ADRIAN STEEL COMPANY WWW.ADRIANSTEEL.COM 906 JAMES STREET ADRIAN, MI 49221 800-677-2726

Publication Number: 40296 Revision Level: CECN Release: 14949

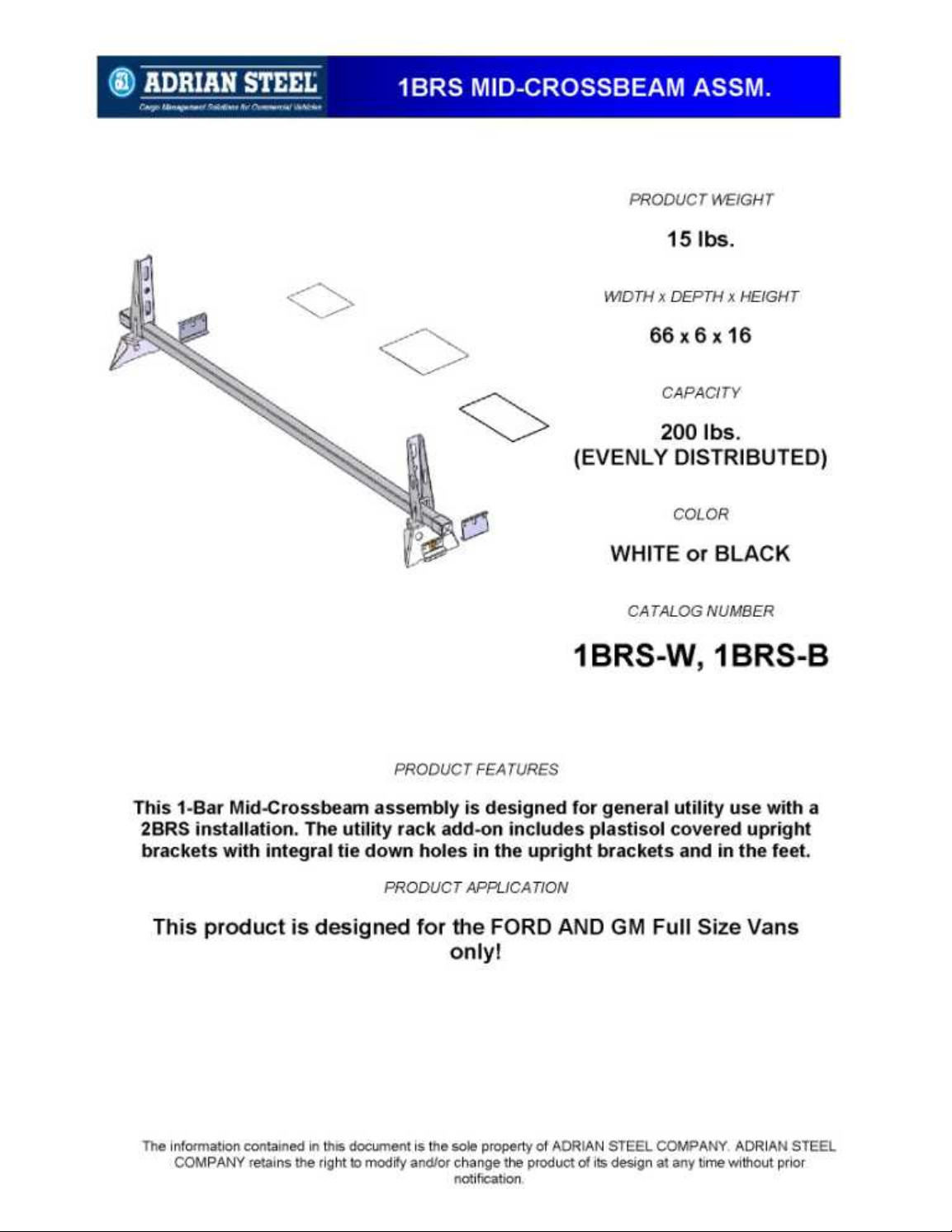

Assembly/Installation Instructions and Owners Manual

PAGE 3

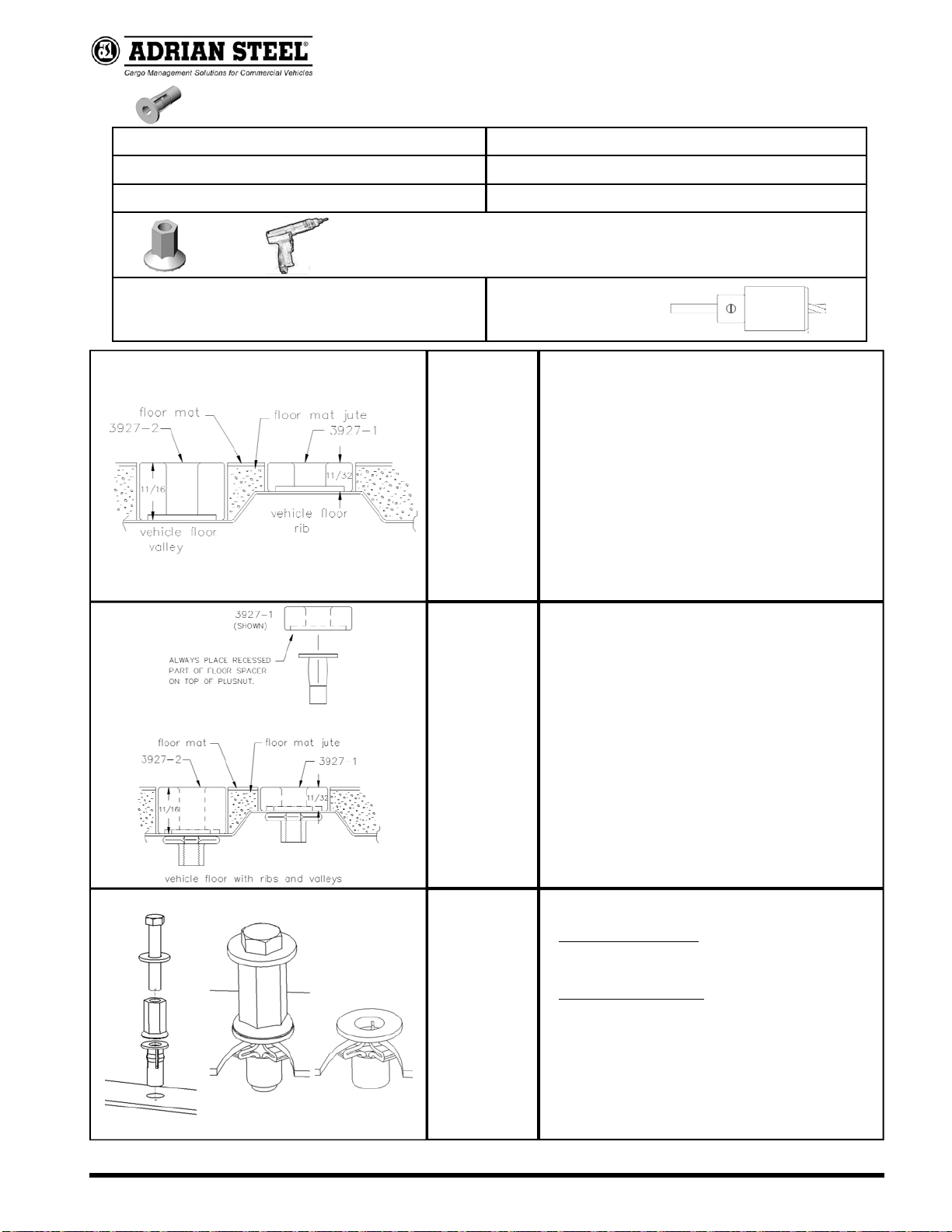

Step

01

Optional

If your vehicle contains carpet or a rubber floor

mat you will need to prepare the mounting loca-

tions. (if not, skip to STEP 02)

Position the product to be installed into the vehi-

cle and once your are satisfied with the mount-

ing locations, mark the mounting locations. Us-

ing a 1-3/16” diameter carpet cutter. Select the

appropriate floor spacers as shown in the illus-

tration to the left. Set those aaside for use later

into the installation process.

Once you have prepared the carpet/floor mat for

Step

02

Prepare

Mounting

Locations

Using a drill and drill bit (see table at top of page

for correct size) drill the mounting holes in the

vehicle sheet metal to prepare for installing the

plusnuts.

If you are thru-bolting at any of the locations

simply drill a hole that is 1/16” larger than the

bolt size(s) for those locations.

Once you have drilled the holes into the vehicle,

the raw metal edges should be sealed using a

self-etching primer to resist corrosion and po-

tential fastener point failure.

Step

03

Setting

Plusnuts

Use a Air Powered Plusnut Setting Gun to “set the plusnut” or if in-

stalling manually with hand tools, assembly the following.

1/4-20UNC Plusnut (FAS0052)

FAS0080 SCREW, HXHD, 1/4-20UNCx2.00, G8

FAS0067 WASHER, FLAT, 1/4”ID

22200-0 PLUSNUT TOOL

5/16-18UNC Plusnut (FAS0091)

FAS0095 SCREW, HXHD, 5/16-18UNCx2.00”, G8

FAS0086 WASHER, FLAT, 5/16”ID

22200-0 PLUSNUT TOOL

Place barrel of the plusnut body in sheet metal thru hole until flange is

flush with sheet metal.

Using a 9/16” combination wrench of plusnut tool body and a second

hand wrench, ratchet, or air tool, rotate the hex bolt head CW to draw

plus nut flanges up (set the plusnut).

Remove hex bolt, washer, and plusnut. Inspect installation.

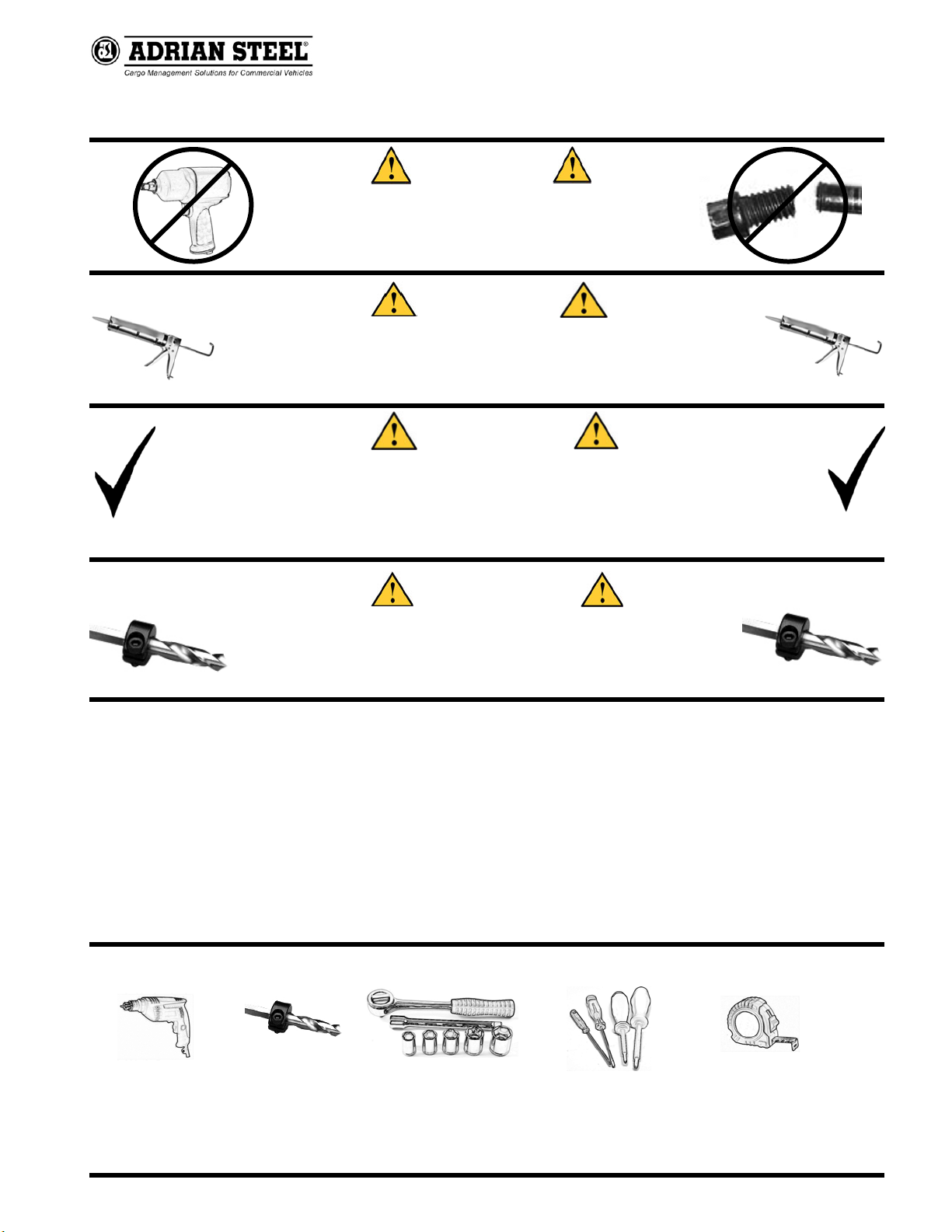

WHEN INSTALLING PLUSNUTS MAKE SURE YOU USE THE CORRECT DRILL

BIT WITH A STOP!

PLUSNUT SIZE DRILL BIT SIZE

¼-20 PLUSNUT, FAS0052 USE A 3/8” DIAMETER DRILL BIT WITH A STOP.

5/16-18 PLUSNUT, FAS0091 USE A 1/2” DIAMETER DRILL BIT WITH A STOP.

NOTE: If your vehicle contains carpet or a rubber

floor mat you will need to prepare the mounting

locations using a 1-3/16” carpet cutter.

1-3/16” DIAMETER

CARPET CUTTER

P.N. 31183-0.

NOTE: A PLUSNUT SETTING TOOL IS REQUIRED FOR PLUSNUT INSTALLATION

AND IS NOT SUPPLIED WITH THIS KIT. ORDER PLUSNUT TOOLS FROM ADRIAN

STEEL (P.N. 22200-0)OR USE AN AIR POWERED PLUSNUT SETTING GUN.

OR