ADITIVA 3D VORON BELT 350 KIT User manual

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 2 | 27

www.belt3dprinterkit.com

Content

Chapter 1 Intro 3

Step 1.1 What is included in this kit? 3

Step 1.2 Needed tools 3

Chapter 2 Disassembling Voron 2.4 front doors and heatbed 3

Step 2.1 Removing front door parts 4

Step 2.2 Removing Heatbed 4

Chapter 3 Preparing frame 5

Step 3.1 Installing bottom plates 5

Chapter 4 Installing Belt and Heatbed system 10

Step 4.1 Preparing rollers 10

Step 4.2 Installing Rollers and Belt 11

Step 4.3 Mounting Heatbed 16

Chapter 5 Finishing installation 18

Step 5.1 Belt holders mounting 18

Step 5.2 Face plate mounting 19

Step 5.3 Installing front STRIP CURTAIN 19

Chapter 6 Klipper and firmware settings 21

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 3 | 27

www.belt3dprinterkit.com

Chapter 1 Intro

Step 1.1 What is included in this kit?

In this kit you will find all the necessary parts for converting your regular Voron 2.4 3d printer

into a sequential Conveyor 3d printer. Parts lists are indicated on each step for better

understanding and guidance.

Step 1.2 Needed tools

In order to fully install this kit, you will need the next tools:

Set of Allen keys

Adjustable wrench or wrench kit

Measuring tape

Vernier caliper

Metal ruler (for alignment)

Chapter 2 Disassembling Voron 2.4 front doors and heatbed

In order to get ready to install this kit, you have to disassembly various segments of the original

3d printer, this part will guide you through entire process of preparation and getting ready to

install new parts.

*Please be aware some original parts will be discarded and won’t be installed.

Figure 1. Assembled Heatbed

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 4 | 27

www.belt3dprinterkit.com

Step 2.1 Removing front door parts

Remove all brackets, panels and hinges from both front doors.

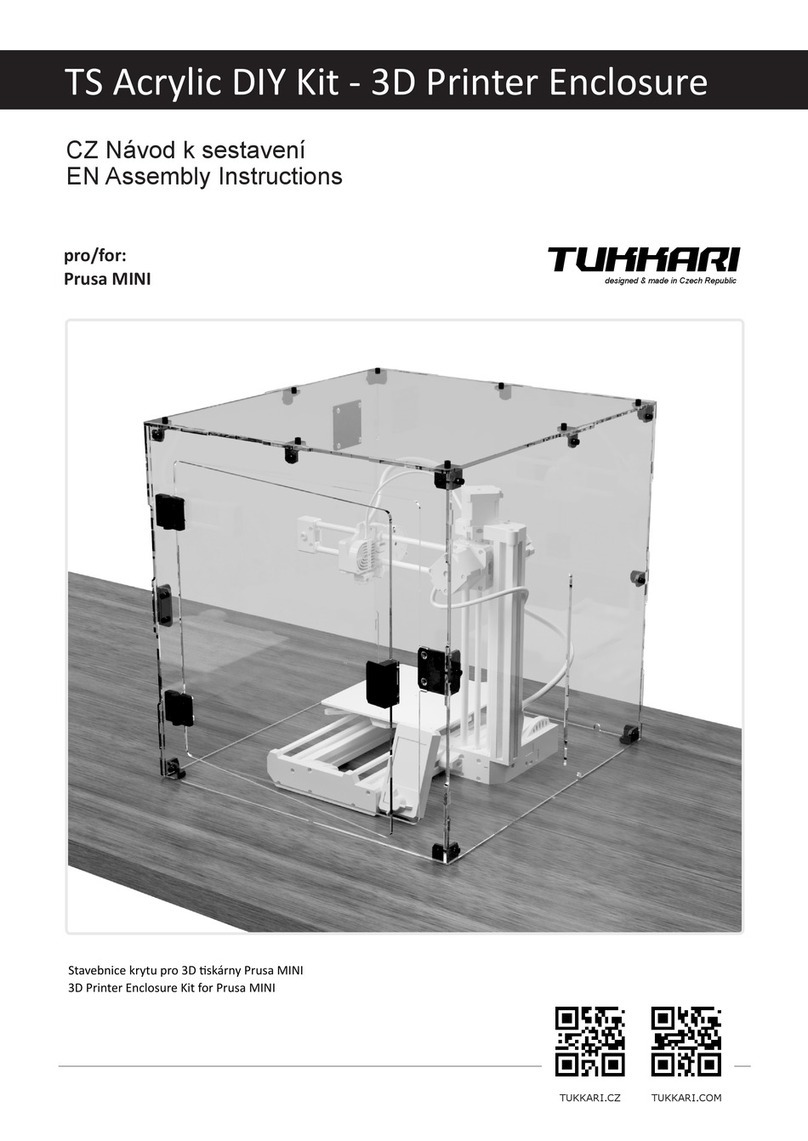

Figure 2 remove highlighted parts

Step 2.2 Removing Heatbed

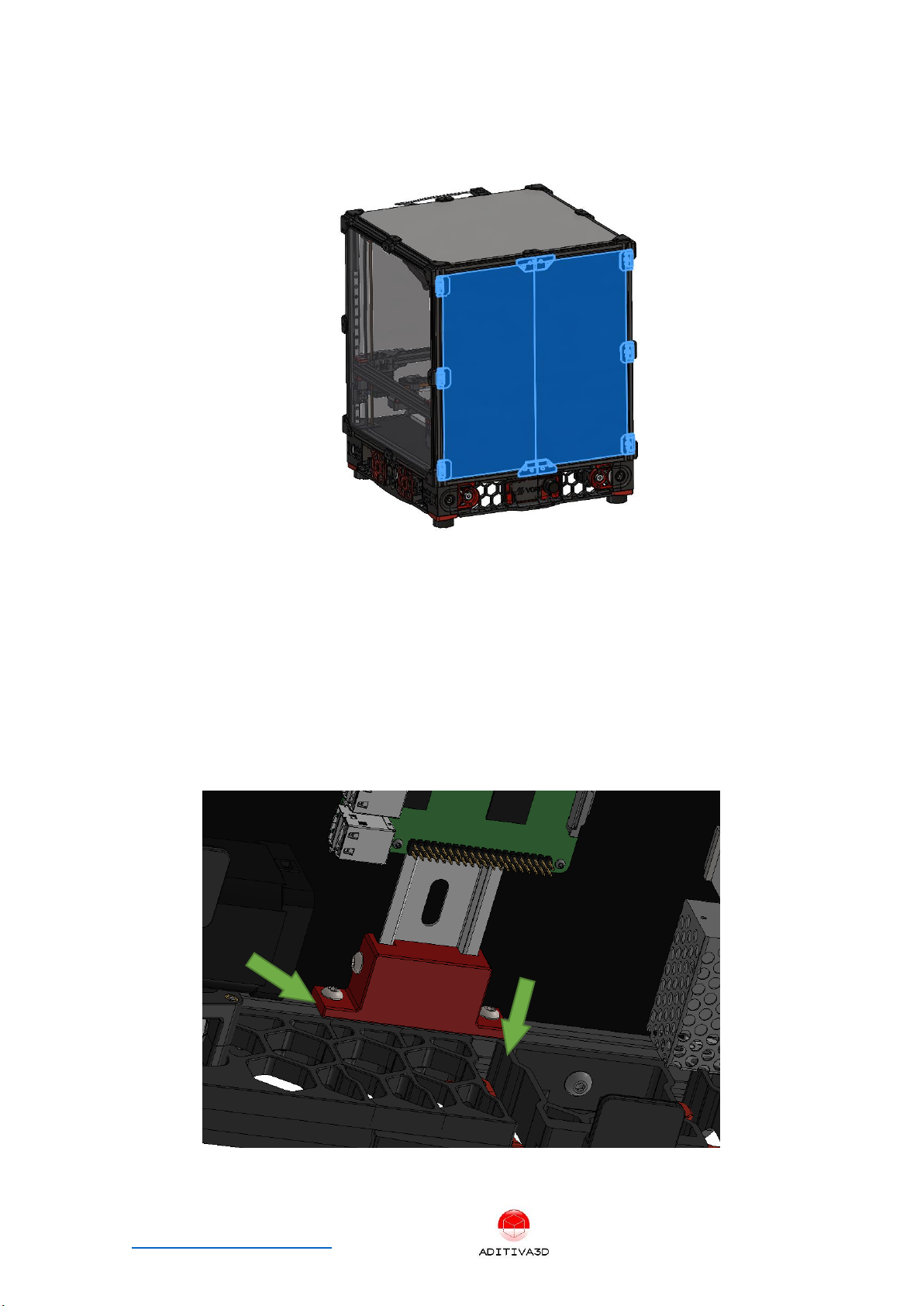

Before starting to remove the heatbed, we need to secure both DIN rails that holds all

the electronic components, so we flip the printer carefully and remove the bottom

panel.

After that, we use the printed BRACKET_DIN_RAIL_X4.STL part and secure the DIN rails

using 4 units M4x8 screws and 2 units T-nuts on each bracket as shown in the next

picture.

Figure 3 Securing DIN rails before removing heatbed bars

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 5 | 27

www.belt3dprinterkit.com

We remove heating bed at this point, by releasing 4 units M3 bolts that holds it down,

it is highly recommended to remove any magnetic base plate, and clean the aluminum

heatbed with IPA in order to remove any glue from it:

*Note: Do not disconnect the heatbed from the electronics, just keep it loose for next

steps.

Figure 4 Removing heatbed screws

Now we can securely remove both 2020 aluminum bars that holds the heatbed, by

removing the 4 screws on each side, you have to disconnect cable from the Z endstop

unit, since it won’t be used:

Figure 5 Removing heatbed support bars

Chapter 3 Preparing frame

We are pretty much ready to install our kit.

Step 3.1 Installing bottom plates

Let’s identify each bracket part first:

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 7 | 27

www.belt3dprinterkit.com

Figure 9: P4 VC90 CNC FRONT RIGHT BRACKET

Next items from the KIT will be used:

ITEM

ITEM DESCRIPTION

Quantity

Type

1

P1 VC90 BACK LEFT BRACKET

1

Kit

2

P2 VC90 BACK RIGHT BRACKET

1

Kit

3

P3 VC90 CNC FRONT LEFT

BRACKET

1

Kit

4

P4 VC90 CNC FRONT RIGHT

BRACKET

1

Kit

5

M5 x 20 mm Screw

2

Kit

6

M5 x 50 mm Screw

2

Kit

7

M5 T-Slot nut

4

Kit

8

M4 x 8 mm Screw

5

Kit

9

M4 T-Slot nut

5

Kit

Install 2 CNC bracket plates as shown in the next picture, M5 screws and M5 T-slot nuts

will be used, left and right sides must be assembled:

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 8 | 27

www.belt3dprinterkit.com

Figure 10 Installing front CNC brackets on each corner of bottom frame

Install 2 back bracket plates as shown in the next picture, M4x8 screws and M4 T-slot

nuts will be used, left and right sides must be assembled, they have to be installed right

next to the timing belt cover:

Note: If necessary and for easier mounting, is highly recommend to remove side panels

to reach those brackets and other parts from the conveyor system

1 M5x20 SCREW +

1 M5 T-SLOT NUT

1 M5x50 SCREW +

1 M5 T-SLOT NUT

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 10 | 27

www.belt3dprinterkit.com

Chapter 4 Installing Belt and Heatbed system

Figure 13 Belt system Assembly

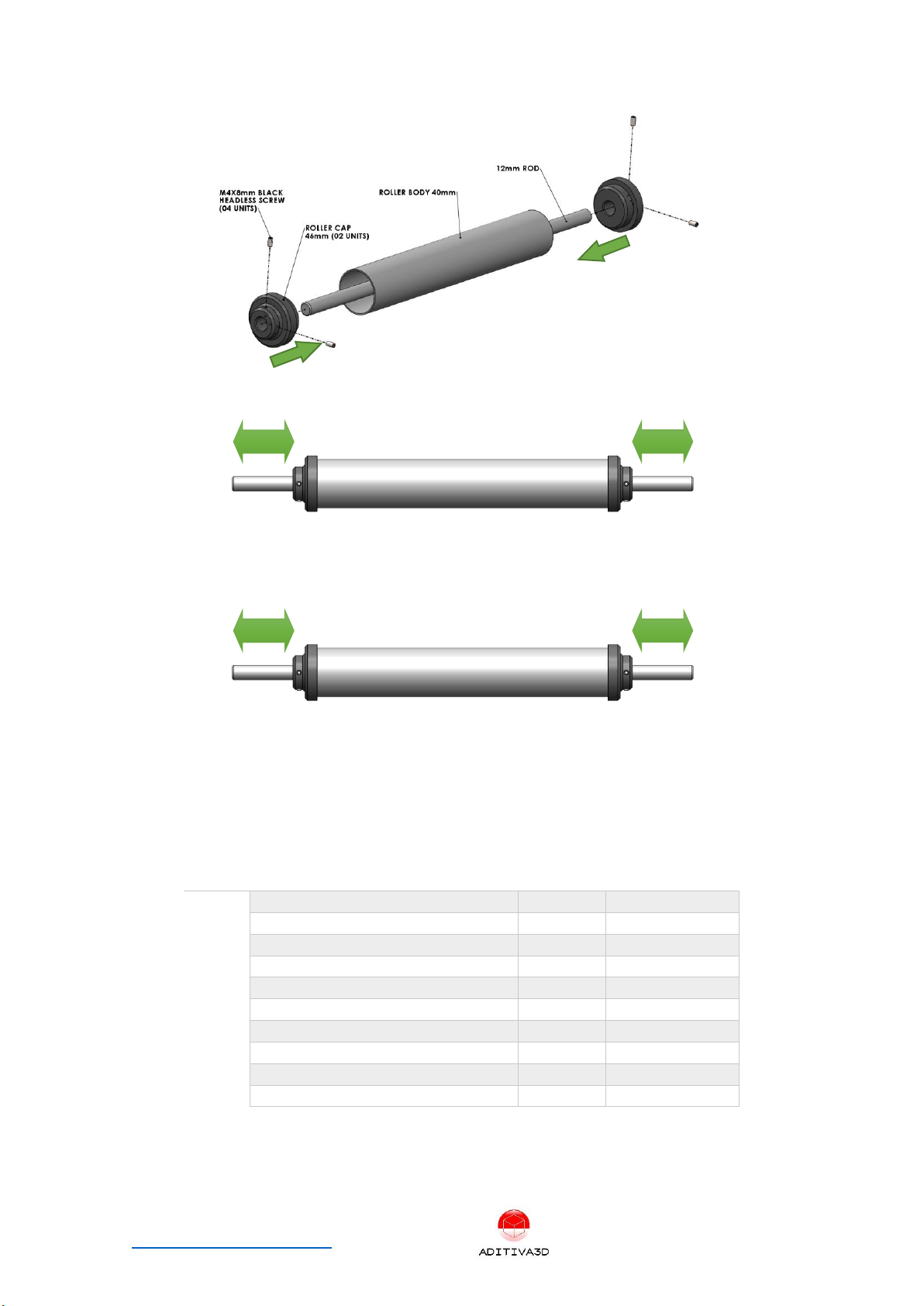

Step 4.1 Preparing rollers

Next items from the KIT will be used:

ITEM

ITEM DESCRIPTION

Quantity

Type

1

Roller BODY 40 mm

2

Kit

2

12 mm ROD

2

Kit

3

Roller Cap 46mm

4

Kit

4

M4x8mm Black Headless screw

8

Kit

Using all the mentioned parts, proceed to assemble them in the next order, first place

12mm ROD inside Rolle BODY 40mm, then insert Roller CAP 46mm on each end, making

sure it all fits very tight, keep in mind that 12mm ROD have to be placed according to

the next pictures. Finally using an allen key, proceed to secure both ROLLE CAP 46mm

with the M4x8mm BLACK HEADLESS SCREWS (02 on each side):

*Note: You have to repeat this process in order to get 2 rollers assembly.

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 11 | 27

www.belt3dprinterkit.com

Figure 14 Roller assembly components

Figure 15 Back roller mounting dimensions

Figure 16 Front roller mounting dimensions

Step 4.2 Installing Rollers and Belt

Next items from the KIT will be used:

ITEM

ITEM DESCRIPTION

Quantity

Type

1

Roller Assembly

2

Kit

2

FLANGE BEARING 12mm

4

Kit

3

M6x16mm SCREW

8

Kit

4

M6 NYLOCK NUT

4

Kit

5

BELT

1

Kit

6

Timing Pulley 60T, Bore 12mm GT2

1

Kit

7

GT2 Timing belt Closed Loop

1

Kit

8

Y MOTOR with GT2 PULLEY

1

Kit

9

M3X6 SCREW

4

Kit

10

M6 Knobs

2

Kit

Insert Flange Bearing 12mm on both sides of one of the Roller:

42 mm

22 mm

32 mm

32 mm

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 12 | 27

www.belt3dprinterkit.com

Mounting the back roller: at this point insert the back roller through the Conveyor

Belt:

Figure 17 Back roller mount

Figure 18 Fix the bearing with M6x16 Screw and M6 Hex nut, on both sides

FRONT ROLLER MOUNT: Take the FRONT ROLLER with FLANGE BEARINGS on it, install

it with M6x30 SCREWS into front CNC TENSIONERS MOVING ELEMENT:

2 M6x8 SCREW +

2 M6 HEX NUT

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 13 | 27

www.belt3dprinterkit.com

ROLLER HAS TO BE CENTERED!

Figure 19 Fix with M6x16 screws

Figure 20 Repeat with the right side

Insert this new FRONT ROLLER assembly through the Conveyor belt, and slide it on the

CNC TENSIONERS slot, and insert both sides M6 Knobs supplied in the kit:

Figure 21 Mounting front roller assembly

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 14 | 27

www.belt3dprinterkit.com

Insert both sides M6 Knobs supplied in the kit:

Figure 22 Inserting M6 Knobs on both sides

Belt tensioning:

One way to check for the right belt tension and alignment is to roll the belt by hand and it

have to move easy, smooth and straight without wobbling or needing to apply too much

force.

Figure 23 Measuring axles on right side

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 15 | 27

www.belt3dprinterkit.com

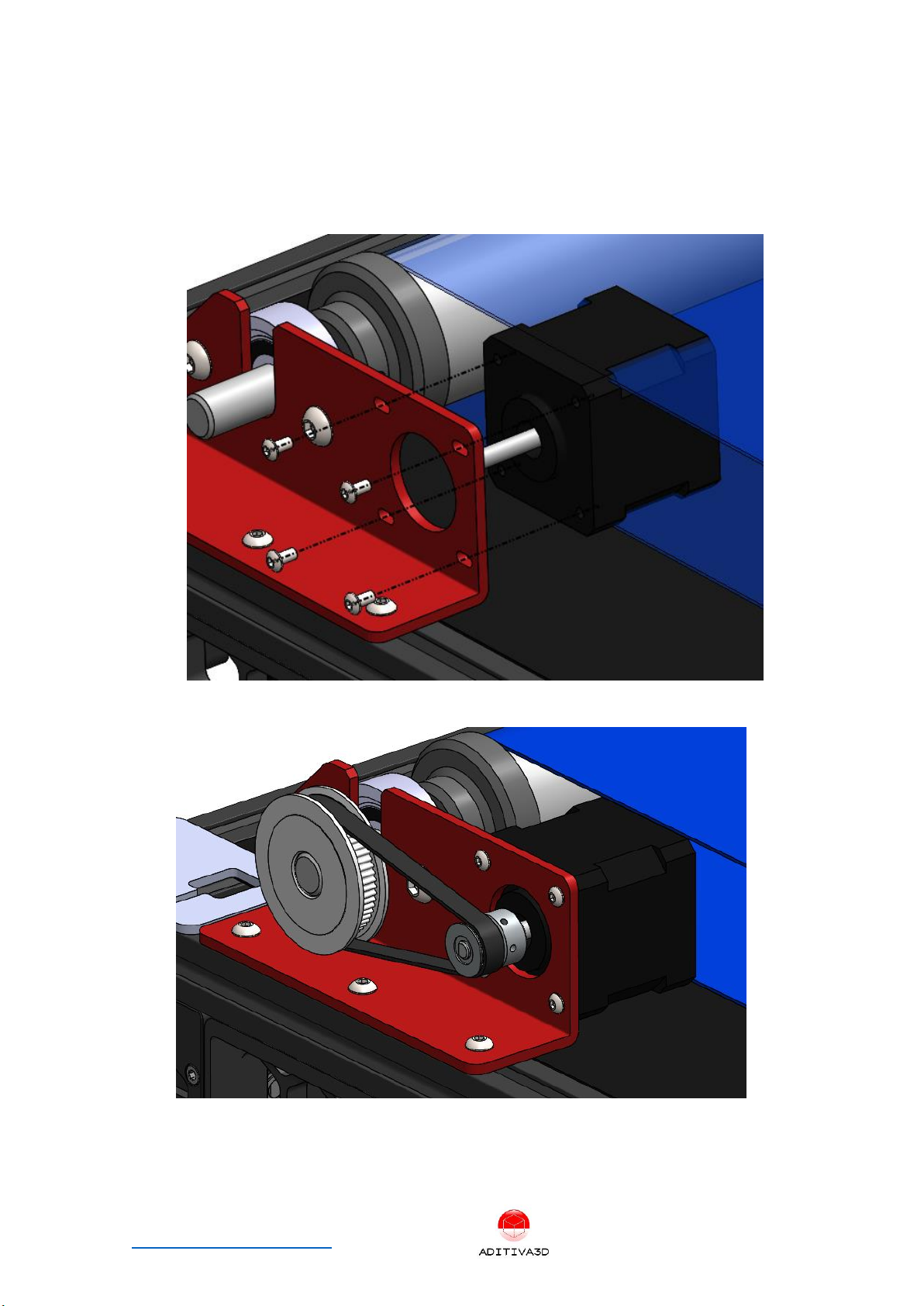

Belt motor installation: On the LEFT FRONT side of machine, take the Timing Pulley 60T,

bore 12mm GT2 and insert it on the end of the REAR ROLLER, then using the original Y

motor and pulley (using M4x8mm Screws and M4 slot nuts), proceed to install it. At this

point place the GT2 Timing Belt Closed Loop and align both pulleys, then adjust the

motor bracket in order to tension the closed loop belt. As shown in the next picture:

Figure 24 Insert included Nema 17, using M3x6 screws, don’t tight them yet

Figure 25 GT2 closed belt + 60T GT2 Pulley and 20T GT2 Pulley, tension and adjust motor screws

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 16 | 27

www.belt3dprinterkit.com

Step 4.3 Mounting Heatbed

Next items from the KIT will be used:

ITEM

ITEM DESCRIPTION

Quantity

Type

1

Original Heatbed without

magnetic sheet

1

Original Part

2

Heatbed mount plate

2

Kit

3

1020 ALU PROFILE

2

Kit

4

M4x8 mm SCREW

10

Kit

5

M4 Slot nut

10

Kit

6

M5x8 mm SCREW

4

Kit

7

M5 Slot nut

4

Kit

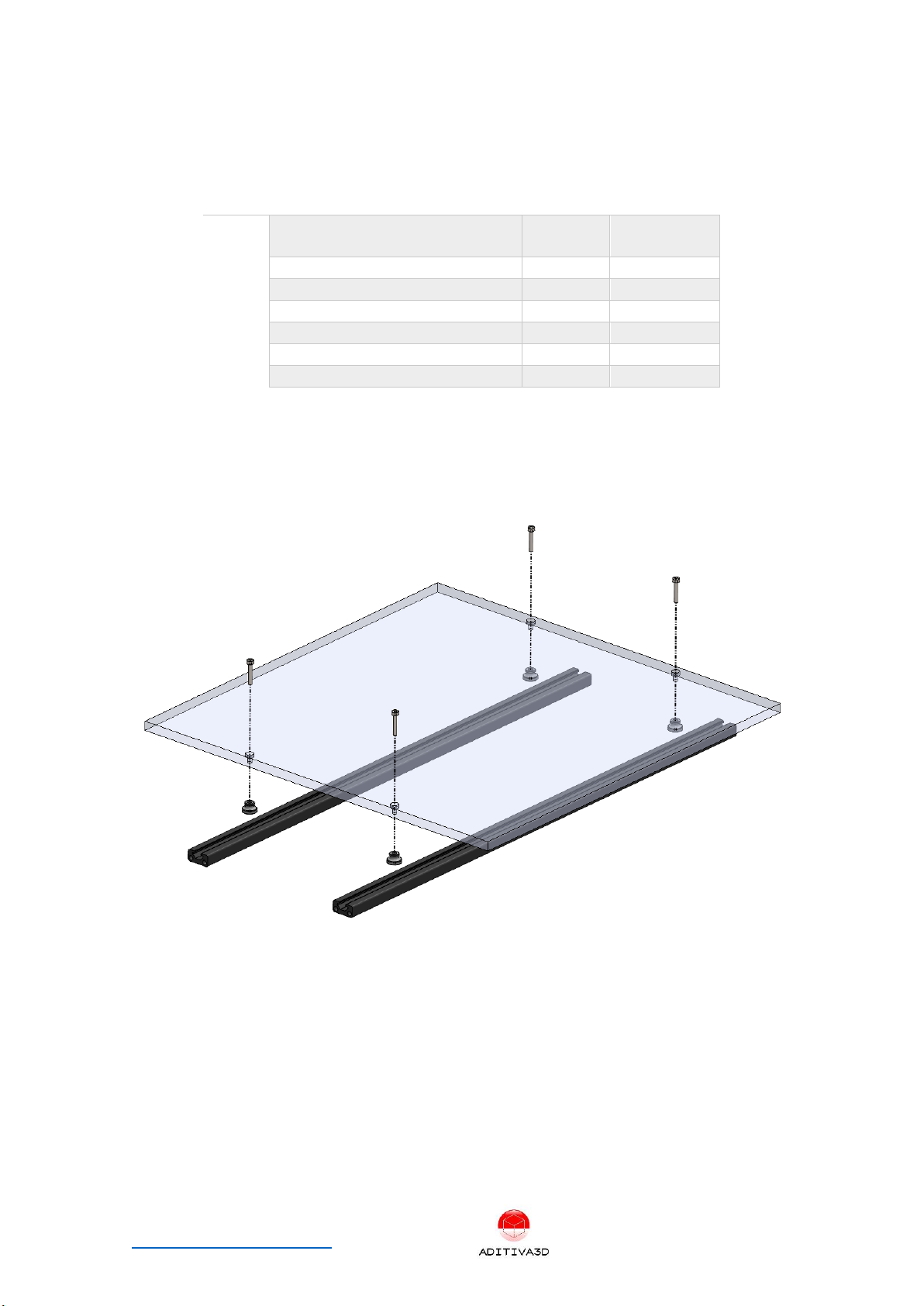

Preparing Heatbed base plate: Take original Heatbed, M4 knurled nuts, M3 screws and

M3 T-nuts, and mount over the 2 units 1020 ALU PROFILE as shown, heated bed has to

be centered:

Figure 26 Heatbed base plate without wheels and showing aligned holes pairs.

Installing heatbed Assembly: Install heat bed element back again.

Proceed to insert Heated bed with support alu bars assembled, from the left side of

machine right under the tensioned BELT. (cable of heatbed will come out from the left

side to the machine and going to the electronic compartment)

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 18 | 27

www.belt3dprinterkit.com

Figure 28 Internal dimension should be 110mm

Chapter 5 Finishing installation

Step 5.1 Belt holders mounting

Belt holders on each side of the Conveyor belt will help to reduce possible warping and

better stability for the belt once printing over it, in order to install them follow the

next scheme and repeat on the opposite side, after that slightly adjust the screws, in

order to get even and slightly pressure over the belt, belt holder should overlap the

belt for about 10 mm or less on each side:

1 M5x25 SCREW +

2 M5 WASHER +

1 SPRING

1 M5 T-NUT

Voron 2.4 Conveyor 90 Belt Kit assembly manual P a g e 19 | 27

www.belt3dprinterkit.com

Figure 29 Belt holder installed, repeat on the left side

Step 5.2 Face plate mounting

Install provided face plate into the front of the machine, using 2 units M5x8 screws

and M5 T-nuts, place it centered on the printer:

Figure 30 Install face plate, keeping a gap of 2mm from the belt

Step 5.3 Installing front STRIP CURTAIN

Strip curtain is required to keep heat inside the chamber, and also for letting parts to

come out easily from the belt.

Use supplied top bracket in order to fix all the strips to the top frame, using M4x8

screws and M4 T-nuts, you can use a piece of blue tape to pre-arrange them first over

a table for easy mounting, overlap is about 12mm for each strip:

Table of contents

Other ADITIVA 3D 3D Printer manuals