IQ23x Series Controllers Installation Instructions TG200539 Issue 2 , 23-Feb-2012 1

Installation Instructions

IQ23x

Series Controllers

Important: Retain these instructions

These instructions shall be used be used by trained service personnel only

If the equipment is used in a manner not specied by these instructions, the protection provided by the equipment may be impaired.

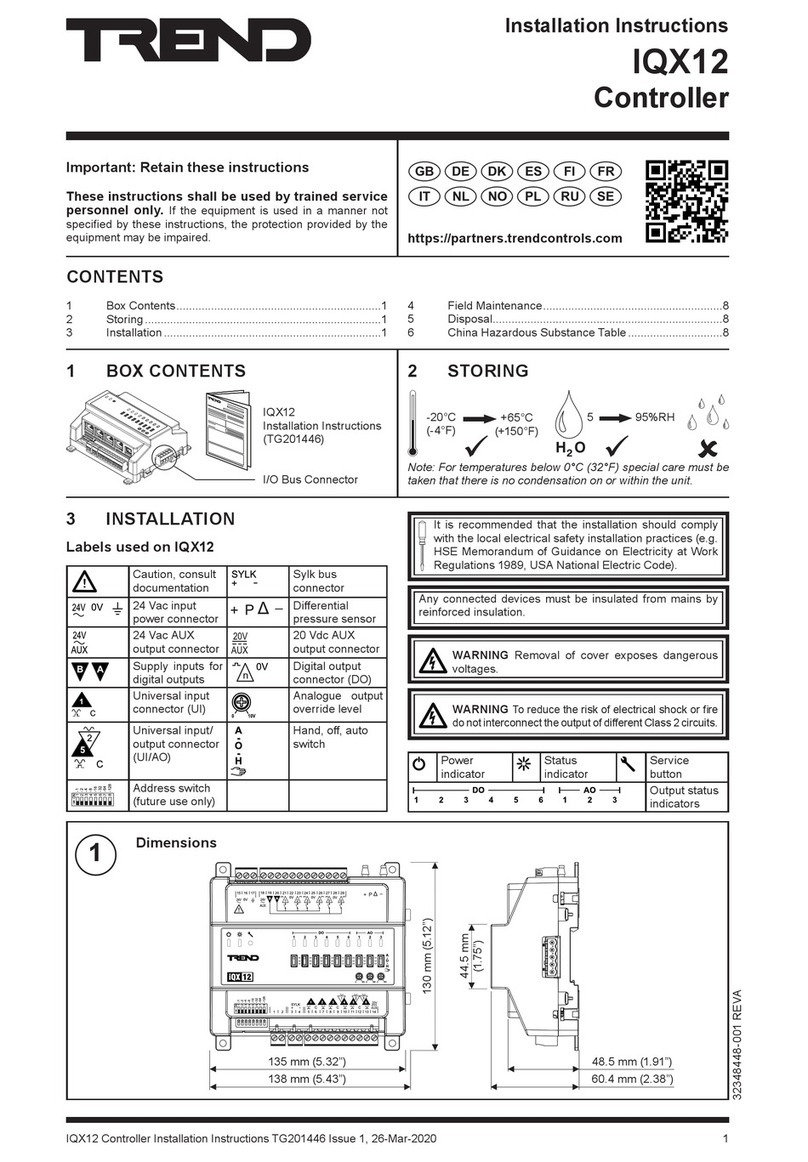

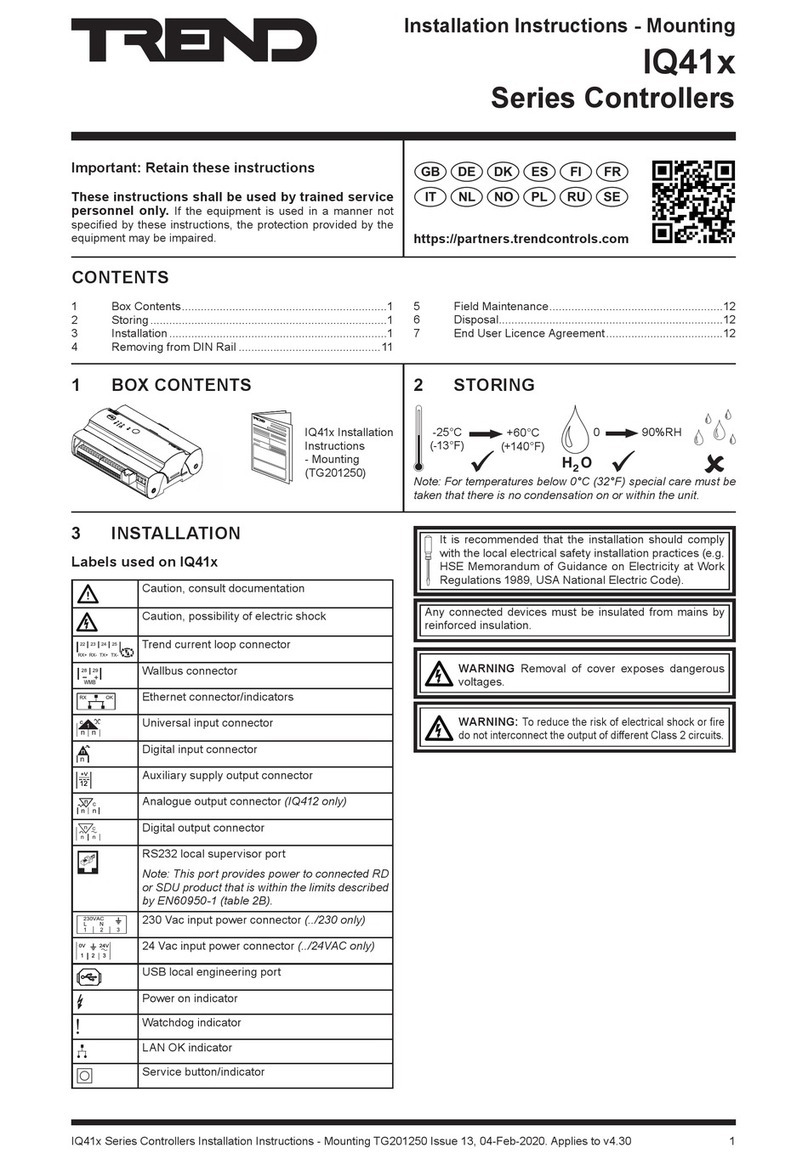

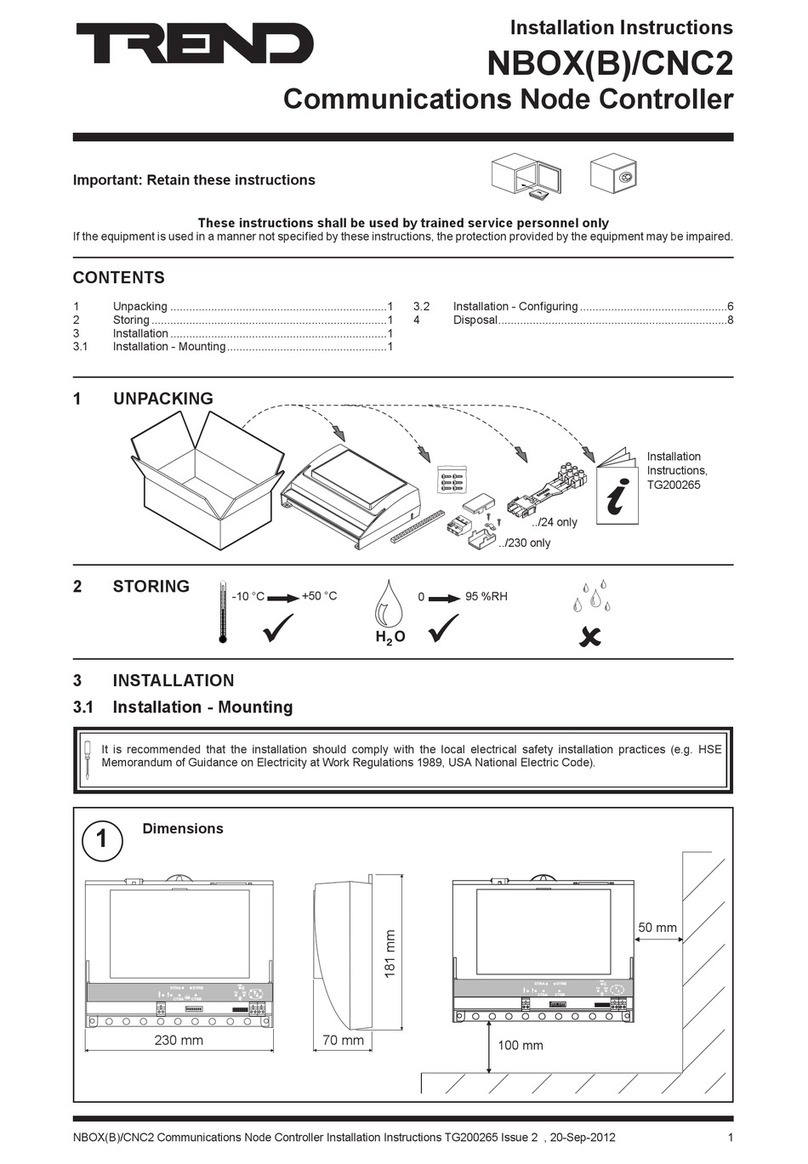

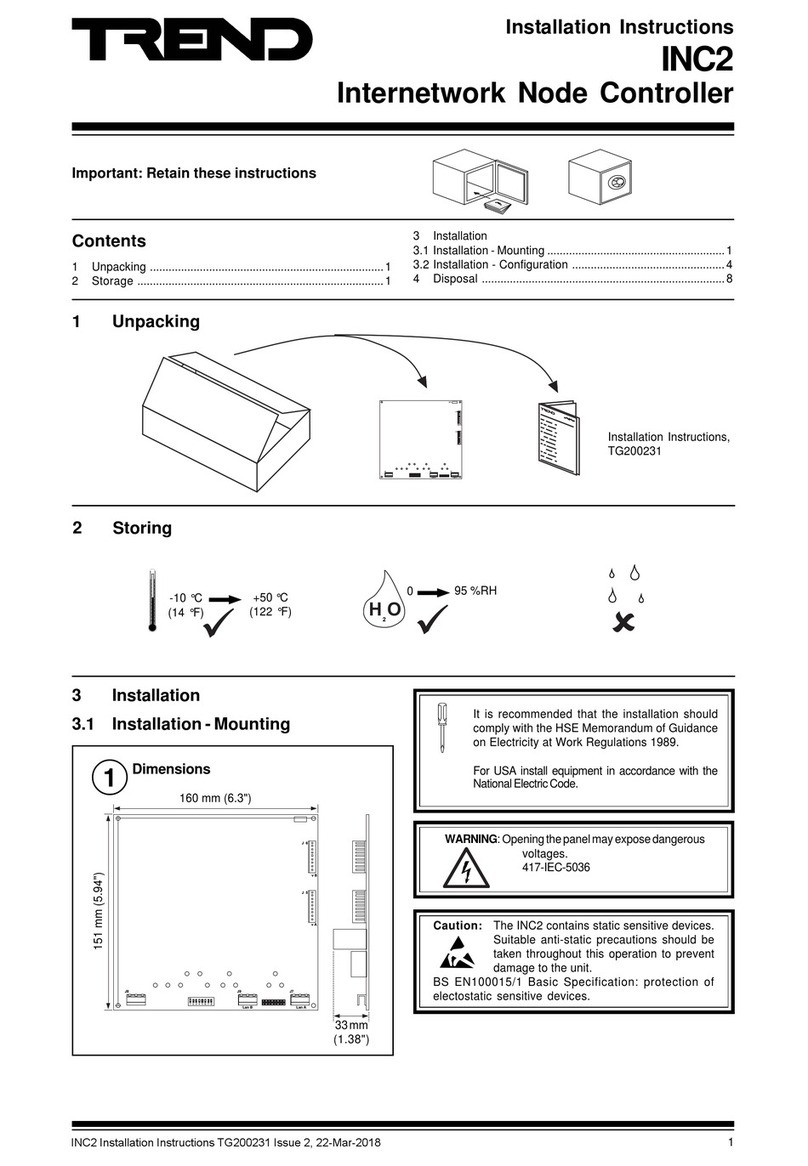

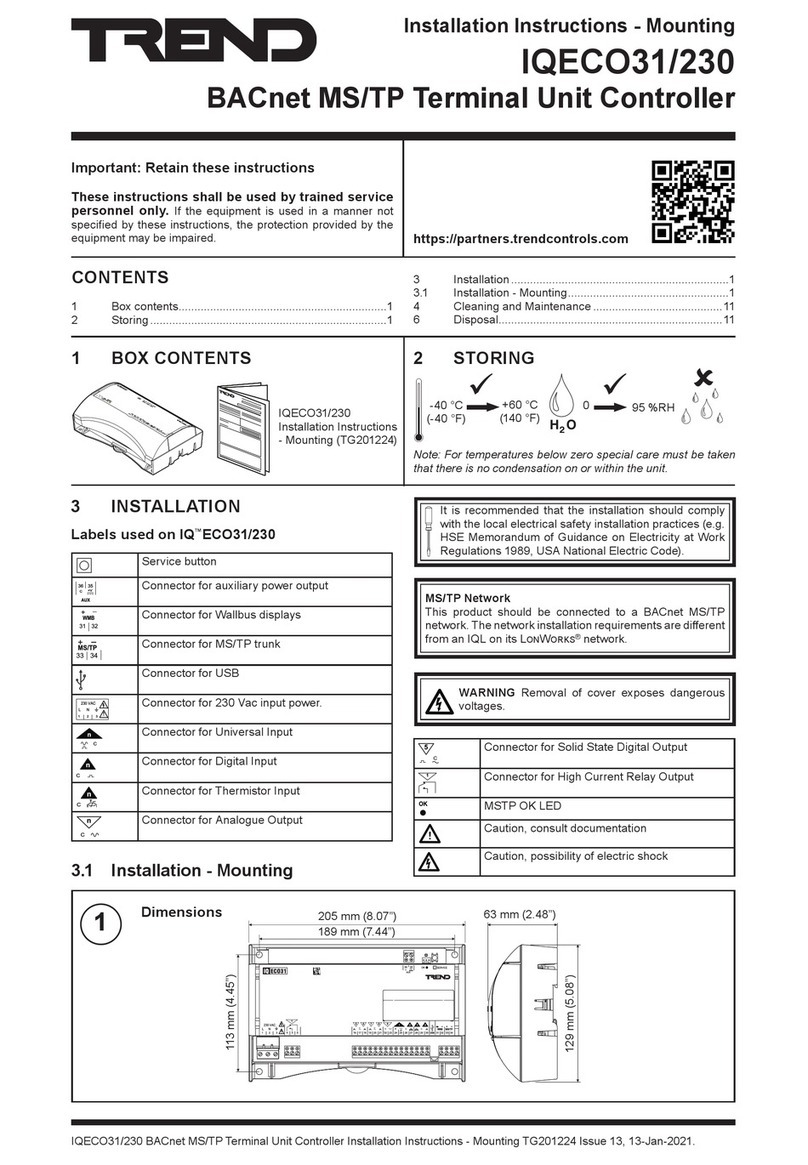

1Dimensions

2Mounting Requirements

Altitude: 2000m (6562’)

3 INSTALLATION

3.1 Installation - Mounting

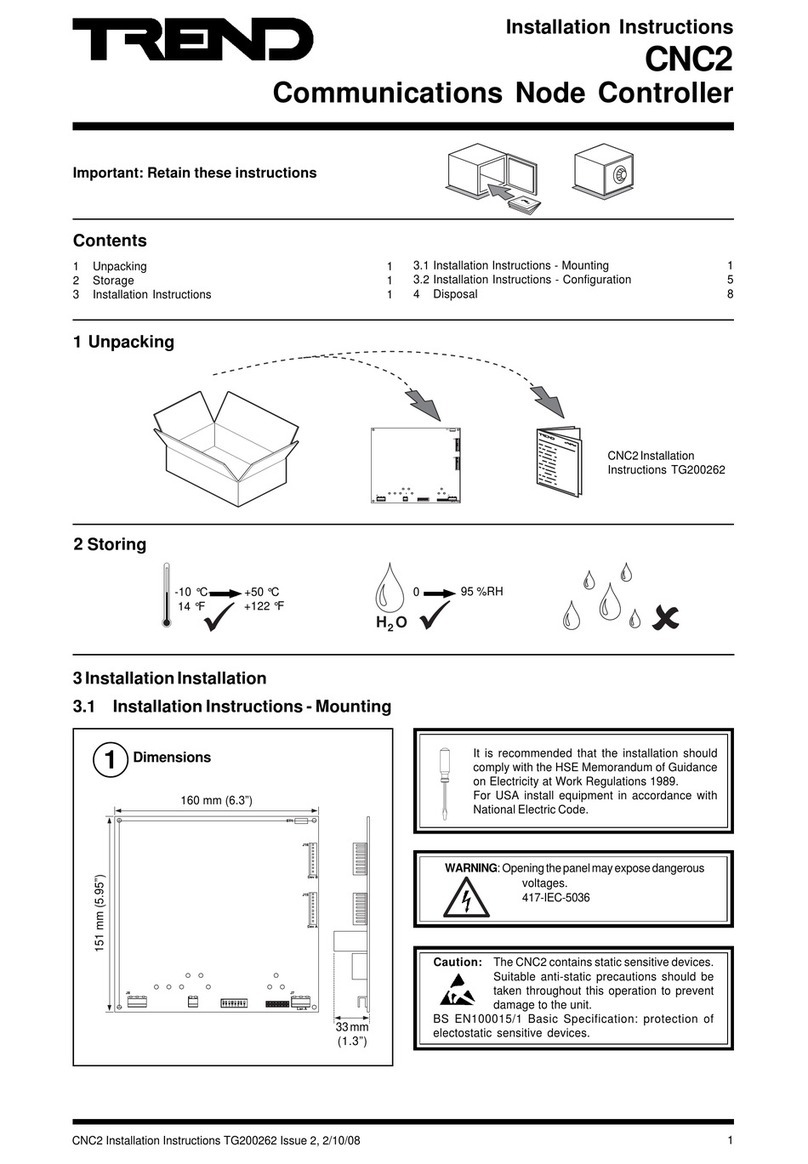

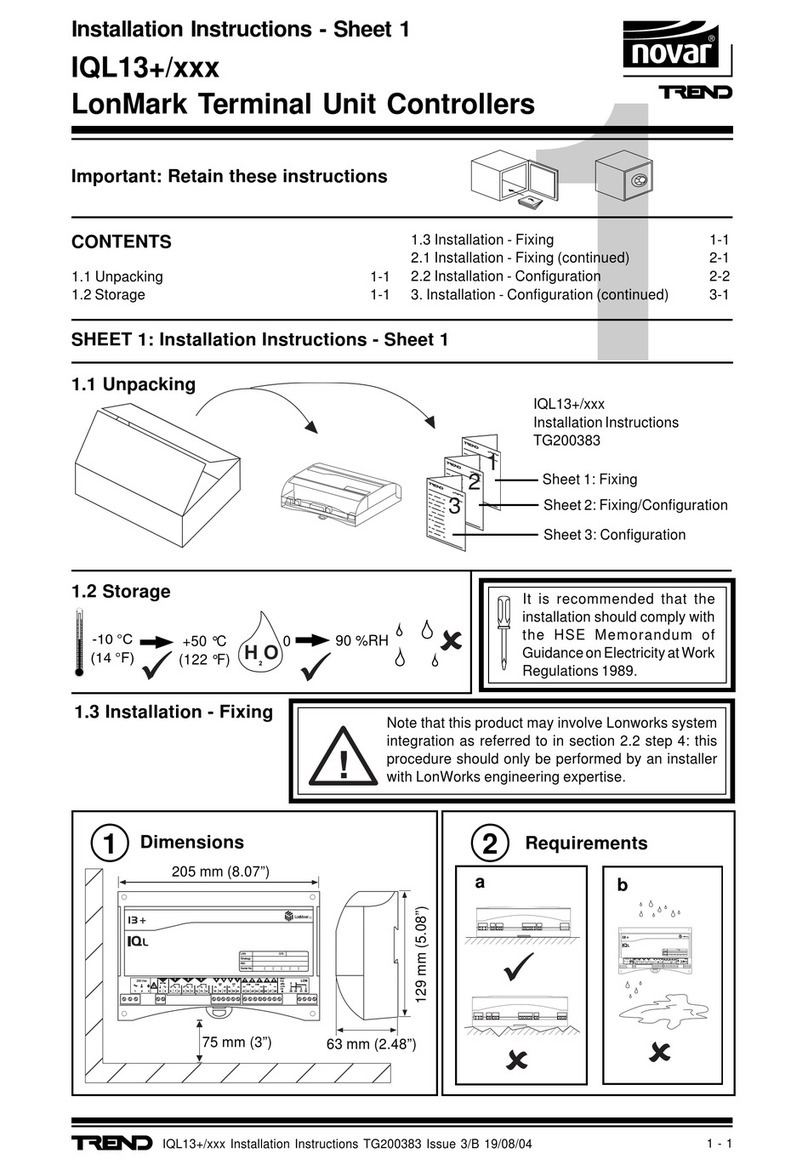

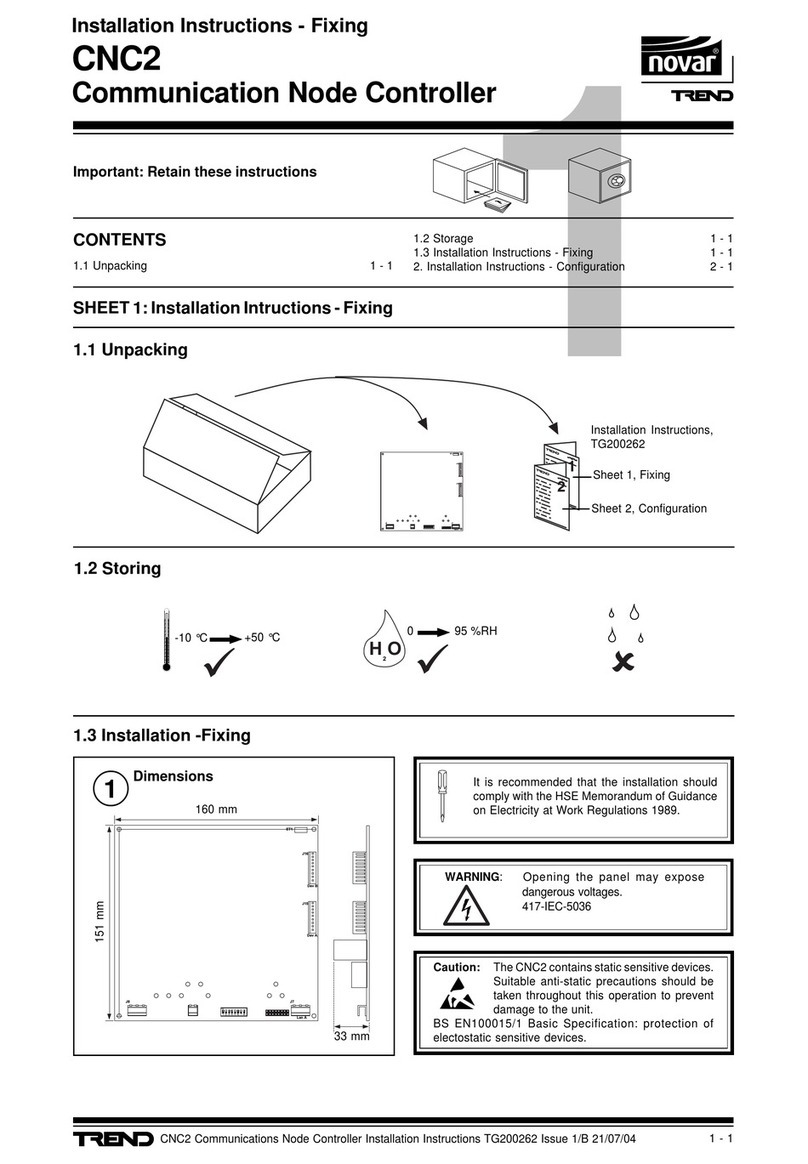

1 UNPACKING

2 STORING

It is recommended that the installation should comply

with the local electrical safety installation practices

(e.g. HSE Memorandum of Guidance on Electricity

at Work Regulations 1989, For USA National Electric

Code).

CONTENTS

1 Unpacking .....................................................................1

2 Storing ...........................................................................1

3 Installation .....................................................................1

3.1 Installation - Mounting ...................................................1

3.2 Installation - Conguring ...............................................5

4 Connecting a Remote 2-Line Display ...........................9

5 Connecting to PC via Supervisor Port ..........................9

6 Connecting to NDP via Supervisor Port .....................10

7 Mounting in an Enclosure, ENCLs/... ..........................10

8 Replacing the Battery ..................................................11

9 Zero Address/Baud Rate Switch Reset ......................13

10 Replacing an IQ111 with an IQ231 ..............................14

11 Replacing an IQ111+ with an IQ231 ............................19

12 Replacing an IQ131 with an IQ233 .............................24

13 Replacing an IQ131+ with an IQ233 ...........................28

14 Installing an Auxiliary Internal Node Board ................32

15 Disposal .......................................................................40

IQ23x Installation

Instructions TG200539

+50 °C 0

-10 °C 90 %RH

RX

TX

OK

A

D

DP

C

B

1

2

8

4

16

32

64

1K2

9K6

19K2

ADDRESS

BAUD

93 mm

(3.66”)

339 mm (13.35”)

299 mm (11.77”)

123 45 6 7 8 9 10

RX

TX

OK

ADDRESSBAUD

SW4

A

D

DP

C

B

a

b

c

2

0 °C +45 °C

0 %RH 90 %RH

d

e

RX

TX

OK

A

D

DP

C

B

1

2

8

4

16

32

64

1K2

9K6

19K2

ADDRESS

BAUD

The unit must

be installed in

an enclosure

conforming to

EN61010-1