handle

rotating

340

degrees

for

easy

access

and

visibility.

The

touchpad

also

provides

a

one

touch

surface

for

controlling

the

chair,

dental

light,

and

cuspidor/

A-dec

relay

module

(a1,

a2).

Left/Right

Conversion

Positioning

the

assistant’s

instrumentation

to

the

opposite

side

of

the

chair

can

be

done

in

a

minimal

amount

of

time.

Loosen

the

support

link

locking

screw

located

under

the

swivel

brake

handle,

unsnap

the

support

link

back

cover,

and

reposition

the

arm

to

the

opposite

side.

Once

the

instruments

are

in

place,

reattach

the

support

link

cover,

and

tighten

the

support

link

locking

screw

finger

tight.

i

$

θες

86.0603.00

a

Le

dec

|

Раде

7

#4

Touchpad

A-dec

500

Assistant’s

Instrumentation

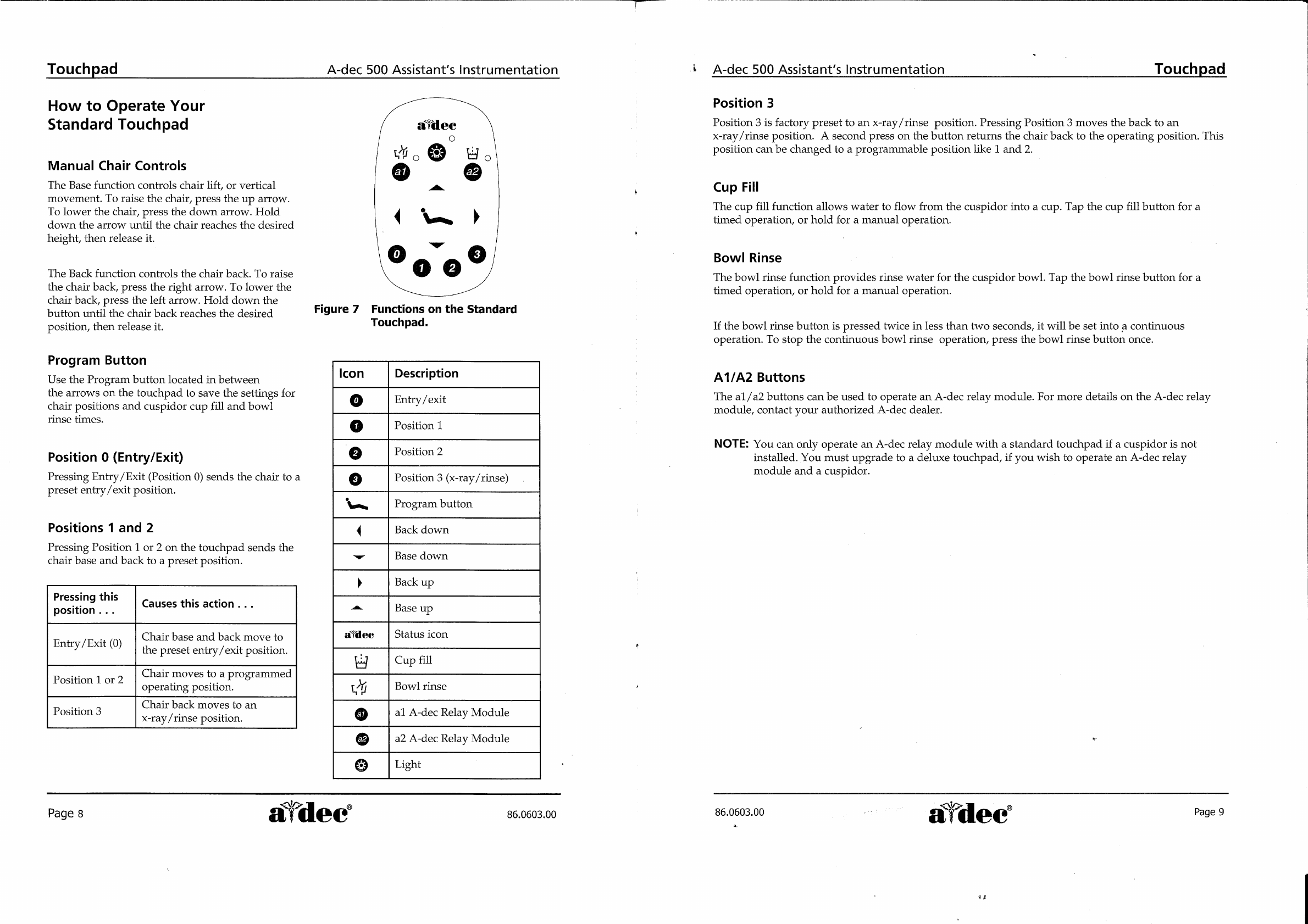

How

to

Operate

Your

Standard

Touchpad

Manual

Chair

Controls

The

Base

function

controls

chair

lift,

or

vertical

movement.

To

raise

the

chair,

press

the

up

arrow.

To

lower

the

chair,

press

the

down

arrow.

Hold

down

the

arrow

until

the

chair

reaches

the

desired

height,

then

release

it.

The

Back

function

controls

the

chair

back.

To

raise

the

chair

back, press

the

right

arrow.

To

lower

the

chair

back,

press

the

left

arrow.

Hold

down

the

button

until

the

chair

back

reaches

the

desired

position,

then

release

it.

Program

Button

Use

the

Program

button

located

in

between

the

arrows

on

the

touchpad

to

save

the

settings

for

chair

positions

and

cuspidor

cup

fill

and

bowl

rinse

times.

Position

0

(Entry/Exit)

Pressing

Entry/Exit

(Position

0)

sends

the

chair

to

a

preset

entry/exit

position.

Positions

1

and

2

Pressing

Position

1

or

2

on

the

touchpad

sends

the

chair

base

and

back

to

a

preset

position.

Pressing

this

position

Causes

this

action...

Chair

base

and

back

move

to

Entry/Exit

(0)

|

me

preset

entry/exit

position.

Chair

moves

to

a

programmed

Position

1

or

2

. , ,

operating

position.

Chair

back

moves

to

an

Position

3

a

x-ray /rinse position.

Figure

7

Functions

on

the

Standard

Touchpad.

Icon

Description

Entry

/exit

Position

1

Position

2

Position

3

(x-ray

/rinse)

Program

button

Back

down

Base

down

Back

up

„|-|

|

fooeeo

Base

up

afdec

Status

icon

Cup

fill

vi

Bowl

rinse

al

A-dec

Relay

Module

a2

A-dec

Relay

Module

61616

Light

Page

8

aldec

86.0603.00

A-dec

500

Assistant’s

Instrumentation

|

Touchpad

Position

3

Position

3

is

factory

preset

to

an

x-ray/rinse

position.

Pressing

Position

3

moves

the

back

to

an

x-ray/rinse

position.

À

second

press

on

the

button

returns

the

chair

back

to

the

operating

position.

This

position

can

be

changed

to

a

programmable

position

like

1

and

2.

Cup

Fill

The

cup

fill

function

allows

water

to

flow

from

the

cuspidor

into

a

cup.

Tap

the

cup

fill

button

for

a

timed

operation,

or

hold

for

a

manual

operation.

Bowl

Rinse

The

bowl

rinse

function

provides

rinse

water

for

the

cuspidor

bowl.

Tap

the

bowl

rinse

button

for

a

timed

operation,

or

hold

for

a

manual

operation.

If

the

bowl

rinse

button

is

pressed

twice

in

less

than

two

seconds,

it

will

be

set

into

a

continuous

operation.

To

stop

the

continuous

bowl

rinse

operation,

press

the

bow]

rinse

button

once.

A1/A2

Buttons

The

a1/a2

buttons

can

be

used

to

operate

an

A-dec

relay

module.

For

more

details

on

the

A-dec

relay

module,

contact

your

authorized

A-dec

dealer.

NOTE:

You

can

only

operate

an

A-dec

relay

module

with

a

standard

touchpad

if

a

cuspidor

is

not

installed.

You

must

upgrade

to

a

deluxe

touchpad,

if

you

wish

to

operate

an

A-dec

relay

module

and

a

cuspidor.

86.0603.00

Lee

에어

are

A.

kd

"dec

때

Touchpad

A-dec

500

Assistant's

Instrumentation

Dental

Light

The

dental

light

button

on

the

touchpad

works

as

a

three-way

switch

allowing

you

to

turn

the

dental

light

on

or

off

from

either

the

touchpad

or

the

dental

light.

A

quick

press

on

the

button

allows

you

to

toggle

between

three

intensity

settings,

depending

on

the

location

of

the

dental

light’s

intensity

switch.

The

dental

light

can

be

toggled

between

composite

and

medium

intensity

settings

or

composite

and

high

intensity

settings.

When

the

dental

light

is

in

the

composite

setting,

the

indicator

light

next

to

the

button

flashes.

The

dental

light

also

has

an

auto

on/off

feature.

When

using

a

programmed

chair

position

(1

or

2),

the

dental

light

will

come

on

when

the

chair

reaches

an

operating

position.

The

dental

light

will

turn

off

automatically

when

Position

0

(entry/exit)

or

Position

3

(x-ray/rinse)

is

pressed.

NOTE:

If

Position

3

has

been

reprogrammed

to

a

programmable

position,

the

dental

light

will

not

turn

on/off

when

Position

3

is

pressed.

How

to

Disable Factory

Preset

Functions

There

are

two

factory

preset

options

that

can

be

turned

on

or

off

from

the

standard

touchpad.

Dental

Light

(auto

on/off)

Auto

On/Off

setting

can

be

turned

off

by

pressing

and

holding

the

Program

button

and

then

the

Light

button

together

for

three

seconds.

One

beep

will

confirm

that

the

factory

preset

has

been

turned

off.

To

return

to

the

factory

preset

repeat

steps.

Three

beeps

will

confirm

that

the

auto

on/off

function

is

on.

Position

3

(x-ray/rinse)

Position

3

can

be

toggled

from

the

x-ray/rinse

position

to

a

programmed

position.

To

program

Position

3,

press

Program

and

then

press

and

hold

Position

3

together

for

three

seconds.

One

beep

confirms

that

the

position

can

be

programmed.

To

return

to

the

x-ray/rinse

position,

repeat

steps.

Three

beeps

confirms

that

the

x-ray/rinse

function

is

on.

4

Page

10

a

dec

86.0603.00

A-dec

500

Assistant's

Instrumentation

Care

Instructions

Touch

and

Transfer

Surfaces

Touch

surfaces

are

those

areas

that

require

contact

and

become

potential

cross-contamination

points

during

dental

procedures.

The

minimum

touch

surface

locations

on

A-dec

500

products

include

the

touchpad(s),

control

head

brake

handles,

and

dental

light

handles

and

switches.

Transfer

surfaces

are

those

surfaces

that

are

contaminated

by

contact

with

instruments

and

other

inanimate

objects.

The

primary

transfer

surfaces

on

the

A-dec

500

product

include

traditional

holders,

Continental”

instrument

pad,

and

trays.

A-dec

recommends

barrier

protection

for

all

applicable

touch

and

transfer

surfaces.

When

used,

barriers

must

be

FDA

market-cleared

barrier

plastic.

Cover-All™

barrier

film

or

any

other

FDA

market-cleared

barrier

film

is

suitable

for

this

application.

Refer

to

your

national

regulatory

authorities

for

barrier

recommendations

specific

to

your

locale.

Barrier

plastics

should

be

removed

and

discarded

after

each

patient

treatment.

For

touch

and

transfer

surfaces

where

barrier

protection

is

not

applicable

or

when

barriers

are

compromised,

please

refer

to

A-dec’s

Equipment

Asepsis

Owner’s

Guide

(P/N

85.0696.00)

for

recommendations

on

proper

cleaning

and

chemical

disinfection.

Heat

Sterilization

High

volume

evacuators

(HVE),

saliva

ejectors

(SE),

and

air/water

syringes

should

be

steam

autoclaved

between

patients.

The

following

protocol

should

be

followed:

HVE

—

steam

autoclave

at

134°C

(273°F),

6

minutes

holding

time

SE

—

steam

autoclave

at

134°C

(273°F),

6

minutes

holding

time

Air

/Water

Syringe

-

steam

autoclave

at

134°C

(273°F),

4

minutes

holding

time

Each

handheld

device

with

air

and

water

lines

should

be

discharged

for

20-30

seconds

between

each

patient

to

reduce

the

chance

of

cross-contamination

as

a

result

of

potential

bio-burden

retraction.

Specifications

Minimum

air,

water

and

vacuum

service

requirements

for

proper

unit

operation:

Air:

2.50

cfm

(70.80

1/min)

at

80

psi

(551

kPa).

Water:

1.50

gpm

(5.68

1/min)

at

40

psi

(276

kPa).

Vacuum:

12

cfm

(339.84

1/min)

at

8

inches

of

mercury

(27

kPa).

Specifications

are

subject

to

change

without

notice.

Ne

86.0603.00

a

dee

Page

11

À.

sê

Conclusion

Thank

you

for

taking

the

time

to

use

the

A-dec

500

Assistant’s

Instrumentation

Owner's

Guide.

We

would

appreciate

any

feedback

or

comments

you

have

about

this

document.

Please

mail,

email

or

phone

us

with

your

comments.

You

can

reach

us

at:

A-dec

Inc.

Technical

Communications

Department

2601

Crestview

Drive

Newberg, OR

97132

Reach

us

by

phone

at:1-800-547-1883

email:

website:

www.a-dec.com

si

aye

dee

A-dec

Inc.

2601

Crestview

Drive

Newberg,

OR

97132

USA

Tel:

1-800-547-1883

within

USA/Canada

Tel:

1-503-538-7478

outside

USA/Canada

www.a-dec.

biz

A-dec

International

Inc.

2601

Crestview

Drive

Newberg,

OR

97132

USA

Tel:

1-503-538-9471

www.a-dec.biz

A-dec

United

Kingdom

Austin

House,

11

Liberty

Way

Nuneaton,

Warwickshire

CV11

6RZ

England

Tel:

0800

ADECUK

(233285)

within

UK

Tel:

44

24

7635

0901

outside

UK

www.a-dec.co.uk

A-dec

Australia

41-43

Bowden

Street

Alexandria

NSW

2015

Australia

Tel:

61

(0)2

9699

4600

www.a-dec.com.au

86.0603.00

2004-1

Rev

A

(04123.13)

©A-dec

Inc.

2004

All

rights

reserved

This manual suits for next models

1

Table of contents

Other Adec Dental Equipment manuals

Popular Dental Equipment manuals by other brands

Heraeus

Heraeus iBond Total Etch Instructions for use

KaVo

KaVo INTRAmatic contra-angle 20 ES Instructions for use

EMS

EMS FT-188 Operation instructions

BG Light

BG Light BLUEDENT XPRESS cordless Operating instructions manual

Jordco

Jordco ENDORING II Instructions for use

Miele

Miele A 317 operating instructions

Schuler Dental

Schuler Dental S-U-AURO-KULI operating instructions

EKOM

EKOM DO 2.1 Installation, operation and maintanance manual

vita

vita VITA FDS operating manual

KERR

KERR SonicFill Instructions for use

DENTAURUM

DENTAURUM tiologic Instructions for use

HAGER WERKEN

HAGER WERKEN PRAXIPOL PS II Instructions for use