Adexa PBF 88/128 User manual

BAKERY & PASTRY OVENS

MANUAL

PBF 88 / 128 PB 1T - 88 / 128 PB 2T - 88 / 128

PB – 2M 88 / 128 PB – 3M 88 / 128

Sayfa 2

ENTRY

DEAR USER,

All of the information specified in the manual has been prepared for our users and the security of

your environment.

Please read these instructions carefully before you begin installing and using our product, let the

people read who will use the product.

This manual involves product handling, installation, operation, cleaning and maintenance

informations with specifications and safety requirements.

Installations of product should be done by qualified persons as described in this manual.

Please follow the rules that we proposed during the usage, maintenance and cleaning.

Please contact us for further informations and opinions.

We hope you satisfied with our product.

Sayfa 3

USE OF PRODUCT

Uses and Conditions

Before first usage(energy must be disconnected)wipe oven’s interior and exterior surfaces

with a wrung fabric dipped in warm soapy water, then dry by wiping with a damp fabric again.

Product has to run in conditions between -5°C,+40°C temperatures and max %65 humidity is

recommended.

NOTE:Do not go beyond the intended use.

The user shoul read this manual and know the product and the applicable safety

requirements and technical specifications.

TRANSPORTATION AND RELOCATION

•Electricity network must be disconnected by competent persons before transport.

•Items should not moved by human power. During transportation products should be taken on

pallets with appropriate methods and should be fixed to the pallets.

•Handling should be done with suitable lifters. Transportation vehicles should be used by

qualified persons.

•In the handling, the original packaging system of the product should be used. If this is not

possible, to prevent the dislocation of the cooking stone, appropriate support elements

should be put or cooking stones should be removed and moved.

INSTALLATION OF THE PRODUCTS

•The product where it will be mounted must be corrected by adjustment and balance; and the

grounding must be made.

•The montage is it will be high from the ground, assembly floor must be strong enought to carry

the weight.

Sayfa 4

BAKERY & PASTRY OVEN

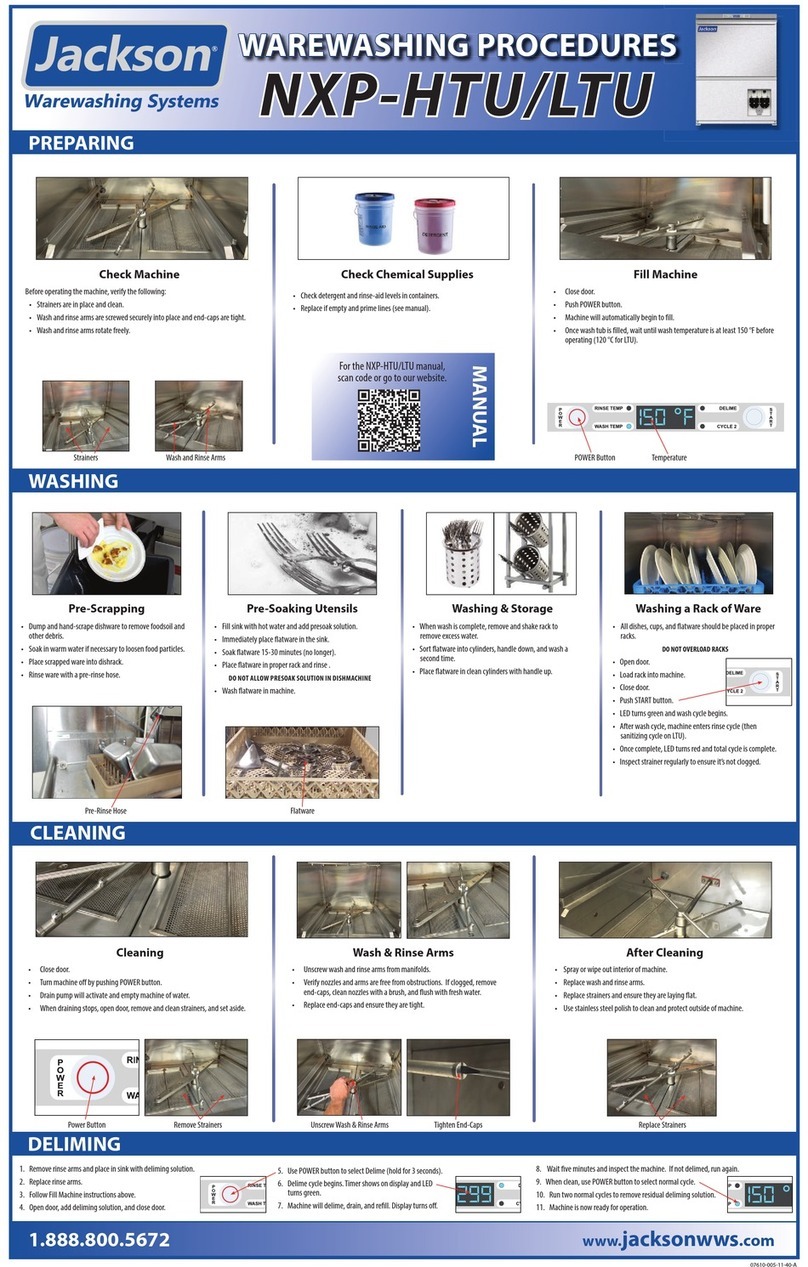

DIGITAL CARD VIEWS

Sayfa 5

INDICATORS AND KEY TRANSACTIONS

TEMPERATURE SET INDICATORS AND INCREASE,

DECREASE KEYS: The set temperature indicates the set

value. Setpoint adjustment can be done by increasing,

decreasing keys at the range of 30ºC and 350ºC . If the

increase or decrease buttons are held down for 3 secons, the

value increases or decreases very quickly. The values shown

in displey will be automatically stored.

In the faults related “Er.x” values are also seen.

TIME INDICATORS AND INCREASE, DECREASE KEYS :

The time display shows the remaining time. Time setting can

be done by incraseing, decreasing keys between the range 1

and 60 minutes. If the increase or decrease buttons are held

down for 3 secons, the value increases or decreases very

quickly. The values shown in displey will be automatically

stored.

Time LED, flashes once per second when the time counting

begins.

UPPER FRONT, UPPER REAR AND BOTTOM SET DISPLAY, LEDS AND ADJUSTMENT KEYS: How long

will the heating circuit goes, sets up with the arrow keys and the value is seen at the indicators related with

resistance. Resistance’s LED lights are active as long as related resistance is enabled. The display shows “0”

when no resistance is active, “10” is seen the resistance is constantly active. Resistances stay enabled 3

times more than the value on the display, in the remaining time the resistances are disabled. Total control time

(period) is 30 seconds. For example if the value entered as 4, the resistance will be enable 12 seconds LED

will go on, for 18 seconds resistance will be disabled and LED will go off.

ON-OFF KEYS AND LEDS: When the device is energized, key LED lights up red. When the

key is pressed, the device is energized. Key LED lights up green and all indicators lights up

also. Pressing the button again deletes indicators and key LEDs lights up red.

TURBO BUTTON AND LED: Key LED lights up when is pressed, all resistances are

activated. tans Indicators show “10” and LED turns on. When the key is pressed again the

LED turns off. The preset resistance levels are seen in the display and the oven will continue

to work according to the proportional value. When the START button is pressed, the turbo is

activated automatically.

Sayfa 6

LIGHT CONTROL KEY AND LED: LED turns on when pressed, lamp relay outputs.

When the button is pressed again the LED turns off and lamp does not relay output.

TIMER ACTIVATING KEYS AND LED: LED turns on when pressed, the time begins

to count down. At the end, the device beeps.

START / STOP KEY AND LED: LED turns on when pressed and switches to position

START. Depending on the setpoint appliance starts to control temperature. Turbo

automatically activated when the measured temperature is below the set value, resistances

work full. Setpoints can change at the start position. Temperature control set will continue to

run according to the new setpoint. Resistance relay stays towed until the measured

tempreature values reach the temperature setpoint and the LED lights. Measuring resistance

value reaches setpoint relay releases, the set temperature LED is off. Pressing a key maket

he device stopped and LED turns off, all of the controls and relays are disabled.

STEAM ON KEY AND LED: Steam on key activates the steam thermostat. The LED flashes

as long as is stays turn on. When thermostat stays off the signal comes to switch input and

steam is ready. The LED stays on continuously.

STEAM OFF KEY AND LED: When pressed steam off button, steam thermostat stays

disabled and lights turn to red.

STEAM KEY AND LED : As long as the key is held down, steam valve output data.

Otherwise, the key does not work and gives audible warning. In faults, control will be

cancelled.

PROGRAM KEYS AND LEDS: Device with steam has 6 program, device without steam has 9 program.

Pressing a random button will bring the value set automatically. To run the sufficient program it is enough to

press the desired program’s button.

Sayfa 7

FAULTS and WARNINGS:

1. Er.1: Furnace top thermocouple (TC) is the open ends of the temperature indicator Er.1

writer. On the other intermittent buzzer and siren relay pull releases. All controls remain

disabled. Failure resolved until the system fails. When the fault corrected setting must be

done again.

2. Er.2: Oven Bottom thermocouple (TC) is the open ends of the temperature indicator Er.2

writer. On the other intermittent buzzer and siren relay pull releases. All controls remain

disabled. Failure resolved until the system fails. When the fault corrected setting must be

done again.

3. Er.3: Oven temperature gauge goes above the upper temperature 400ºc'n Er.3 writer. On

the other intermittent buzzer and siren relay pull releases. All controls remain disabled.

Failure resolved until the system fails. When the fault corrected setting must be done again.

4. Er.4: Er.4 writer indicator When the oven temperature rises above the lower temperature

400ºc'n. On the other intermittent buzzer and siren relay pull releases. All controls remain

disabled. Failure resolved until the system fails. When the fault corrected setting must be

repeated

5. Er.5: Limit thermostat (LT1) Er.5 writers on the temperature display when the input signal.

On the other intermittent buzzer and siren relay pull releases. All controls remain disabled.

Failure resolved until the system fails. When the fault corrected setting must be done again.

4. Ur.1: if you press the steam ready when the desired temperature is key if you tried to be

active not arrive steam valve relay device gives an audible warning. (Without steam devices

do not have this feature)

ADDITIONAL HIDDEN FEATURE:

To see bottom of the oven (stone) pushing the BOTTOM UP key shows the temperature on the

time display. To see the time again it is enought to push one of the two keys on the Time

display.

Sayfa 8

WARRANTY CONDITIONS

1. The warranty period starts from the date of delivery and duration of 1 (one) year.

2. On the date of sale, without factory and vendor approval documents are invalid. To take

advantage of warranty must be guaranteed.

3. The product, installation, use, maintenance use mounted as described in the manual registration

and is guaranteed against defects in material and workmanship defects that may arise.

4. Determination of the fault which is under warranty, fixed shape and determine the position

belongs to the competent service.

5. The warranty, installation, use and maintenance manual to complying with the conditions and

guarantees of the product is guaranteed only the rights or compensation can be claimed under any

other name than that.

6. Warranty document or guarantee in terms of the product on the product, model, and serial

number on the information indicating the erasure, erasure or void the warranty if the change is

made.

7. Warranty applies only material that can be formed in time and workmanship defects and

malfunctions related to the scope of maintenance and repair of failures against içerir.garant parts

are repaired and replaced free of charge.

8. In the run at different voltages other than on products and operating instructions specified in the

manual installation, use, cleaning and out of warranty due to failure to comply with the relevant

provisions applied to maintenance operations.

9. Installation must be done by a qualified service representative and inform the service should be

provided in case of replacement of the product.

10. Authorized Dealers installation outside the responsibility, unloading and removal damages and

breakdowns that may occur during the delivery process, warranty processing görür.ayn the way,

warranty is the elimination of damages and failures will be given by external factors during use of the

product.

11. intervention authorized service malfunctions during the warranty excludes the guarantee of

intervention products edebilir.yetkisiz person.

12. In case of dispute Izmir courts are competent.

This manual suits for next models

4

Table of contents

Other Adexa Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Bartscher

Bartscher Deli Plus I D instruction manual

Italian Gelato

Italian Gelato SKYLINE instruction manual

Angelo Po

Angelo Po 0G0FT1G Use and installation manual

Fri-Jado

Fri-Jado HD 3 installation manual

Belshaw Brothers

Belshaw Brothers Donut Robot Mark VI Operator's manual

YATO

YATO YG-03087 instruction manual