ADITIVA 3D ARTILLERY SIDEWINDER X1 BELT User manual

Sidewinder X1 Belt Kit assembly manual P a g e 2 | 30

www.belt3dprinterkit.com

Content

Chapter 1 Intro 3

Step 1.1 What is included in this kit? 3

Step 1.2 Needed tools 3

Chapter 2 Disassembling ARTILLERY SIDEWINDER X1 3

Step 2.1 Remove spool holder 3

Step 2.2 Disconnecting ribbon wires 4

Step 2.3 Removing original Z axis system 4

Step 2.4 Removing original Top frame 5

Step 2.5 Y axis and heatbed assembly 7

Chapter 3 Preparing frame 7

Step 3.1 Building Main Frame 7

Step 3.2 Preparing extruder assembly 9

Step 3.3 Preparing X axis 11

Chapter 4 Installing movement mechanisms 13

Step 4.1 Top Corner Pulleys 13

Step 4.2 Installing diagonal movement Shaft and motor 14

Chapter 5 Installing Belt and Heatbed system 18

Step 5.1 Preparing rollers 18

Step 5.2 Installing Rollers and Belt 19

Step 5.3 Installing Heatbed 23

Chapter 6 Finishing installation 25

Step 6.1 Filament holder 25

Chapter 7 Electronics and firmware 26

Step 7.1 Electronics 26

Step 7.2 Firmware 26

Chapter 8 Calibrating bed and 45° axis endstop 26

Step 8.1 Calibration 26

Chapter 9 Slicer settings 27

Sidewinder X1 Belt Kit assembly manual P a g e 3 | 30

www.belt3dprinterkit.com

Chapter 1 Intro

Step 1.1 What is included in this kit?

In this kit you will find all the necessary parts for converting your regular Artillery Sidewinder x1

3d printer model into a Belt 3d printer (CR30 style), but some additional 3d printed parts might

be necessary as well (STL files will be provided). Parts lists are indicated on each step for better

understanding and guidance.

Step 1.2 Needed tools

In order to fully install this kit, you will need the next tools:

Set of Allen keys

Adjustable wrench or wrench kit

Measuring tape

Vernier caliper

Metal ruler (for alignment)

Chapter 2 Disassembling ARTILLERY SIDEWINDER X1

In order to get ready to install this kit, you have to disassembly various segments of the original

3d printer, this part will guide you through entire process of preparation and getting ready to

install new parts.

In this part of the process, various electrical components will be temporarily disconnected for

practical purposes, you have to install them later though.

*Please be aware some original parts will be discarded and won’t be installed.

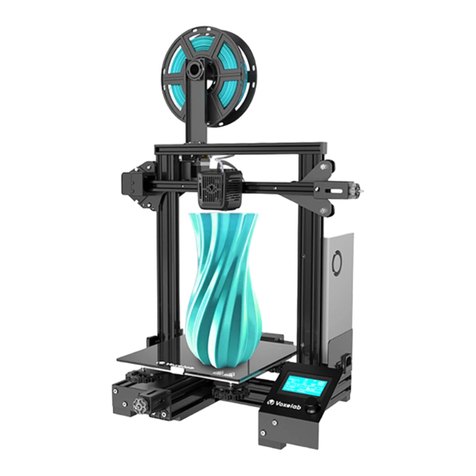

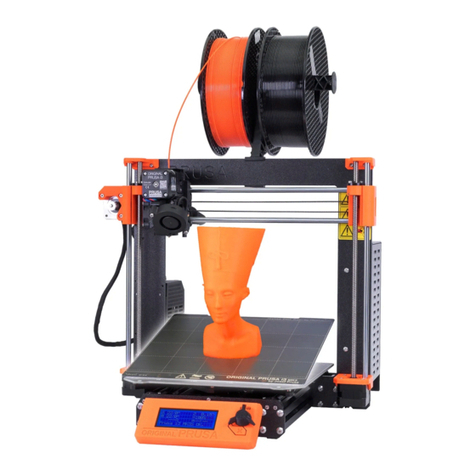

Figure 1. Assembled Sidewinder X1

Step 2.1 Remove spool holder

Remove spool holder using allen key, spool holder is reused later, save it along with its

m4 screws and t-slot nuts.

Sidewinder X1 Belt Kit assembly manual P a g e 4 | 30

www.belt3dprinterkit.com

Figure 2 Removing spool holder

Step 2.2 Disconnecting ribbon wires

Disconnect Z axis ribbon wire, from the base and the gantry, save it for later use.

Figure 3 disconnecting Z ribbon wire

Disconnect X axis ribbon wire from hotend carriage

Step 2.3 Removing original Z axis system

Disconnect Z motors cables.

Using an allen key remove Z motor bracket (m3 screws), leadscrew and Z nut (2 x m3

screws).

Sidewinder X1 Belt Kit assembly manual P a g e 5 | 30

www.belt3dprinterkit.com

Also remove Z endstop, remove Z endstop cable as well.

Figure 4 Removing Z axis moving system

Items to discard: Z couplers, Z motor brackets, Z endstos, leadscrews, brass nuts.

Items to save for later use: Z motors, Z endstop (including its 2 x m3 screws)

Step 2.4 Removing original Top frame

Using an Allen key, remove 4 M5 screws from the bottom of both Z columns.

Z columns and X axis assembly will be reused.

Sidewinder X1 Belt Kit assembly manual P a g e 7 | 30

www.belt3dprinterkit.com

Step 2.5 Y axis and heatbed assembly

Using an Allen key, remove bottom cover, and rubber feets.

Using an Allen key, remove 2 x m5 screws that holds Y axis system with heatbed

assembly.

Save Y axis and heatbed assembly for later use, discard 2 x m5 screws.

Figure 7 Removing bottom cover

Figure 8 Removing Y axis

Chapter 3 Preparing frame

Step 3.1 Building Main Frame

Next items from the KIT will be used:

ITEM

ITEM DESCRIPTION

Quantity

Type

1

2040 V-Slot 590 mm

2

Original Z columns

2

2040 V-Slot 778 mm

2

Kit

3

2040 V-Slot 550 mm

2

Kit

4

2040 V-Slot 471 mm

1

Kit

5

2020 V-Slot 511 mm

3

Kit

6

P1 CORNER FRONT BRACKET L

1

Kit

7

P1 CORNER FRONT BRACKET R

1

Kit

8

P2 CORNER BACK LEFT

1

Kit

9

P3 CORNER BACK RIGHT

1

Kit

Sidewinder X1 Belt Kit assembly manual P a g e 8 | 30

www.belt3dprinterkit.com

10

P4 CORNER TOP

2

Kit

11

M4 x 18 mm Screw

6

Kit

12

M4 x 8 mm Screw

16

Kit

13

M4 Slot nut

22

Kit

14

M5 x 8 mm Screw

10

Kit

15

M5 Slot nut

10

Kit

Assemble the aluminum bars arranging them as shown in the next picture (Figure 9):

Figure 10 Extrusions frame assembly

Use the plates as shown next:

3

4

3

5

1

1

2

2

Sidewinder X1 Belt Kit assembly manual P a g e 9 | 30

www.belt3dprinterkit.com

Figure 11 Plates distribution, and screw usage on each

Step 3.2 Preparing extruder assembly

ITEM

ITEM DESCRIPTION

Quantity

Type

1

P8 head plate

1

Kit

2

Fan Duct 3d printed part

1

Kit

3

EXTRUDER BOARD SUPPORT

3d printed part

1

Kit

4

VOLCANO SHARP NOZZLE

0.4MM OR 0.6MM

1

Kit

First, disassemble original extruder

Using P8 head plate, reassemble extruder and hotend parts as shown in the next

pictures:

10

6

8

9

7

M5x8 Screws

5 units each

M4x8 Screws

8 units each

Sidewinder X1 Belt Kit assembly manual P a g e 11 | 30

www.belt3dprinterkit.com

Figure 15 Hotend PCB board mounting detail

Figure 16 Modified head mounted

Step 3.3 Preparing X axis

ITEM

ITEM DESCRIPTION

Quantity

Type

1

P5 side X axis

2

Kit

2

M5x30 Screws

6

Original

4

M5 nylock nuts

6

Original

5

M5 SPACER

4

Original

6

ECCENTRIC SPACER

2

Original

7

M5X8 SCREWS

6

Kit

8

Y AXIS BELT PLATE

2

Kit

9

M4x8 Screws

4

Kit

10

M4 Slot nut

4

Kit

Sidewinder X1 Belt Kit assembly manual P a g e 12 | 30

www.belt3dprinterkit.com

Take X axis assembly from original top frame and get it ready for modifications.

Using P5 side X axis, M5x30.

Figure 17 Left Y carriage assembly, holes to be on the back side

Figure 18 Right Y carriage assembly, holes to be on the back side

M5x30

ECCENTRIC SPACER

M5 nylock nut

M5x30

M5 SPACER

M5 nylock nut

Sidewinder X1 Belt Kit assembly manual P a g e 13 | 30

www.belt3dprinterkit.com

Figure 19 Mounting new carriages on both sides using M5x8 screws

Figure 20 Y axis belt plate, left side

Figure 21 Y axis belt plate, right side

Chapter 4 Installing movement mechanisms

Step 4.1 Top Corner Pulleys

Next items from the KIT will be used:

ITEM

ITEM DESCRIPTION

Quantity

Type

1

Top Corner bracket

2

Kit

2

Pulley 20T, Bore 5mm GT2

2

Kit

Sidewinder X1 Belt Kit assembly manual P a g e 14 | 30

www.belt3dprinterkit.com

3

M5x20mm Screw

2

Kit

4

M5X8X1 PRECISION SHIM WASHER

2

Kit

5

M5 Nylock Nut

2

Kit

6

M5x8 SCREW

4

Kit

7

M5 T-NUT

4

Kit

Top Corner Pulleys brackets location, install both sides using M5x8 Screws and M5 T-

nuts:

Pulley installation detail, Top Corner Plate has M5 threaded hole, insert M5x20 Screw

(with Pulley and washer) but do not adjust it, keep it a little bit loose, enough to keep

rotation free, then secure from the other side with the M5 Nylock Nut, tune

adjustment until the assembly is very tight but still free rotation:

Figure 22 Pulley mounting detail

Repeat process for the right side.

Step 4.2 Installing diagonal movement Shaft and motor

Next items from the KIT will be used:

ITEM

ITEM DESCRIPTION

Quantity

Type

1

8mm ROD 530mm

1

Kit

2

Timing Pulley 60T, Bore 8mm GT2

1

Kit

3

Pulley 20T, Bore 8mm GT2

2

Kit

4

8X16X5 Flange Ball Bearing

2

Kit

Sidewinder X1 Belt Kit assembly manual P a g e 15 | 30

www.belt3dprinterkit.com

5

M5x8 Screw

4

Kit

6

GT2 Timing belt Closed Loop

1

Kit

7

Pulley 20T, Bore 5mm GT2

1

Kit

9

M4x8 Screw

2

Kit

10

M4 Slot Nut

2

Kit

11

Z Axis Original Motor

1

Original part

12

M3x6 Screw

2

Original part

13

GT2 6mm BELT

2 METERS

Kit

14

RED Nylon ZIP TIE

8

Kit

15

TOP Z leadscrews SUPPORTS

2

Original part

Slide next components into 8mm ROD 350 mm, keep same direction of each

component as shown in the next picture, DO NOT ADJUST THEM YET:

Shaft will be installed in the rear part of the printer:

Insert 8mm ROD 530mm with previous mounted items into both sides holes.

Secure both sides of shaft using 8X16X5 Flange Ball Bearing and M5x8mm Screws,

adjust screws on both sides:

530 mm

TOP Z leadscrews SUPPORTS

Sidewinder X1 Belt Kit assembly manual P a g e 16 | 30

www.belt3dprinterkit.com

Center 8mm ROD 530mm on both sides, push Pulleys against flange bearings then

adjust Headless Screws of both pulleys

Install motor and pulley, adjust tensioning on closed loop belt:

Install diagonal GT2 BELTS, tension both sides and using a measure tape check for “X

axis” alignment on both sides, taking bottom side of diagonal bars, belts must be

secured with provided Zip ties, cut excess of belts:

Sidewinder X1 Belt Kit assembly manual P a g e 18 | 30

www.belt3dprinterkit.com

Figure 23 Secure belts with Nylon Zip ties, 4 on each side

Chapter 5 Installing Belt and Heatbed system

Figure 24 Belt system Assembly

Step 5.1 Preparing rollers

Next items from the KIT will be used:

ITEM

ITEM DESCRIPTION

Quantity

Type

1

Roller BODY 40 mm

2

Kit

Sidewinder X1 Belt Kit assembly manual P a g e 19 | 30

www.belt3dprinterkit.com

2

12 mm ROD

2

Kit

3

Roller Cap 46mm

4

Kit

4

M4x8mm Black Headless screw

8

Kit

Using all the mentioned parts, proceed to assemble them in the next order, first place

12mm ROD inside Rolle BODY 40mm, then insert Roller CAP 46mm on each end,

making sure it all fits very tight, keep in mind that 12mm ROD have to be centered

with the roller body. Finally using an allen key, proceed to secure both ROLLE CAP

46mm with the M4x8mm BLACK HEADLESS SCREWS (02 on each side):

*Note: You have to repeat this process in order to get 2 rollers assembly.

Figure 25 Roller assembly components

Figure 26 Rod is centered with roller body

Step 5.2 Installing Rollers and Belt

Next items from the KIT will be used:

ITEM

ITEM DESCRIPTION

Quantity

Type

1

Roller Assembly

2

Kit

2

FLANGE BEARING 12mm

2

Kit

3

BLOCK BEARING 12mm

2

Kit

4

M6x18mm SCREW

4

Kit

5

M6x30mm SCREW

4

Kit

6

M6 NYLOCK NUT

8

Kit

7

BELT

1

Kit

8

Timing Pulley 60T, Bore 12mm GT2

1

Kit

9

GT2 Timing belt Closed Loop

1

Kit

10

Y ORIGINAL MOTOR with its PULLEY

1

ORIGINAL PART

11

Y MOTOR BRACKET

1

ORIGINAL PART

x mm

x mm

Sidewinder X1 Belt Kit assembly manual P a g e 20 | 30

www.belt3dprinterkit.com

12

M3X6 SCREW

2

ORIGINAL PART

13

M4X8 SCREW

2

Kit

14

M4 SLOT NUT

2

Kit

Insert Flange Bearing 12mm on both sides of one of the Roller:

Insert Block Bearing 12mm on both sides of the other Roller:

REAR ROLLER MOUNT: Take the ROLLER with FLANGE BEARINGS on it, install it with

M6x18 SCREWS and M6 NYLOCK NUTS, please be aware in this step belt have to be

inserted as shown in the next picture. Secure both FLANGE BEARINGS by adjusting its

screws to hold it in place.

ROLLER HAS TO BE CENTERED!

At this point, no alignment is required, since it is mounted into round exact holes on

the side plates:

Table of contents

Other ADITIVA 3D 3D Printer manuals