Advanced Instruments 4250 User manual

4255 Rev11 032317

The Advanced® Cryoscope

Model 4250

User’s Guide

ii

Advanced®Cryoscope Model 4250 User’s Guide

Copyright

This user’s guide is copyrighted by dvanced Instruments with all

rights reserved. Under copyright laws, this guide may not be reproduced

in any form, in whole or part, without the prior written consent of

dvanced Instruments.

© 2005 dvanced Instruments.

dvanced Instruments has reviewed this guide thoroughly. ll material

contained within is believed reliable, but the accuracy and completeness

are not guaranteed or warranted, and are not intended to be representa-

tions or warranties concerning the product described.

Microsoft®and Windows®are registered trademarks of Microsoft

Corporation in the United States and other countries. Intel®is a regis-

tered trademark of Intel Corporation in the United States and other

countries. ll other trademarks are the property of dvanced

Instruments.

Hot-Line®Service

If you have any questions or problems regarding the proper operation of

your instrument, please contact our Hot-Line Service department by

calling one of the following numbers.

• 800-225-4034 (toll-free within the US and Canada; after normal

business hours, dial extension 2191)

• +US 781-320-9000 (elsewhere)

• 781-320-0811 (fax)

Table of Contents

iii

Safe Use vii

Symbol Conventions vii

General Cautions viii

FCC Requirements ix

Supplies, Parts & Accessories xi

Calibrators & Standards xiii

Foreword: Theory and Technique xv

Figure 1: Standard Freezing Curve xvii

Chapter 1 — Installation & Setup 1

Step 1 — Find a location for the instrument 1

Step 2 — Obtain additional items 1

Step 3 — Unpack the instrument 2

Step 4 — Install the heat transfer fluid 2

Step 5 — Load printer paper 5

Step 6 — Power up the instrument 5

Step 7 — Prime the heat transfer fluid pump 7

Step 8 — Run a diagnostic test 8

Step 9 — Set date and time 9

Step 10 — Set language preference 9

Step 11 — Check initial factory calibration 9

Step 12 — Proceed to Chapter 2 10

Figure 2: Model 4250 Cryoscope and Accessories 3

Figure 3: Load Printer Paper 6

Figure 4: Prime the Heat Transfer Pump 8

Table 1: Model 4250 Cryoscope Packing List 3

Chapter 2 — Instrument Operation 11

Hazardous material cautions 11

Function of major components 12

Sample preparation 17

Sample handling 17

Standards & controls 18

Selecting plateau mode 18

Before testing samples 19

Repeatability tips 20

Sample test procedure 23

Sample test errors 25

Changing operating settings 25

Using the RS-232 port 33

Figure 5: Model 4250 Components and Controls 12

Figure 6: Keypad Layout and Functions 14

Figure 7: Back Panel 15

Table 2: Barcode Port Connections 16

Table 3: Setup Menu Items 26

Chapter 3 — Standards & Quality Control 35

Repeatability and accuracy 35

Standards and controls 35

Maintenance of standards 36

Quality control implementation 36

Chapter 4 — Calibration 39

Calibration procedure 39

Celsius and Hortvet 40

Calibration notes 41

Chapter 5 — Troubleshooting & Service 43

Service & maintenance cautions 43

Obtaining service 44

Routine maintenance 46

Shutdown and storage 47

Troubleshooting checks 47

iv

Advanced®Cryoscope Model 4250 User’s Guide

Internal diagnostic tests 48

Fuse replacement 55

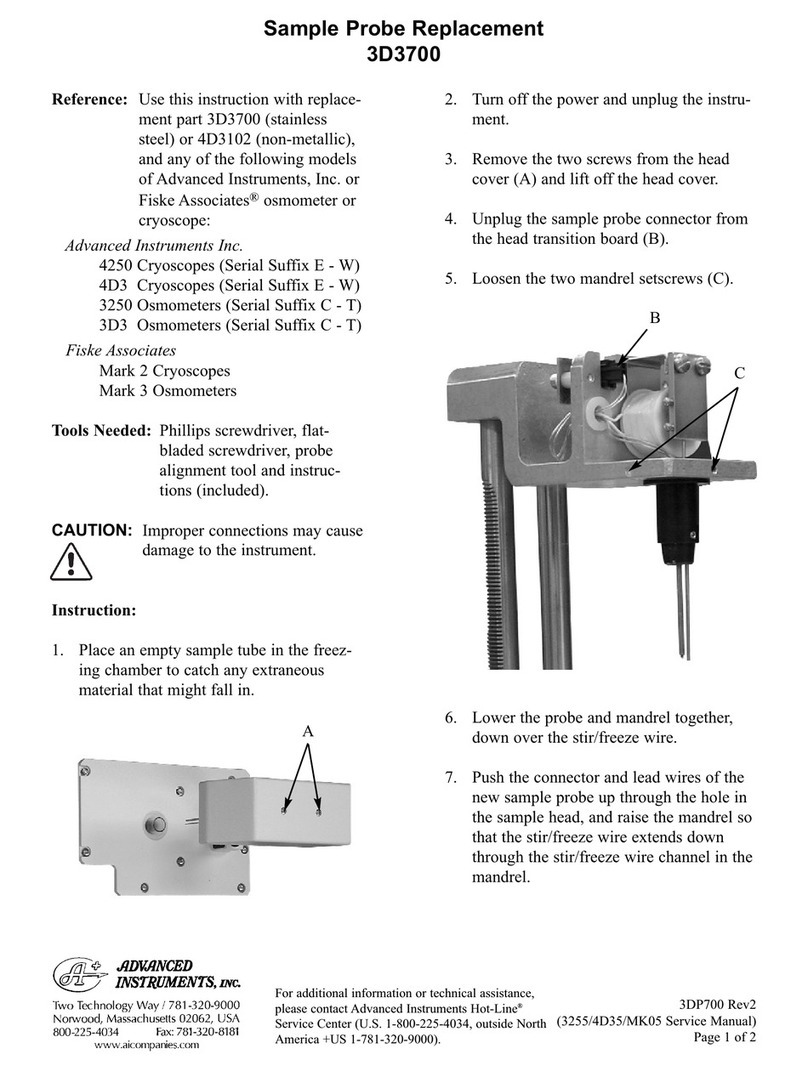

Sample probe checks and replacement 55

Mandrel, probe and stir/freeze wire alignment 59

Stir/freeze amplitude adjustment 61

Figure 8: Fuse Replacement 56

Figure 9: Probe and Stir/Freeze Wire Alignment 60

Figure 10: Operating Head 63

Figure 11: Mandrel, Probe and Stir/Freeze Wire Adjustment 65

Table 4: Test Menu Items 49

Appendices

ppendix — Troubleshooting Table 67

ppendix B — Product Specifications 75

ppendix C — Regulatory Notices 77

ppendix D — Warranty & Warranty Duties 81

ppendix E — Supplemental RS-232 Information 85

ppendix F — Symbol Definitions 89

ppendix G — Product Disposal and Recycling 93

ppendix H — Service Log 95

Index 97

v

Table of Contents

Notes:

vi

Advanced®Cryoscope Model 4250 User’s Guide

vii

Safe Use

To reduce the risk of bodily injury, electric shock, fire, and

damage to your instrument, please read and observe the precau-

tions in this User’s Guide.

• If the product is used in a manner not in accordance with the

equipment design, operating instructions or manufacturer's

recommendations, the operation of the product may be

impaired to the extent that a safety hazard is created.

• Do not attempt to perform electrical work if you are not

fully qualified. This manual is not a substitute for electrical

training.

Symbol Conventions

The exclamation point within an equilateral triangle is

intended to alert the user to the presence of important operat-

ing and maintenance (servicing) instructions in the literature

accompanying this product.

The lightning flash with arrowhead symbol within an equi-

lateral triangle is intended to alert the user to the presence of

uninsulated dangerous voltage within the product's enclosure

that may be of sufficient magnitude to constitute risk of elec-

tric shock to persons.

The static symbol within an equilateral triangle is intended

to alert the user to the presence of internal components that

could be damaged by static electricity.

This static symbol is intended to alert the user to the pres-

ence of a specific component that could be damaged by stat-

ic electricity.

viii

Advanced®Cryoscope Model 4250 User’s Guide

This symbol indicates the presence of alternating current ( C).

This symbol indicates the presence of a fuse.

This symbol indicates the presence of protective earth ground.

This symbol indicates the power is ON.

This symbol indicates the power is OFF.

NOTE dditional symbol definitions are available in ppendix F.

General Cautions

• This product should be operated only with the type of power source

indicated on the product’s electrical ratings label. Refer to the instal-

lation instructions included with the product.

• If the power cord provided is replaced for any reason or if an alter-

nate cord is used, the cord must be approved for use in the local

country. The power cord must be approved for the product’s listed

operating voltage and be rated at least 20% greater than the ampere

ratings marked on the product’s electrical ratings label. The cord

end that connects to the product must have an IEC 60320 connector.

• Plug the product into an approved grounded electrical outlet.

• Do not disable the power cord’s grounding pin.

• If an extension cord or power strip is used, make sure that the cord

or strip is rated for the product, and that the total ampere ratings of

all products plugged into the extension cord or strip do not exceed

80% of the cord’s or strip’s rating limit.

ix

Safe Use

• Route power cords so that they will not be walked on, tripped on, or

pinched by items placed upon or against them. Pay particular atten-

tion to the plug, electrical outlet, and the point where the cord exits

the product.

• Do not pull on cords and cables. When unplugging cords or cables,

grasp the corresponding connector.

• Do not install or use this product in any area subject to extreme

short-term temperature variations, or locations that exceed the speci-

fied operating environment temperatures.

• Never use this product in a wet area.

• To avoid injury or fire hazard, do not operate this product in an

explosive atmosphere.

• Do not install or use the product on an unstable, non-level work sur-

face.

• Do not operate this product with the covers removed or unsecured.

FCC Requirements

• WARNING: Changes or modifications to this unit not expressly

approved by dvanced Instruments could void the user’s authority

to operate the equipment.

• This equipment has been tested and found to comply with the limits

for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment

generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no

guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or televi-

sion reception, which can be determined by turning the equipment

x

Advanced®Cryoscope Model 4250 User’s Guide

off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit different from

that to which the receiver is connected.

- Consult the dealer or an experienced radio TV technician for

help.

Supplies, Parts &

Accessories

xi

PART DESCRIPTION

2- mp Time Delay (T) Fuse for 100-130V

Barcode Scanner

Clapper

Heat Transfer Fluid

Heat Transfer Fluid Filter

ir Filters (package of 6)

Printer Paper (5 rolls)

Operator/Supervisor Keys

Probe/Stir Wire lignment Tool Kit

Mandrel

Power Cord (specify voltage and country)

One-way Check Valve

PART NO.

70022

330016

3C2241

3D 811

4D3710

3D2340

FL 835

3D3185

3L 700

3LH500

4D3705

To order parts and accessories, contact the Advanced Instruments

Customer Service Department by using one of the following num-

bers.

• 800-225-4034 (toll-free within the US and Canada)

• +US 781-320-9000 (elsewhere)

• 781-320-3669 (fax)

xii

Advanced®Cryoscope Model 4250 User’s Guide

PART DESCRIPTION

Replacement Sample Probe with Mandrel and one 10-mL

ampule of Probe Bin Setting Fluid (Non-Metallic)

Replacement Sample Probe with Mandrel and one 10-mL

ampule of Probe Bin Setting Fluid (Stainless Steel)

Sample Tube Rack

Sample Tubes marked at 2-mL and 2.5-mL

RS-232 Cable, 3 meters

Service Manual, 3250/4250

Stir/Freeze Coil

Stir/Freeze Wire

dvanced®User Information CD-ROM

Quick Instruction Card

User’s Guide

Yoke

Software Update CD-ROM

Software Update Kit (CD-ROM and Cable)

PART NO.

4D3102

3D3700

3L 846

3L 823

RS232-

C BLE

3255SM

3D2404

4LH243

90P01

4250-7

4255

3LH230

SFW006

SFW008

Calibrators & Standards

xiii

To order calibrators and standards, contact the Advanced

Instruments Customer Service Department by using one of the

following numbers.

• 800-225-4034 (toll-free within the US and Canada)

• +US 781-320-9000 (elsewhere)

• 781-320-3669 (fax)

DESCRIPTION

-422 m°H Calibration Standard (-408 m°C)

-621 m°H Calibration Standard (-600 m°C)

-530 m°H Lactrol®530 Reference Solution (-512 m°C)

PART NO.

3L 023

3L 033

3L 030

NOTE dvanced Instruments cannot guarantee the stated

instrument performance specifications and accuracy of

test results unless dvanced Instruments brand consum-

ables are used with the instrument. Use of consumables

from manufacturers other than dvanced Instruments is

not recommended and may adversely affect system cali-

bration, performance, operation, and accuracy of test

results. For information on obtaining these standards

and controls, contact dvanced Instruments or an

authorized representative.

xiv

Advanced®Cryoscope Model 4250 User’s Guide

Notes:

xv

Foreword

The Theory of Cryoscopy

Principles of Milk Cryoscopy

When a solute is dissolved in a pure solvent, the colligative or

concentrative properties of the solvent change by a constant

amount in direct proportion, within reasonable limits, to the

solute concentration. Of these properties, measurement of the

freezing point, where applicable, allows the concentration of the

solution to be easily determined with great precision.

The freezing point of pure water is precisely 0°C at atmospheric

pressure. Most solutes impede the crystallization of water and

depress its freezing point in proportion to their concentration.

Milk is a water-based solution with various solids in suspen-

sion. The solutes normally present in milk lower its freezing

point by a nearly constant amount.

Instrumentation

The dvanced Cryoscopes are instruments designed for the

extremely precise determination of the concentration of solu-

tions by means of freezing point measurement. They utilize

high precision thermistors to sense the sample temperature, to

control the degree of supercooling and freeze induction, and to

measure the freezing point of the sample.

dvanced Cryoscopes can routinely determine differences of

2 m°C.

xvi

Advanced®Cryoscope Model 4250 User’s Guide

Freezing Point Thermodynamics

The quickest and most precise way to measure the freezing point of a

solution is to supercool it several degrees below its freezing point and

then mechanically induce the sample to freeze. The heat of fusion sud-

denly liberated causes the sample temperature to rise toward a plateau,

wherein the intrinsic sample thermodynamics maintain a temporary adi-

abatic liquid/solid equilibrium. The time over which equilibrium devel-

ops and is maintained is a function of the thermal characteristics of the

sample, the temperature differential between the sample and its environ-

ment, and the ability of the intervening materials to conduct heat. The

equilibrium temperature is, by definition, the freezing point of the solu-

tion.

Optimum precision by this method results from a carefully engineered

instrument. In the 4250, the sample environment is temperature con-

trolled to maximize the efficiency of the instrument without distorting

the freezing plateau. sensitive probe monitors the sample temperature,

controls the degree of supercooling and freeze induction, and measures

the freezing point of the sample. The tip of the sample probe is precise-

ly positioned in each sample. utomatic stirring during sample cooling

and crystallization minimizes sample temperature gradients and gener-

ates a uniform insulating slush which helps stabilize the equilibrium

plateau.

Careful attention to sample-handling and to simple maintenance proce-

dures (e.g., heat transfer fluid replenishment, and probe and stir/ freeze

wire cleanliness) will ensure continued high performance.

Figure 1 illustrates the temperature of a sample as it progresses through

the freezing cycle, and shows the action of the instrument at each stage.

lthough the freezing point plateau in a properly-designed cryoscope

appears flat for a considerable period, extending ideally for many min-

utes, an amplified plot of the plateau temperature would show a very

gradual curve, peaking as the temporary adiabatic condition breaks

down. The “freezing point”of a sample has been defined as the warmest

temperature achieved during equilibrium. Unfortunately, the warmest

xvii

Foreword

temperature achieved during equilibrium can only be definitively deter-

mined after the fact, requiring the sample temperature to be monitored

for a substantial period, through and beyond the “peak”. In addition, the

measurement is demonstrably more repeatable somewhat earlier on the

plateau, where the freezing and melting processes are more adiabatical-

ly balanced.

Commercial cryoscope users, observing that similar samples have simi-

larly sloped freezing point curves under similar conditions, traditionally

have solved this dilemma by taking timed plateau measurements and

calibrating accordingly; it simply is not economical to wait for less-

repeatable peak readings. In order to maintain agreement between dif-

ferent instruments, milk cryoscope manufacturers traditionally have

incorporated plateau timers set for a reasonable compromise between

accuracy and efficiency. Though the length of the plateau varies with

the constituents and size of the sample, we have found freezing point

measurements taken at approximately 30 seconds after the initiation of

crystallization to be most repeatable with 2-mL samples.

Certain milk regulating agencies still mandate or recommend other

times or measurement at the peak of the plateau. The 4250 is factory-set

for 30-second plateau measurements, but it may be set easily at 60 or

90 seconds or for plateau seeking, if desired, as described in Chapter 2,

“Operating Instructions”in this user’s guide.

Figure 1: Standard Freezing Curve

xviii

Advanced®Cryoscope Model 4250 User’s Guide

It is only appropriate to correlate freezing points determined using the

same plateau reading mode. Determinations made using different mea-

surement modes will not yield identical results.

Hortvet, Celsius and the freezing point of milk

The two calibration standards selected to bracket the milk freezing point

range were originally thought by Julius Hortvet to freeze at -422 m°C

and -621 m°C. Later, they were more correctly found to freeze at -407.4

m°C and -599.6 m°C, respectively, a factor of 1.0356 warmer. Both

milk freezing point scales derived from these two sets of numbers are

still in use today. Modern milk freezing point publications often distin-

guish between the two scale units by referring to the former scale as

m°H (Hortvet) and the latter as m°C (Celsius). Either scale may be

selected in the 4250.

R. W. Henningson found that, though varying slightly with breed and

diet, the freezing points of authentic samples of pure, fresh milk from

healthy cows in the U.S. and Canada average -540.4 m°H (-521.8

m°C)2. The freezing point average was -543 m°H (-524 m°C) in

England and Wales3.

s soon as it leaves the cow, however, milk becomes susceptible to both

dilution and contamination. Cows' milk found to have a freezing point

warmer than established regional norms may be suspected to have been

somehow diluted. Cows' milk found to have a freezing point colder than

these norms may be suspected to have soured or become contaminated.

Combinations of both effects are quite possible but seldom unde-

tectable.

The O C, PH and other regulatory organizations recommend -525

m°H (-507 m°C) as a confirmation level; that is, observations of milk

freezing points warmer than -525 m°H (-507 m°C) should be presumed

to indicate added water, but be confirmed by additional observations on

authentic samples from the same herd. The British Standards Institution

recommends that observations of milk freezing points warmer than -529

m°H (-511 m°C) be confirmed.

xix

Foreword

However, any added water reduces productivity. The confirmation level

recommended above is based on national averages. If you find that your

local herd averages allow the establishment of a colder local confirma-

tion level (even with natural variations taken into account), you can

thereby reduce added water accordingly.

Under routine conditions where close comparisons are made between

authentic herd samples and delivered milk, less than 1% added water

generally can be detected. Close field and plant follow-up can assure an

actual added water level under 0.5% in market milk; some authorities

claim 0.2%.

For an excellent summary of the role of milk regulatory agencies in the

United States, please refer to E. H. Marth’s article, Assuring the uality

of Milk4.

Percent deviation from base (% DFB)

Early milk freezing point investigators often thought the solute concen-

tration of milk to be more constant than it actually is. Contemporary

milk cryoscopy literature often referred to a concept called “% added

water”which, it was thought, could be calculated using a fixed base,

without actually measuring the sample with no added water. This con-

cept assumed that milk samples with freezing points equal to or colder

than the local average (usually called the “base”) to contain 0% added

water, and pure water to contain 100% added water. Using this assump-

tion (with the -540.4 m°H (-521.8 m°C) national average as the base),

the current -525 m°H (-507 m°C) confirmation level would represent

2.8% added water:

100 (540 - 525) / 540 = 2.8%

and would approximately correspond to the often-used 3% “cut-off”

level, which thus allows for a small amount of natural variation and

measurement error.

lthough we now know that the actual “percent added water”of a sam-

ple cannot be determined without measuring the same sample with no

added water, it can be seen that the percent deviation from some

xx

Advanced®Cryoscope Model 4250 User’s Guide

arbitrarily-selected freezing point value can be useful in quantifying rel-

ative deviation. For example, having determined the average local freez-

ing point and normal variation of the milk of a particular cow, herd or

breed, one can estimate the percentage of deviation due to a particular

condition, disease or additive.

The option to set a base freezing point value and have the cryoscope

calculate the percent deviation from the base, of each sample tested, has

been built into the Model 4250. However, since it is no longer accept-

able (nor accurate) to label all positive deviations from a base value as

“added water,” we suggest reporting deviations from a base as “% DFB”

(percent deviation from base). Using % DFB in this manner can provide

a guideline for estimating the quality of milk samples in respect to the

base established. ll unknown samples of milk run against this base

value will show a deviation above or below the base.

The 4250 calculates the percent deviation from the base (% DFB) as

follows:

DFB = (base value - observed value)/base value x 100

s noted, part of this deviation is attributable to natural variation and

measurement error. Factors other than the addition of water to milk,

which can cause additional positive deviations from the base (DFB),

include:

1. Poor herd condition

2. Poor feed and/or pasture conditions

3. Drought conditions

4. Extended milk storage, CO2decrease

Factors which can cause unacceptably negative deviations from the base

(% DFB) include:

1. Dirty sample tubes

2. Sour milk

3. Chlorine sanitizer in the milk sample

4. Milk adulterated by salt-fortified water

Table of contents

Other Advanced Instruments Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Terumo

Terumo Harvest SmartPReP 2 Operator's and service manual

RADWAG

RADWAG MAC Series user manual

Syngene

Syngene G:BOX mini 6 Installation quick guide

Sartorius stedim

Sartorius stedim Sartocube ECO Series user manual

Gilson

Gilson PIPETMAN Classic P2 quick guide

Digitus

Digitus DN-651141 Quick installation guide