CreatBot F160 User manual

CreatBot 3D Printer

User manual

English V7.3

Henan Suwei Electronics Technology Co., Ltd.

- 1 -

Pro

CONTENTS

Icon conventions

Tip icon to remind users to have a good method or technique.

Note icon, to remind the user must be given adequate attention.

Prohibition icons, prevents users from unauthorized operation.

22/04/ 2020

- 2 -

Notice ················································3

Machine Diagram

Front ············································4

New Printer Head ··················· 5

Printer Operation

Leveling Platform ··················· 6

Paving Crepe Paper··············· 6

Load Filament ·························· 7

Unload Filament····················· 8

Main menu ······························· 9

Status page ······························ 10

Detail page ······························· 11

Printing page ··························· 12

Axis operation ························· 13

Filament menu ························ 14

SD Card/U-disk ······················· 15

Setting menu ··························· 16

Info. menu ································· 16

Software Operation

CreatWare Setup ·················· 18

Quick Print UI ······················· 19

Print Your First Model ········ 19

Full Setting UI ······················· 20

Mouse Operation ················ 21

Model Rotate/Scale ············ 21

Model Mirror ·························· 22

View Mode ······························ 23

Right Click on Model ··········· 24

Toolpath Structure ················ 24

Basic Setting ··························· 25

Advanced Setting················· 26

Expert Setting ························ 27

Skirt/Brim/Raft······ ······ ······· ··· 28

Plugins ····································· 28

Start/End GCode ·················· 29

Dual Head Printing ·············· 29

Align Dual Head Horizon ··· 30

Align Dual Head Vertical ···· 31

Add Multi Type Printer ······· 31

Using skills

Installation section ·············· 32

Software ·································· 33

Change filament ··················· 33

Frequently Asked Questions

Paving Kapton ······················ 34

Change Fuse ·························· 35

Adjust Z Limit ························ 35

Print PLA and ABS ··············· 35

Specifications ······························ 36

Notice

Read First

Thank you for choosing CreatBot 3D printer!

This manual contains important information about the installation, use,

maintenance and common problems of CreatBot 3D printer. Please read this

manual carefully before using 3D printer. All losses caused by the breach of the

notes and the operation process of the operation process will be borne by the user.

Please use the filament provided by CreatBot, or high quality filament by third

manufacturers. Due to the use of third party inferior material caused by the failure

of the printer, the loss will be borne by the user.

Software running environment, 2G or above processors, at least 1G memory,

compatible with Windows, MAC, or Linux, please use memory as much as possible.

I wish you have fun with CreatBot 3D printer!

Danger Warning

The nozzle's temperature will reach 300 degrees, don't touch.

The platform's temperature will reach 120 degrees, don't touch.

Please make sure that the printer connected to the ground.

Do not attempt to open the case, be careful of electric shock.

Working Environment

The 3D printer can work in the indoor environment of 5 ℃ to 30 ℃.

Long-term not use of the printer, be sure to keep off dust, moisture.

Long-term not use of the filament, please be sealed to prevent deterioration.

- 3 -

CONTENTS

Icon conventions

Tip icon to remind users to have a good method or technique.

Note icon, to remind the user must be given adequate attention.

Prohibition icons, prevents users from unauthorized operation.

22/04/ 2020

- 2 -

Notice ················································3

Machine Diagram

Front ············································4

New Printer Head ··················· 5

Printer Operation

Leveling Platform ··················· 6

Paving Crepe Paper··············· 6

Load Filament ·························· 7

Unload Filament····················· 8

Main menu ······························· 9

Status page ······························ 10

Detail page ······························· 11

Printing page ··························· 12

Axis operation ························· 13

Filament menu ························ 14

SD Card/U-disk ······················· 15

Setting menu ··························· 16

Info. menu ································· 16

Software Operation

CreatWare Setup ·················· 18

Quick Print UI ······················· 19

Print Your First Model ········ 19

Full Setting UI ······················· 20

Mouse Operation ················ 21

Model Rotate/Scale ············ 21

Model Mirror ·························· 22

View Mode ······························ 23

Right Click on Model ··········· 24

Toolpath Structure ················ 24

Basic Setting ··························· 25

Advanced Setting················· 26

Expert Setting ························ 27

Skirt/Brim/Raft······ ······ ······· ··· 28

Plugins ····································· 28

Start/End GCode ·················· 29

Dual Head Printing ·············· 29

Align Dual Head Horizon ··· 30

Align Dual Head Vertical ···· 31

Add Multi Type Printer ······· 31

Using skills

Installation section ·············· 32

Software ·································· 33

Change filament ··················· 33

Frequently Asked Questions

Paving Kapton ······················ 34

Change Fuse ·························· 35

Adjust Z Limit ························ 35

Print PLA and ABS ··············· 35

Specifications ······························ 36

Notice

Read First

Thank you for choosing CreatBot 3D printer!

This manual contains important information about the installation, use,

maintenance and common problems of CreatBot 3D printer. Please read this

manual carefully before using 3D printer. All losses caused by the breach of the

notes and the operation process of the operation process will be borne by the user.

Please use the filament provided by CreatBot, or high quality filament by third

manufacturers. Due to the use of third party inferior material caused by the failure

of the printer, the loss will be borne by the user.

Software running environment, 2G or above processors, at least 1G memory,

compatible with Windows, MAC, or Linux, please use memory as much as possible.

I wish you have fun with CreatBot 3D printer!

Danger Warning

The nozzle's temperature will reach 300 degrees, don't touch.

The platform's temperature will reach 120 degrees, don't touch.

Please make sure that the printer connected to the ground.

Do not attempt to open the case, be careful of electric shock.

Working Environment

The 3D printer can work in the indoor environment of 5 ℃ to 30 ℃.

Long-term not use of the printer, be sure to keep off dust, moisture.

Long-term not use of the filament, please be sealed to prevent deterioration.

- 3 -

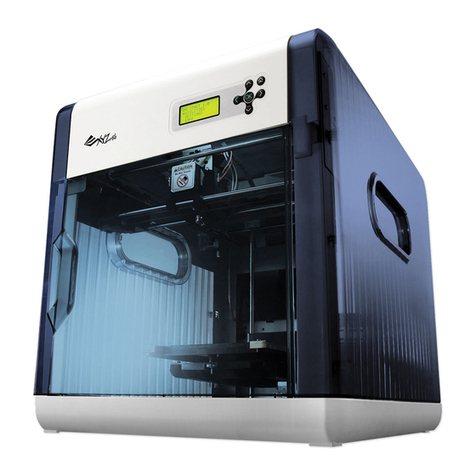

Machine Diagram

Front

- 4 -

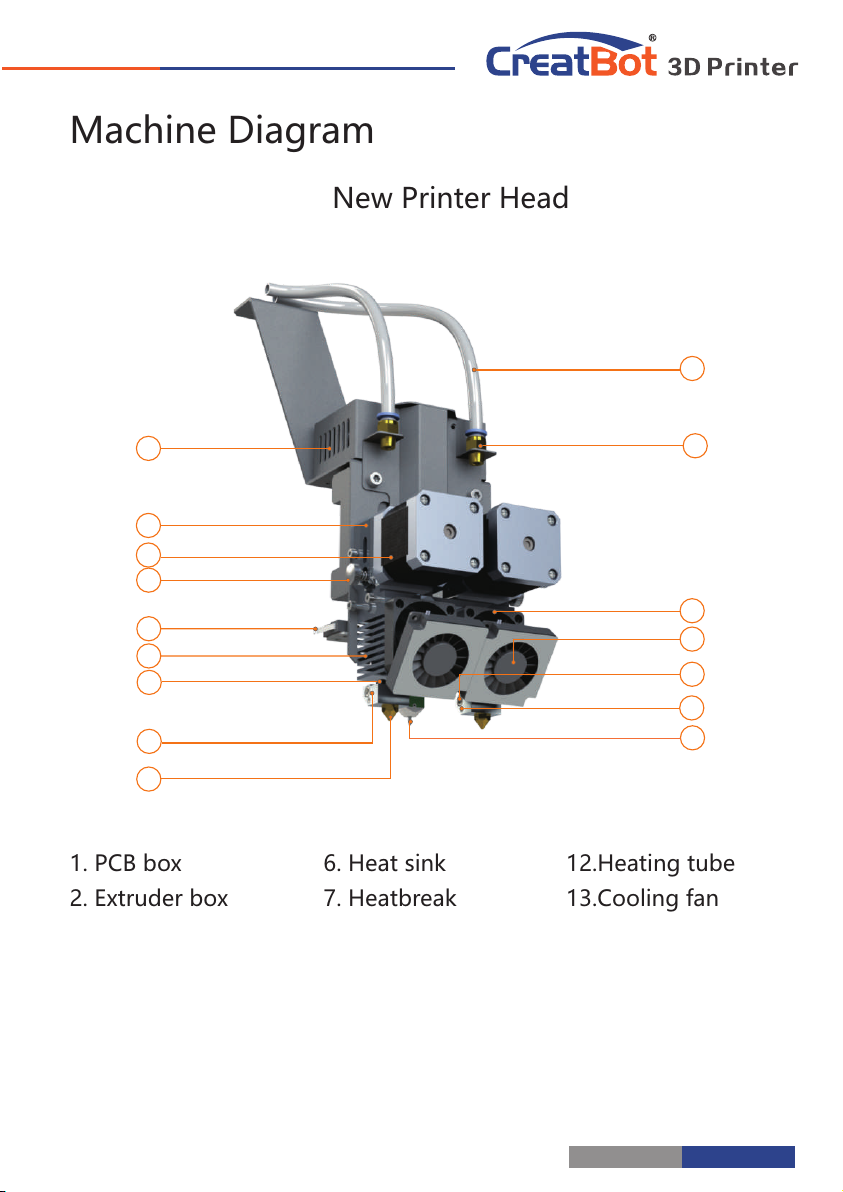

Machine Diagram

New Printer Head

- 5 -

1. PCB box

2. Extruder box

3. Extruder motor

4. Filament press

button

5. X limited switch

6. Heat sink

7. Heatbreak

8. Heat block

9. Nozzle

10.Bltouch

11.Thermistor

12.Heating tube

13.Cooling fan

14. Cooling fan

15.Connector

16.Feeding tube

1

6

4

8

9

15

16

12

2

5

11

3

7

13

14

10

1

5

8

Indicator light

Universal Wheel

U disk input

Power switch

7

6

4

3

2

USB input

Stop button

Switch lock

Touch screen

Machine Diagram

Front

- 4 -

Machine Diagram

New Printer Head

- 5 -

1. PCB box

2. Extruder box

3. Extruder motor

4. Filament press

button

5. X limited switch

6. Heat sink

7. Heatbreak

8. Heat block

9. Nozzle

10.Bltouch

11.Thermistor

12.Heating tube

13.Cooling fan

14. Cooling fan

15.Connector

16.Feeding tube

1

6

4

8

9

15

16

12

2

5

11

3

7

13

14

10

1

5

8

Indicator light

Universal Wheel

U disk input

Power switch

7

6

4

3

2

USB input

Stop button

Switch lock

Touch screen

Machine Diagram

F1000 Has three new features

- 6 -

Hot Chamber system can make inside

temperature up to 60 degree.

Filament dry room have 2 temperature

options to set. (45 degree /65 degree.)

Note: The PLA,PVA,HIP filaments are disable

the drying function of the consumables bin.

Auto leveling system

Auto-leveling working plate make leveling easily

Leveling Platform

Printer Operation

- 7 -

23 °C 23 °C 23 °C 23 °C

0°C 0°C 0°C 0°C

Machine Diagram

F1000 Has three new features

- 6 -

Hot Chamber system can make inside

temperature up to 60 degree.

Filament dry room have 2 temperature

options to set. (45 degree /65 degree.)

Note: The PLA,PVA,HIP filaments are disable

the drying function of the consumables bin.

Auto leveling system

Auto-leveling working plate make leveling easily

Leveling Platform

Printer Operation

- 7 -

23 °C 23 °C 23 °C 23 °C

0°C 0°C 0°C 0°C

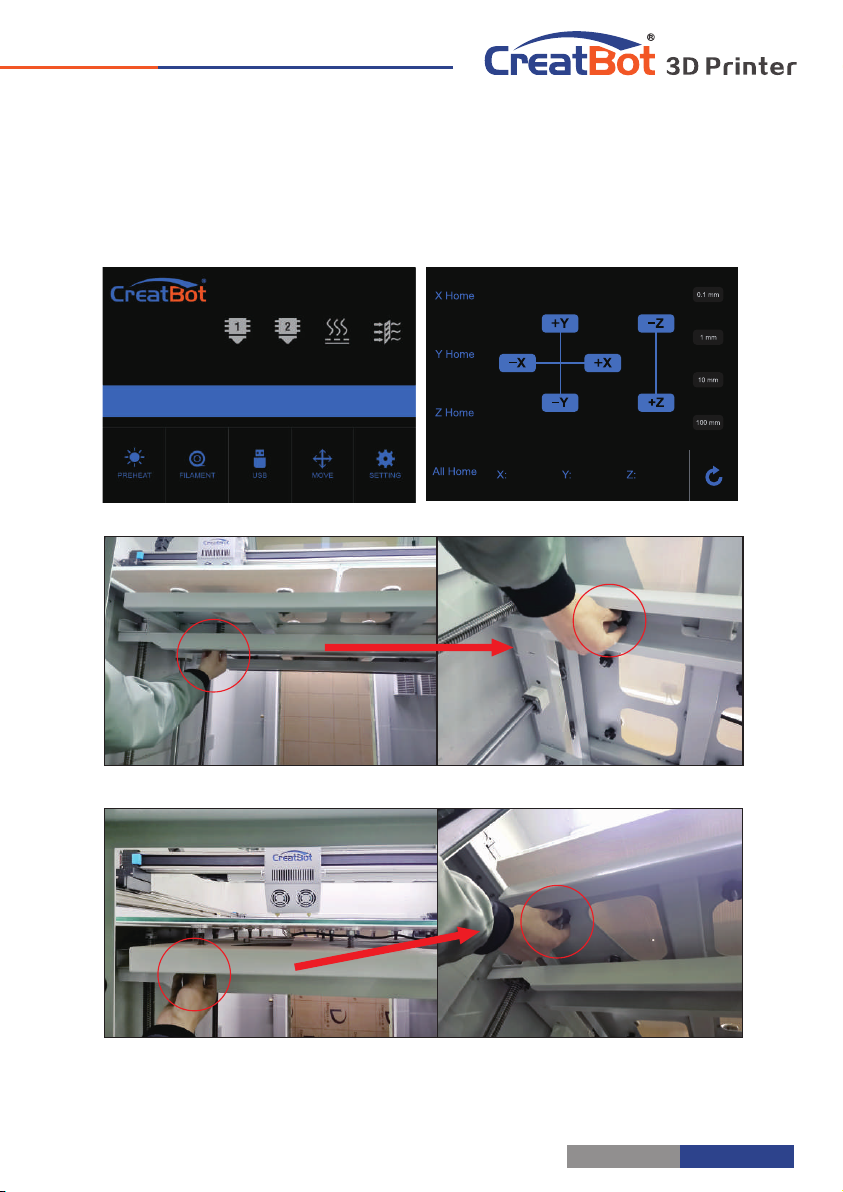

How to levelling the bed for the first time?

The entire platform consists of beams, brackets and four glass

platforms.

Ⅰ Leveling platform manually

1. Turn on the printer.

2. On touch screen, press “Move axis” -> “All home” to return the axis XYZ to zero.

3. Then press “-Z” until the “ Z ” value become 0 and the nozzle go near to the

platform.

4. Adjust the 4 nuts under the beam so that the bracket is in a horizontal

position parallel to the beam.

5. Move the extruder by hand to 4 corners and center of bed. During this

movement, tighten or loosen 4 black nuts below the bed to make sure the

distance between nozzle and bed is 0.05mm -0.1mm around. (Approximately the

thickness of one piece of paper)

6. Repeat above movement process several times and finally adjust the

platform so that each platform is positioned horizontally relative to the

X/Y plane. Leveling the 4 glass platform in return.

Ⅱ Auto leveling

1Go to "Settings "--" auto leveling "— " Probe on the screen. Wait for the Probe to complete.

2.Enter "setting" -- "Z home" on the screen, confirm the height of Z

platform is 0 on the status page, and Observe the distance between the

nozzle and the platform.

3.Z offset (Servo Z offset) is in the automatic leveling menu option. If

the nozzle is too far away from the platform, increase the Z offset value

(0.1mm each time); If the nozzle is too close to the platform or even

touches the platform, reduce the Z offset value (decrease by 0.1mm each

time).

4. Probe need to be redone once you increased or decreased the Z offset.

- 8 -

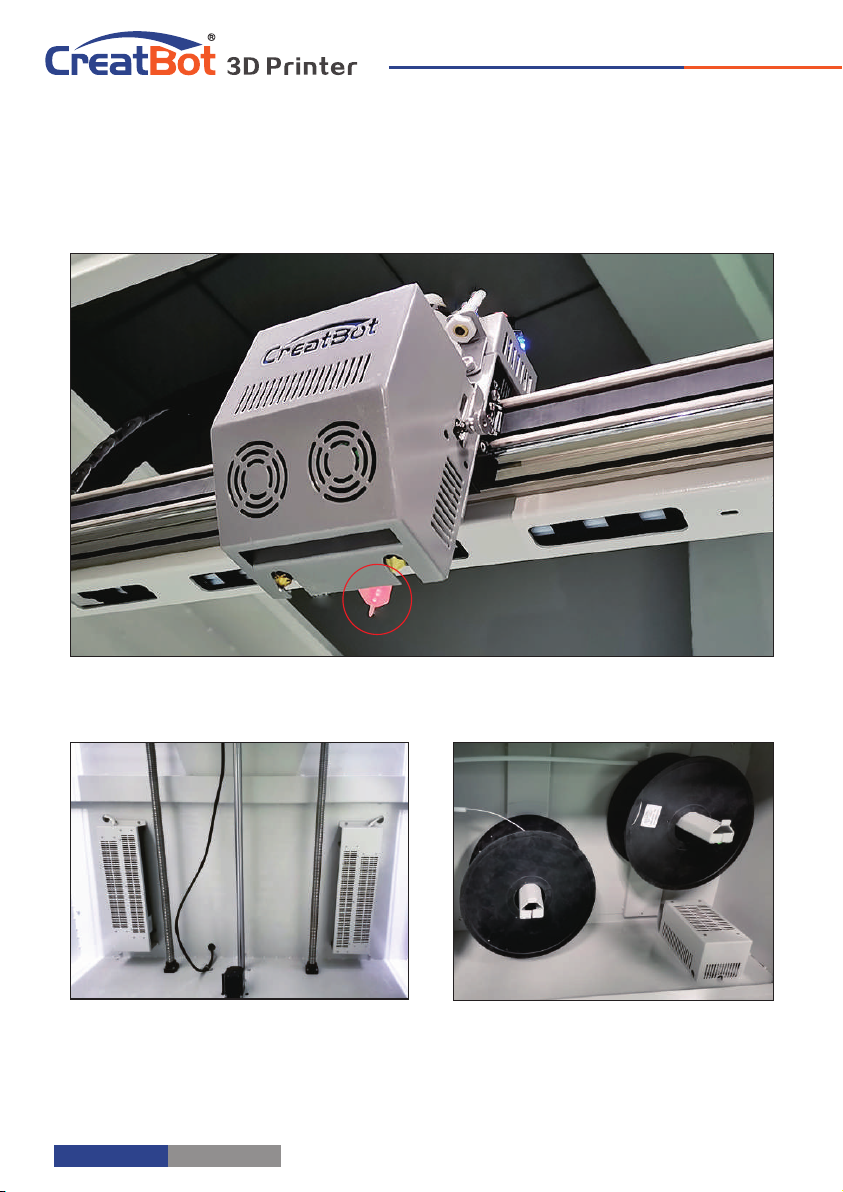

Printer Operation

Load Filament

Preheat head Straightened filament

1.Preheat the hotend before loading filament.

2.Straightened filament and check the filament do not self-winding.

3.load filament,and fix it on the filament shelf.

4.load the filament until filament beyond quick fitting. Insert

filament to extruder hole manually and through it until melted and flowing

naturally.(Or choose extrude filament on touch screen).

5.Tighten the compression nut, tightness appropriately. Do same like the photo in

red area. (Do not overtight, otherwise filament will be cut off. )

Notice: Pressed filament too tight or too loose will affect normal wire feeding.

Tighten the nut

Load filament

- 9 -

23 °C 23 °C 23 °C 23 °C

0°C 0°C 0 °C 0°C

- 9 -

How to levelling the bed for the first time?

The entire platform consists of beams, brackets and four glass

platforms.

Ⅰ Leveling platform manually

1. Turn on the printer.

2. On touch screen, press “Move axis” -> “All home” to return the axis XYZ to zero.

3. Then press “-Z” until the “ Z ” value become 0 and the nozzle go near to the

platform.

4. Adjust the 4 nuts under the beam so that the bracket is in a horizontal

position parallel to the beam.

5. Move the extruder by hand to 4 corners and center of bed. During this

movement, tighten or loosen 4 black nuts below the bed to make sure the

distance between nozzle and bed is 0.05mm -0.1mm around. (Approximately the

thickness of one piece of paper)

6. Repeat above movement process several times and finally adjust the

platform so that each platform is positioned horizontally relative to the

X/Y plane. Leveling the 4 glass platform in return.

Ⅱ Auto leveling

1Go to "Settings "--" auto leveling "— " Probe on the screen. Wait for the Probe to complete.

2.Enter "setting" -- "Z home" on the screen, confirm the height of Z

platform is 0 on the status page, and Observe the distance between the

nozzle and the platform.

3.Z offset (Servo Z offset) is in the automatic leveling menu option. If

the nozzle is too far away from the platform, increase the Z offset value

(0.1mm each time); If the nozzle is too close to the platform or even

touches the platform, reduce the Z offset value (decrease by 0.1mm each

time).

4. Probe need to be redone once you increased or decreased the Z offset.

- 8 -

Printer Operation

Load Filament

Preheat head Straightened filament

1.Preheat the hotend before loading filament.

2.Straightened filament and check the filament do not self-winding.

3.load filament,and fix it on the filament shelf.

4.load the filament until filament beyond quick fitting. Insert

filament to extruder hole manually and through it until melted and flowing

naturally.(Or choose extrude filament on touch screen).

5.Tighten the compression nut, tightness appropriately. Do same like the photo in

red area. (Do not overtight, otherwise filament will be cut off. )

Notice: Pressed filament too tight or too loose will affect normal wire feeding.

Tighten the nut

Load filament

- 9 -

23 °C 23 °C 23 °C 23 °C

0°C 0°C 0 °C 0°C

- 9 -

Unload/Change Filament

Printer Operation

23 °C 23 °C 23 °C 23 °C

0°C 0°C 0 °C 0°C

1. Enter "Filament" menu ->"Unload filament", and select the head you

want unload.

2. Wait for the nozzle heated to a suitable temperature.

3. After reching temperature, feeder will send a certain number of filament,

and then automatically withdraw filament.

4. To manually unload filament, same as above mentioned.

Unload filament menu Preheat head

Pull out filament

Unloading filament

- 10 -

0

225

300

150

75

Unload

Extrude

Retract

Head 1

Unloading filament...

- 11 -

Touchscreen

Printer Operation

Main Menu

Preheat PLA Move axis Filament menu

Resume Setting Open U-disk

Cool down

USB unavailable

Z up Pause Stop Z down

23 °C 23 °C 23 °C 23 °C

0°C 0°C 0 °C 0°C

Unload/Change Filament

Printer Operation

23 °C 23 °C 23 °C 23 °C

0°C 0°C 0 °C 0°C

1. Enter "Filament" menu ->"Unload filament", and select the head you

want unload.

2. Wait for the nozzle heated to a suitable temperature.

3. After reching temperature, feeder will send a certain number of filament,

and then automatically withdraw filament.

4. To manually unload filament, same as above mentioned.

Unload filament menu Preheat head

Pull out filament

Unloading filament

- 10 -

0

225

300

150

75

Unload

Extrude

Retract

Head 1

Unloading filament...

- 11 -

Touchscreen

Printer Operation

Main Menu

Preheat PLA Move axis Filament menu

Resume Setting Open U-disk

Cool down

USB unavailable

Z up Pause Stop Z down

23 °C 23 °C 23 °C 23 °C

0°C 0°C 0 °C 0°C

210℃

200.0℃

Status Page

45℃

40.0℃

Touch and set up the temp of the nozzle.

Preset nozzle temperature

Current nozzle temperature

45℃

40.0℃

Touch and set up the temp of the nozzle.

Preset nozzle temperature

210℃

200.0℃

Touch and set up the temp of the

45℃

40℃

Touch and set up the temp of the nozzle.

210℃

210℃

- 12 -

Printer Operation

210℃

200.0℃

45℃

40.0℃

Touch and set up the temp of the

45℃

40.0℃

Touch and set up the temp of the hotbed.

Current platform temperature

Preset platform temperature

210℃

200.0℃

Touch and set up the temp of the hot wind.

Preset hot air temperature

Current hot air temperature

45℃

40℃

Touch and set up the temp of the

210℃

200℃

Current nozzle temperature

- 13 -

Current printing progress

60.00% 00:00 Z:0.00

Detail page

Printer Operation

Change Pause Stop

210℃

200.0℃

Status Page

45℃

40.0℃

Touch and set up the temp of the nozzle.

Preset nozzle temperature

Current nozzle temperature

45℃

40.0℃

Touch and set up the temp of the nozzle.

Preset nozzle temperature

210℃

200.0℃

Touch and set up the temp of the

45℃

40℃

Touch and set up the temp of the nozzle.

210℃

210℃

- 12 -

Printer Operation

210℃

200.0℃

45℃

40.0℃

Touch and set up the temp of the

45℃

40.0℃

Touch and set up the temp of the hotbed.

Current platform temperature

Preset platform temperature

210℃

200.0℃

Touch and set up the temp of the hot wind.

Preset hot air temperature

Current hot air temperature

45℃

40℃

Touch and set up the temp of the

210℃

200℃

Current nozzle temperature

- 13 -

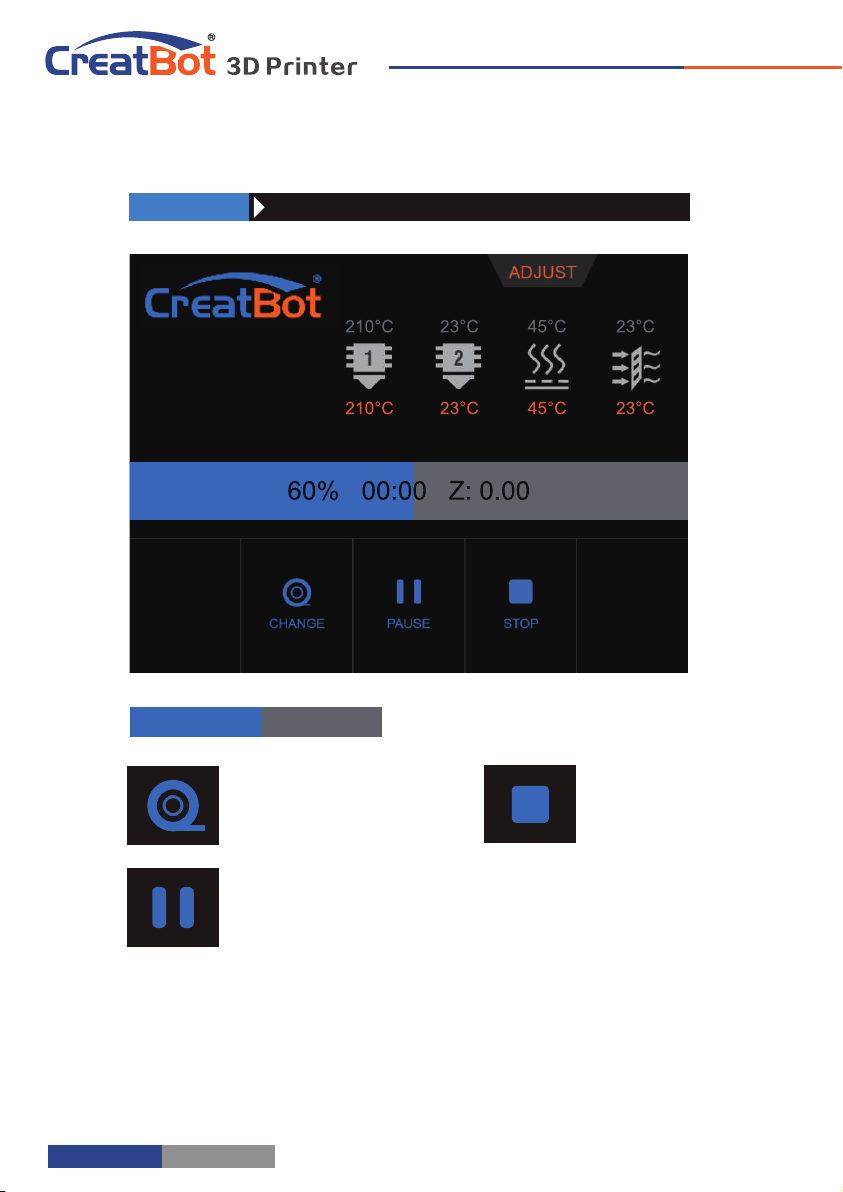

Current printing progress

60.00% 00:00 Z:0.00

Detail page

Printer Operation

Change Pause Stop

Click and

enter a value Head 1

#1 extruder

Head 2

#2 extruder

(unavailable)

Back

Extrude

filament

Retract

filament

Filament menu

Adjust value

when

extrude/retract

filament Retract filament

Unload

- 14 -

Printer Operation

Pause and Change

filament.

Pause print

Current printing progress

60.00% 00:00 Z:0.00

Cancel print

Printing page

- 15 -

Printer Operation

Click and

enter a value Head 1

#1 extruder

Head 2

#2 extruder

(unavailable)

Back

Extrude

filament

Retract

filament

Filament menu

Adjust value

when

extrude/retract

filament Retract filament

Unload

- 14 -

Printer Operation

Pause and Change

filament.

Pause print

Current printing progress

60.00% 00:00 Z:0.00

Cancel print

Printing page

- 15 -

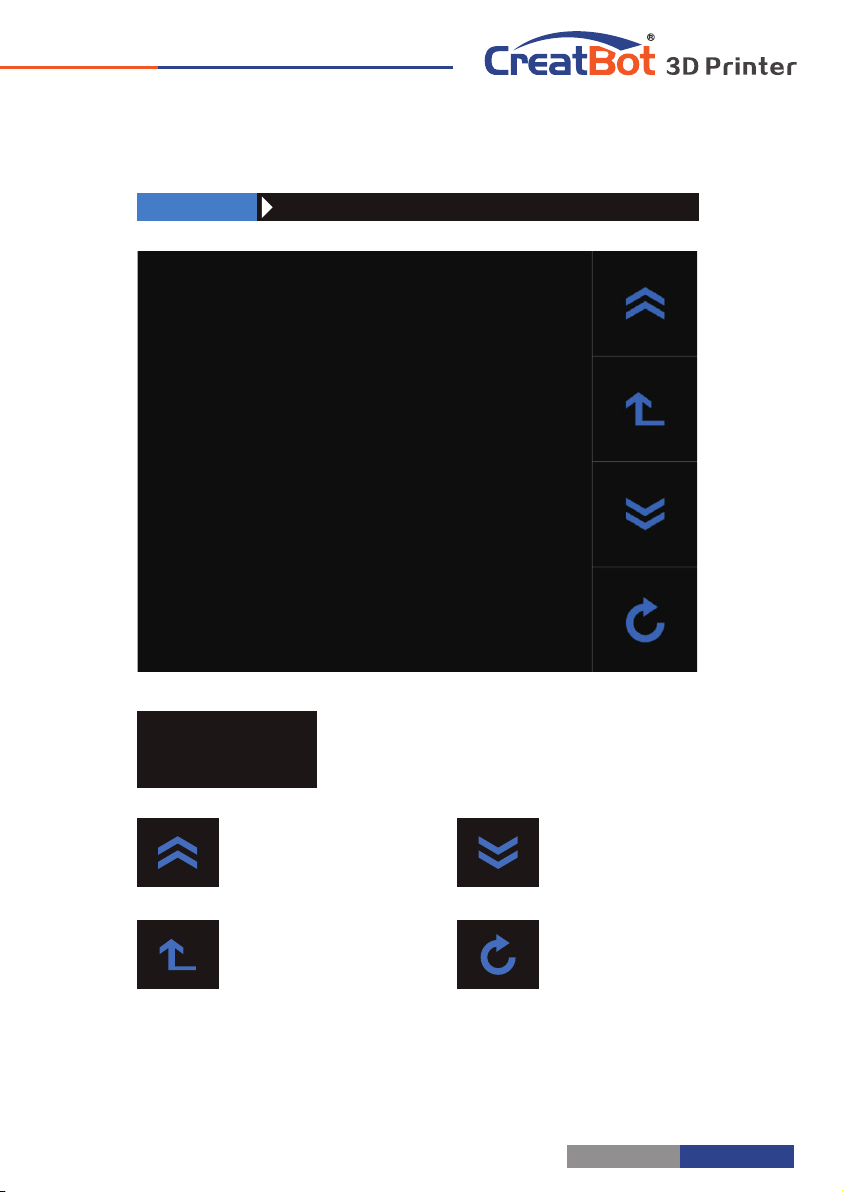

Printer Operation

- 16 -

Click and choose a

file to print

Last page

Superior menu

Next page

Back

file1.gcode

file2.gcode

SD Card/U-disk

Printer Operation

file1.gcode

file2.gcode

- 17 -

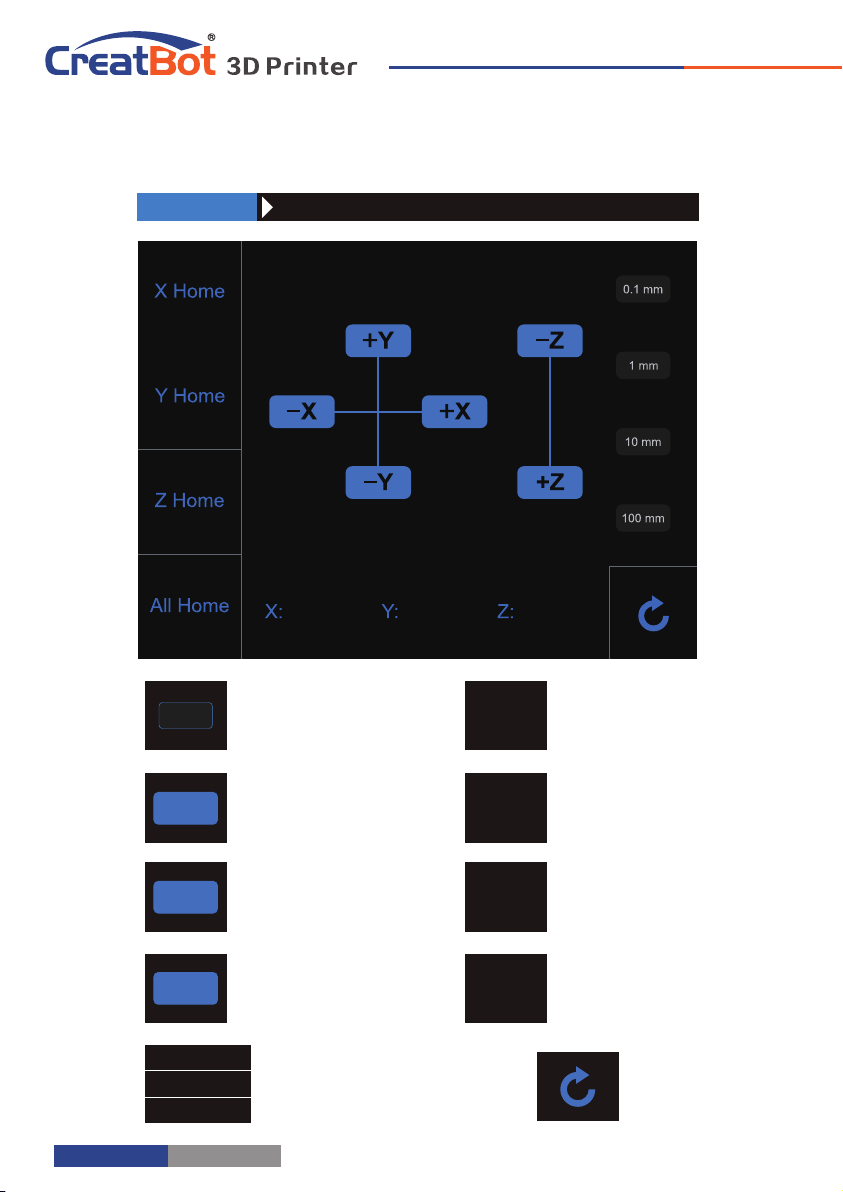

Move X to home

Move Y to home

Move Z to home

All axis to home

1mm X Home

Y Home

Z Home

All Home

±X/Y

- Z

+ Z

Back

Minimum units

Move X/Y axis

Z up

Z down

Axis operation

X:

Y:

Z:

00.00

00.00

00.00

X,Y,Z current

position of

hotend.

Printer Operation

- 16 -

Click and choose a

file to print

Last page

Superior menu

Next page

Back

file1.gcode

file2.gcode

SD Card/U-disk

Printer Operation

file1.gcode

file2.gcode

- 17 -

Move X to home

Move Y to home

Move Z to home

All axis to home

1mm X Home

Y Home

Z Home

All Home

±X/Y

- Z

+ Z

Back

Minimum units

Move X/Y axis

Z up

Z down

Axis operation

X:

Y:

Z:

00.00

00.00

00.00

X,Y,Z current

position of

hotend.

Printer Operation

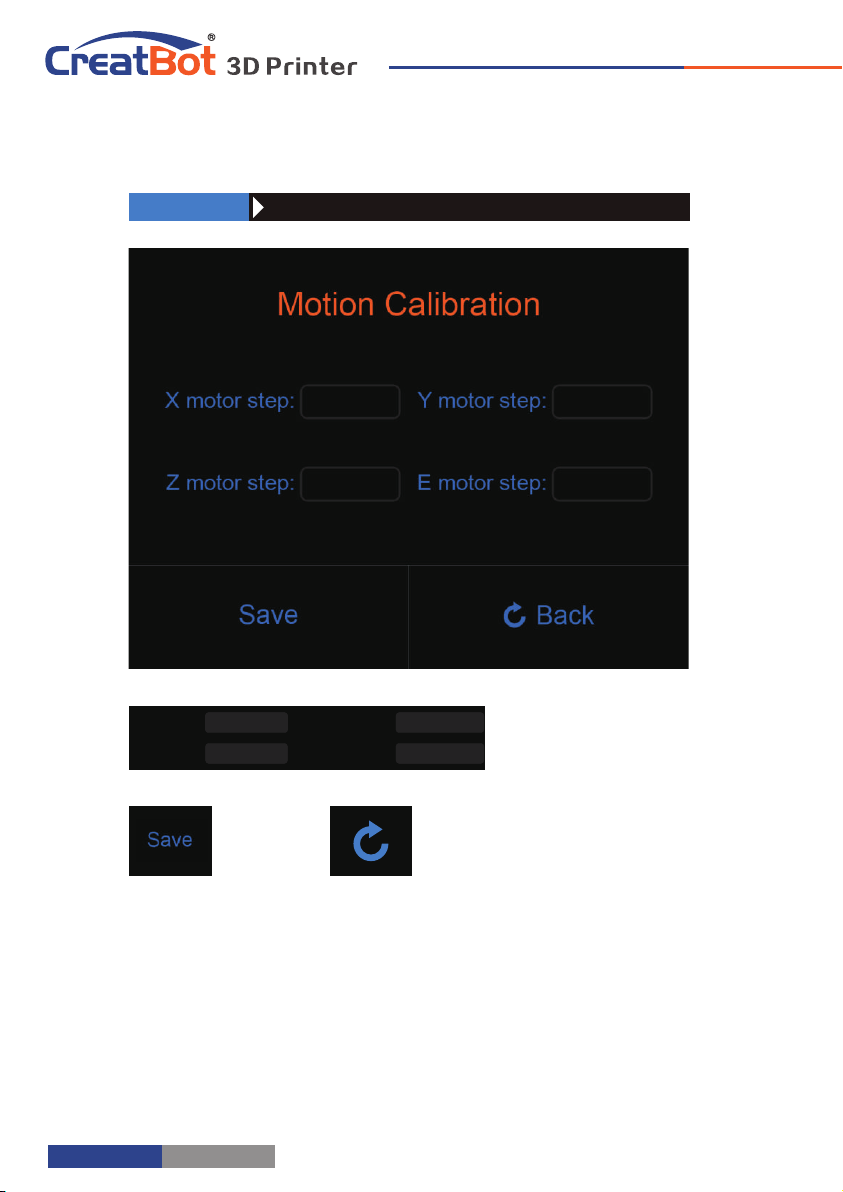

X/Y/Z and exturder motor

setting (range:5-9999)

Save Back

Setting menu

X step:

Y step:

Z step:

E step:

106.6667

1600.0000

106.6667

128.0000

- 18 -

Printer Operation

106.6667

1600.0000

106.6667

128.0000

- 19 -

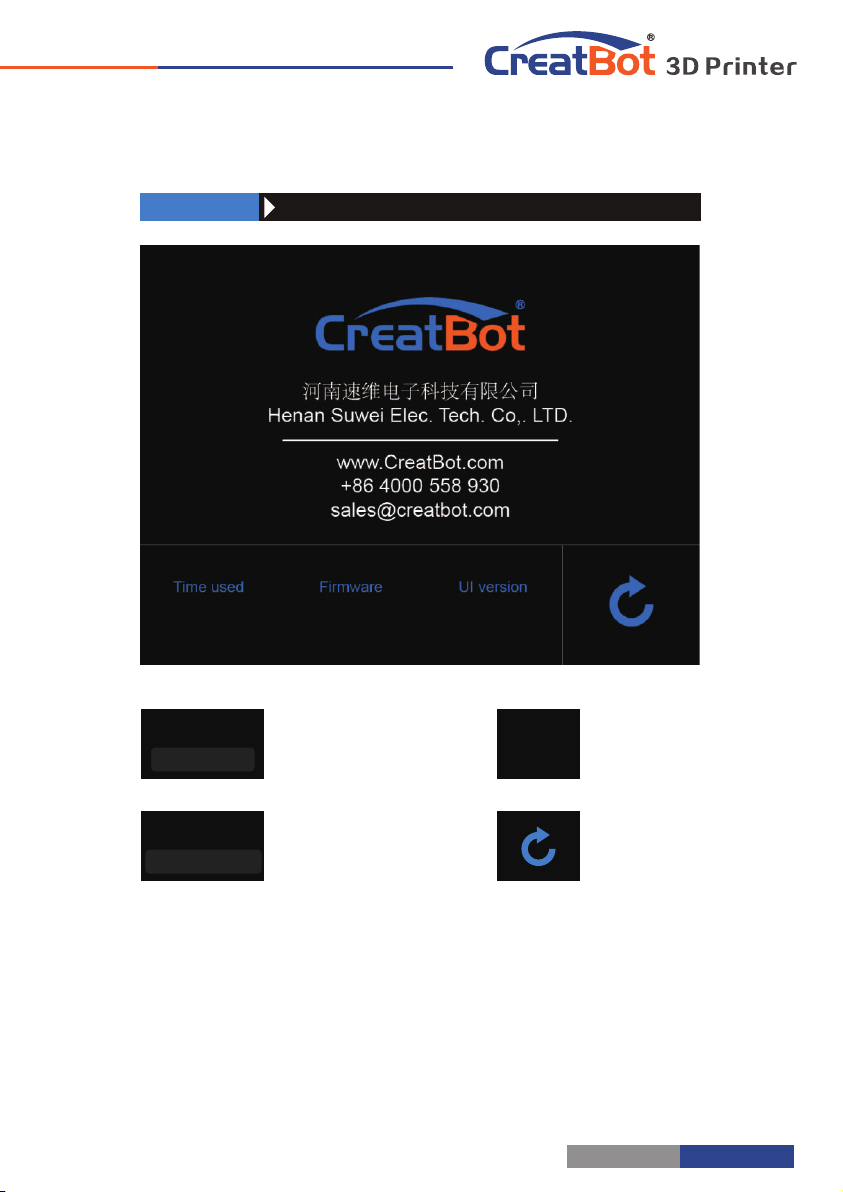

Info. page

Print time used

Firmware version Back

Screen version

V5.0.0

Time used

0000:00:00

Firmware

V6.0.XXXXXX

Printer Operation

0000:00:00 V6.0.XXXXXX V5.0.0

X/Y/Z and exturder motor

setting (range:5-9999)

Save Back

Setting menu

X step:

Y step:

Z step:

E step:

106.6667

1600.0000

106.6667

128.0000

- 18 -

Printer Operation

106.6667

1600.0000

106.6667

128.0000

- 19 -

Info. page

Print time used

Firmware version Back

Screen version

V5.0.0

Time used

0000:00:00

Firmware

V6.0.XXXXXX

Printer Operation

0000:00:00 V6.0.XXXXXX V5.0.0

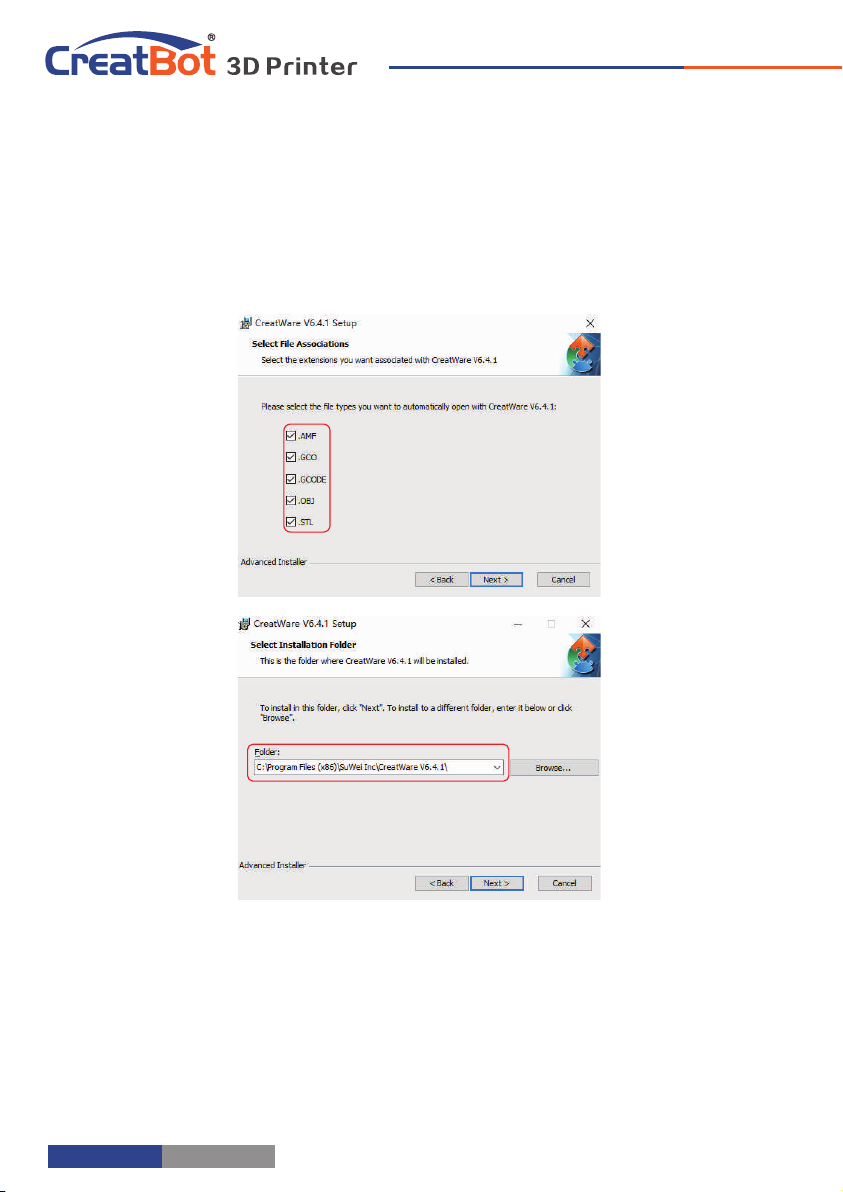

Software Operation

CreatWare Setup

Download CreatWare installation package from the CD-ROM or

www.CreatBot.com, follow the prompts to install the software, try

using the default installation path as well.

Please associated common 3D file format.

Installation path can not contain non-Latinn characters.

Please associated common 3D file format.

When there is a driver digital signature, please choose to agree. When

finished the driver folder will locate at installation directory.

The software will select the correct language according to your OS,

please select the right machine type and number of nozzles and ignore the

other option and guide.

- 20 - - 21 -

Quick Print UI

Software Operation

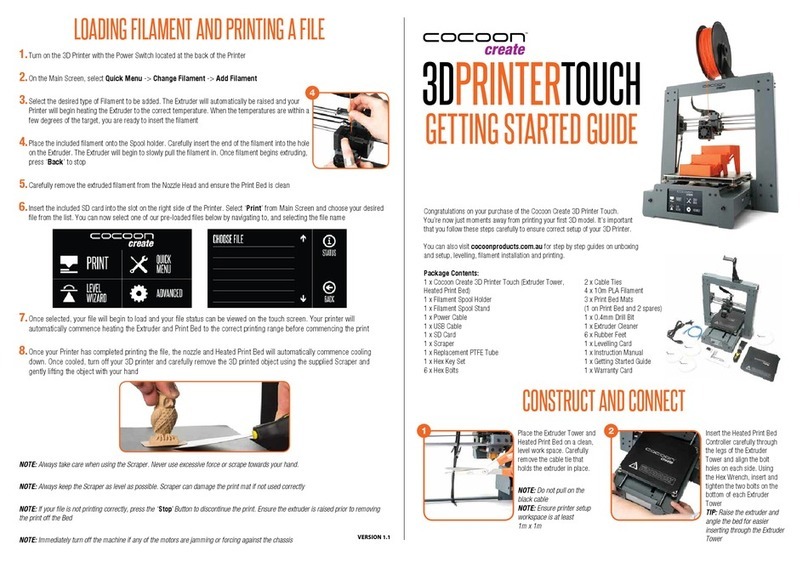

Insert U-disk to the card reader, open the CreatWare, load 3D

model file , choose correct filament and option , finally click [1] [2]

save button , you can now finish slice model.[3]

Insert U-disk to the printer, browse and select the Gcode file

you just saved, the printer will automatically start to heating, when

the temperature reaches, the printing will start.

When insert U-disk, the toolpath will saved to

the U-disk.

The file name can not contain non-Latinn

characters.

Print Your First Model

Load model Save toolpath

31

2

Normal

Overhang

Transparent

X-Ray

Layers

This manual suits for next models

8

Table of contents

Other CreatBot 3D Printer manuals