ADEEPT AWR-A User manual

01

02

03

04

05

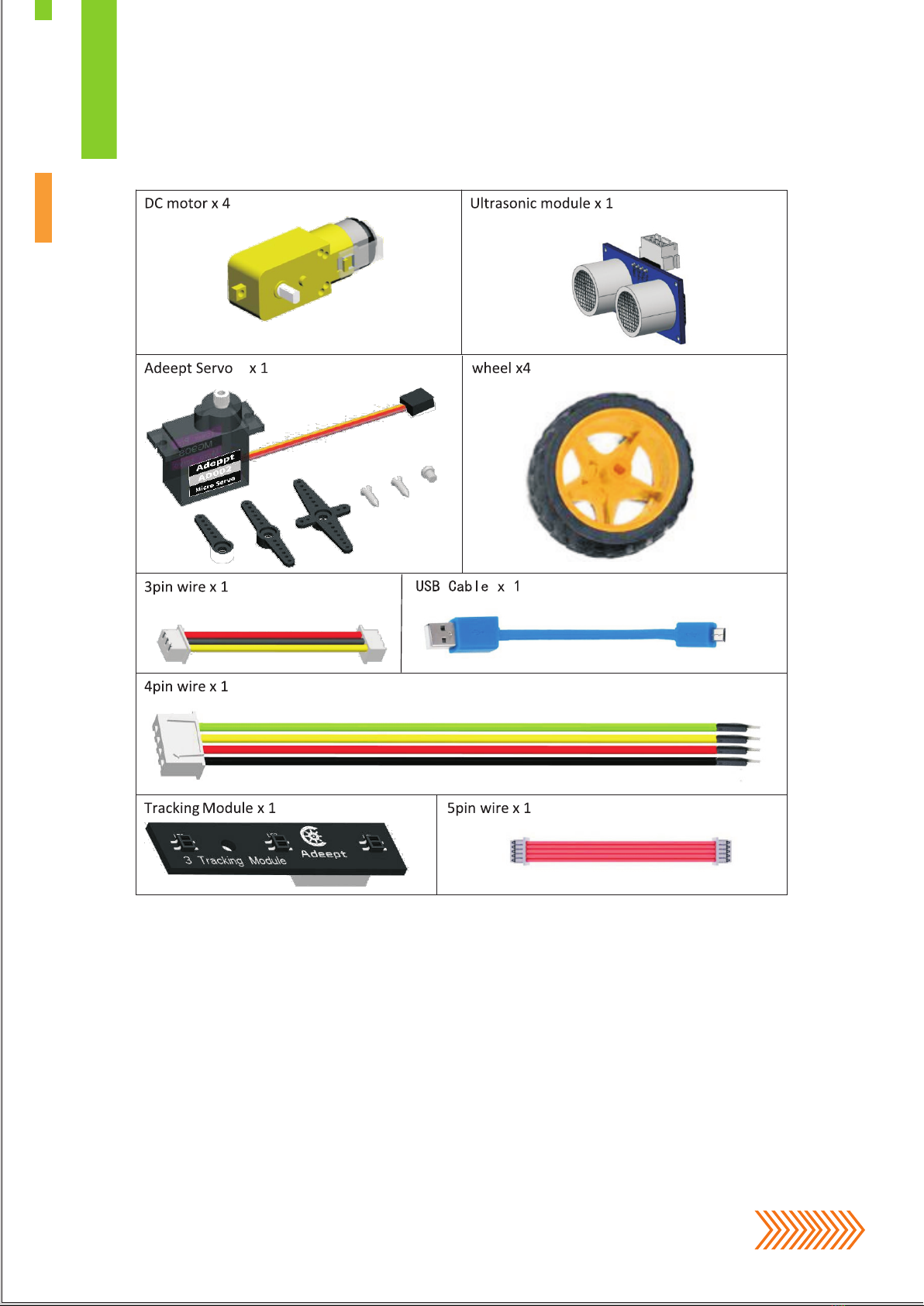

Take out the plates we will use.

Take out the car acrylic plates,

peel off the films.

Peel off the protective film on

the two sides of the plates.

Car Assembly.

06

Take out two sets of motors (four motors one set),

pay attention not to break the wire connected to

the motor, handle gently.

First we take out the materials we need

according to the picture on the left:

1x set of motors

1x A01 acrylic plate

4x silver M3*30 screw

4x M3 nut

Pass two silver M3*30 screws from the

protruding surface through the fixing

hole of the motor.Note: First install the

motor welded with four wires.

Use the cross wrench to screw the

M3 nut onto the M3*30 screw.

Note that the screw can't be too tight.

If the M3 nut is tightened too much,

it will not be rotated after the motor

is energized.

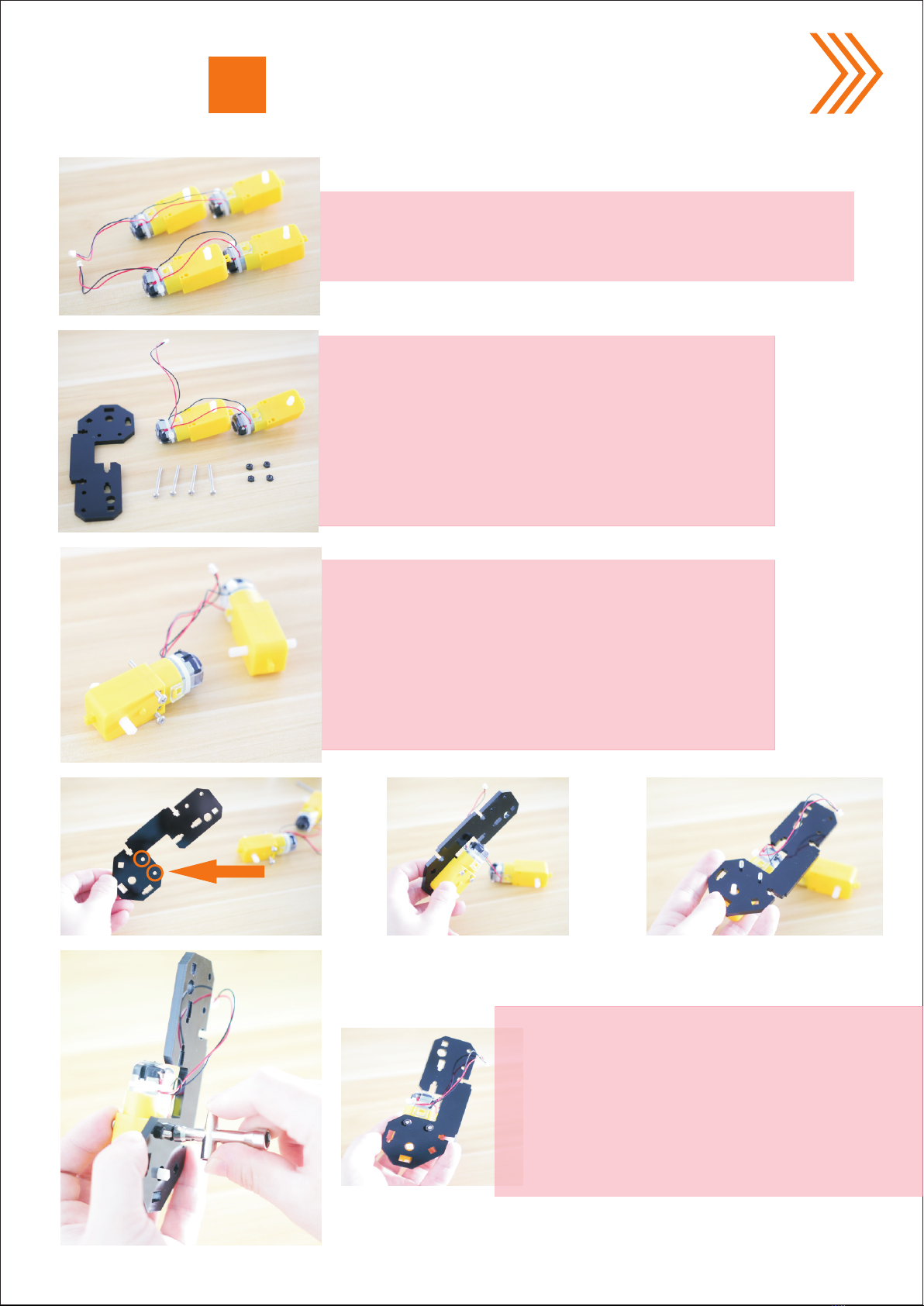

Motor Part assembly.

07

On the left is an installation drawings

of one assembled set of motor.

Note: The M3*30 screw cap is on the

protruding face.

Assemble another part according to the above

method. Note that the motor needs to be installed

on the other side of the acrylic plate. Two sets of

motors are symmetrically mounted.

Use the cross wrench to fix two M3 nuts

to two M3*30 screws.Note that the screw

cannot be tightened too much.

Next pass two M3*30 screws through

the other motor.

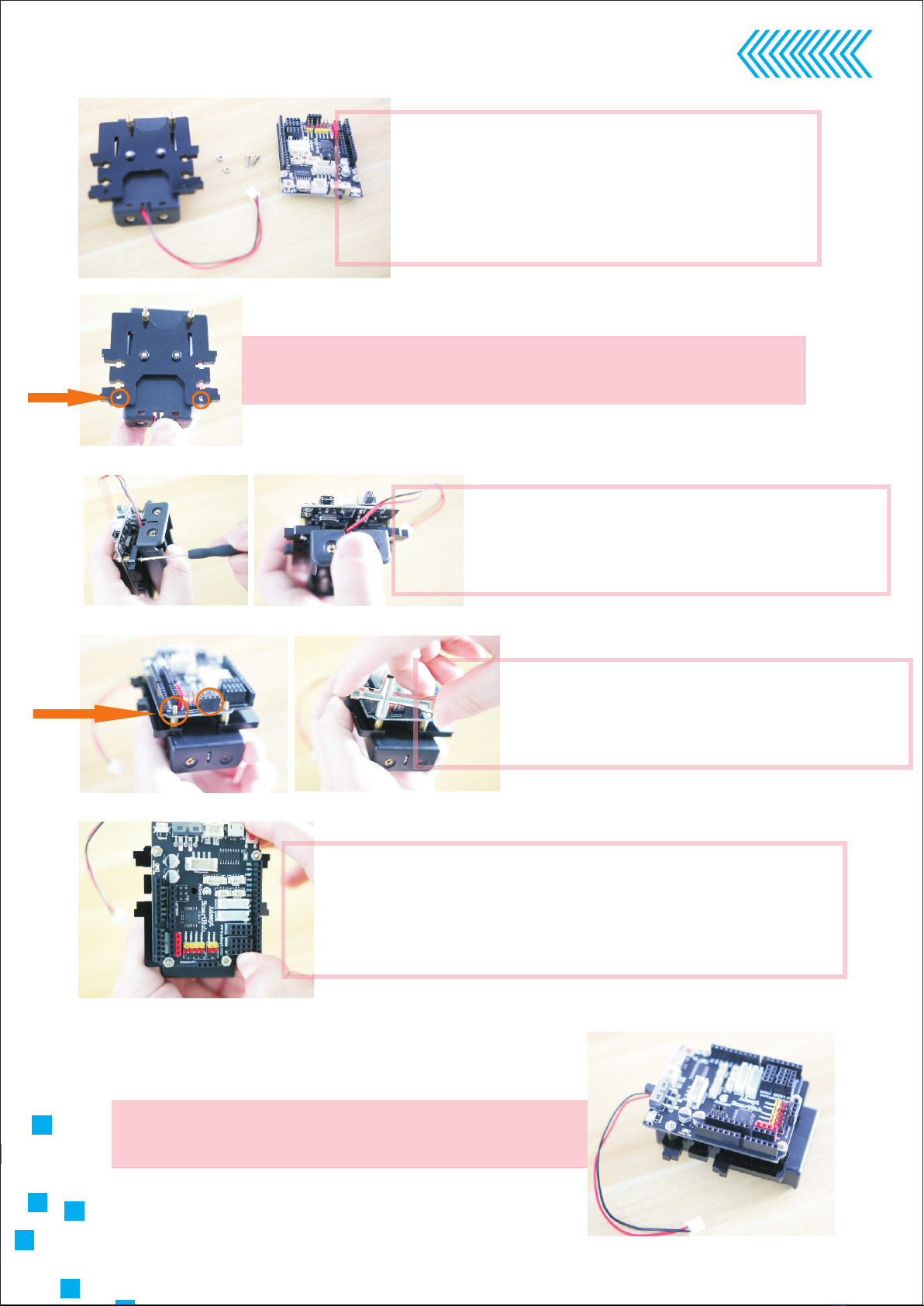

08

Attach the 3-CH Tracking Module to A02 as shown

in the figure. Note that the direction of the 5Pin

wire interface is to the right. If it is to the left,

the car tracking function will not work properly.

Pass two black M2*10 screws through the

two holes as shown.

Screw two black M2 nuts onto the M2 screw.

Use the small screwdriver to tighten the screws.

Connect the 5Pin wire to the

3-CH Tracking Module.

Tracking Module assembly.

Materials needed to assemble

the tracking module:

1x A02 acrylic plate

1x 3-CH Tracking Module

2x black M2*10 screws

2x black M2 nut

1x 5Pin wire

09

Materials needed to assemble the

WS2812 RGB LED:

1x A03 acrylic plate

1x 3CH WS2812 RGB LED

2x black M2*10 screws

2x black M2 nut

1x 3Pin wire

Attach the WS2812 to the acrylic plate.

Pass two black M2*10 screws through

the acrylic plate and the WS2812 module,

and screw two black M2 nuts into the

other end. Use the small screwdriver to

tighten the screws.

Connect the 3Pin wire to the "IN" connector.

Note that it is the one with white lines on the

3CH Ws2812 RGB LED. If connected wrong,

WS2812 will not work properly.

Ws2812 RGB LED Assembly.

Front and back after screwing.

10

Materials needed to assemble the car base A04:

1x A04 acrylic plate

2x silver M2.5*8 screws

2x M2.5*6+6 copper standoff

Pass two silver M2.5*8 screws through

the two holes on the acrylic plate.

Screw the two M2.5*6+6 copper standoffs

onto the M2.5*8 screws as shown in the figure.

Pay attention to the position of the copper

standoffs. If the copper standoffs are mounted

on the other side of the acrylic plate, the

subsequent installation of Adeept Smart

Hub will fail.

Materials needed to assemble the battery holder:

1x A04 acrylic plate

1x 16850 battery holder

2x silver flat head M3*10 screws

2x black M3 nut

Fix the battery holder on the A04 acrylic

plate as shown in the figure. Pay attention

to the wiring position of the battery holder.

If the battery holder is installed reversely,

the wiring will not be able to connect to the

power connector of Adeept Smart Hub.

Car base Assembly.

11

Use the cross wrench to fix the black M3

nut to the silver flat head screw M3 * 10.

Note that the screws here should be

tightened to prevent them loosening

and the battery holder to fall.

Materials needed to assemble the

Adeept Smart Hub:

1x Adeept Smart Hub

2x silver M2.5 nut

2x M2.5*6+6 copper standoff

Fix the copper standoff in these two

positioning holes.

Pass the M2.6*6+6 copper standoff

through the positioning hole as

shown in the figure, fix the other

end with silver M2.5 nut.

On the right is the effect

after assembling.

12

The car base after assembling is as shown.

Pass the M2.5*8 screw through the A04 acrylic plate.

Materials needed to assemble the base:

1x A04 acrylic plate

2x silver M2.5 nut

2x silver M2.5*8 screws

1x Adeept Smart Hub

Use the small screws to screw two

M2.5 screws to two M2.5*6+6 copper

standoffs.

Use the cross wrench to fix two silver

M2.5 nuts to the M2.5*6+6 copper

standoffs as shown.

Note: If the silver M2.5 nut is not easily screwed

onto the M2.5*6+6 copper standoff, push the

black 4Pin female header of the P7.

13

Place the A02 acrylic plate on the

via of the A01 acrylic plate as shown.

Pass the black M3*12 screw

through the A01 acrylic plate

and tighten the M3*12 screw

with the large screwdriver.

Motor And Tracking Module Assembly.

Use the small screwdriver to place

the black M3 nut into the position

as shown.

Materials needed to assemble

the motor and tracking module:

1x A01 acrylic plate

1x black M3*12 screw

1x black M3 nut

1x A02 acrylic plate

On the right is the real product

after assembling.

14

Fix The Base.

Use the small screwdriver to place the two black M3

nuts into the position as shown.Note: Be careful not

to let the M3 nut slip off the A04 acrylic plate.

Fix A04 to this position on the A01 acrylic

plate as shown.

Use the large screwdriver to tighten the

M3*12 screws.

On the right is the effect after assembling.

Materials needed to fix the base:

1x A01 and A02 acrylic plate

1 x A 0 4 a c r y l i c p l a t e

2 x b l a c k M 3 *1 2 s c r e w

2x black M3 nut

Place two black M3*12 screws into the position

as shown.

15

Car Base Assembly.

Materials needed to assemble the car base:

1x A01 and A04 base

1x A02 acrylic plate

1x A05 acrylic plate

1x A06 acrylic plate

1x A01 acrylic plate

The effect diagram when get to this step.

Place the A06 acrylic plate

on the A01 acrylic plate as

shown.

Place A05 on A01 acrylic plate as shown.

Place A03 acrylic plate on A01

acrylic plate as shown.

16

Fix the A01 acrylic plate to the car base.

On the right is the effect after assembling.

As shown, use the small screwdriver to

place the black M3 nut on the screw hole

on the A02 acrylic plate.

Use the small screwdriver to place

the two black M3 nuts in the position

as shown.

Pass the black M3*12 screw through

the A01 acrylic plate and use the large

screwdriver to tighten the M3*12 scre

Pass two black M3*12 screws

through the A01 acrylic plate

and tighten the M3*12 screws

with the large screwdriver.

17

Ultrasonic Module Assembly.

Install the ultrasonic module on

A07 acrylic plate.

Connect the 4Pin wire with ultrasonic module.

Materials needed to assemble

the servo module:

1x Adeept AD002 Servo

2x black M2*10 screw

2x black M2 nut

1x A08 acrylic plate

Materials needed to assemble

the ultrasonic module:

1x A07 acrylic plate

4x silver M1.4*6 self-tapping screw

1x ultrasonic module

1x 4Pin wire

Install the servo on the A08 acrylic plate as

shown in the figure, pass two black M2*10

screws through the A08 acrylic plate.

Install four silver M1.4*6 self-tapping screws

into the ultrasonic positioning holes and use

the small screwdriver to screw the screws vertically

into the A07 acrylic plate.Note: if you find that

A07 is difficult to screw in, you can try to turn over

the A07 acrylic plate and screw it in again.

18

Screw two black M2 nuts onto the two

M2*10 screws and tighten the M2*10

screws with the small screwdriver.

Materials needed to assemble the head of the car:

1x A09 acrylic plate

1x ultrasonic module

1x Ad002 servo module

6x black M3*12 screw

3x black M3*25 nylon column

Pass the wires of the servo and ultrasonic

module through the hole of A08 acrylic plate.

Mount the ultrasonic module on the A08 acrylic plate.

Screw three black M3*12 screws through

the A08 acrylic plate and screw three black

M3*25 nylon columns onto the M3*12

screws as shown.

Cover the A09 acrylic plate on the A08 and the

ultrasonic module.

19

Table of contents

Other ADEEPT Educational Equipment manuals

Popular Educational Equipment manuals by other brands

Fisher-Price

Fisher-Price R2157 manual

sparkfun

sparkfun Weevil Eye Information & Instructions

John Lewis

John Lewis Illuminated globe quick start guide

Aircatglobal

Aircatglobal VirtualFly VF-G1000 user manual

Saltillo

Saltillo ALT-Chat Quick reference guide

adafruit learning system

adafruit learning system MatrixPortal M4 manual