Advanced Instruments Anoxomat III User manual

Anoxomat® III

User’sGuide

AN3005EN Rev 5

2Anoxomat® III User’sGuide

Contents

Contents.............................................................................2

Safe use..............................................................................3

Foreword............................................................................5

Chapter 1

Installation and setup .....................................................6

1.1 Find a location for the instrument................................................... 6

1.2 Additional items needed for installation...................................... 6

1.3 Carton contents..................................................................................... 6

1.4 Installing the gas supply .................................................................... 7

1.5 Install the recipe printer (optional)................................................ 9

1.6 Connect to a computer or network (optional).......................... 9

1.7 Power up the instrument ................................................................... 9

1.8 Set up System Language..................................................................10

1.9 How to input data................................................................................10

1.10 Setting up the instrument...............................................................10

1.11 Standard gas mixture..........................................................................11

1.12 Registration setup (optional).......................................................... 11

1.13 Activating the printer (optional) ..................................................12

1.14 Activating the data interface (optional)....................................13

Chapter 2

Operating the Instrument ............................................ 14

2.1 Function of major components......................................................14

2.2 Operating the instrument ................................................................14

2.3 Process report......................................................................................15

2.4 End of recipe........................................................................................15

Chapter 3

Optional functions......................................................... 17

3.1 Barcode scanner................................................................................... 17

3.2 Registration input screen.................................................................17

3.3 Pre-programmed recipes.................................................................17

3.4 Additional jar connections ..............................................................18

3.5 Additional gas connections ............................................................18

3.6 User programming function ...........................................................18

3.7 Activating pre-programmed or user-defined recipes..........20

3.8 Thermal/dot matrix printer............................................................20

3.9 Data Interface......................................................................................20

Chapter 4

Maintenance....................................................................22

4.1 Maintaining the Anoxomat.............................................................. 22

4.2 Maintaining jars ..................................................................................22

Chapter 5

Troubleshooting and service ..................................... 24

5.1 Service and maintenance cautions ..............................................24

5.2 Obtaining service...............................................................................24

5.3 To return an instrument for repair or replacement............... 25

5.4 Troubleshooting checks..................................................................25

5.5 Hardware test program ...................................................................25

5.6 Fuse replacement ..............................................................................25

Appendix A

Troubleshooting table ................................................. 26

Appendix B

Parts and accessories .................................................. 30

Appendix C

Product specifications..................................................32

Appendix D

Regulatory notices ........................................................33

Appendix E

Warranty and warranty duties................................... 34

Appendix F

Supplemental RS-232 information ............................37

Appendix G

Symbol definitions.........................................................38

Appendix H

Product disposal and recycling.................................40

3Anoxomat® III User’sGuide

Safe use

WARNING: To reduce the risk of bodily injury, electric shock, fire, and damage to your instrument, please read and observe

the precautions in this User’s Guide.

If the product is used in a manner not in accordance with the equipment design, operating instructions or manufacturer’s

recommendations, the operation of the product may be impaired to the extent that a safety hazard is created.

Do not attempt to perform electrical work if you are not fully qualified. This manual is not a substitute for electrical

training.

Symbol conventions

The list of symbols below is for reference only. Not all symbols shown may be used on this instrument or in the

accompanying documentation.

The exclamation point within an equilateral triangle is intended to alert the user to the presence of important operating

and maintenance (servicing) instructions in the literature accompanying this product.

The lightning flash with arrowhead symbol within an equilateral triangle is intended to alert the user to the presence of

uninsulated dangerous voltage within the product’s enclosure that may be of sucient magnitude to constitute risk of

electric shock to persons.

The static symbol within an equilateral triangle is intended to alert the user to the presence of internal components that

could be damaged by static electricity.

This static symbol is intended to alert the user to the presence of a specific component that could be damaged by static

electricity.

This symbol indicates the presence of alternating current (AC).

This symbol indicates the presence of a fuse.

This symbol indicates the presence of protective earth ground.

This symbol indicates the power is ON.

This symbol indicates the power is OFF.

Additional symbol definitions are available in Appendix G.

Safe use

4Anoxomat® III User’sGuide

General cautions

• This product should be operated only with the type of

power source indicated on the product’s electrical

ratings label. Refer to the installation instructions

included with the product.

• If the power cord provided is replaced for any reason

or if an alternate cord is used, the cord must be

approved for use in the local country. The power cord

must be approved for the product’s listed operating

voltage and be rated at least 20% greater than the

volt-ampere (VA) ratings marked on the product’s

electrical ratings label. The cord end that connects to

the product must have an IEC 60320 connector.

• Plug the product into an approved grounded electrical

outlet. Exposure to AC voltage could lead to electric

shock, burn or electrocution. Please be aware of any

exposure of AC voltage in the power cord.

• Do not disable the power cord’s grounding pin.

• If an extension cord or power strip is used, make sure

that the cord or strip is rated for the product, and that

the total ampere ratings of all products plugged into

the extension cord or strip do not exceed 80% of the

cord’s or strip’s rating limit.

• Route power cords so that they will not be walked on,

tripped on, or pinched by items placed upon or

against them. Pay particular attention to the plug,

electrical outlet, and the point where the cord exits the

product.

• Do not pull on cords and cables. When unplugging

cords or cables, grasp the corresponding connector.

• Do not install or use this product in any area subject to

extreme short-term temperature variations, or

locations that exceed the specified operating

environment temperatures.

• Never use this product in a wet area.

• To avoid injury or fire hazard, do not operate this

product in an explosive atmosphere.

• Do not install or use the product on an unstable,

non-level work surface.

• Do not operate this product with the covers removed

or unsecured.

FCC requirements

WARNING: Changes or modifications to this unit

not expressly approved by the party responsible for

compliance could void the user’s authority to

operate the equipment.

This equipment has been tested and found to comply

with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to

provide reasonable protection against harmful

interference when the equipment is operated in a

commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction

manual, may cause harmful interference to radio

communications. Operation of this equipment in a

residential area is likely to cause harmful interference in

which case the user will be required to correct the

interference at his own expense.

If you have any questions or problems regarding the

operation of this instrument, please contact our technical

support department:

Advanced Instruments, LLC

Two Technology Way

Norwood, MA 02062, USA

Phone: 781-320-9000

Web: www.aicompanies.com or www.anoxomat.com

Email: info@aicompanies.com or info@anoxomat.com

Technical support/product service

Phone: U.S. and Canada 800-225-4034

+1 781-320-9000

Email: techsupport@aicompanies.com

Customer service/orders

Phone: 800-225-4034 or +1 781-320-9000

Email: orders@aicompanies.com

5Anoxomat® III User’sGuide

Foreword

Intended use

The Anoxomat uses the widely known McIntosh and Fildes system of evacuation and replacement to create anaerobic

environments. The Anoxomat® quickly creates anaerobic, microaerophilic, or capnophilic and hypoxic environments to

cultivate bacteria in jars using a reliable automated evacuation/replacement method. The Anoxomat® can create exact,

repeatable conditions with gas mixtures within 0.5% of the required value.

The Anoxomat® is designed to cultivate oxygen-sensitive organisms in anaerobic jars using a system that reliably sustains

environments for proper growth. The Anoxomat is useful to the following disciplines:

• Microbiological and bacteriological research

• Clinical microbiology laboratories

• Medical research

• Biotechnology research and manufacturing

• Pharmaceutical research and manufacturing

• Food safety microbial testing

• Environmental monitoring

• Academic research

• Industrial applications

6Anoxomat® III User’sGuide

Chapter 1

Installation and setup

In order to set up your instrument properly, it is important that you read and follow the steps in this section.

Please follow these steps carefully and be sure to read Chapter 2—Instrument Operation before attempting to run

your instrument.

1.1 Find a location for the instrument

When choosing a location for your Anoxomat, make sure

to meet the following criteria.

Adequate space

• Instrument dimensions:

12 × 9 × 13 inches (30.5 × 23 × 33 cm).

• Keep workplace free of debris and allow 6 inches

(15 cm) of clear space on each side of the instrument.

• Allow space for jars and accessories, such as a printer.

Electric outlet availability

Your instrument needs to operate within five feet

of a properly grounded, three-prong electrical

outlet capable of continuously supplying 2

amperes at 220V and 5 amperes at 100-110V. If the

instrument is not grounded properly, its operation may

be impaired and a safety hazard may exist. Therefore, be

sure to test the outlet and record the results before

operating your instrument.

1.2 Additional items needed for installation

• Adjustable wrench to tighten the dual stage regulator.

• 5/8 in & 11/16 in wrenches to tighten the hose/fitting

gas connection(s).

• Gas cylinder containing appropriate anaerobic mixture.

• Dual stage regulator. See Installing the gas supply on

page7.

1.3 Carton contents

Quantity Description

1 Anoxomat III

1 Parts package

• Gas hose(s) and fittings or gas tube(s)

• Jar tube test plug

• Soft-touch pen

1 USB stick containing

• User’s guide

• Data Interface spreadsheet template

1 AC line cord

Accessories and optional parts

• Jar

• Petri dish holder

• Palladox™ catalyst (disposable sachet)

• 1 Recipe printer (optional)

• 1 Barcode scanner (optional)

Chapter 1 Installation and setup

7Anoxomat® III User’sGuide

Unpacking

1. Carefully unpack the carton and inspect the contents

for damage.

Save the shipping material in case you need to

transport the instrument.

2. Use the packing list to verify you have all items.

Notify your receiving department immediately if items are

missing. Advanced Instruments is responsible for items

reported missing within 10 days of a shipment’s arrival.

3. If an item is damaged, save the shipping material for

inspection by the insurer.

4. Notify the dealer and Advanced Instruments within 24

hours for your warranty and insurance to apply.

5. Have the transportation company inspect items,

complete a “Report of Concealed Damage,” and file

your claim.

6. Notify Advanced Instruments immediately for repair or

replacement.

7. Complete the online warranty card at:

aicompanies.com/warranty

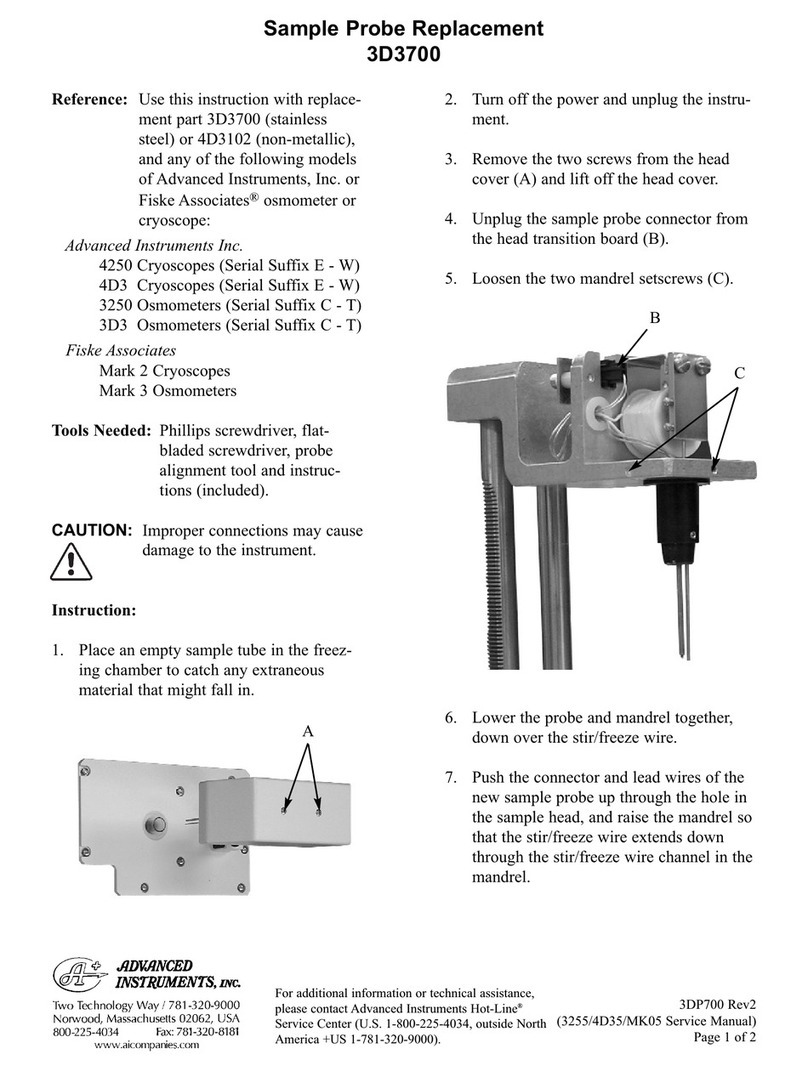

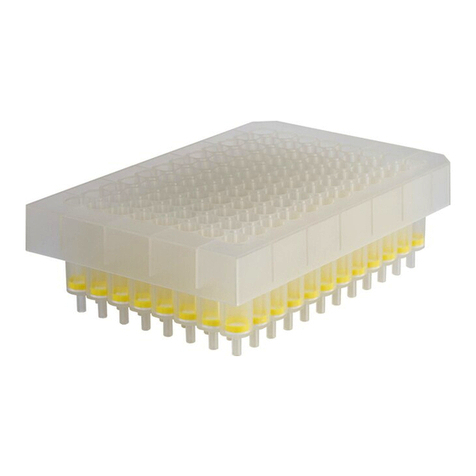

Anoxomat III and accessories

1.4 Installing the gas supply

To use the Anoxomat, you'll need to connect at least one

gas cylinder with a standard gas mixture used for

anaerobic as well as for microaerophilic bacteria

cultivation (see Standard gas mixture on page11).

Before you begin, make sure the gas cylinder valve is o

until the gas supply is fully installed.

Caution: Improper connections may cause the instrument

to malfunction.

Regulator requirements

• Reverse thread for mixed gases

• Dual-stage

• Reads 0–3.45 bar (0–50 psi)

• Required connections:

• 220V systems: 8 mm (5/16 in.) hose-barb fitting

• 100 or 110V systems: 1/4 in. NPT port

• Capacity max. 5 m3/hr (176 ft3/hr)

• Regulator shall comply with safety standards

• Gas cylinder equipped with a CGA350 fitting on tank

• Working pressure: 1.75 bar ± .15 bar 25.5 ± 2 psi

• 220V system: Gas tube is 8 mm (5/16 in.) inner

diameter; working pressure of 15 bar (218 psi).

• 100V or 110V system: Gas hose is 8 mm (5/16 in.) inner

diameter; working pressure of 172 bar (2500 psi) or

less.

Chapter 1 Installation and setup

8Anoxomat® III User’sGuide

Connecting the gas supply to a 220V system

See Installing the gas supply before you begin.

1. Mount the regulator on the gas cylinder

using the adjustable wrench.

2. Tighten the regulator per manufacturer’s

recommendations to avoid gas leakage.

3. Set the regulator's gas pressure to zero.

4. Using the provided tube clamps on each end, connect

the gas tube to the regulator and the gas input #1

(see the Rear connector panel).

5. Tighten the gas tube clamps.

Rear connector panel

This image is for reference only. Your Anoxomat system

may have dierent connections.

This

6. Open the gas cylinder’s main supply and set the

regulator gas pressure to 1.75 ± .15 bar

(25.5 psi ± 2 psi).

7. Repeat for each gas connection.

Connecting the gas supply to a 100V or 110V system

See Installing the gas supply before you begin.

1. Mount the regulator on the gas cylinder using the

adjustable wrench.

2. Tighten the regulator per manufacturer's

recommendations to avoid gas leakage.

3. Set the regulator's gas pressure to zero.

4. Hand-tighten the gas fitting into the regulator.

Use a 5/8 in. wrench to fully tighten the fitting.

5. Hand-tighten the metal gas hose to the gas fitting.

Use an 11/16 in. wrench to fully tighten the hose.

Chapter 1 Installation and setup

9Anoxomat® III User’sGuide

6. Hand-tighten the other end of the hose to the gas

fitting on the back of the Anoxomat. Use an 11/16 in.

wrench to tighten the hose.

7. Slowly open the gas cylinder valve and set the gas

regulator to 1.75 bar ± .15 bar 25.5 ± 2 psi.

8. Repeat for each gas connection.

1.5 Install the recipe printer (optional)

1. Connect the printer cable to the RS232 socket on the

rear panel of the Anoxomat.

2. Install the roll of printer paper.

3. Connect the printer's power cord to the Anoxomat's

printer power connector.

See Activating the printer (optional) on page12.

The red protection label contains important

information and setup codes for the Key Operator, and

should be stored in a safe place. See Fig. 1.1.

1.6 Connect to a computer or network (optional)

If your Anoxomat includes a data interface to a computer

or network:

• Use a “cross-link” Ethernet cable to connect

the Anoxomat directly to the network card of

the computer.

• Use a standard patch cable to connect to a network.

See instructions for Activating the data interface

(optional) on page13.

1.7 Power up the instrument

1. Connect the power cord to the Anoxomat and into a

power outlet.

2. Remove and set aside the red protection label

(Fig. 1.1)from the touchscreen.

Keep the red label in a safe place as it contains

configuration access codes.

Fig. 1.1: Red touchscreen protection label

3. Turn on the power switch and wait for the Main

operation screen to display.

4. The Anoxomat is equipped with a touchscreen that

responds to the soft-touch pen supplied with the

instrument or the tips of your fingers. The touchscreen

may not respond well if you press with the flat of your

finger. Never use sharp objects, pens, pencils, or

anything that would leave a mark on the screen.

Chapter 1 Installation and setup

10 Anoxomat® III User’sGuide

1.8 Set up System Language

Your Anoxomat contains multiple languages. The

supported languages are: Chinese, Dutch, French,

German, Japanese, Korean, Russian, and Spanish.

1. To set the language, press Language on the Setup

screen.

2. Select the language.

3. Press Close and reboot the system.

The system displays in the selected language.

1.9 How to input data

When programming or changing settings in the

Anoxomat, you must enter data on an input line using an

onscreen keyboard. Using the soft-touch pen or your

fingernail, tap in the input line to position a blinking

cursor, and a keyboard appears.

1.10 Setting up the instrument

This section is restricted for use by the Supervisor, who

is required to enter the Set-up Code from the red label

(Fig. 1.1)before defining or changing settings.

1. Press Setup. The setup code screen displays with

keyboard.

2. Enter the Setup Code from the red label (Fig. 1.1)and

press Ok. The main Setup screen displays.

Set up gas connection(s)

The Anoxomat allows a maximum of three gas supply

connections. For each gas connection, you need to

specify the gas mixture on the Setup screen.

For Gas #1, select the gas composition of your gas from

the corresponding pull-down menu.

Specify the gas composition for each gas supply.

See Standard gas mixture on page11.

If your gas composition is not available from the pull-

down list, you can define the mixture by selecting

Other gas-composition. This screen appears:

Enter the required percentages in each field and press

Close to exit the screen and save changes.

If the second or third gas connection is not used, leave

the field empty or select None.

Setup date and time

If your Anoxomat is equipped with a printer and/or is

using a data interface, the date and time of a process

appears on the printout or in the database.

To set the date and time, press Date/time on the Setup

screen. Enter the date as DD-MM-YYYY (e.g., 30-04-2010

= April 30, 2010). Based on 24-hour clock, set the time in

HHMM (e.g., 09-07 = 9:07 AM).

Exit Setup

Press Close to return to the Main Operation Screen.

Chapter 1 Installation and setup

11 Anoxomat® III User’sGuide

Application Gas Composition

O2CO2H2N2

Primary gas supply (alternative 1) – 10.0% 10.0% 80.0%

Standard microaerophilic recipe 6.0% 7.1% 7.1% 79.8%

Standard anaerobic recipe 0.0% 10.0% 10.0% 80.0%

Primary gas supply (alternative 2) ˜ 10% 5% 85%

Standard microaerophilic recipe 6.0% 7.1% 3.6% 83.3%

Standard anaerobic recipe 0.0% 10.0% 5.0% 85.0%

Table 1.1: Gas supply mixtures and jar composition results

1.11 Standard gas mixture

The standard gas mixture could have a composition as

specified in the line “Primary gas supply” in Table 1.1,

along with the resulting jar mixture using the standard

recipes.

The Anoxomat processes the recipes independent of

the gases or gas mixtures used.

You must use the primary gas connection (gas #1) for

your anaerobic gas mixture cylinder. Normally, the

secondary gas connection (gas #2) is used for the 100%

CO cylinder, and the third gas connection (gas #3) is

used for the H mixture cylinder.

WARNING: Gas mixtures with hydrogen greater

than 10% are considered flammable. Gas mixtures

with concentrations of oxygen above the normal 21%

atmospheric significantly increases the risk of ignition

and fire. Never use such hazardous gas mixtures with the

Anoxomat.

For other jar composition results, see Starting a recipe

using the Registration Input screen.

1.12 Registration setup (optional)

If you purchased the optional Registration feature, you

receive a setup code that allows you to configure your

Anoxomat to record additional information on how

samples are processed, and who processed them (see

Starting a recipe using the Registration Input screen).

The details are stored in the Anoxomat, can be printed

with the optional recipe printer, and can be transferred

to a computer using the optional data interface.

1. On the Setup screen, press Registration. The Unlock

Registration screen appears.

2. Enter the Registration Code from the red label

(Fig. 1.1)and press Ok.

Chapter 1 Installation and setup

12 Anoxomat® III User’sGuide

3. The main Registration screen appears.

4. Using the keyboard, enter the Lab ID and Dept. ID.

Jar setup

If you configure the jar setup, the user is prompted to

input data (e.g., Jar ID, contents of jars, job reference,

etc.) before each recipe is started.

1. On the Registration screen, press Jar Setup.

The Jar Setup screen displays a list of options and

corresponding checkboxes.

2. Using the soft-touch pen or your fingernail, select the

fields you want to include by tapping each box to

place a checkmark. If you checked a box by mistake,

tap again to remove the checkmark.

3. If you select the “Authorized by” checkbox, a blank line

for signature/name authorization appears on the

printout.

4. Press Close to save your settings and exit to the

Registration screen.

For each field selected, the user can enter the respective

information for each jar connected. If no information is

entered, a blank line appears on the printout. However, if

the “Required” checkbox is selected, the user must enter

the information.

The ID separator is used when multiple patient plates are

scanned and processed in the jar.

Register users

To limit access to the Anoxomat, user IDs can be

established to identify the technician before every recipe

is run.

1. On the Registration screen, press Register Users.

2. In the “Add user” section of the screen, enter the

user’s full name as you want it to appear on the

printout and in the database.

3. Enter the user code for the user. The user code does

not appear anywhere but must be entered each time a

recipe is started.

As long as even a single user has been registered to use

the Anoxomat, the Anoxomat cannot be operated

without entering a correct user code.

4. Press Submit to add the name and code to the list of

registered users.

5. Repeat steps 2–4 for each registered user.

6. To delete a registered user, select the entry from the

Registered Users list and press Remove.

7. Press Close to save your settings and exit to the

Registration screen. When you're finished configuring

Jar Setup and Register Users, press Close.

1.13 Activating the printer (optional)

If the optional thermal or dot matrix printer is installed,

you must activate the printer before use.

Only printers supplied by Advanced Instruments are

compatible with the Anoxomat system.

1. On the Setup screen, press Printer. The Connect

Printer screen displays with keyboard.

Chapter 1 Installation and setup

13 Anoxomat® III User’sGuide

2. Enter the Printer Code from the red label (Fig. 1.1)and

press Ok. The Printer screen appears.

3. Choose the correct printer type and press Test Printer.

4. Select Printout Automatically to print the Anoxomat

recipe cycle information without prompting the user

at the end of each cycle.

1.14 Activating the data interface (optional)

If you purchased the optional Data Interface feature, you

need to setup and activate the software before you can

transfer data to a network or PC.

1. On the Setup screen, press Interface.

2. Enter the Data Interface Code from the red label

(Fig. 1.1)and press Ok. The Network Settings screen

appears.

Connecting to a network

Use a standard patch cable (Ethernet Cable) to connect

to a network. Select Obtain an IP address automatically

and reboot the Anoxomat. The IP Address and Subnet

Mask appears in the network settings

Connecting directly to a PC

Use a “cross-link” Ethernet cable to connect the

Anoxomat directly to the network card of the PC.

Contact your system administrator for a range of IP

addresses to be used and enter a fixed IP address .

Set the IP address of the network card in your PC within

the same range. Reboot the Anoxomat to activate the

connection. (See Data Interface on page20.)

14 Anoxomat® III User’sGuide

Chapter 2

Operating the Instrument

In order to run your instrument properly, it is important that you read

and adhere to the instructions in this section.

2.1 Function of major components

Operation of the instrument is quicker and easier if you

become familiar with the locations and functions of the

components, systems and controls.

Maximum gas supply pressure to the Anoxomat

should never exceed 2 bar absolute.

Jars and Petri dish holders

Petri dish holders are available for all jars and for the

usual Petri dishes. See Parts and accessories for more

information.

Palladox™ disposable catalyst

The disposable palladium catalyst is in a permeable

plastic pouch (sachet). It is for single-use only. Dispose

each sachet after every incubation to ensure proper

oxygen removal.

Quantity of disposable catalyst used per jar test

Jar Type Sachets needed

AJ9022 (holds 6 plates) 1

AJ9023 (holds 12 plates) 1

AJ9025 (holds 12 plates, microtiter plates) 2

AJ9049 (holds 12 plates) 1

AJ9050 (holds 24 plates) 2

AJ9028 (holds 36 plates) 3

Use the sachet at room temperature.

Clip the disposable sachet under the standard jar's lid or

place it in the ergonomic jar's designated slot.

Dispose of the sachet in accordance with lab procedures

and local biohazard waste disposal regulations.

2.2 Operating the instrument

Before use always check the jar for cracks or

damage.

1. Place inoculated dishes, tubes, microwell plates, or

other samples in the jar using the Petri dish holder.

2. Add the required number of sachets to the jar for

anaerobic bacterial cultivation.

Use an optical oxygen indicator strip or appropriate QC

plate in the jar.

3. Place the lid on the jar and slide the jar clamp over the

lid. Hand-tighten the jar clamp screw.

Note: If you're using ergonomic jars, close the clamps on

each side of the jar lid.

4. Connect the jars to the Anoxomat by pushing the jar

tube connector into the snap-shut coupling on the jar

lid.

Chapter 2 Operating the Instrument

15 Anoxomat® III User’sGuide

If the Jar tube connector does not snap in place, pull the

outer ring of the snap-shut coupling downward.

5. Choose the appropriate recipe on the Main screen by

touching the microaerophilic or the anaerobic button

or the saved recipe button (for any personalized

recipes).

The button is highlighted when the recipe

is active.

6. For the standard microaerophilic and anaerobic

recipe, a standard quality assurance level has

been set as default. The Anoxomat automatically

enables this quality assurance level. To disable the

quality assurance setting, press Quality Assurance

enabled: level 1. The button changes to Quality

Assurance disabled. Details of the recipe are displayed

on the right-hand side of the main screen (see Active

Recipe screen.

Always enable the Quality Assurance option during

anaerobic and microaerophilic process to avoid any

failure or loss of patient samples.

7. Press Start located below the touchscreen.

2.3 Process report

During a recipe run and completion, the processing

report appears on the screen:

Recipe

Jar test

results

Recipe status

Screen icons

Appears in the connected column. Jar is under

vacuum. Possibly partly processed in a previous run.

Jar passed the test. Jar is ready to be disconnected

and placed in the incubator.

In the Ready column, this indicates the process is

complete.

Jar failed the test. Processing stops on that jar. The

jar may be disconnected.

Active Recipe screen

Gas-input test

When the Gas-input test fails, this means the pressure

supplied by the regulator to the Anoxomat is lower than

1.6 Bar or higher than 1.9 Bar. Only the gas connection

needed for the specific recipe selected is being tested.

Jar-leak test

Checks the integrity of the jar and hose under a deep

vacuum condition.

Failure of this test is rare in a properly maintained

system. See Troubleshooting and service.

Seal-leak test

Checks the integrity of the jar under a slight vacuum

condition.

This test fails occasionally, often due to a dirty o-ring

seal. Wipe the seal with a lint-free wipe soaked with IPA.

Catalyst-activity test

Confirms that the catalyst is removing oxygen at a

sucient rate.

Failure of this test occasionally occurs if an insucient

number of sachets are used or if the sachets are reused.

2.4 End of recipe

As soon as a appears in the jar's Ready column, the

jar is ready for incubation and you can disconnect it.

Print recipe (optional)

If a printer is connected, you are prompted to

print out the recipe just finished. The recipe can also

be printed out at a later stage. The software can be

personalized to print without any request on the main

screen.

Chapter 2 Operating the Instrument

16 Anoxomat® III User’sGuide

Disconnect and incubate

Disconnect the jar by pulling the outer ring of the

snap-shut coupling downward. The jar tube should snap

out of the coupling. This closes the snap-shut coupling

and maintains air tightness of the jar.

Hold the black tube with your other hand when

disconnecting from the jar.

To leave the process report screen, press Start. The

Anoxomat returns to the Main screen and is ready for the

next job.

The last performed recipe stays active. You can check

this on the Active Recipe screen.

17 Anoxomat® III User’sGuide

Chapter 3

Optional functions

3.1 Barcode scanner

The Anoxomat documents the full culturing process.

Instead of using the keyboard to type the information

into the registration input screen, you can also use a

barcode scanner. This is especially useful in case

samples/Petri dishes have individual barcodes

attached to them. To activate the barcode scanner

purchased from Advanced Instruments, a code is

generated that can be then entered to the Anoxomat

software. Note that the preferred sample ID entry

method on the instrument is by barcode scanner to

reduce transcription errors.

3.2 Registration input screen

The Anoxomat oers an optional Registration Input

screen which allows you to identify your laboratory, limit

the use of the Anoxomat, and determine which user

processed which samples with the Anoxomat.

(Registration setup (optional))

Starting a recipe using the Registration Input screen

1. Press Start. If you've registered one or more users, the

Details screen appears.

2. Enter the user code and press Start.

The Jar Content screen appears.

3. If you activated one or more jars (see Jar setup), you

are prompted to input details for each connected jar. If

you marked any of the fields “required” during jar

setup, you cannot continue without completing the

respective field.

Use the screen keyboard to specify details for each jar

connection. Use the horizontal scroll bar to display other

options or use the Barcode scanner if the jars use the

barcode labeling system.

4. When finished, press Start to continue the recipe.

3.3 Pre-programmed recipes

Pre-programmed recipe for oxygen level, gas mixture

and evacuation level

Rather than accept the standard microaerophilic recipe

with a resulting oxygen level of 6%, you may wish to

incubate using a dierent recipe (i.e., Helicobacter

species with 5% oxygen). Oxygen levels can be set

between 0% and approximately 18%.

If you purchased secondary gas supplies for your

Anoxomat, these gas supplies need to be programmed

according to your specifications. Oxygen levels can be

demanded between 0% and 18%. CO and/or H levels

can be chosen within certain limitations, depending upon

the required O level and the installed gas mixtures.

Maximum evacuation level in the standard program is a

default setting:

• anaerobic recipe: 205 mbar

• microaerophilic recipe: 294 mbar

If this level of vacuum may be harmful to cell culture or

the agar, recipes can be programmed with the following

maximum evacuation levels: 400, 500 or 600 mbar.

Chapter 3 Optional functions

18 Anoxomat® III User’sGuide

You can order one or more recipes according to your

specification from Advanced Instruments or your local

supplier. These pre-programmed recipes are saved in the

Anoxomat for future reference. (See Activating pre-

programmed or user-defined recipes).

3.4 Additional jar connections

If you need to process multiple jars at the same time, you

can order additional jar connections (including software

update). The Anoxomat allows a maximum of 4 jar

connections.

Note: You must send the instrument to the factory or your

distributor. End-users cannot perform these modifications.

3.5 Additional gas connections

If your type of culture or research requires more than

one gas supply, you can order one or more additional

gas connections (including software update). The

Anoxomat allows a maximum of three gas connections,

and a total maximum of five connections (jars and

gases). Refer to the Standard Gas Mixture section in

Chapter 1 for additional information.

Secondary gas supplies

For creating non-standard atmospheres, other gas

mixtures can be connected if more gas connections

are available.

Gas

Connection

Cylinder Contents Usage

Primary

N2Nitrogen 85%

Standard

anaerobic and

microaerophilic

recipe

CO2

Carbon

Dioxide 10%

H2Hydrogen 5%

Secondary 1 CO2

Carbon

Dioxide 100% Increased levels

of CO

Table 3.1: Primary and one secondary gas supply

Gas

Connection

Cylinder Contents Usage

Primary

N2Nitrogen 85%

Standard

anaerobic and

microaerophilic

recipe

CO2

Carbon

Dioxide 10%

H2Hydrogen 5%

Gas

Connection

Cylinder Contents Usage

Secondary 1 CO2

Carbon

Dioxide 100% Increased levels

of CO

Secondary 2

H2Hydrogen 10%

(max) Variable levels

of H

N2Nitrogen 90%

Table 3.2: Primary and two secondary gas supplies

3.6 User programming function

The user programming function gives you the ability to

program recipes. This option may be helpful if you

expect to need more than a few pre-programmed special

recipes. These pre-programmed recipes are saved in the

Anoxomat for future reference.

Creating a user-defined recipe

If your Anoxomat is equipped with this option, you'll

receive a programming code that allows you to unlock

this feature and create your own recipes.

1. Program recipes. Press Program recipes on the Main

screen.

2. New recipes. Press New recipes at the bottom of the

Program Recipes screen.

Chapter 3 Optional functions

19 Anoxomat® III User’sGuide

3. Unlock program. The first time you use this feature,

you must supply a code to unlock the program on the

Unlock Programming screen.

If you purchased this option with the Anoxomat, the

code is found on the red protection label. If you

purchased this option later, the code is supplied by your

local dealer.

Enter the code and press Ok. The New Recipe screen

appears.

4. Define end percentage O. In the gas composer

partition of the screen, define the end concentration

O either by moving the scroll bar to the right, or by

using the scroll button. The result is visible in the

result partition.

5. Define other gas components. After defining the O

level, the Gas 1 level has to be moved at least one click

to the right. If more than one gas cylinder is

connected and defined, more options for gas

composition appears on the screen. For example, if a

100% CO gas is connected, the ability to determine

the CO end-concentration in the jar is available. Your

choice is limited by the specified O percentage and

the composition of the gas in the secondary cylinder.

More than one solution is possible. By changing the

position of the scroll bars of Gas 1 and Gas 2, the result

of the mixture becomes dierent.

6. Define maximum evacuation level.

The catalyst test is only performed in case a required

oxygen level of 0% has been chosen. The “No Catalyst

Test” button, should be used when creating a new recipe

and a catalyst is a not required.

The maximum evacuation level in standard recipes is a

default setting of 205 mbar. As this may be harmful to

the culture or the agar, recipes can be adapted to 400,

500 or 600 mbar. Depending upon the required O level,

the Anoxomat may perform more cycles than usual to

reach the gas mixture in the jar.

7. Specify the recipe name. Click in the space and the

screen keyboard appears. Enter the description for this

recipe. The name and other relevant information of the

recipe appears in the Active Program section on the

Main screen.

8. Save the recipe. Press Close to save your new recipe.

The recipe can be revised at any time.

Changing a user-defined recipe

To change a user-defined recipe, select Program recipes

at the bottom of the Main screen. Select the recipe you

want to change, and the Edit Recipe screen appears.

After making your changes, press Close to save

the recipe.

Chapter 3 Optional functions

20 Anoxomat® III User’sGuide

3.7 Activating pre-programmed or user-defined recipes

To use pre-programmed or user-defined recipes, press

Saved recipes on the Main screen and choose the recipe.

The recipe is active and listed on the Main screen.

3.8 Thermal/dot matrix printer

Once you have purchased, installed and activated the

thermal or dot matrix printer, you can request a printout

of each recipe run on the Anoxomat.

A detailed printout of each jar can be attached to the

lids using small clips available from Advanced

Instruments, thereby eliminating any mix-up of jars.

If the optional Registration Input screen was configured

and activated in your Anoxomat, the additional

information is included on the printout.

After a recipe has completed its test, you'll see a prompt

to print out the recipe. The recipe can also be printed

out at a later stage. By selecting Print at the bottom of

the Main screen, you have the option of printing or

reprinting the last five recipes.

3.9 Data Interface

All data regarding a recipe is stored in Anoxomat

memory; however, the data memory is limited. When

the memory storage reaches 60% capacity, a message

appears reminding you to transfer the data and

clear the memory.

Transferring data to a web page

Use this option to transfer the data into an existing

external system (e.g., LIMS software system) as a CSV

(comma separated values) file.

1. Start your web browser.

2. Connect to Anoxomat address. Type anox and the

serial number without the hyphen character (e.g.,

anox0312001) in the address bar.

The serial number can be found on the red protection

label (Fig. 1.1)and in the Anoxomat Setup screen.

If you use a fixed IP address, you can enter the IP

address of the Anoxomat in the address bar. The IP

address can be found in the Network Settings screen

(see Activating the data interface (optional)).

3. Your Anoxomat web page appears, displaying your

serial number. Click on Recipes.

The CSV file is generated and displayed.

Transferring data to a Microsoft Excel® database

The Excel® database provided by Advanced Instruments

includes search, additional input, and statistical

evaluation functions. Copy the Excel® file provided on the

USB memory stick to the computer on which you

transfer the recipes, and then open the file. The Excel®

file consists of various tab sheets.

Get data from the Anoxomat

1. From the menu bar, choose Anoxomat > Get Recipes.

A pop-up window appears.

2. Enter the name (anox + serial number; e.g.,

Anox0312001) or the IP address (e.g., 172.24.2.17) of

the Anoxomat, and click Ok.

Anoxomat's data is transferred to the file in tab sheet

“RecipesDB”.

Only new data is generated and added to the

existing data. The Anoxomat memory is not

cleared automatically.

Other manuals for Anoxomat III

1

Table of contents

Other Advanced Instruments Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Time Electronics

Time Electronics 1017 Technical instructions

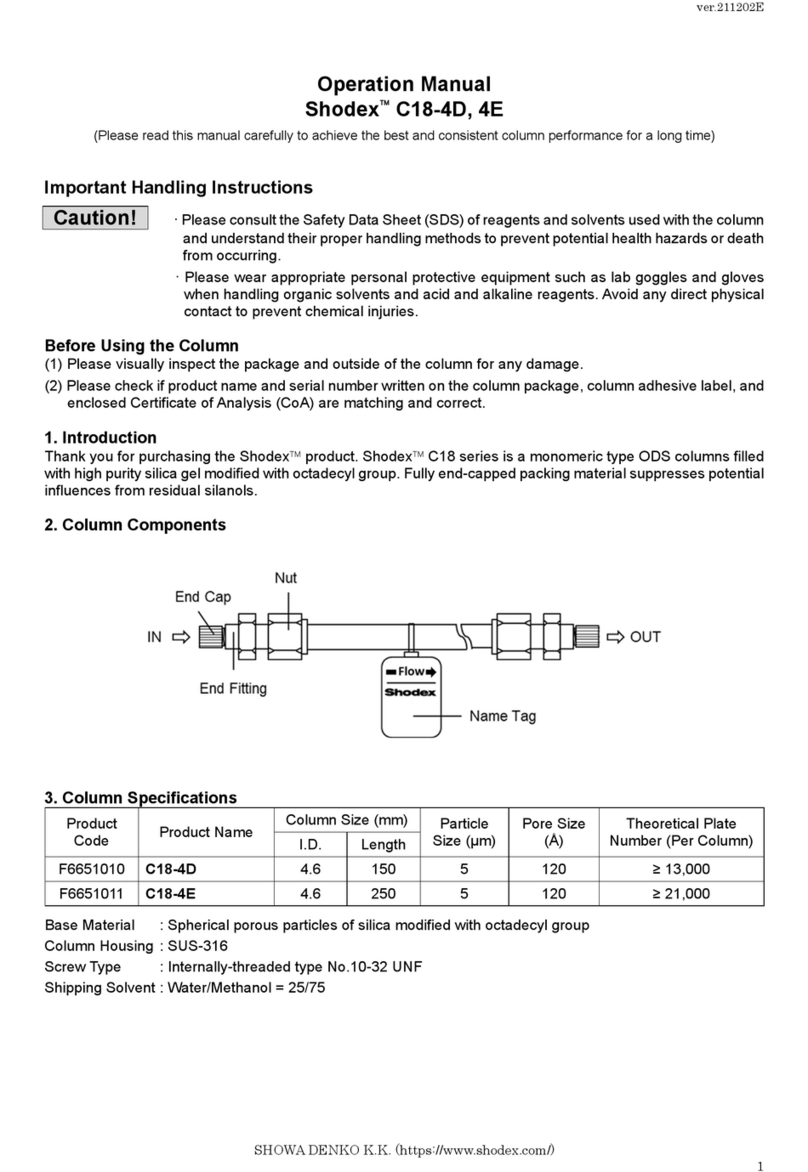

Shodex

Shodex C18-4D Operation manual

REITEL

REITEL SUPERSTEAM operating instructions

Woodley

Woodley Clinispin Micro III user manual

Amersham Biosciences

Amersham Biosciences MegaBACE 500 Planning guide

HAVER & BOECKER

HAVER & BOECKER USC 200 S operating instructions